Leaderboard

Popular Content

Showing content with the highest reputation on 11/01/24 in all areas

-

I like that! As long as the composition of the stick can allow whittling it down to a fine point, job done. Also, pegwood isn't cheap for what it is. I've harvested my own pith before from an elder bush/tree that grows near me. It depends when in the year it is picked to how spongy it is. Picking it in the spring and summer yields the best results. Now that stuff certainly isn't cheap. I'm always amazed at how many products are aimed at 'watchmakers' with the view that we must be totally inept to not make it ourselves. Sometimes it is just easier to buy a tool, but sometimes making one is so much better. Hand levers... buy them, seriously? I know some watch enthusiasts haven't the skillset (yet!) to fabricate tools and parts and a lot of my students haven't picked up a file since they were last in school, but the look on their faces when their tool excels the bought version. Classic! Here's some pics of the technicians from Mr. Jones Watches who made their hand levers last year. A very talented crew and a credit to Crispin Jones. I am careful how I use the word 'Pegging' because of the connotations, but also I once told a student to 'peg-out' the jewels holes and when I came back around to his workbench, he had pushed all the jewels out from the bridges and mainplate and had them in a neat little pile! When I told him that wasn't what I meant, he said 'That's no problem, I'll push them all back in again using the pegwood.' Simple!4 points

-

4 points

-

3 points

-

how was it ? , go have a cuppa and a sit down to recover....on second thoughts...maybe dont sit down. I'm actually crying with laughter H , you've just made my day3 points

-

So why would "the industry" be wasting money on using epilame if it didn't make a difference ? They are the ones who would know. They need to save every penny to be competitive. Do we believe the word of 'amateurs', or the companies who have been manufacturing watches for decades, and are invested in making maximum profits? In engineering (think car manufacturers) it's always the case of manufacturers being accused of cutting corners to save money. I can think of no other instance where they have been accused of overspending (i.e. using epilame) when not necessary.3 points

-

I might like to try this. Looks like they clamp steel rods in a vise at a slight incline then file flat against the vise until there's a wafer thin end, anneal & bend, harden & polish?2 points

-

Just by way of an update, I successfully fitted the new mainspring with T-ends. No filing of the ends was necessary and it is a good fit. If of interest (as these threads pop up in Google searches), the spring reference is GR6449T. this is for the earlier (pre 1907) H7 variant of cal 52. I did leave the now redundant rivet in place but conveniently the force of the new mainspring against the inside wall of the barrel made it pop neatly out.2 points

-

The "autocorrect" feature requires at least a full cycle to right itself. Manually run the minute hand through a full hour and it should be in sync.2 points

-

I'd suggest working on the bare case only! Take the movement & dial out first; it allow the case to be cleaned rather more easily, and the empty case is also easier to hold while working on it!2 points

-

2 points

-

oh minor little problem here perhaps? What is epilam? Epilam is her variety of substances stearic acid I believe was the first one. But over the years has evolved into other substances and whatever these substances are dissolved in also plays a role in problems. For instance several years ago somebody posted on the Internet that I know of shops that were very concerned about this the solvent that the epilam was dissolved in a evaporate it extremely fast. But unfortunately typically anytime something evaporates really fast it gets cold or basically removes the heat and the object gets cold. Unfortunately cold steel products in an environment of moisture in the air will form droplets of water and ultimately rust. I know several years ago this was a concern there was the website that had pictures of look at all the rust. I knew I shop that was so concerned that she had a hairdryer on radiant producing hot air so they can immediately place the part in the hot air to evaporate without getting the part cold at all. then evolution the new stuff is environmentally friendly supposedly. It no longer instantly evaporate civet's left uncovered and Omega recommends it as the final rinse in the cleaning process with only a few items that are left out. Basically the balance wheels left out I know we've had discussions of epilam so somewhere I posted pictures of what's left out now. But Omega's amusing for this because in the early 60s they epilam everything except the balance wheel and pallet fork but in the case the balance wheel you were to put epilam on the pith wood and stick the pivots in so that they would have epilam. Then they went to just doing the escapement and now they're back to doing everything almost then the modern shock jewels they been epilam with some unknown process probably a vapor process. ETA has technical communications with service information that up until recently didn't cover epilam at all. This is because most the watch companies had supplemental information that we never see typically. But in their manufacturing information sheets you find out that the balance staffs and escapement have epilam. oh other minor little things that would affect the discussion would be as epilam older likes to evaporate as and evaporates the concentration of whatever increases people using older bottles with higher than whatever concentration conceivably will have thicker coatings and conceivably that may be causing some of this problem? In addition to the fact of all the various epilam's conceivably are different chemistry. interesting so if it wears off causes a problem then what would be the outcome of that problem? this is interesting because? In the case of the escapement it shouldn't be a problem because the escapement components are covered with epilam and allowed to run dry which wears the epilam off before you put the lubrication. Oh and regarding epilam placement and wearing off I've attached a PDF where they talk about in manufacturing removing the epilam before lubricating. Now the interesting problem is when you epilam the entire watch and it's all over the keyless and conceivably it will mix with lubrication but epilam is normally at a microscopic level so it can't really have that much effect although I am curious as to what bad affects people are seeing? we also end up with application problems in your discussion? For instance if you look at modern technical sheets or Omega they use a very little grease and a heck of a lot of oil on the keyless. For instance as far as I can tell any time you use 9010 if you would like it to stay wherever you put it you should use epilam. If you look at Omega's oldest documents they use 9010 on the keyless the lightest oil and yes they epilam. But what if you were to use grease like 9405? In which case you wouldn't have to epilam the whole darn watch. Then there is the escapement epilam's to keep the oil in place but what if you use 9415 which is a grease with interesting properties. So if you're using a grease on your escapement would you still need the epilam? one of my amusements with horological lubrication is the lack of why they do any of the things they do. they were also missing of the complete picture in other words the supplemental information of what we're supposed to be doing or not and what exactly the factory is doing as I mentioned up above epilam ing the balance staff is almost I don't think I've ever seen a reference to doing that right yet it's being done. I would really be curious about the part on increasing amplitude I'm not sure how epilam would play any role in that at all. then as long as are recommending things like oil on the keyless obviously keeping the oil in place epilam would be necessary. The unfortunate problem of lubrication choices epilam or anything we do is it takes time to find out if you did poorly. in other words if you can examine a watch that you know you service X years ago you can look at it carefully and see if you chose wisely or whether you made a mistake. GB1057607A-1 epilame.pdf2 points

-

I have stopped buying pegwood. I make my own. I have several large French Lilacs in my yard, and the pruned and dried branches and twigs once liberated from their bark make great pegwood shafts. The wood is hard and dense, and sharpens down to a very fine point. I practiced on old donor movements to ensure that it does not scratch the finishes or damages the jewels. I then run the pegged movement pieces through my cleaner after getting the larger pegwood remnants off with Rodico or a blower.2 points

-

No harm in having a look but there just appears to be too much that's corroded away. I think it's something that would be better milled than spun on a lathe.1 point

-

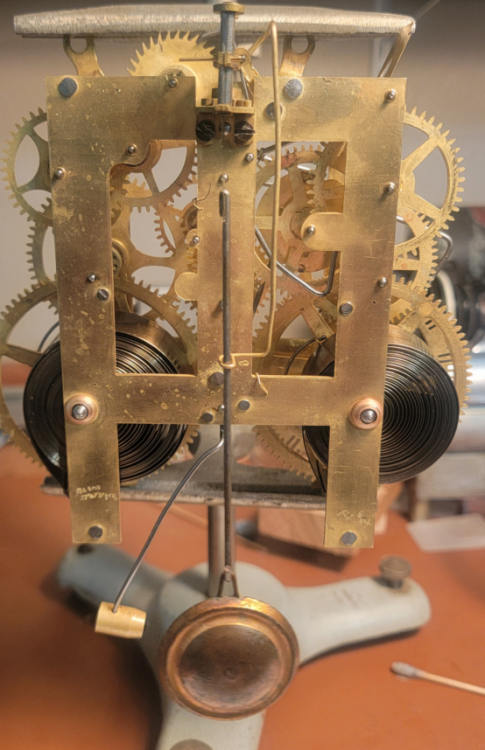

Nothing. I have the clock on the stand for regulating. Once that is finished, it will go back into the case. BTW, that is faux marble accents.1 point

-

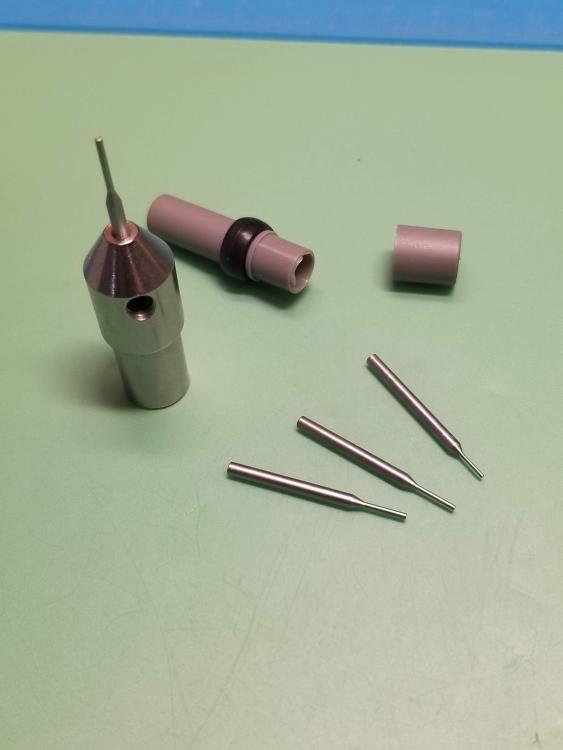

the lower settings are quite interesting in that the spring can come out quite easy. But going back in is usually a challenge and the best way would be to remove the entire setting. then ideally in addition to a jeweling tool you should have the special pushers that come in a set that looks like this1 point

-

then in addition to some existing and some not existing the majority of them only partially exist if they exist at all. Many of the watch companies felt that wherever was servicing their watch was probably a professional watchmaker so basic guides explaining lubrication of every single caliber probably do not exist. So a lot of times the only cover unique features of the watch. Then when they were scanned from paper to PDF typically scanned by material houses solely for parts not for servicing. then in addition to parts manuals websites covering parts are handy this one is nice. Yes there others I just like this one for most stuff. http://cgi.julesborel.com/ then you go to the Bulova section and ultimately get here http://cgi.julesborel.com/cgi-bin/matcgi2?ref=BUL_11BLCD then just because it has a price listed doesn't mean it's available sometimes it will tell you if it's discontinued but don't assume because there's a price that they still have it in stock. What's nice is you click on the part names ever give your cross reference the everything cross references to handy when you're trying to find the part then they fail part number you can go to the main site and do a search and see if they actually have it in stock or something like this I would probably go to eBay as there's all sorts of parts more than likely. http://www.julesborel.com/ the problem with the watch companies are a lot of them are in name only. In other words they were purchased or combined with other companies and have moved and anything in the past is now gone. So Bulova is part of citizen and they've moved so I would be really surprised if they had anything at all plus I'm very surprised that they could even service the watch more than likely they would send it out. In addition to probably whoever's answer your request doesn't even know what it is anyway for instance Bulova made a tuning fork watch called a Accutron. But now Accutron is just a brand or division of Bulova. If you wanted to send your tuning fork watch to them they have a very tiny list of preferred people across at least the US who would service the watch they will not service it themselves at least the prior generations. I've heard a rumor that are coming out with a new tuning fork watch so that probably have to service that. then if you're looking for Bulova stuff this is an interesting site https://mybulova.com/vintage-bulova-catalogs1 point

-

I decided that, for a pivot that never makes a full rotation...perhaps only 20 degrees...I would just assemble after cleaning and see how it goes. It is running nicely! Anybody ever seen a solid escape wheel?? BTW, this is an E. N. Welch. I date it somewhere between 1885 and 1899. In 1903 Welch was taken over by Sessions.1 point

-

There are a few currently on eBay but I'd be interested in a close up photo once it's cleaned to see the intricacies as I wonder if one could be machined or even cast.1 point

-

Hello and welcome from Leeds, England. Some manuals exist and some don't. Not sure about yours.1 point

-

You need to remove it from the case and look it over. Chimes normally put themselves right in 2 hours. Post some photos so we can see the movement of both sides and between plates than we can advise.1 point

-

Cyclops, So I can push the pins in from both sides...and then they just spring back out again. Is there some trick to pushing them in from both sides to remove the pin? Do you have to do both sides at the same time? Hi all. So I figured it out. There was a pin in the center, with springs on both sides. The outer parts of the link are connected and move in unison. So I had to push one side pin in, and pull the link end up a bit, then try the other side. At least one time I managed to do both sides as once and the link outside ends rotated up and I was able to disassemble it. But it wasn't easy...1 point

-

I( think that dial ring is too far gone for a repaint.1 point

-

Nice friendly response on this friendly forum. I am considering wether or not I should be using epilame and therefore I am reasearching the product and asking the good members of this forum for their input. Now if I'm reading that there is a possibility that if the product could possibily contaminate the lubrication, is this not a good place to seek an opinion?1 point

-

1 point

-

Ha! John And Neverenough, it is so nice to hear from both of you again it's been quite a while! I've had the year to take care of some things I needed to do, and I am back attending my watch repair courses here, and I have made a firm resolution to be more focused about watches. Thank you very much and as rjenkinsgb and caseback suggest I'll be taking it apart. And Rich, nooooooo, you do not need my address and you do not need to inform the authorities here in my town. Although I do appreciate your quick witted response to what you perceived as an emergency, the police have adopted the attitude that if you can't lick' em you should join them, and in my case that means they come for the complaints / concerns and stay for the coffee. They know all about me. Thank you anyway though that was lovely of you.1 point

-

This happens if the pivots of sliding gear wheel and min. recording runner are blocked by dirt and old oil (both shall not get oil). Disassemble and clean them. Frank1 point

-

1 point

-

Hallelujah I think the topic of pegwood was lost long ago here Rich, HectorLooi just revived it in the most hilarious manner1 point

-

That is one of the newer, safer solvents developed over the last few years - I was referring to the historical start-stop and variations in usage mentioned in some posts above, and safety factors in yours. eg. One-dip (Trichlorethylene / PERC) has only recently been replaced by B-Dip (Benzine). I remember Carbon Tetrachloride being banned, after common use for many decades - and being commonly replaced by PERC, believed at the time to be a safe alternative. Things change as risks are discovered and regulations change. Look at Radium as an extreme example of changes in safety perceptions and regulation - in the early 20th century it was added to numerous things from "Health elixirs" to clothing & cosmetics!1 point

-

Do any of the sizes & angles in this page make sense with the measured taper? https://littlemachineshop.com/reference/tapers.php More info here: https://en.wikipedia.org/wiki/Machine_taper#Types1 point

-

An easy answer Mike ......They wouldn't. . Yeah I'd have that checked out Scott, might not end well, or at least direct the feelings towards Bergeon's accounting department. Wonderful stuff , i used to purposely sit in my local Rex laundrette when i was a nipper of about 5 or 6 just to keep warm and breathe in the Perc odour that filled the room.1 point

-

I have mixed feelings on the whole issue, I use epilame but every time I do I have a nagging voice in the back of my mind asking if I am just "Drinking the Kool-Aid"... I think that, cost asside, there is little down side with the sensible use of epilame, so why not? But, I have yet to see real evidence that it either prolongs service time and/or reduces wear in components and/or increases amplitude. All of the 'evidence' I have seen is anecdotal which is understandable due to the complexity and multi-year testing that would be required to prove (or dis-prove) the case for using epilame. So I remain on the fence, and I will continue to use it and ignore that nagging voice.... oh and the other one telling me to burn things... but that's a different story1 point

-

The crash has caused damage, so disassembly is required to assess and repair that. (Unless you have a magic wand that is ). A crash like the one you discribed will very likely have at least caused one or more pivots to bend or break.1 point

-

Who said it wears off ? I think its best to understand how it works first before siding an opinion. We had this discussion about a year ago with different views what it does and how best to apply it In fact i contacted Episurf with that exact question and received a very nice prompt email from their head of technical, David periot ? Cant quite remember his exact name? unfortunately i deleted it about two weeks ago while clearing out to make some message space , but the email is floating around in the forum's archives somewhere. Basically he declined to give instructions of its use and said different watchmakers use different application methods, some use the rub off method and some do not. I always used to think of the rub idea as creating a groove or divot through it to make walls where the lubrication will not go. It does in fact increase surface tension, cohesive force where its placed. Instead of the lubrication wetting a surface it beads up, the molecules draw themselves together resisting the surface. I seem to remember there is a specific angle of the bead on the surface. Similarly to a freshly waxed car , water will bead on the paintwork surface. There are different names for the surface tension of oil and water, I'll try digging up the info. Anyway its easy to recognise an epilamed cap jewel and you will notice the effect, seen it many times still present on big old jewels. The oil beads up instantly and can be dragged around the surface of the jewel often making its way back to the center, its the pivot that keeps the oil in position. Its also likely the properties of the old jewels play a part in this but its strange to watch it, reminds me of the old movie " The Blob " So before i shoot myself, search Epilame / Fixadrop and read all the posts there.1 point

-

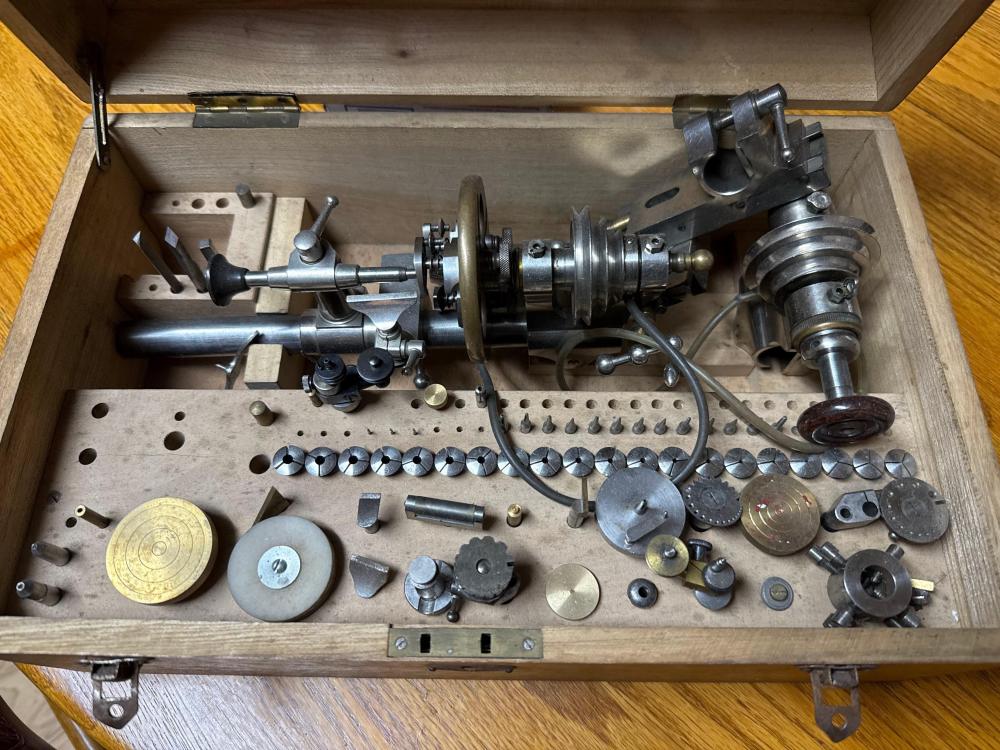

I'd like to get a watchmaker's lathe, but there's a mind boggling array of lathes, collets, accessories, etc. out there to wrap my head around. I know a watchmaker with several lathes and he has offered to sell me this Lorch 8mm lathe plus a motor for $1200. I'm just trying to get some feedback on if this would be a good set to start with and for that price. Two headstocks, one with a faceplate Collets up to 4.2mm. He thinks he has a spare 5mm collet to add to the mix. X-Y cross slide Partial milling attachment Motor He'll throw in some other bits and pieces. I do realize that there are other things that I will be needing to go along with this (belts, speed controller, gravers, etc), just to get going with it.1 point

-

Seems like Roterham Watch Co movement. They are not rare and parts a relatively interchangeable.1 point

-

I bought these two and they work very well. I also liked that they came in a case. https://www.aliexpress.us/item/3256802449978843.html https://www.aliexpress.us/item/3256807258243597.html I also picked up a set of nylon dies but they are crap so I didn't link those.1 point

-

Guy’s, I know we like to go off on tangents for a post or two but lubricant discussion has its own forum section dedicated to those arguments, this thread is meant to be discussing favourite yootoobers. thanks Tom1 point

-

Four Weeks later, it finally looks finished, Luming the dial went well, the finish is a bit too goldy was hoping for more of a brown. Looks great compared to how it started though, the hairline cracks in the dial cleaned out well. Now to find a new watch to work on (Before I decide to have a second go at the lume).1 point

-

I am using the nylon dies that came with my first cheap press. You can get a set of those for pretty cheap from AliExpress. There's also aluminum dies for a bit more and combination aluminum and nylon dies.1 point

-

To me, that set doesn't need that much work. Soak the parts in some Evaporust for a day. Rinse with water and immediately dry them thoroughly with a hair dryer. Spin each stake in a drill and rub with them with some fine steel wool. Check the holes in the stakes and stumps and clean them out with a fine needle or broach. Put the parts on some paper towels, sprinkle some oil onto them, then rub them around, leaving just a fine coat of oil on them. With any vintage tool that I get, I do a derusting, cleaning and oiling as needed to make sure they will usable far into the future. I believe any of the Invertos will have a floating die plate. For those, the central hub that the die plate spins on seems a bit undersized, to allow that floating.1 point

-

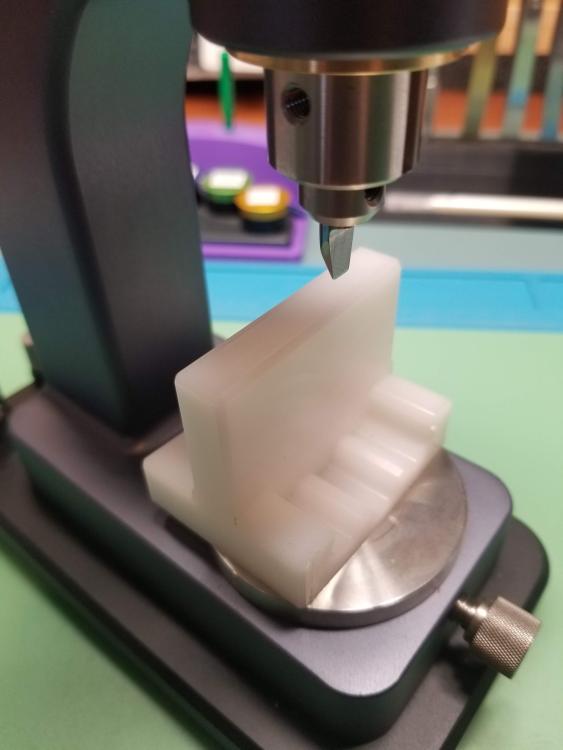

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:1 point

-

Hi there! Please drop by the introductions area to introduce yourself to the forum. It isn't really possible to judge much about a pocket watch without seeing the insides, because that's where the quality lies. Without a good size reference, I would guess you have a 6 size watch movement there in a spread case or maybe 0 size, so it won't probably be among the more valuable Railroad grades of watches. And often most of the value of a watch is in its case if the case has a high gold content. It's difficult to tell what your case is made from here, but something will almost certainly be stamped on the inside of the back cover about the case. The number of jewels in the movement affects its value because that also affects its potential for accuracy. The movement of every Elgin watch will have a serial number stamped into its plates, easy to find and read. You can then put that number into https://pocketwatchdatabase.com to get a lot of information about when it was made, how many like it were made, etc. On the whole, unless they are a rare grade or in a gold case, Elgin watches in clean and working condition are not exceptionally valuable - about $75 to $150. That's largely down to the fact that Elgin (and some other American companies) made tens of millions of watches, and a lot of them are still around. The highest quality railroad grade watches tend to be worth a few hundred more. Once you identify your watch's grade from its serial number, you can search ebay for "Elgin grade xyz" and find recent sales to get a sense of what people are paying. Also, don't be afraid to open it up. These watches were meant to be opened occasionally and without special tools. Find a slim knife but not too sharp (if you don't have a case knife), and look for a little gap on the hinged back where you can fit it. Cover the knife blade in a plastic ziploc bag to avoid scratches and push it into the gap. Do not pry, just push. The case should pop right open and reveal a lot of helpful information.1 point

-

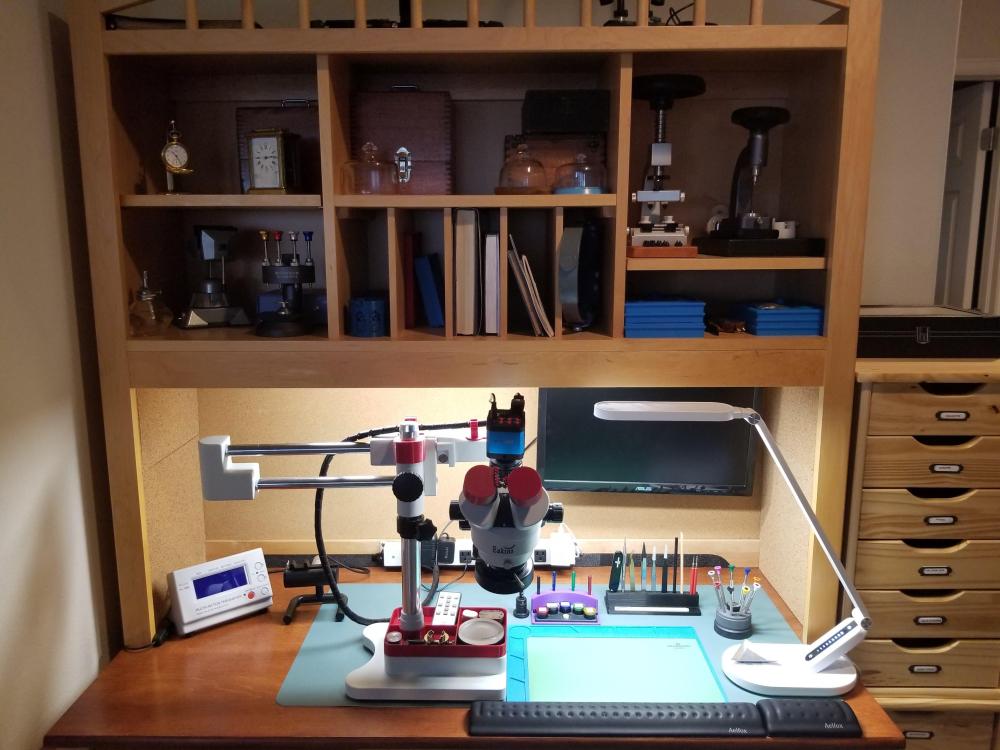

My setup has continued to evolve. Not ideal, I know, but it works well for the tight real estate that I have. Added an optical microscope. Takes up a lot of space, but so much nicer than using a loupe or magnifying visor. Better on my back, for sure. Added two sets of drawers for projects, parts and tools. Keeps me better organized. I now use the desk drawers for tools and supplies that I more commonly need. The hutch and drawer units are handy to store all of the tools that I have been acquiring. The computer wrist rests help corral parts. I plugged up the gap between the hutch and desk with some foam, where some parts liked flying to. I also added some cork board to the sides of the hutch for a bit of parts ping abatement. There's only one part (a screw) that pinged away that I haven't been able to find, even with the big magnet wand that I keep off to the left of the desk. Lighting is still something that I want a better solution for. The microscope gets in the way of a portable desk light. I did buy a unit with two adjustable lights for the times that the microscope ring light provides too much glare for photography, but it's awkward to use and isn't as bright as I'd like. I keep my ultrasonic cleaner and watch cleaning machine down in my basement.1 point

-

sorry late, it says place under the pinion, I would place cupped down position for more tension.... https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://mccawcompany.com/guide/hamilton-626-627-628-629/&ved=2ahUKEwjRu9T3jIyJAxXorokEHbq5BCsQFnoECB0QAQ&usg=AOvVaw1vapdX3DnUGJ6ZtduDhEcn1 point

-

It does get scarred or deformed or just contaminated with time. I skim the surface in the lathe, but it can simply be filed too, but way way faster in the lathe.. It does need a bit of a textured surface; I use a thin section coarse file to scratch it up after turning in hte lathe (thin so that it lays flat on the suface).1 point

-

Do you need to return the tin / zinc / plexiglass surface to flat once in a while, and how do you do it? I can imagine the surface becoming concave in time, or does that not happen because of the embedded abrasive?1 point

-

Thank you all for answers! As I guess this tool will be in my tool collection without any use before I buy another one in full set.1 point

-

1 point

-

1 point