Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/24 in Posts

-

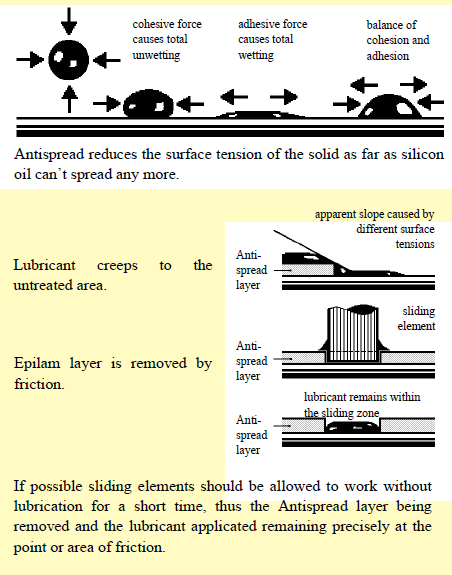

Like John says, you want to treat the pallet stones, but not the fork slot or pivots. When I had my machine that applied stearic acid vapor, the instruction was to not treat the fork at all, or balance, but everything else got it; this machine was made in the 60s. 25 years ago we were taught to treat the whole fork with the more modern Fixodrop (and service manuals also said this), but it was found that areas like the fork pivots and slot, that remain unlubricated, could have issues. When running the escapement dry to "wear off" the epilame, the actual epilame layer is like a couple of molecules thick, and the contact area also extremely small. There is no measurable amount of epilame removed. But the now non-treated areas hold the lubricant, while the treated areas prevent it from creeping away. There is no issue with the epilame contaminating the oil. I use it on all watches, at least the escape wheel, pallet stones, and cap jewels. Depending on the design of the movement, I might treat other areas if there's a chance of oil creeping away.5 points

-

I remember when I was teaching I had a student who giggled every time I said "cock". He lost it when I told him the pivots in cylinder escapements are called "tampons".4 points

-

3 points

-

I think that was a phase he was going through. The last time I spoke with him, he's back to epilame and lubricating the pallet stones. His think-tank group from China came up with a new invention, a epilame pen. It has either a felt tip or brush tip and a reservoir for epilame. Something like a auto-oiler and felt tip pen. It reduces evaporation of the epilame and allows precise placement of epilame. Let's see if it makes it to market.3 points

-

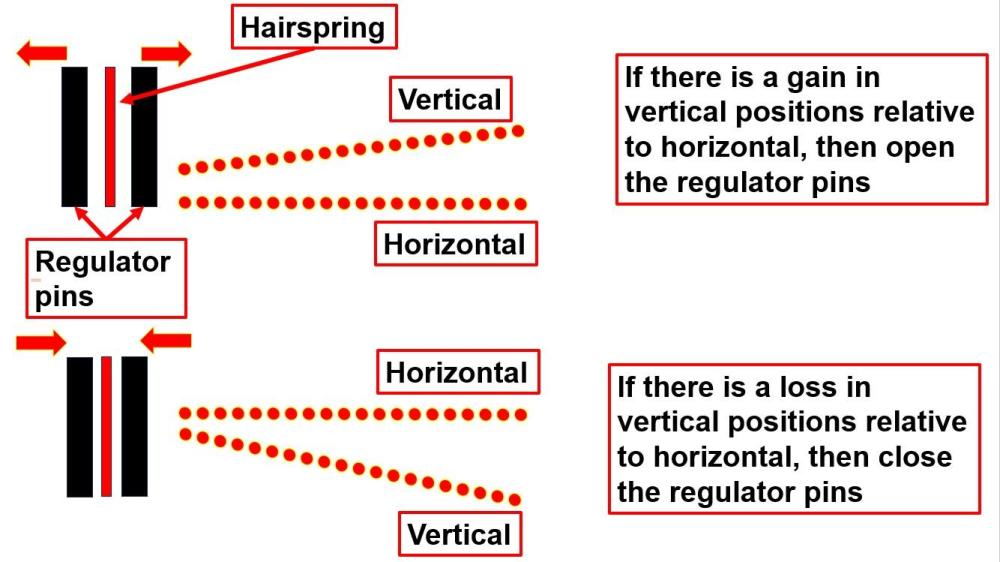

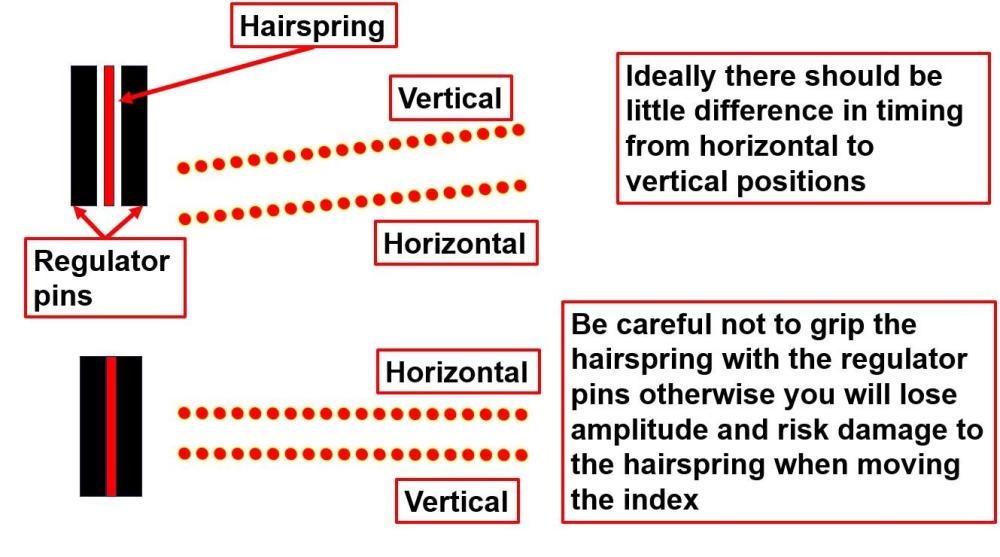

Not sure if anyone's reading this thread, but I thought I'd round it off in case anyone comes later wondering what the outcome was. Further investigation revealed that I had failed to completely tighten the pallet bridge. Although each screw only moved no more than about a quarter of a turn, this seems to have made a difference and the watch is running better with only a few seconds difference between dial up and dial down, and no sign of the extra sounds on the trace. Given that I don't have the tools or expertise to adjust the depth of the Diashock setting for the balance, I'm going to leave it even though I still think its end shake is excessive, at least until I can test it on the wrist for a few days once I've finished the case restoration.3 points

-

2 points

-

2 points

-

2 points

-

Yes the entire escape wheel, the issue is when the contact points are not lubricated as in the case of pallet fork pivots. I guess it doesn't matter where the epilame lays, the problem is when is epilame between two dry points of contact. And this may all just apply to a type of epilame at a particular point in time. This happens a lot a name that is applied to many different things, that dont all fully relate.2 points

-

But it's OK on the plate side jewels...? Taking a step back to look at the forrest (for the trees), the point of this stuff is to keep the lubrication where it's intended. If you don't use too much oil, surface tension and capillary action do a fine job of this, right? Did for a long time anyway. At some point, I suppose, the oils could migrate away, but how long does that take? If a service interval on your typical watch is 2 years (Omega's Co-Axial movements get a bit longer), and one assumes this is due to breakdown/oxidation of the oils, are you gaining anything? I am definitely no Epliame or Fix-o-drop expert, but it seems to me this is one of those deals where you're chasing the last 1% of perfection in the idiom I can't quite remember where 99% of your time is spent chasing the last 1% of perfection. By all means, chase it, but I wouldn't worry about it too much until you've achieved the 99th percentile. Just a little perspective...2 points

-

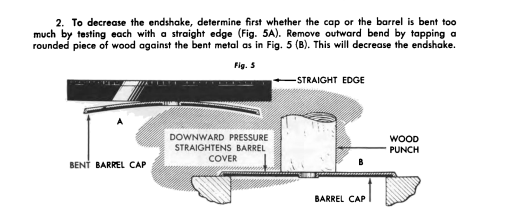

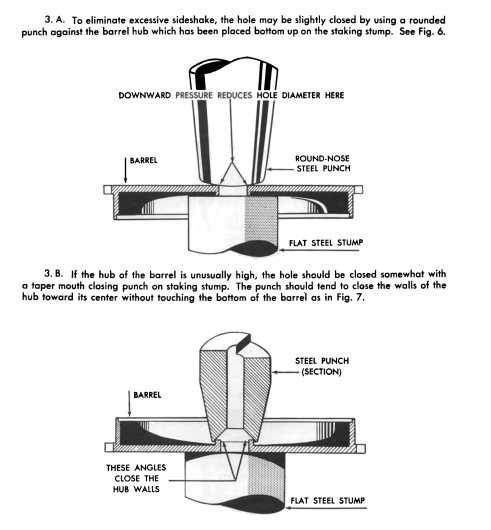

The endshake of the balance is too much. You need a little, but not too much. I try to imagine the correct amount as being about the pivot thickness. The arbor to barrel end shake - you need a little, but not so much that the barrel can hit anything. To reduce it - It's also important to check the sideshake in the barrel and bridge. These are things I always do. Too much at the bridge, the hole can be closed using a rounded punch as shown below (then use a smoothing broach).2 points

-

Ha! John And Neverenough, it is so nice to hear from both of you again it's been quite a while! I've had the year to take care of some things I needed to do, and I am back attending my watch repair courses here, and I have made a firm resolution to be more focused about watches. Thank you very much and as rjenkinsgb and caseback suggest I'll be taking it apart. And Rich, nooooooo, you do not need my address and you do not need to inform the authorities here in my town. Although I do appreciate your quick witted response to what you perceived as an emergency, the police have adopted the attitude that if you can't lick' em you should join them, and in my case that means they come for the complaints / concerns and stay for the coffee. They know all about me. Thank you anyway though that was lovely of you.2 points

-

Hi! I'm a swede in my 30s that has recently begun tinkering with watches. As much as I'm learning about watches I'm also trying to learn to be patient, both while working on a watch, not getting riled up when something doesn't work as I'd like, as well as when I'm waiting on watch parts that I'm destroying as a beginner. So far I'm finding it very exciting, and amazingly rewarding when actually getting an old beaten up watch to work properly. I've learned a lot from this forum and now I'm happy to start being a part of it!1 point

-

debatable Jill, t'was genuine concern..... mostly for your dog....a pocket watch missile lauched at his skull might leave him permanently keeping one eye on the time ma'am1 point

-

I'll take some pics once dry - I think it's inevitable that I look for a NOS one, though I could possibly push that down the line for a few weeks... Meanwhile, just because it feels good... friends reunited: An idea of coverage... It's covered... Probably by too much! Might thin it back with IPA on the front side. We'll see... Here's another under the glass and gasket... It's definitely rough and I'll want another but in the short term it might do me...1 point

-

Just got this yesterday, a G Boley bevelled bed type in pieces. The plating is starting to wear through in places, but it is generally quite clean and after adjusting and oiling the headstock bearings, they seem to still be in perfect condition. Pretty good for being around 100 years old?? I got a faceplate with it, and one collet. There is no centre in the tailstock, just the tubular clamp. The tailstock bore seems to be around 6.6mm ? I need to either find or make a cross slide or rest for it. The only bits that are missing are some of the brass washers from the clamping screws, and the pin for the indexing arm - both easy to fix. I am curious about the collets. A lot are advertised as "6mm", however the parallel section on these is actually 6.5mm; is the 6mm the thread size, or are they a different standard?1 point

-

In my research Rob there 3 main collet sizes for this style of lathe as well as the dbar Geneva style. 6, 6.5 and 8mm. 6 & 6.5 are no longer made anywhere, some 8mm like WW are still made new. 6mm you see fairly regularly on the bay, 6.5 are much rarer. Hopefully one of our more knowledgeable members will add more. Tom1 point

-

Be good to see what it's dried how the corrosion on the top has covered.1 point

-

Yes, like Never said, it's no issue on parts that get lubricated. Capillary attraction keeps the oil at the pivot-jewel interface.1 point

-

Found it! Thanks! Even so, to make your hand-removing levers you need to purchase the material (silver steel rod, brass bar) and the tools (vice, files, etc.) It would be a fun project so I wouldn't mind the cost but there are so many other things to do and to spend your money on so perhaps some time in the future.1 point

-

I think we need to stop now Walking around a supermarket with a big smirk on my face1 point

-

And after you clean out the hole with your pegging tool, do you then dip it in lube and peg it a little more?1 point

-

You could download the BHI sample lesson 1 @VWatchie starting page 124 of the pdf is the instructions to make hand levers in lesson format. they look very similar to the ones @Jon showed that his students made. Tom1 point

-

I Googled the word pegging, and it came up with all sorts of non-offensive suggestions. However, there was a Reddit page that suggested "mature content" but required logging in to read, and I wasn't interested in logging in. Anyway, see if I can figure it out. Hmm, let's see... We have something that is round, long, and stiff (the peg wood) and insert it into a hole that has previously been lubricated (oil), and then we move around the peg wood until we're done. No, don't think I can crack it. Maybe when I get older and a bit more mature.1 point

-

For doing the pallet stones, I have worked with guys who use a pipette, like the above mentioned syringe, dipping the stone into the end. Another uses a very fine artist brush to apply it. I grab the fork in a pair of tweezers, then dip closed #5s into the Fixodrop to suck some up, and open them slightly, dipping the stones into the product now between the tweezer tips (I think my method is the least practical, but I'm used to it). The thing is, according to the instructions, the part to be treated should soak in the product for some time. You don't get that with the above application techniques. Still, seems to work fine. I should ask someone who's done brand training how Omega or Swatch recommend applying it.1 point

-

He shows the technique in the video, essentially just pushing a droplet to the end of a syringe and then "dipping" the pallet stones into the droplet (easier to see than describe)1 point

-

A little dramatic Neverenough, at no point do I say that this treatment causes catastrophic failure and destruction, on the contrary, I fully appreciate the excellent qualities and benefits of this coating and understand it's widespread use in the industry. As outlined above, my concern through my logical thought process was the after market application method, and thanks to the excellent response from nikelsilver and others my concern has been addressed and should I decide to take the plunge and gear up for epilame, I have nothing to worry about. Hectorlooi's epilame pen sounds like a good idea.1 point

-

You could make this H with very little guidance no problem . Just have a go, if you mess up then make another attempt. Me thinks you underestimate your ability sometimes. I bought pegwood from cousins, it was so bitty... i got fed up of having crumbs all over my bench, whitewood toothpicks are better than the stuff i bought. I also use bamboo..i know we discussed once that its silica composition can scratch....brass yes if too heavy handed with it ...so its likely a bit hard for old brass plate bearings......it doesn't damage jewels....I've looked at x100. I remember mention of mdf sticks, I think a hardish tight grained white timber would be a good option......holly, boxwood and yew would be worth experimenting with. I keep a wooden pegging tool permanently dipped in a solvent.....now there's a connotation to think about1 point

-

There not the easiest of movement to work on. You should try putting one together without spring clamps. I did for a bit of a challenge it took hours.1 point

-

I think somewhere in the discussion group we have covered epilam perhaps before may be perhaps? But the basic procedure is the escape wheel is treated. Pallet fork is a little more tricky as you only want to treat the pallet stones themselves You Do not want to treat the whole pallet fork. Then depending upon which epilam you have There allowed to dry sometimes with warm air sometimes without. Preferably the dust free environment. Then it goes in the watch is run from little bit the running action will scrape off the epilam..Then lubricate with your favorite method for lubricating the escapement. Oh and I always think of epilam for the escapement I keep forgetting they liked epilam the whole darn watch so maybe we're not even discussing the escapement epilam as I'm not sure you specify where the problem actually is?1 point

-

I wonder how many more horological terms that we use on a daily basis have other connotations.1 point

-

Haha absolutely not H , even i would ban you from the forum if you said " is it ...................? " if I had the power to do so and I'm as open about things as anyone can get . I'm sure a quick google search will answer it for you..........I await you your..... imoji ....lol.1 point

-

FWIW. Alex Hamilton has a great video on epilame, with a nice detailed discussion of exactly where/when/why it's suitable. His conclusion IIRC: - he doesn't use it in his own watches. - uses it on professional work as "it is expected" - don't bother if you are just starting - only apply directly to surfaces with a syringe,1 point

-

Fantastic! I don't know how to make them, but they look amazing. What is the type of metal/alloy? If/when I visit your workshop, I would really like to have a go at it. I have Horotec hand-levers. They work fine (although expensive), but these look like they could be a lot better. I'd even be interested in buying a pair if you or one of your students would be willing to make me one. For those of us who are not native English speakers, I can only guess. Am I right in assuming that it would not be appropriate to explicitly explain what the connotations are?1 point

-

The steel in those American clocks is as soft as s***. Those black American cases are made to look like black slate like the French use but in fact they mostly wood. I have seen a few made of iron.1 point

-

then in addition to some existing and some not existing the majority of them only partially exist if they exist at all. Many of the watch companies felt that wherever was servicing their watch was probably a professional watchmaker so basic guides explaining lubrication of every single caliber probably do not exist. So a lot of times the only cover unique features of the watch. Then when they were scanned from paper to PDF typically scanned by material houses solely for parts not for servicing. then in addition to parts manuals websites covering parts are handy this one is nice. Yes there others I just like this one for most stuff. http://cgi.julesborel.com/ then you go to the Bulova section and ultimately get here http://cgi.julesborel.com/cgi-bin/matcgi2?ref=BUL_11BLCD then just because it has a price listed doesn't mean it's available sometimes it will tell you if it's discontinued but don't assume because there's a price that they still have it in stock. What's nice is you click on the part names ever give your cross reference the everything cross references to handy when you're trying to find the part then they fail part number you can go to the main site and do a search and see if they actually have it in stock or something like this I would probably go to eBay as there's all sorts of parts more than likely. http://www.julesborel.com/ the problem with the watch companies are a lot of them are in name only. In other words they were purchased or combined with other companies and have moved and anything in the past is now gone. So Bulova is part of citizen and they've moved so I would be really surprised if they had anything at all plus I'm very surprised that they could even service the watch more than likely they would send it out. In addition to probably whoever's answer your request doesn't even know what it is anyway for instance Bulova made a tuning fork watch called a Accutron. But now Accutron is just a brand or division of Bulova. If you wanted to send your tuning fork watch to them they have a very tiny list of preferred people across at least the US who would service the watch they will not service it themselves at least the prior generations. I've heard a rumor that are coming out with a new tuning fork watch so that probably have to service that. then if you're looking for Bulova stuff this is an interesting site https://mybulova.com/vintage-bulova-catalogs1 point

-

It sounds like you are doing the correct thing. Sometimes you cannot get them in without pushing the chaton out a little. Do you have a jewelling tool?1 point

-

1 point

-

I like that! As long as the composition of the stick can allow whittling it down to a fine point, job done. Also, pegwood isn't cheap for what it is. I've harvested my own pith before from an elder bush/tree that grows near me. It depends when in the year it is picked to how spongy it is. Picking it in the spring and summer yields the best results. Now that stuff certainly isn't cheap. I'm always amazed at how many products are aimed at 'watchmakers' with the view that we must be totally inept to not make it ourselves. Sometimes it is just easier to buy a tool, but sometimes making one is so much better. Hand levers... buy them, seriously? I know some watch enthusiasts haven't the skillset (yet!) to fabricate tools and parts and a lot of my students haven't picked up a file since they were last in school, but the look on their faces when their tool excels the bought version. Classic! Here's some pics of the technicians from Mr. Jones Watches who made their hand levers last year. A very talented crew and a credit to Crispin Jones. I am careful how I use the word 'Pegging' because of the connotations, but also I once told a student to 'peg-out' the jewels holes and when I came back around to his workbench, he had pushed all the jewels out from the bridges and mainplate and had them in a neat little pile! When I told him that wasn't what I meant, he said 'That's no problem, I'll push them all back in again using the pegwood.' Simple!1 point

-

oh minor little problem here perhaps? What is epilam? Epilam is her variety of substances stearic acid I believe was the first one. But over the years has evolved into other substances and whatever these substances are dissolved in also plays a role in problems. For instance several years ago somebody posted on the Internet that I know of shops that were very concerned about this the solvent that the epilam was dissolved in a evaporate it extremely fast. But unfortunately typically anytime something evaporates really fast it gets cold or basically removes the heat and the object gets cold. Unfortunately cold steel products in an environment of moisture in the air will form droplets of water and ultimately rust. I know several years ago this was a concern there was the website that had pictures of look at all the rust. I knew I shop that was so concerned that she had a hairdryer on radiant producing hot air so they can immediately place the part in the hot air to evaporate without getting the part cold at all. then evolution the new stuff is environmentally friendly supposedly. It no longer instantly evaporate civet's left uncovered and Omega recommends it as the final rinse in the cleaning process with only a few items that are left out. Basically the balance wheels left out I know we've had discussions of epilam so somewhere I posted pictures of what's left out now. But Omega's amusing for this because in the early 60s they epilam everything except the balance wheel and pallet fork but in the case the balance wheel you were to put epilam on the pith wood and stick the pivots in so that they would have epilam. Then they went to just doing the escapement and now they're back to doing everything almost then the modern shock jewels they been epilam with some unknown process probably a vapor process. ETA has technical communications with service information that up until recently didn't cover epilam at all. This is because most the watch companies had supplemental information that we never see typically. But in their manufacturing information sheets you find out that the balance staffs and escapement have epilam. oh other minor little things that would affect the discussion would be as epilam older likes to evaporate as and evaporates the concentration of whatever increases people using older bottles with higher than whatever concentration conceivably will have thicker coatings and conceivably that may be causing some of this problem? In addition to the fact of all the various epilam's conceivably are different chemistry. interesting so if it wears off causes a problem then what would be the outcome of that problem? this is interesting because? In the case of the escapement it shouldn't be a problem because the escapement components are covered with epilam and allowed to run dry which wears the epilam off before you put the lubrication. Oh and regarding epilam placement and wearing off I've attached a PDF where they talk about in manufacturing removing the epilam before lubricating. Now the interesting problem is when you epilam the entire watch and it's all over the keyless and conceivably it will mix with lubrication but epilam is normally at a microscopic level so it can't really have that much effect although I am curious as to what bad affects people are seeing? we also end up with application problems in your discussion? For instance if you look at modern technical sheets or Omega they use a very little grease and a heck of a lot of oil on the keyless. For instance as far as I can tell any time you use 9010 if you would like it to stay wherever you put it you should use epilam. If you look at Omega's oldest documents they use 9010 on the keyless the lightest oil and yes they epilam. But what if you were to use grease like 9405? In which case you wouldn't have to epilam the whole darn watch. Then there is the escapement epilam's to keep the oil in place but what if you use 9415 which is a grease with interesting properties. So if you're using a grease on your escapement would you still need the epilam? one of my amusements with horological lubrication is the lack of why they do any of the things they do. they were also missing of the complete picture in other words the supplemental information of what we're supposed to be doing or not and what exactly the factory is doing as I mentioned up above epilam ing the balance staff is almost I don't think I've ever seen a reference to doing that right yet it's being done. I would really be curious about the part on increasing amplitude I'm not sure how epilam would play any role in that at all. then as long as are recommending things like oil on the keyless obviously keeping the oil in place epilam would be necessary. The unfortunate problem of lubrication choices epilam or anything we do is it takes time to find out if you did poorly. in other words if you can examine a watch that you know you service X years ago you can look at it carefully and see if you chose wisely or whether you made a mistake. GB1057607A-1 epilame.pdf1 point

-

I have mixed feelings on the whole issue, I use epilame but every time I do I have a nagging voice in the back of my mind asking if I am just "Drinking the Kool-Aid"... I think that, cost asside, there is little down side with the sensible use of epilame, so why not? But, I have yet to see real evidence that it either prolongs service time and/or reduces wear in components and/or increases amplitude. All of the 'evidence' I have seen is anecdotal which is understandable due to the complexity and multi-year testing that would be required to prove (or dis-prove) the case for using epilame. So I remain on the fence, and I will continue to use it and ignore that nagging voice.... oh and the other one telling me to burn things... but that's a different story1 point

-

Or maybe I could just grind a matching profile on the other end and centre the cutter in the holder...1 point

-

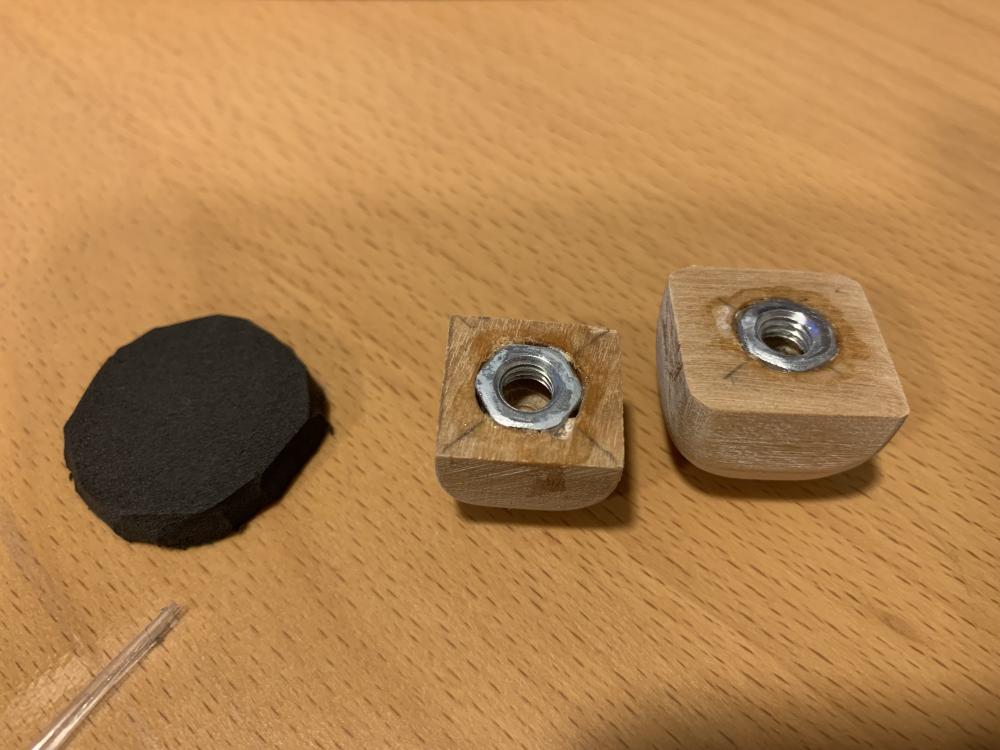

I actually did this a few days ago to put my 1st acrylic dome in. I have one of the cheap lever style chinese presses. I sanded down some scrap wood, put an M6 nut into the back and just used some super glue to hold it in. I put a small piece of foam over the dome when pushing on the crystal. Without the foam, I broke a crystal, but I chalked that up to also being too large and being the 1st time I have tried this, was using way too much pressure to make the larger size fit. The smaller size down is the one that ended up fitting.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)