Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/24 in all areas

-

Why the evangelism approach? Most of us here are repairing mechanical watches where this would not work on any practical level for us? I am always interested in horological innovations however, me personally I don’t see this as one, more of a fashion or fad TBH. I personally would turn anyone away asking me to fix an oil filled watch as it would just ruin my day. Tom I approved your latest post but still this is not really a general thing and very niche. Tom Oh, I also have known quite a few divers from SBS to commercial deep see divers and quite a few in between and they would laugh at anyone using a watch rather than a dive computer.3 points

-

While not cheap, the Vallorbe "buff" files are fanstasic. Vallorbe says they are equivalent to a 10 cut file, but you can get an even finer finish with a lighter touch. They're cagey about what exactly they are coated with ("composite abrasives"), but they will cut tungsten carbide no sweat, and ruby too. An added bonus is the handle is also coated, so you can use the handle for manky work, keeping the formed end in better shape. I use the escapement files, but the needle files are the same just larger. https://www.cousinsuk.com/product/escapement-buff-files?code=F59706 https://www.vallorbe.com/en-ch/products/files/buff-files3 points

-

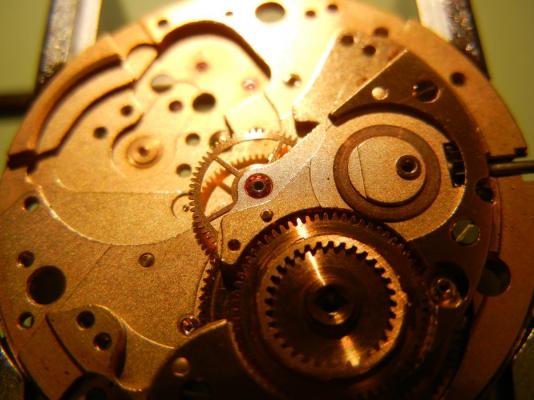

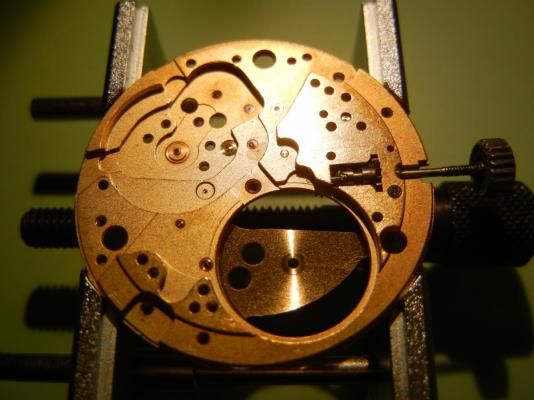

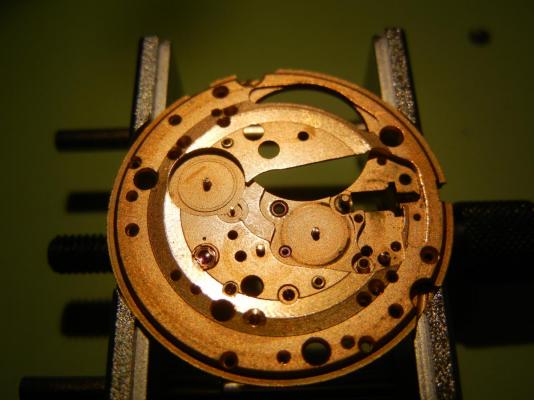

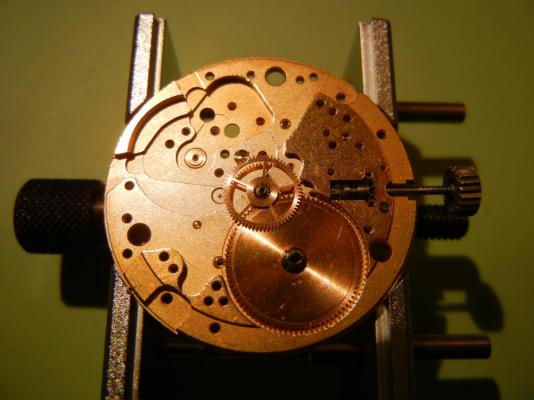

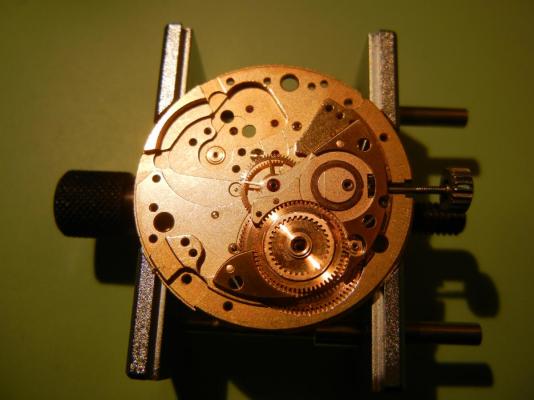

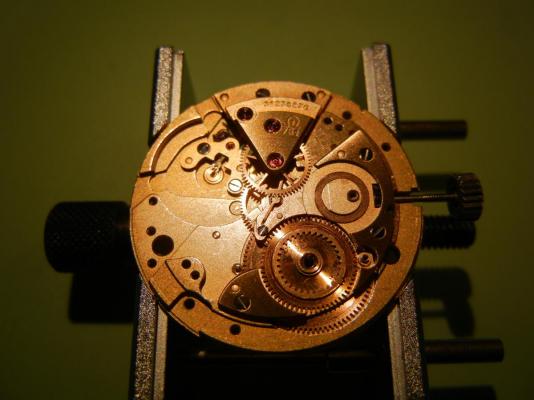

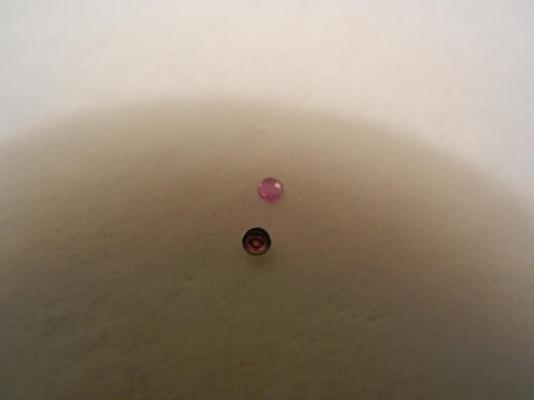

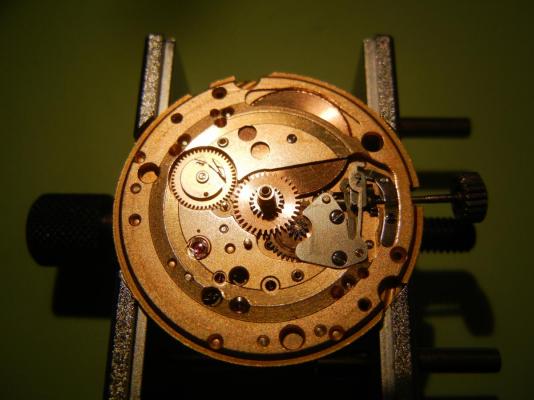

…my Watch O’ the Day today. This one is under monitoring as it was a mess and I just buttoned it up. A bit of a scam this one was as it was messed up in a way only someone experienced would have done… The hairspring was out of the regulator and bent in a way so the balance wheel would turn just enough so the auctioneer could write ‘ticking’. The banking pins were bent outwards about as far as they could move and it tricked me for a long time. A picture from WatchGuy solved it… …the roller was supposed to look like this but someone had replaced it with a one piece far too large to fit, though it looked fine in the watch. My mistake . I filled the wheel with the missing screws and rebent the over-coil to see what the escapement was doing, so I get to the bad roller in a roundabout way… I sourced a new balance. The hairspring needed some heavy correction and so far its holding. I may go back and repeat the service as I spent much time messing with the escapement…3 points

-

I'm confused as to why you would like to remove the hands? Typically on the stopwatches as you have a picture of the hands are attached to heart shaped cam parts on the other side of the dial. Those of friction on with the spring onto a driveshaft. The hands typically are hammered on with considerable force because otherwise when returning to zero they will go past. Typically in a repair the dial is removed and the hands and the heart-shaped cams the dial are all one unit is no need to do anything with them. Otherwise if you really want to remove the hands they make a special tool that goes on either side of the hand sorry I don't have a picture right now and then a center pin would push down and lift the handoff because you can't pry them off like normal hands you need a special tool for stopwatch hands. It's very similar to a tool you'd used to remove gears off the end of the shaft its friction Don.3 points

-

Here is my haul from the Friday swap meet and 1st Saturday of the month vintage fair. 11 watches for $9.50US (£7.30) each. They all work except the accutron (hopefully just an accucell which is on its way) and the Gruen with a broken staff) the Illinos pocket watch (from 1919) is missing the crystal and the dial is beat but really runs nice and the movement is very nice. It was part of a lot that was $1 and pulled down the average of the other 10! The Tissot rock watch is in the original box and the receipt from a cruise ship in Jamaica from 1991 shows someone paid $110US. Love the hunt, and then the opening and research into the piece. The Ultramar has a Felsa 690 auto with 25 j. The center seconds pinion is broken and seconds hand is missing. Had the correct new acrylic. On the Accutron nice case and original crown. It was a presentation piece for 25 years at Goodyear 1975. 25 years for a rolled gold watch. Oh well better than nothing; hope he got a good pension as well. The Autocrat A new bow is on the way as well as crystal.3 points

-

Niche is niche, I.e. very little application in the real world. I don’t personally see any benefits to a watchmaker at all. Tom2 points

-

It’s a very edge case for the benefit of doing this, mostly marketing for Sinn. How many watches will ever get below 2m of water? In the real diving sphere this is not even a consideration. Tom2 points

-

2 points

-

Sounds like the rotor is fouling something. Could be that the rotor bearing is loose which your watchmaker should have picked up on. Alternatively, it might be that your watchmaker swapped some screws and the rotor is fouling on the screw heads (I did that with the case clamp screws on an ETA 2472, so I know it's possible). In either case, you don't want the rotor scraping against anything and potentially shedding metal shards into the movement. I'd suggest going back to your watchmaker and asking him/her to take another look.2 points

-

I noticed from my aforementioned dalliance that they step in automatically for disputes below a certain dollar threshold. No idea what that is, but there's no way a human was involved in that interaction based on the speed of it. I had a dispute a while ago for a larger amount, and it was much more involved.2 points

-

OK, it's just with you being a new member and posting this in the. New to watch repair ** Safe Zone For Learner Watch Repairers **2 points

-

Morning people hope we are all well, Paypal coughed up for my missing parcel today, only one day after raising the issue . I suspect its a one off as it's the first time i have asked paypal to step in2 points

-

The hands are fitted without oil, so they should be dry . Use wide hand levers. They give more control and the load is spread more to avoid damaging the dial.2 points

-

1 point

-

A little over a week ago I tried making something resembling a balance staff for the first time. It wasn't for any specific watch, just trying to get a feel for how the gravers and steel "worked". I got encouraging feedback , so today I decided to try again. Now for an actual project, a Junghans J47 with both balance staff pivots broken. I do actually have some new balance staffs for this specific movement, so that made it easier to get good measurements. I won't ask you to spot the differences between the DCN staff and mine (my wife sometimes says I'm snotty enough already), but any feedback is greatly appreciated.. Tonight I'll fit the wheel, finish the pivots on the jacot tool and see if it will actually work..1 point

-

Hello and a genuine welcome. If you don't know why people took offence at your first post then perhaps you never will. Even the professionals on here are quite humble.1 point

-

42531 https://www.ebay.ca/itm/124572809479 Edit On second look I'm not sure the eBay listing above is an actual 42531 Should be more like this that's just been sold. https://www.ebay.co.uk/itm/1351142284621 point

-

I saw that, impressive work! Your post is what got me thinking that mere mortals also have a chance at making useful stuff out of metal. I've been amazed at what the machinists on youtube can do, but it's always seemed like witchcraft... But do did watchmaking, until I got into it. Well, a lot of it still baffles me to be honest. Yes, and I wonder if the old staff was even the correct one. The hairspring collet and roller are both slightly cracked as if forced onto a too-large staff. I realize that at this point I should consider replacing the balance complete, but where's the fun in that. Hang on, the serial number stamped into the case back of the one you linked to matches mine! The exact perlage pattern doesn't match though, so can't be the same case back. Is "1407096" not the serial number then? I'm confused.1 point

-

The OP staff is press-fit, like in Seiko and Orient. The AS staffs are riveted type1 point

-

1 point

-

I approved this post because it doesn't break any forum rules but I think for a first post claiming that our minds are closed is a bit arrogant.1 point

-

I recently picked up a watch/clockmaker job lot with some very fine diamond files, not vallorbe, but look decent. So they are out there. Tom1 point

-

It's a great excuse to get a watchmakers lathe, a feintaster, and..., and... I have recently made my first working balance staff and posted the result on this forum after getting feedback and encouragement on my first attempt. There is a lot of help available here.1 point

-

…to try and address your issue- I beleive it would be unusual for a Grand Seiko to have original glue exposed on the dial side. Too much quality control at factory for that to happen. More likely this is dirt or old oil or yes, perhaps a post factory reglue for some reason… Hodinkee sent me an article with many photos of vintage GS, some with heavy patina but no brown spots by the markers… https://www.hodinkee.com/articles/a-tour-of-grand-seiko-part-21 point

-

Yes it's just that it's such a rare dial I thought someone may have pieced something together. Date & Lion on rear is correct for December 1964. I think you're right in that something has been done to reattach the dial markers.1 point

-

You certainly haven't wasted my time I enjoy helping. The best clock oil is Windles Clock Oil and it isn't expensive.1 point

-

Put a tiny drop of 9010 on the hands and try lifting just one hand at a time. Are you using hand levers or Presto tool?1 point

-

I hope it works out for you. Once you get the set, you might want to do a cleanup on the frame. The die plate holes look to be dirty. If it was mine, I'd disassemble the frame, give it a good cleaning and lightly oil it. Maybe put the die plate through an ultrasonic cleaner. On mine, I also cold blued the central hub, stake holder and screws.1 point

-

Ernest Tope would be the man down there, he does very nice work.1 point

-

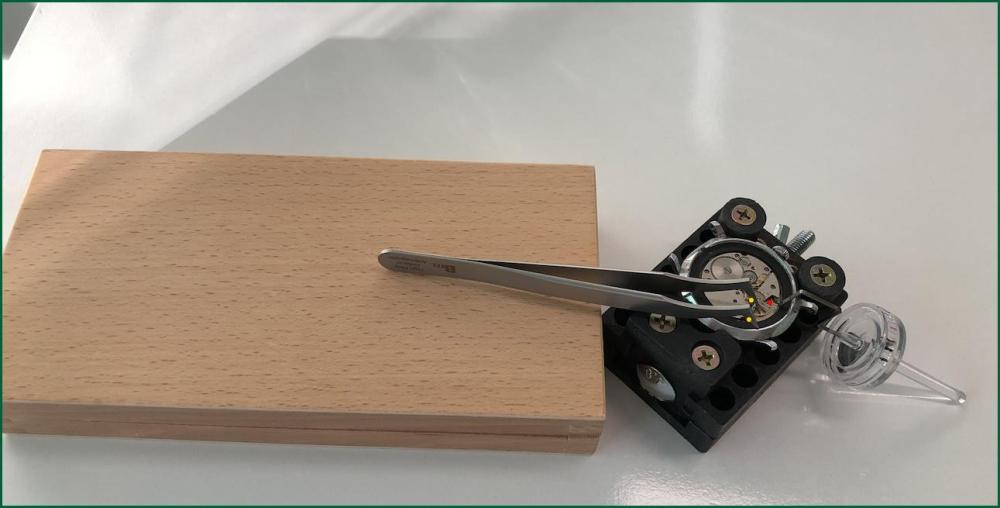

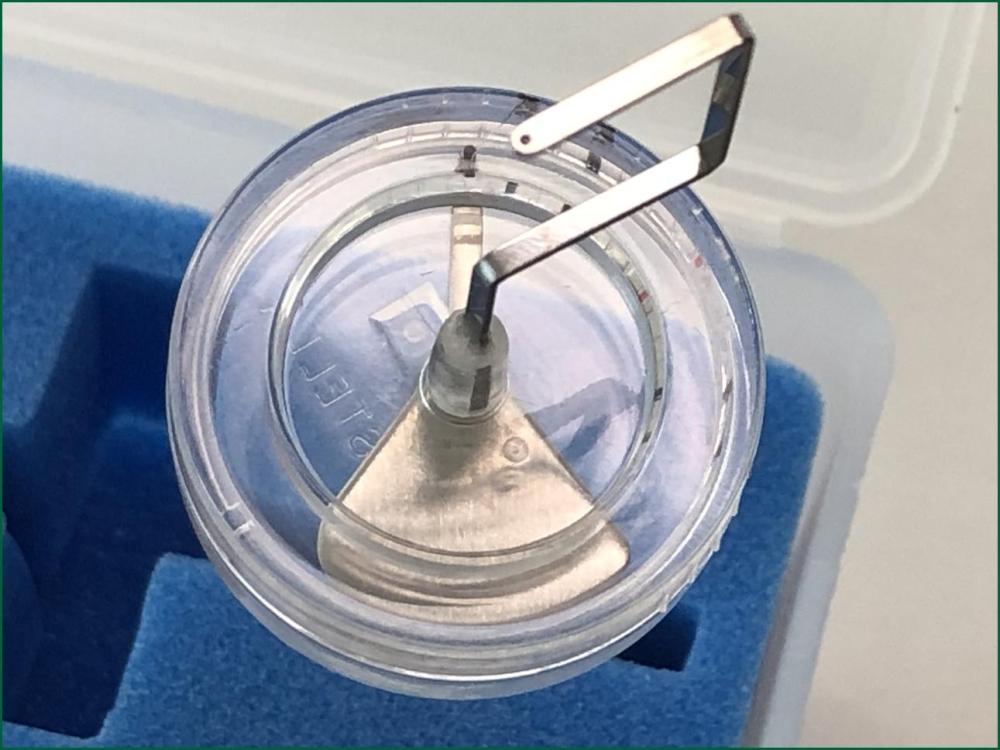

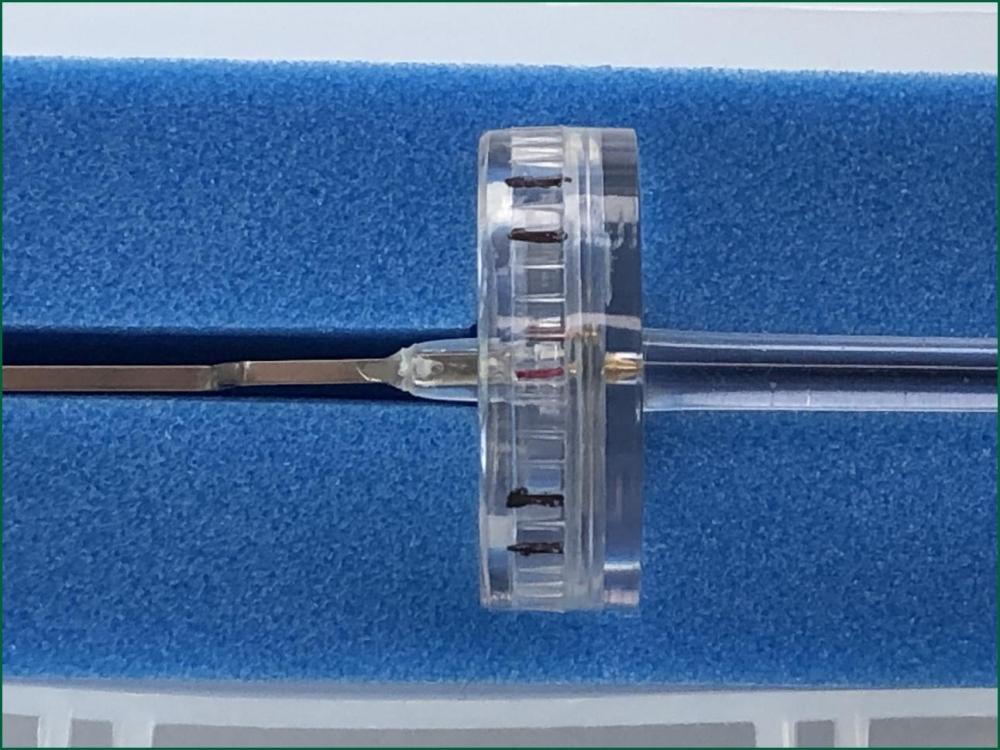

Yesterday I regulated the rate using my newly acquired Microstella tool. What I feared could become a difficult and gruelling experience turned out to be very pleasant. When I finished, I reflected on how much easier it would be if all movements were regulated similarly to this Rolex calibre 3135. It turned out to be not only quite simple but also very precise. @Jon's tips and video as well as @Endeavor's and @Mark's tips (links in previous posts) were very useful. I don't have a tripod for my phone so I can show how I held my hands but at least the picture shows my setup except for the watch itself which is a junk watch as the Rolex watch is currently spinning on my Cyklomat. I am right-handed so I held the tweezers with my left hand which could rest safely on the wooden box and handled the Microstella tool with my right hand which could rest safely on the work bench. The advantage of this type of small (and inexpensive) case holder as seen in the picture is that the Cyclops eye above the date display is in a cavity in the holder which means that the watch case wont tilt. In general, I think it's easier to regulate the rate while the movement is on a movement holder as seen in Jon's video, but I still decided to do the adjustment with the movement mounted in the case, and since Rolex advertises the Microstella tool this way I wasn't too hesitant. By letting the inside of the tweezers rest against the balance bridge (the yellow dots), as Endeavor describes, I got good stability and could grip the rim of the balance wheel without the risk of accidentally moving the tweezers sideways, lengthwise, or vertically. After that, it was no problem to place the tool over the Microstella screw (the red dot) and rotate. Following Rolex's instructions, I stopped the balance wheel by pulling the crown out to its extreme position and then carefully rotating the balance wheel until the first of the two screws needing adjustment was aligned with the most convenient way to hold the Microstella tool in relation to the screw. What I didn't realise, which scared me a bit in retrospect, was that the impulse pin could have caught on the outside of the fork horn as I rotated the balance wheel. I guess you can probably feel if that would happen, but I think you need to be a little observant of this which is why I mention it. The tool itself I bought at Cousins. It is a rather expensive Korean clone of the original Rolex tool and works well but does not give a feeling of really high quality. What is critical is that the fit with the Microstella screws is precise and there is nothing to complain about. Something to complain about is the weight on the inside of the tool which is supposed to always hang vertically and indicate how much you have rotated the tool. On my copy, the weight rotates so slowly that it almost loses its function. Perhaps I got a Friday afternoon model but maybe it can be adjusted. To compensate, I made marks with a permanent marker on the wheel to make it easier to see how far I should rotate it. It worked well. When rotating the Microstella tool, you must try to keep an eye on both the screw and the tool. There is a risk of focusing only on the tool and slipping off the screw, thinking that you are still rotating the screw but in reality, you are only rotating the tool. The screws are seated with relatively high friction (as Jon mentioned) but because we are working in a microscopic environment, there is still a risk that you do not notice that you have slipped off the screw while rotating the tool. So, that sums up what proved to be a pleasant experience. The current rate while the watch is spinning on my Cyklomat is +1.6 seconds/day so I think I'm done, and I'm pretty sure I didn't upset the poise. I'll do some measuring on PCTM a bit later.1 point

-

If you are looking for someone in the U.S. who can make the minute wheel and replace the jewel, Matt Henning is excellent. For more info on the movement, post it over at the NAWCC forum on complicated watches. Rjenkins has narrowed it to a Patek related movement, but someone made the base (LeCoultre, etc.).1 point

-

Sorry for the question, but, do You know how to replace such jewel? It is rolled one and not pressed like modern jewels. You must not screw up the way the movement looks by deforming the stone seat or leaving any kind of marks there. This is not a movement to learn on.1 point

-

You need to find out why the teeth of the wheel stripped, if not the same thing could happen to a new wheel.1 point

-

From some very quick research, it seems the Swiss Tiffany company shared the Patek Philippe factory at one time, and used their movements. That serial fits the Patek Philippe movements, and would put it early in the 1905 - 1910 range. Info from here: https://german242.com/en/patek-phillipe-cie-geneve-serial-numbers/ The movement does appear to be similar to Patek Philippe ones from circa 1900, as this one: https://somlo.com/products/18ct-yellow-gold-hunter-case-minute-repeater-pocket-watch1 point

-

1 point

-

I remember when I was teaching I had a student who giggled every time I said "cock". He lost it when I told him the pivots in cylinder escapements are called "tampons".1 point

-

I’m now eagerly awaiting the “I made my first pallet fork” post well done on your achievements @caseback Tom1 point

-

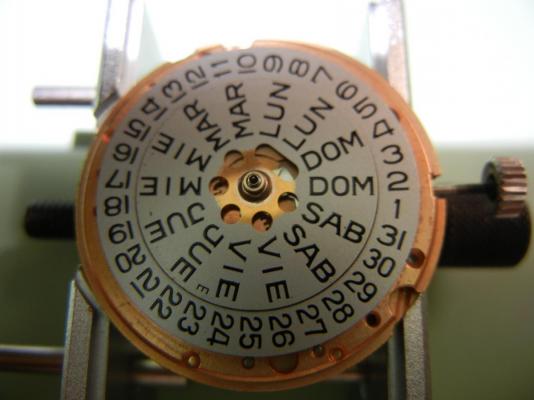

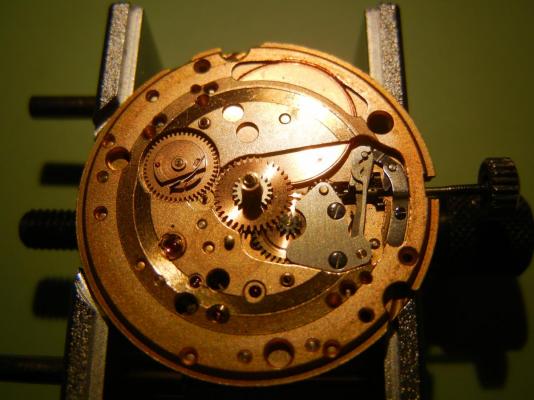

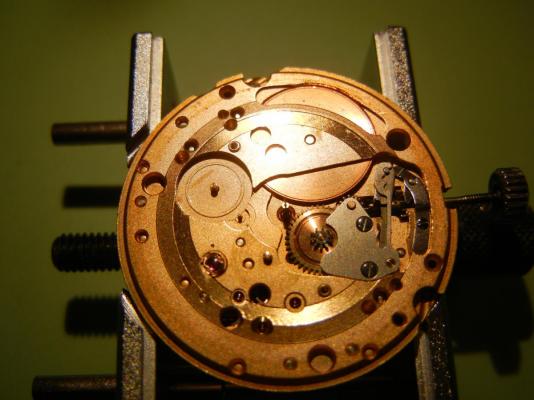

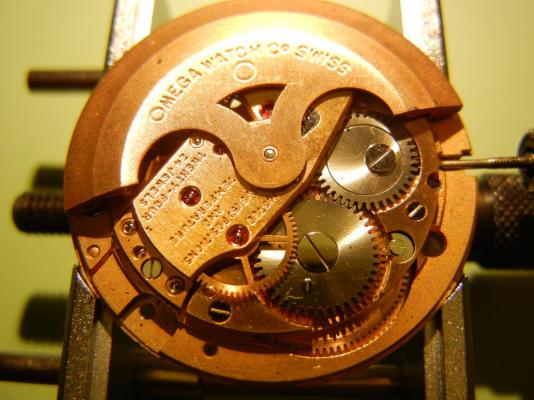

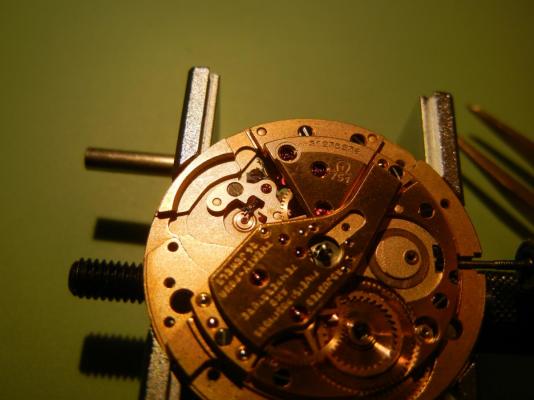

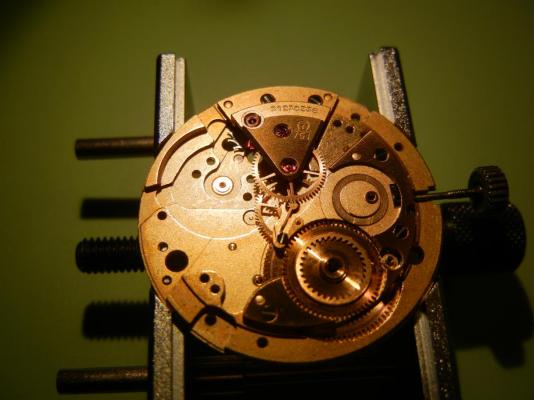

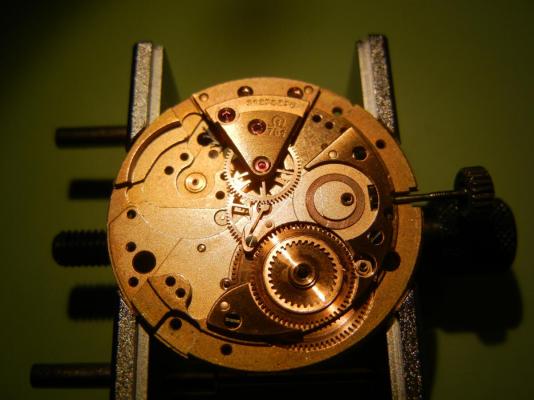

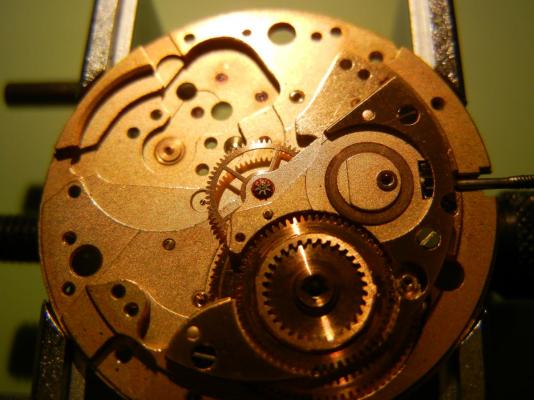

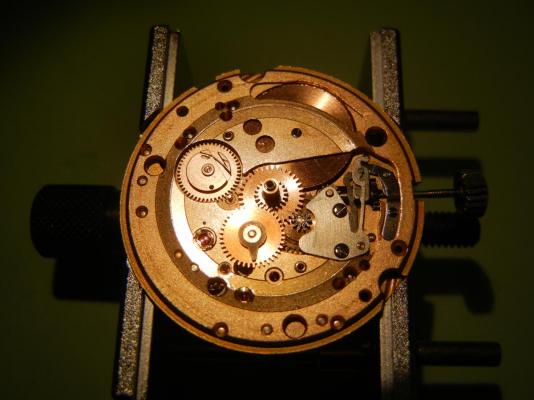

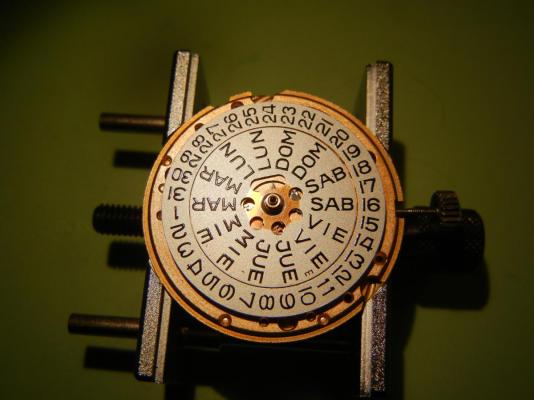

My favorite watch---a stainless steel omega with a missing bezel. I finally got the courage to give it an overhaul even though it runs perfectly. It is original in everything except the darn bezel is gone---its hard to find one these days but I almost don't mind becasue it looks very clean. I beganby very carefully uncasing: I immediately noticed the movement was cradled in an additional metal ring with screws The dial itself has a curious ridge around it that I figured out is to help stabilze it when mounted on that ring. The dial is also held in place with screws of course. The day (in spanish) and date wheels, and a complicated quick set mechanism that took me a while to rebuild: The movement is very nice and finished to a high level--something very different compared to my pin pallets watches I like so much The bridge was intimidating with its separate level of gears and jewels And continuing with the tear down: It was nice having a separate bridge for the drive gears Rebuilding was straighforward: I opted out of taking apart the bridge and just cleaned it as best I could and carfully checked it afterward Lets face it: The incablock sping system makes it very easy to clean the jewel and cap. Much better than novodiac spring I am used to: For the dial side I have to admit I got a little careless and overlooked some key details about the where the quick set mechanism should be positioned. Because of this I had to redo it twice--meaning I had to remove the dial and hands AFTERI had put the whole watch together when I discovered I could not set the date properly. The day is in Spanish which is fine because I am proficient and I like the abbreviations. The dial looks great ...YES I DID GET THAT LITTLE BIT OF RODICO OFF! The watch is recased and is ready to be worn. Its keeping the same great time as before I took it apart which is good! Hope you guys enjoyed the walk-through.1 point