Leaderboard

Popular Content

Showing content with the highest reputation on 11/09/24 in Posts

-

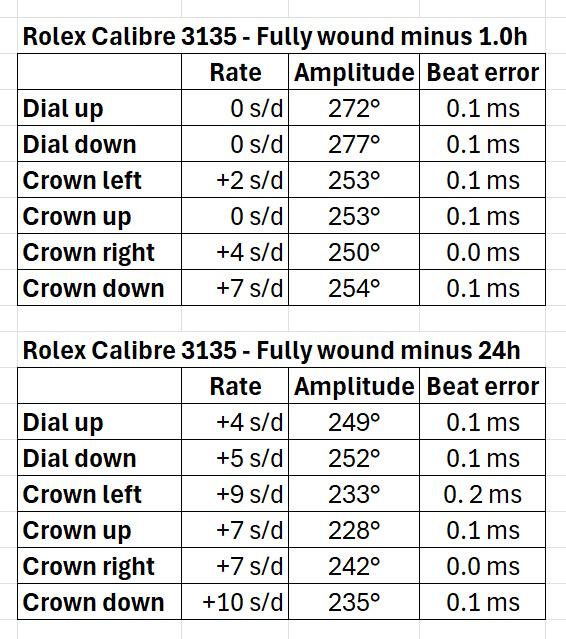

Tomorrow it is finally time to hand over the watch to the owner so this may be my last post in the thread. It feels a bit solemn. It has been an educational and fun time to have had the privilege of servicing and repairing this beautiful Rolex Oyster Perpetual Date with its fantastic movement calibre 3135. All the help and information you have so generously shared has been crucial, so again a big, big thank you. Special thanks to @Jon for sharing his professional and in-depth experience and to @Knebo for the encouragement (and facts) between us enthusiasts. I am sure many others will appreciate and benefit from this thread in the future. The final challenge was to regulate the rate with the Microstella tool as described in my previous post, which I did in two rounds, most recently yesterday. Here are the final results measured with PCTM. Each measurement is averaged over three minutes. It is very satisfying to see that all values and performance tests, including the rate, are now well within Rolex's specified limits.9 points

-

A bargain it certainly is not. These types are novelty clocks. You are right about the age. Not worth spending money on. The hands are made of plastic and so are the roman numerals. The original Cuckoo Clocks never hung on walls never had weights and certainly never had hanging pendulums hanging outside under the case. The original ones had fusee movements and you would wind them like any normal clock the pendulum would hang in side the case from the back plate, the hands and numerale were made of ivory some were decorative they would be on tables or a plinth that was fixed to the wall. They are expensive to buy like over £2,000 Here is a picture of the sort of clock I'm talking about.2 points

-

If the plug was wired as Red-Live & Black-Neutral as the Red only goes to the rheostat then yes I'd expect at least the top part where it's fitted to have potentially been live. In the past nothing was labelled and there was no standard for colours.2 points

-

Ok, I now understand that the Diashock setting does not have parallel sides that can be height adjusted: it has a fixed height and needs to be pushed all the way in. I have a Seiko 7S26C donor movement and I used it to experiment with my recently acquired staking set. I pushed the Diashock setting out of the mainplate, then pushed it back in. Then I swapped to the 6105 and gave the Diashock a good push. I couldn't feel any movement, but with the pallet and balance reinstalled I can now see light between the balance and the pallet bridge when it is dial down and I'm hoping it has moved it enough. That's enough for today, but when I get to it next I'll take the pallet out again and re-do the free oscillation test with the pallet bridge in place. With the pallet in it is swinging for about 22s in DD and something similar (as best I can tell) DU and about 18 or 19s in crown up. I was hoping for more but I guess the pallet takes a little of its inertia each swing so the real test will require that removed. I would like to do the experiment of flipping the capstone at some time, but I'm not sure about doing it on this movement just now. Perhaps I'll try it when I'm doing the final reassembly and lubrication, but at the moment its looking like it won't be necessary.2 points

-

Thought i would just make some members aware of a pitfall with ordering from aliexpress... but not just Ali...but any out of country company that uses EVRI. Two months ago I ordered some tools from Ali , they used Evri parcel delivery at this end to make the final journey in the UK.. Evri's driver dumped my parcel on my door step while I was out, normally I would get three attempts then it would be dropped off at a pick up point for me to collect. I returned home around 4 hours after the delivery to find that some scroat had walked up to my front door and walked off It. The last 2 months i have spent backwards and forwards with Evri and Ali trying to resolve the issue. Evri being extremely unhelpful and unresponsive to my emails and requests to resolve the issue. the deal is that the buyer must approach the seller to handle the situation, which i did, he was also very unhelpful and said i must deal with the delivery company direct. After endless Emails to Evri, their managers and the CEO and promises to fix the situation for me, I eventually received a phone call this morning, most probably due to a huge rant from me in an email yesterday containing all manner of threats. The Evri agent drafted me an email while i was on the phone with him, explaining the driver's cock up, something that ive been asking for 6 weeks. Hopefully Ali will accept this as an " official proof" of lost parcel. Looking forward to a positive outcome in the next few days, I also have my bank contacting me to help as well. . just to add when i first made evri aware of the stolen parcel, there was no offer to remedy the situation only a promise that it would'nt happen again......which it did 3 weeks later left in a plant pot on my front door step......ffs.....I ask you....." THICK AS F__K ! "1 point

-

Yeah, I know I lucked out on the set. The seller already told me he is sending out replacement stakes for sure and the sub-punches if he has them. Yeah, I was going to ask if there was a method to the organizing madness but I forgot. Glad to hear I am not the only person who finds the organization of the stakes questionable. As for the balance staff remover part I have to admit I put it there because I could not figure out where it belongs! It is the only place where I could fit it and not rattle around. I looked on the net, but could not find a picture that showed that part (or I could not see it in the picture, which is more likely). Thank you for the web site. Hopefully the seller sends me the stakes, so I will not have to buy them but just in case!!1 point

-

That maybe sufficient to test the operation of the machine but due to lack of earthing and unknown condition of the insulation along with the individual cores to the motor a rewire would be the only way to ensure safe use. If it is to be powered up then it needs to be on a variac with current monitoring to slowly increase the voltage. Edit Also before power is put anywhere near it the heater, motor and rheostat should be checked for any shorts.1 point

-

1 point

-

Yes, love it!!! Dave's watch parts currently has a 26C (but not a plain 26) and several 36 stakes available, used. https://www.daveswatchparts.com/StakingTools.html Sorry but my last response got tacked on to a reply to GP (who I purchased a very nice set from). Here's what I said: Dave's watch parts currently has a 26C (but not a plain 26) and several 36 stakes available, used. https://www.daveswatchparts.com/StakingTools.html I've bought several times from Dave and he's very response. If he has the part it will be much cheaper than Ebay. Looks like you got a nice set.1 point

-

Glad to hear that the set looks good and the transaction was smooth. As it is a vintage set, there are likely to be some issues. Yours seem minor. You might be able to find replacement stakes for 26 and 36 either from the seller or on eBay. You could try straightening the one stake by clamping it in a drill press chuck and hitting it with a mallet opposite of the bend. Not sure how successful that will be as I believe that they are hardened steel. Trying to straighten the sub punch might end up with it broken. Not sure just what the sub punches are useful for, as I haven't used any of mine yet. Maybe someone more experienced can chime in on that. On closing a barrel arbor hole, since that is an Inverto, you can find two adjacent numbered round tipped stakes with one placed on the bottom and the other used from the top. You can also use a rounded stump on the bottom. A bit of a note on organizing the stakes. Not sure why K&D organized them as shown on their stake diagram. You do have extra stakes in your set (above and beyond the 100 that would have come in the set), so it is good to group them together by type. I organized mine in columns, based on stake type, to make it easier on myself. Strange that part of a balance staff remover is sitting on top of the frame, where the jeweling handle goes. That should be down next to the other balance staff remover.1 point

-

Don't just strip it all out as whoever you get to rewire it should want everything still in situ. Please also make sure that they check and earth each individual metal part that needs it. Purely industrial so no diyers should be anywhere near them.1 point

-

Yes you'd expect that but it ain't always the case. In the past we built control panels with an Incoming Isolator so you've got a Brown and Blue wire on the top and the 'Electrician' needs to connect their wires to the bottom. The amount of calls we had asking which wire goes where was unbelievable so now we have to wire the bottom of the Isolator to terminals marked L&N1 point

-

Do your free oscillation test with the pallet bridge fitted but not the pallet fork. As you said Just thinking, bottom pivot might be short, you have excessive endshake for a reason.1 point

-

It's hard to be sure just from photos, but to me the termination of the yellow-insulated wires inside the housing looks fine. Not the cable joins, though. I'd replace the whole mains cable with a new one of suitable length. You need an electrician. If you don't know an electrician, ask around your local friends and family; there's a good chance someone will. Even if you do the wiring yourself you should have an electrician check it for the integrity of the insulation, etc. If the motor does not work, or works intermittently, it might just need new brushes, as these are designed to wear and be replaced. Again, your friendly electrician should be able to help you.1 point

-

Welcome to the forum. Do you intend on diving with it? If not then I'd expect any half decent watch repairer to be able to replace the battery and back gasket if necessary.1 point

-

At least you have the clock and a challenge, you would only have been renting the pint anyway Tom1 point

-

1 point

-

Allegedly a hand painted USSR watch (3 actually, and the other two photos are even worse) having what appear to be Raketa 2614N movements. I got the three for the price of a couple of parts movements, and though the seller is purported to be in New York some odd communications give me doubts. Maybe I'll get a few neat custom painted Raketas next week or maybe I'll get something lesser in a month.1 point

-

Andy’s suggestion is the way it should be done. Scissors ain’t gonna cut it nor will the other tool you have. If you can glue a ring of some sort to the metal outside of the clear caseback with a lever attached to it it may be possible, use superglue which will come of easily with acetone. If it wasn’t a see through caseback it would be relatively easy to do this, damage to the crystal would be a concern. Tom1 point

-

1 point

-

It all depends how it was wired at the plug but expect that's why it's been sold as the seller made presumptions based on the wire colours and couldn't get it to work. Edit Looking at the video my major concern over the wiring would be that the earth just appears to be connected to the rheostat.1 point

-

I received the staking set yesterday and between last night and tonight I examined all the parts, and I am extremely happy with my purchase. The set looks even better than the pictures. It is a complete set (the seller included also the 11 reamer that was missing from the listing). Although the seller had no rating, he was very responsive and willing to share additional pictures and answer all questions, so I took a chance, and I am glad I did. I examined all parts under the microscope and tested all stakes. I found only 4 problems: Stake 26 is not straight. Stake 36 is slightly chipped on the face. The smallest sub punch is slightly bent. The third smallest sub punch I already contacted the seller, but even if he does not have replacement parts for the broken items, I am ecstatic at my purchase. I have a few questions: Are there any tests I should perform to make sure that everything is kosher other than what I already did? For the bent sub punch (see pictures) can I straighten it? I was thinking of heating it before straightening it, and then annealing it. My only fear is that the part is so small that heating it up too much would destroy it. What temperature should I shoot for? I have a hot plate that goes up to 400C. Would this be enough to soften the material? I know I have to heat it much higher when annealing, but is 400C enough to soften it? One of the first things I want to do with the set is to practice reducing the diameter of the bridge hole for the barrel. The video I watched tell me to use two round face solid punches to perform the procedure. However, I do not have two such punches. Can I use a flat stump and a round face punch and tap on one side and then the other? Thank you, claudio1 point

-

1 point

-

A suggestion... Why just not assemble without the spring and put it after all is assembled (without the screw or whatever goes in the hole)? Not that I have tried - never touch such movement, but it seams like it is meant to be done as I say.1 point

-

If I'm not mistaken, the thickness of the endstone itself won't influence the endshake. This is because the part facing the pivot is flat. Only the fact the new endstone will have no divet will have a small effect.1 point

-

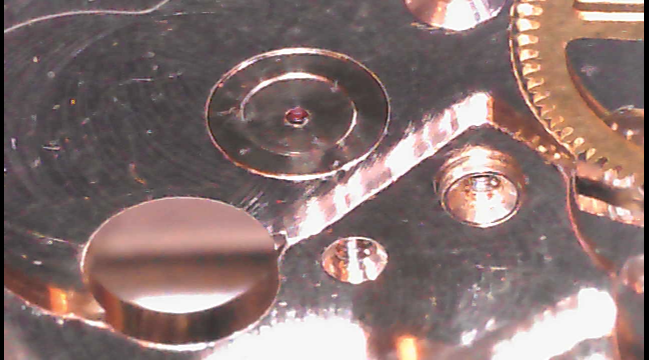

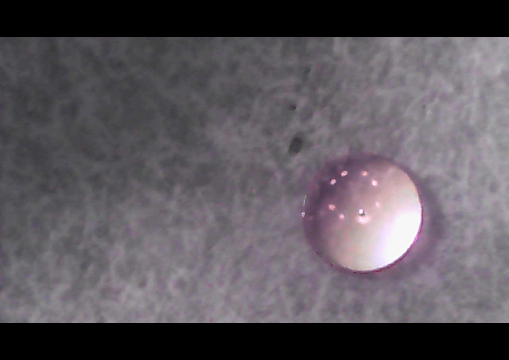

I'm still not sure what happened with the accident, but I'm leaning towards thinking that I displaced the pivots from their settings without actually breaking anything. What I've done since: Checked Diashock jewels and settings: no problems visible. Cleaned, oiled and reinstalled. Installed just the balance and did a free oscillation test. All good: balance oscillates for about a minute. Installed the pallet fork and checked its end shake. Looks good: perhaps 0.02 mm end shake. Inspected the interaction between pallet fork and impulse jewel. The jewel is fully engaged with the fork at both extremes of the end shake and never comes close enough to the guard pin to touch it, and the guard pin lines up well with the safety roller, although the balance may be sitting a little low when it is at the lower extreme of the end-shake. Examined the clearance between the balance and the pallet bridge. At the lower extreme of the end shake there appears to be no visible clearance. Repeated the free oscillation test with the pallet and bridge installed. No good: balance oscillates for less than ten seconds before coming to a complete stop. I've made a YouTube playlist of the handful of short videos I made of these inspections. https://www.youtube.com/playlist?list=PLP95CUmMHEso3B-6tp3O1Qnqzz1tzdl2W My conclusion is that the balance is rubbing on the pallet bridge. I don't think this was caused by my accident as I was concerned about the lack of clearance before that, and it would also explain the issues the watch had with very different timing dial up vs dial down. I'm aware that turning the lower capstone over might fix this, but I'd rather fix it properly if I can. It's my understanding that the Diashock setting is friction fitted to the mainplate so I should be able to adjust it with a jewelling tool, right? (Sorry about the upside-down photos.) I am going to get a new cap jewel for this setting as the current one has a divot: I should probably wait until I have the replacement before I do anything about the end shake in case the new stone has a different thickness.1 point

-

Surely this isn't the wiring diagram for the machine bought Andy. Theres not a single correct connection to that extension. Bigjay.....make sure you trace those wires through the machine and label them up with our current cable colours. Or rip it all out and start again, regardless of what you do plug it into a circuit with rcd protection please.1 point

-

That is a Junghans logo on the back of the timer movement and I would bet the mechanism is very similar to the many old Junghans alarm clocks, should any spare parts be needed or you wish to practice on one. You might take this over to the All Things Clocks area of the forum for some quick pointers or reviving a gummed up clock. Since this is not a precision timekeeper, simply giving the whole assembled movement a bath in a solvent and some fresh clock oil on the pivots might be all it needs.1 point

-

i dont remember any difficulty with them....i thought you'd give up so i reassembled it and put it back in storage . Let me see whats going on, I'll pull it back out....yep i know that sounds way wrong.... what I can say I am what I am1 point

-

1 point

-

1 point

-

Those are collectible sought after pieces and fetch pretty good ££, when fixed. How about two cheap Seiko 5s. Some folks start with cheap tools. Watchmakers screwdriver set n No4 tweezers, and lighter fluid for cleaning. Rgds1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

Get yourself a sewing machine motor and foot control it is ideal for a watchmakers lathe. That is what I had.1 point

-

I would like to second a point already made by a few others, just so it's clear. This looks like a real collector's item, and worth more than perhaps you realise. I advise you not to attempt anything yourself and to get professional help with it.1 point

-

Sorry for the question, but, do You know how to replace such jewel? It is rolled one and not pressed like modern jewels. You must not screw up the way the movement looks by deforming the stone seat or leaving any kind of marks there. This is not a movement to learn on.1 point

-

See, there is simple way to take the dial off without damaging it's legs. Disassemble the rear side of movement in order to get to the holes where dial legs go in. Then You must fix the movement as to be able to press the legs trough the holes and in the same time the dial to be free to go down. Press the legs little by little first one then the other, again the first one and so on until the dial is free. In the end You will be able to etch the screws in alum or sulfuric acid1 point

-

Thanks John, I think that is where the problem started for this watch. It was taken for a battery replacement by the diver (owner) and the technician didn't tighten the crown and the then owner didn't check (assuming done by the battery replacer) and of course the salt water flooded in. It came to me as a parts watch. As part of my watch repair journey, I am excited to see if I can at least get the analogue time function to work again. It would need a factory service if it were to ever go beneath the waves again, as would any dive watch purchased from ebay or etsy etc. rob1 point

-

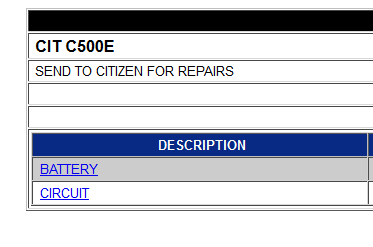

one of the problems with a watch like this is parts as you can see from the image below the most part parts are not available this watch is supposed to go to the factory for servicing. So the link for those not familiar with what kinda watch were looking at. Notice a reference is all the way back to 85 and sometime way back then I worked in a shop authorized to work on C's and watches they handled citizen warranty repair's. But if one of these came in we wouldn't touch the thing because as a dive watch and they didn't want take the liability of if something happened to the diver basically anything related to this it went back to the factory https://www.hodinkee.com/articles/citizen-aqualand-birth-of-a-legend-end-of-an-era1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)