Leaderboard

Popular Content

Showing content with the highest reputation on 11/10/24 in all areas

-

So I went to use the collet holder on the lathe to finish off the new pivot that I have made for a quartz movement. Why, you ask when quartz movements are so cheap. The challenge. Anyway, got the collet out that I wanted to use. Put the collet holder on the lathe, collet in and tightened the collar to see how it all went. Uh oh. Everything goes tight with the collet nearly 5mm from the end of the collar. that isn't right, I say to myself. So, the issue. The cause. Looks like a washer that is trapped at the bottom of the bore on an angle. It is actually all one part and something has gone wrong when it was being machined. I would suggest that the previous owner never used this. There is no brand on it so it may be a cheapie. Anyway, the setup. I did try to initially set it up to use a tungsten carbide tip boring tool that I have, but it didn't have the length that I needed to get to the bottom of the bore. So HSS it is. Part of the way through the machining. Machining finished. Didn't need to take the bore diameter all the way to the other bore diameter. Did need to face off the internal face at the top of the collet taper though. The collet collar removed from the lathe before I took it off the facep[late. And the final result. I now have a usable collet holder. I'm really chuffed that I still have a skill that I learnt a lot of years ago.4 points

-

2 points

-

2 points

-

They must have some kind of slipping clutch or ratchet drive between the main shaft and "clock" train, so the winding can be done without forcing the train to run backwards at crazy speeds. That's the part I'd try to locate and investigate?1 point

-

1 point

-

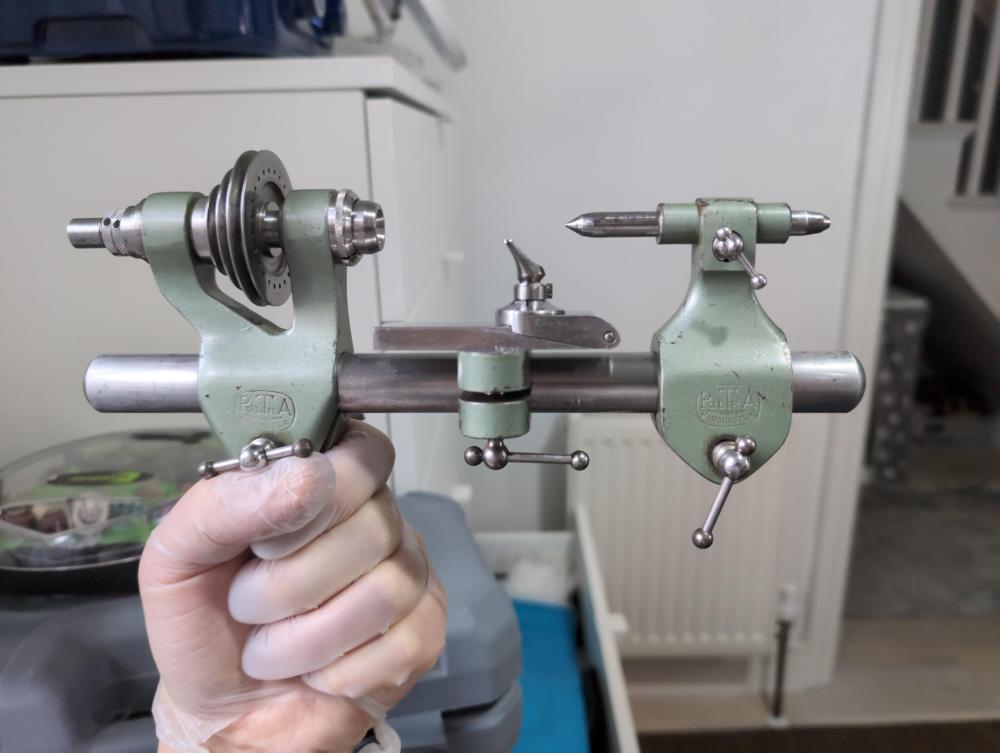

I place an anvil that just fits over the staffs shoulder in the bottom part of the tool to support the wheel as close to the staff as possible. I place a pusher that just fits over the top pivot in the spindle, mount the staff with wheel between them, carefully move the spindle down until it just clamps the staff and then give the spindle one sharp twist down. This gives me more control then using the staking set, but like with a lot of procedures: it's a personal preference. Also, I work under a microscope and the horia is easy to hold in one hand on it's side to give me a good view when placing the balance. I found this video on youtube of someone using the same method:1 point

-

1 point

-

So, I decided to give it a go, as you say watchweasol its a challenge. I dropped the movement into my ultrasonic bath ran it through a couple of cycles, rinsed it off and dried it with the wife's hairdryer and lo and behold it runs and strikes. I would normally strip it first but thought I'd live dangerously for once. The chains are very rusty, so I need to find a way to clean them before reassembly. I have a question and would be grateful if anybody can tell me how to work out the correct weights to use? The movement is quite small , about 7cm x 6.6cm if that helps.1 point

-

Ideally someone new to watch repair should practice on watches that do not require as many tools as you're going to need to replace the balance staff. Then ideally should practice on watches and learn how they work learn how to take apart put them back together learned what a balance wheel should look like when it's functioning and slowly build up a skill set before tackling replacing a balance staffs. Which is why typically most people will purchase a balance Complete as they don't have to deal with all the problems and purchase the thousands of dollars of tools that you really should have to replace the balanced staff jewels etc. To avoid running two simultaneous discussions here is a link to somebody who's ask the exact same question about a staking set.1 point

-

I think at this stage in your journey your best option would be to get complete balances. You can then look more into what's involved with replacing a staff on a test movement further down the line.1 point

-

You'll need levers to remove then spring, then a roller remover for the roller and finally a staking set to remove the staff.1 point

-

You will need staking tool and plenty of practice, just to restaff this balance wheel properly. Many beginners are happy as long as their watch runs and keep good time on wrist, posing the balance is next, so you need a tool for that. I wouldn't recommend any of the above for beginners, cuz your looking at approx 1K then you might decide watch repair isn't your thing. Your best bet is to buy a new complete balance, next comes regulating the movement. Rgds1 point

-

what happened to the jewel? In 1st pic it is there, in 2nd it is missing. These jewels are available, you can also harvest an identical one from another movement. Fixed with a bit of shellac.1 point

-

Welcome to the forum. Depending on the movement you may be able to buy replacement jewels either original or generic. With the balance staff you'd need a lathe and a lot of experience to either repair or make a new one so again your best option would be to just get either a new staff or even complete balance, again depending on the movement.1 point

-

@Bigjay, This timer is like alarm clock. The difference is the alarm that is turned on in the end of the time the timer counts. But, it is nothing complicated or confusing. If it doesn't wind smooth, then You have to determine where the obstruction is, as it can be in winding the timer spring, or the alarm spring. So You should separate one from another and try them one by one. This will be possible if the big steel wheels on the front are removed, then the arbors turned in winding direction to check resistance. The construction of spring wheels (first wheels) contains ratchet and click that allows the arbor to be turned in winding direction without the wheel rotation. This is the place where the resistance should be. Have in mind that waiting for the timer to stop in end position doesn't mean the spring is unwound, as the steel wheels limit the rotation1 point

-

I have a cuckoo clock as well that was my parents from when dad went to Germany for training prior to us going to the NT and dad working for Nabalco. Mine is an external weight, external pendulum number as well, but it was my parents, who are both gone, so it will get rebuilt. Al lot of work required as the humidity in the NT was not a friend.1 point

-

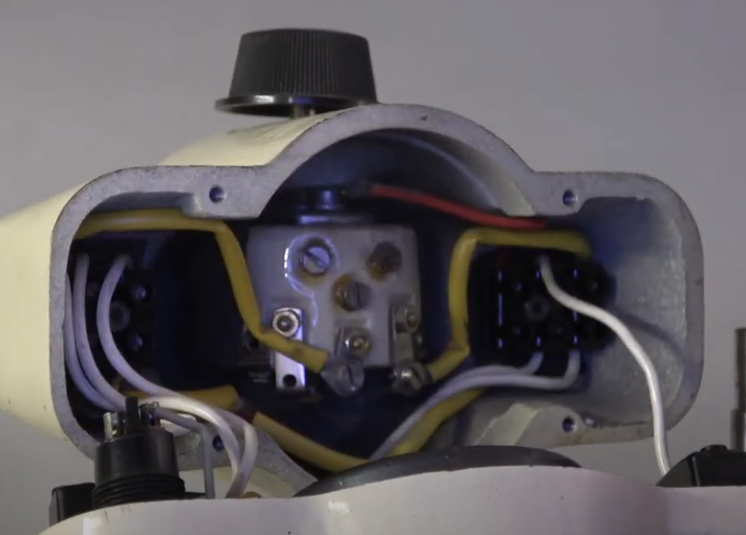

Looking at others the only earth appears to the top of the rheostat so the base, control housing and motor cover are all relying on bolts and touch contact for earthing which isn't adequate. The earth to the rheostat doesn't even appear to be their on the OPs. Edit The above photo is a clip from the YouTube video.1 point

-

Hi Michael. A nice little clock well worth the price of a pint, German usually could be Hubert Herr. All the points you mention are not insurmountable, uneconomic to repair and sell but as a project well worth doing . It’s a challenge. If you need material for the bellows let me know I have sone tyveck. I love them they are interesting. Got two already.1 point

-

A bargain it certainly is not. These types are novelty clocks. You are right about the age. Not worth spending money on. The hands are made of plastic and so are the roman numerals. The original Cuckoo Clocks never hung on walls never had weights and certainly never had hanging pendulums hanging outside under the case. The original ones had fusee movements and you would wind them like any normal clock the pendulum would hang in side the case from the back plate, the hands and numerale were made of ivory some were decorative they would be on tables or a plinth that was fixed to the wall. They are expensive to buy like over £2,000 Here is a picture of the sort of clock I'm talking about.1 point

-

At least you have the clock and a challenge, you would only have been renting the pint anyway Tom1 point

-

Allegedly a hand painted USSR watch (3 actually, and the other two photos are even worse) having what appear to be Raketa 2614N movements. I got the three for the price of a couple of parts movements, and though the seller is purported to be in New York some odd communications give me doubts. Maybe I'll get a few neat custom painted Raketas next week or maybe I'll get something lesser in a month.1 point

-

Sometimes a bit of bur on a tooth that lifts the hammer can cause such a thing or on the part of the hammer that makes contact just be careful as you do not want to file lots away as it will cause loads of trouble, if it is that a little grease try that first.1 point

-

Not here, John. The same outdated rubbish like inches - says the continental European . Frank1 point

-

That became evident on the day i joined Richard1 point

-

Hello , good evening and welcome. What bit have you only just figured out ?1 point

-

1 point

-

…a country that perfected the term porch pirate…and in some locations including mine is no longer prosecuting theft.0 points