Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/24 in all areas

-

The purpose for the newbies section is where questions can be asked and anyone who participates with an answer is supposed to answer the question. I often thought in addition to this section where all questions will be answered no matter what. We should have a section of answers to common questions preferably with out a discussion. This is where the common things could be a commonplace and then the fine details of specific watches or whatever specific for the person could be answered in the discussion without repeating so much material. So you've asked the question in the right place and if we have a lengthy discussion it's exactly what it's supposed to happen. Typically alcohol is used to Dissolve shellac although there are other substances that will work. Then elevating the temperature will speed things up considerably. Woodworking stores can be a interesting place in that they will have substances for dissolving shellac as it's used as a wood finish. Plus they will typically sell shellac in flake form. Although unless you have a lot of friends they usually sell it in a bag enough the last million years. At least if it's used for watches. Then you do want to make sure it's a natural shellac that hasn't been processed I have a vague memory of somebody having I think was somehow processed in it didn't quite work right but I can't quite remember the exact discussion. But I do know that the flake shellac from the woodworking store works really nice as somebody gave me some of the bag that they had purchased. Then whether or not the roller jewel slides out will basically be your discovery. Depending upon a variety of factors roller jewel's can range from a loose fit all the way to where basically their friction in the hole. Then depending upon how well they fit you can also be a challenge when inserting them again that it stays in place while you're putting the shellac on. This is where sometimes dissolving the shellac In alcohol in making a Glue works well to hold things in place. Then shellac is used because when it's warmed up you can move the roller jewel around and get it exactly where it's supposed to be versus variety of other substances that shouldn't be used. Then now that your hairspring is free of the balance wheel just a reminder you want to keep that hairspring with that balance wheel. A typical newbie question is something happen to my hairspring which is quite common it mysteriously gets tangled up can I swap with a an typically you cannot. That's because each hairspring was specifically manufactured to go with that balance wheel to just keep your hair Springs and balance wheels together.3 points

-

After trying a mainspring that has slightly less strength (0.10 vs 0.11), that rebanking issue went away. I still get a healthy amplitude. So, I was finally able to finish up my grandfather's watch.3 points

-

I picked this up as part of a lot 8 days ago. I showed the haul in the 10:10 club thread. But this was actually in a bag of 10 watches for $5US. No crown and the stem was broken at the threads. Sourced a new low dome and stem. I had picked up a lot of old GF crowns and one from bottle 21 works nicely. Still need to take another mm or 2 off the stem though. The kicker was that the staff was broken. I was at a different Vintage Market today and found this beat up Gruen Precision with no caseback that looked similar so snapped it up for $10US. Turns out they are both 510s with the donor movement being a N510ss, which has the added benefit of the incablic shock system on the balance. Seems to have crossed over nicely and is now running. Will need a thorough clean and regulation. Don't think the dial side balance jewel and incabloc will cross over though.3 points

-

I do admire the philosophy of the innovation and manufacturing in the home country in Germany. However I do have a feeling it is flawed in several ways. It would seem to me to be able to recreate a , now traditional style Elma/L&R style device to retail for a little more but still less than the heinous asking price we now see for the vintage stuff that we will likely have to do work on to make it safe and work properly. Some of the stuff members here have achieved for much less money I think are as good and in some cases better. OK, you don’t get a warranty with a hand knitted one but you do know how it works, went together and where to get comparable parts. just my comments on it. Tom Oh, just remembered, as @Neverenoughwatches will, I did say it’s just a whirly thing2 points

-

Well, fortunately, on this friendly forum this is limited to a friendly exchange of views! This is how we learn and keep it enjoyable.2 points

-

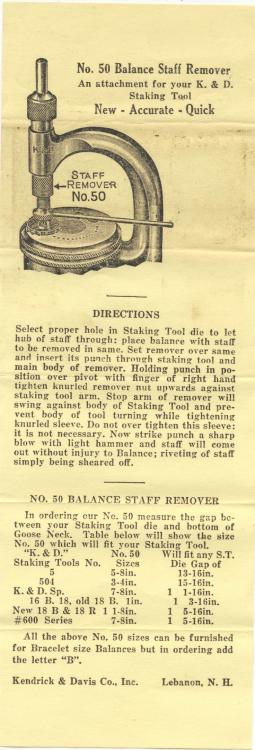

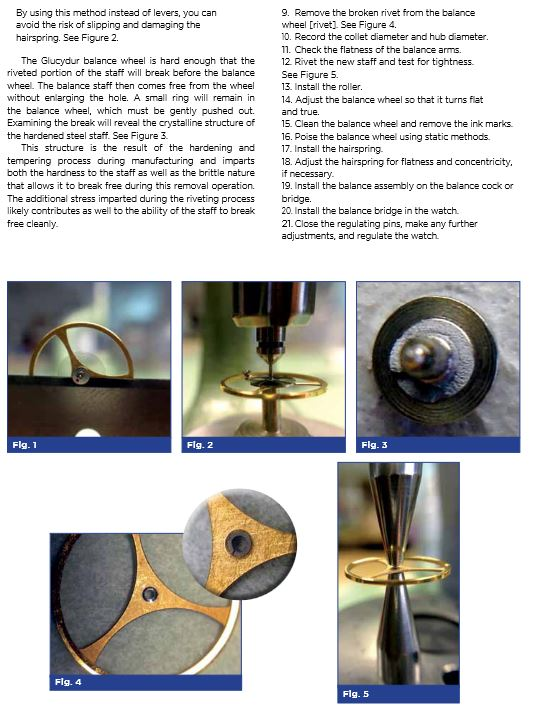

Unfortunately and watch repair there are a number of subjects that will result in extremely heated debates over procedural stuff and unfortunately this will be one of them. I am limited deliberately skip over some of the fine details that people like the bicker over and only look at a generalization of the minor problem of what I've quoted above. In the case of a staking set or the platex tool Which I do not have there is usually a method such as image below a accessory device that is used to hold the balance arms down when the staff is knocked out. This is designed to prevent the balance arms from getting warped. Then here's an example of pushing the staff out without supporting. Rolex uses this for some other watches because as the image shows the hairspring cannot be removed the staff has to be pushed out. But the balance staff has been designed for this purpose and the balance wheel will withstand the rivet breaking. Unfortunately not all balance wheels can have balance staffs removed in this method for a variety of reasons which have been discussed elsewhere on the message board. When I was in school the instructor before driving a staff out word just weaken the rivet a very tiny bit. In other words you put the balance in the lathe and just took the tiniest a bit of material off the rivet. Then we end up with lots of variations like Rolex, Elgin and I believe Hamilton all of made balance staffs that are designed to fracture. But not all of their balance staffs were designed that way. So basically when you go to drive a staff out if it does not want to come out with a minimal amount of force then you should use a lathe. Then depends upon your preference either cut the hub or the rivet as driving a staff out that does not want to come out is usually not in your best interest at all. It will depend upon what your balance wheel is made of? In other words as long as your balance wheel is not made out of steel you can use alum to dissolve the staff out.2 points

-

Just as it is with 3D printing today. Spend half your time making more parts to improve the tool. What's old is new is old again, it was ever thus.2 points

-

Thank you so much for this! I dont feel so much if an idiot now that this guy is as confused by the movement as I am! My timer does not wind up as smoothly as his so something is amiss, and the balance seems permanantly fixed to mine so have to be very careful when dissassembling as dont just want the train to fall out. Gonna find part 2 and study that video a few times before tackling mine as dont want to break or ruin mine. Thanks again! Jason. Well, I decided to disassemble it and embark on a journey of discovery….. undid the bolts hold the two plates together and the mainsprings exploded and train wheels fell out!!! 5 hours later trying to rewind and fit the uncontained mainsprings, and align the pivots for the train whilst holding tension until I could fit the alarm mechanism, trying to refit the balance wheel without breaking it and many expletives it is back together and ticking away. The two silver wind wheels would not come off at all. Lubricated and still a bit stiff to wind but I am not taking it apart again…. Ever!! Learned a lot about how the mechanism works though so been educational if nothing else!!2 points

-

1 point

-

It be ok to have this neat little unit i guess but what guarantee does it have ? Providing the seller is still around that is. How much is the main component if that stops working, can you get spare jars if one breaks. Theres a lot to be said for nipping down to your local hardware shop to grab another jar or buying half a dozen for 20 bucks.....jumping onto ebay to buy another motor for 15-20 bucks......swapping out any part yourself in minutes for very little cash. I like reliability....i like changability just as much.1 point

-

I've been communicating directly with the Nestromo/designer. He's tested it will all the common fluids, including the solvents and ammoniated/waterless fluids. And a year into sales, he's not had any complaints about the material. The plastic is also ok with temperatures up to 120 °C. So putting the whole basket in the oven (at <60 °C to be safe with shellac) for drying is ok.1 point

-

Welcome to the forum. Does the ring around the movement with the slot by the crown not come out?1 point

-

Well, I don't know either. But the new Elma basket frames are also plastic. And some of the forum's DIY creators have also successfully used plastic. Hahaha, yes, you got me there I'd probably still like a vintage Elma the most, and I'd be ok with the size. But the small size of the Nestromo is a plus. And then I compared the Nestromo with the DIY machines. So yea, not fully consistent, I suppose..1 point

-

Not sure if it's just the photo but I'd have another look at the bottom pivot. Also what's the bottom jewel like?1 point

-

that it is Tom, look at your washing machine , most of the plan will come from there. It spins one way and then the other......chuck in a few agitation ideas and you have the perfect watch part cleaner. I guarantee its doable for less than 100 smackers......wayyyy less1 point

-

You pointed out yourself some of the flaws around around spinning off and the jars. I also have concerns about the injection moulded plastics, with the old stuff that is metal and unlikely to need replacing, plastic I’m not so sure. Your comment about the forum diy solutions confuse me, weren’t you originally looking for a “traditional “ Watch part” cleaning machine? That would be much larger than anything I’ve seen here. Tom1 point

-

There has been versions of this over the last few years. I even thought about making one a couple of years ago, i talked myself out of it for some reason, i think it was the inconvenience of the spinning off and drying that put me off. But simple enough to make.....this is just a very neat little unit. I wouldn't swap my set-up that is nothing like this ...that i cobbled together for anything.1 point

-

Could you elaborate on the flaws you see? I agree that there are some cool DIY machines out there in our forum members' homes. I've looked at them carefully. A few things that I'm missing in most members' DIY machines in comparison to this Nestromo one: - most DIY machines from forum members are large (including the stand) - I don't think I've seen one with bi-directional rotation - most don't "keep a lid" on the jars when spinning excess liquid. With the solvents, I think that's a factor I consider relatively important. - many DIY machines require access to (and skill with) a 3D printer and that's also a lot of work that we need to factor into any price comparisons. I hope this doesn't sound like criticism of any member's achievements of DIY machines. If anything, I'm trying to be constructive. I am really full of admiration for the machines you've built! I honestly don't feel capable to do it myself (in most cases).1 point

-

Looking at the photos I think it’s a front loader, you will need to remove the bezel and crystal to get the movement out. Tom1 point

-

1 point

-

Had a crystal switch around - fitted an original in this one and put the VTA one back in the 8110. Yobokies bezel insert is also here, which I suspect will be a medium-long term solution to finding an original bezel. Probably going to wait until the dial ring arrives to fit it... It's starting to look very fresh!1 point

-

The seller that scammed me on Kleinanzeigen.de was also rated well and had a long-standing account. It's easy for a scammer to create several accounts and give themselves good feedback. My scammer also sent me an Id card that wasn't his (as I later found out). Scammers steal identities and accounts. I might be over-cautious now, but as they say "fool me once..." Also on eBay, two fake buyers tried to scam me. They also had well-rated accounts. They probably hacked these accounts altogether. In that case, they contacted me outside of eBay and then pretended to pay into an HSBC escrow account. But the confirmation email coming from "HSBC" was a fake. Anyway, let's please also talk about this Nestromo watch cleaning machine!1 point

-

1 point

-

That is very odd. The Dutch seller has been active for 12 years and has sufficient (and recent) positive feedback registered. Marktplaats is an ebay company and so is Kleinanzeigen (I believe Kleinanzeigen is owned by Marktplaats and they are owned by ebay..) and Marktplaats indicates they have verified the sellers identity and bank account number. On the other hand, the German seller has been active since 2021 and also has received positive feedback. Neither of the sellers would have risen a red flag.. I have asked the Dutch seller why his photo's also show up in a German site. It could well be he is both Dutch and German based. He wouldn't be the only one. I'll let you know what his/her response is. I contacted the Dutch seller and he confirmed it is indeed the same/his machine. I advised him to mention that in both Marktplaats and Kleinanzeigen to avoid raising unneccessary suspicions1 point

-

oh wow, be REALLY careful with that ad!!! The EXACT same machine is also on the German "kleinanzeigen.de" site where I got scammed! And the address/Zip code is NOT close to the Netherlands. Gerade bei #Kleinanzeigen gefunden. Wie findest du das? https://www.kleinanzeigen.de/s-anzeige/elma-uhrmacher-reinigungmaschine-ultraschall-bad-ultraschallgena/2814581879-157-191991 point

-

1 point

-

Yes Edit To elaborate on this for others down the line if there's anything printed in the battery well it's more than likely to be the battery size or the Citizen 280- reference.1 point

-

The fastest way is using heat. There are several post on this forum on using and/or making a pallet heater. I use a "copper" coin on a hotplate. IPA (not the beer) works slower by softening/dissolving the shellac. Same methods for applying the shellac.1 point

-

1 point

-

Sounds like anywhere between winding stem and barrel, teeth didn‘t mesh but sat above each other. You should test correct meshing in that range befor applying force. I think you know now . Frank1 point

-

Funny this discussion - already cleared to the utmost detail - gets started again and again by newer members who don‘t know about it. Surprising that long time members get tired of repeating discussion and reasons? I will just repeat this link. Frank1 point

-

The latest in CuriousMarc's series about repairing a 1960s Atomic Clock. This time its an OCX - or to be more precise a double oven controlled crystal oscillator, from the early 1960s. These were used to keep your precision time source in step with an accuracy of parts to 10^-11 Somewhat more precise than the average crystal oscillator that probably adorns your wrist. If you haven't seen the rest of the series, and interesting time pieces are just the thing to brighten up your day, the rest of the series of videos are well worth watching.1 point

-

1 point

-

I passed up the chance to buy a Molfres tool 2 years ago......bigggg mistake ,I've never seen one since.... think it was only up for 120 quid. The better punching out methods such as a platax tool, unruh-max and K&D staff removal tools rely on keeping the balance wheel tight down so the staff pops out cleaner leaving less damage to a non steel balance wheel.....still not as good as cutting away the hub or dissolving the staff. Usually caseback usually , quite funny to see the occasional disagreement raise in temperature....cant help but think to myself ' grow the hell up, we're supposed to be adults ' Much worse carryings on with the facebook groups , some members get so petty over there. Tbf some of it is due to language barriers and non native English speakers not fully grasping how to put their point across, we definitely have to make allowances for some folk.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

The only current maker (and for some decades so) is Horia/Steiner. The runners are matched to the tool, so even if you have one with a diameter that corresponds- Steiner runners are 8.80mm- the chances that it lines up correctly are small. The other older tools are often unbranded at all, so finding a matching runner is next to impossible.1 point

-

Hi Elie and welcome to the forum. Please let us hear more about your background re why you are investing so much time and effort into formal training. I'd also be interested in why you chose to do Mark's courses before the BHI school, and how the two compare with and complement one another.1 point

-

Well done on having the courage to have a go. You will have learned a lot from your experience: frustration and expletives are all part of the journey. Andy is dead right about letting the springs down, I remember doing something similar and the thing nearly bit my hand off. Once learned, never forgotten! Your timer is now working better than it was and you are more competent in your hobby.1 point

-

I guess that I cannot count. The 5th photo does look like jeweling stumps.1 point

-

No more Elma. Three step L&R in my Pearl machine and I Liquinox in the ultrasonic with an IPA rinse. I was satisfied with the Elma regimen but pricing on L&R is recently a little better. I also do a better job of pre-rinsing now which extends the life of the L&R in the Pearl machine so I’m less concerned with the cost…1 point

-

1 point

-

The video is showing how to do a particular Rolex staff. With some Rolex balance staffs the only way they can be removed is by pushing them out sort of. I was at a lecture once were somebody demonstrated basically push the staff until the rivet breaks with a very satisfying pop sound. This is because the balance staff is designed to break at the rivet. Unfortunately not all balance staffs will break like that which is why other tools are sometimes required. Unfortunately with the balance staffs are doesn't actually seem to be a universal perfect method and other methods may be required to avoid damaging the balance wheel.1 point

-

They must have some kind of slipping clutch or ratchet drive between the main shaft and "clock" train, so the winding can be done without forcing the train to run backwards at crazy speeds. That's the part I'd try to locate and investigate?1 point

-

I am curious about how exactly do you do this and why you did not use your staking set to remove the staff? I find actually multiple sources of information are good. Like in addition to the videos books are nice in the absence of books websites where you can download PDFs of the book. So for instance the website below has lots of PDFs. The ones that you should be looking at would be 1945 TM9-1575 War Department Technical Manual Basically a training manual for watch repair. Then a little farther down Joseph School of Watch Making. This was the textbook for the Bulova school of watchmaking and you want to download the entire book because you're going to need a lot of sections out of this book to replace a balance staff. https://mybulova.com/vintage-bulova-catalogs1 point

-

On the other hand, if you are already sure you want to invest not just time but also some €'s in tools, go watch some of the several available video's on the subject on youtube (and watch them several times more until you can visualize the steps) and invest in the tools required. The tools I used for my first balance staff replacement were: - handlevers to remove the hairspring; - roller table remover (lots of types available, but I used the Bergeon 2810) - Clone horia tool to remove the wheel from the staff (best practice would be to cut the rivet using a lathe, but that raises the complexity level and the investment in tools..). I use the Horia clone with original Seitz pushers because their quality is better and I have them. - Staking set. We don't know what your skill level is, but if you feel comfortable giving it a go: by all means, watch some video's, work careful and give it a go! You're not working on expensive pieces, so why not.1 point

-

@Bigjay, This timer is like alarm clock. The difference is the alarm that is turned on in the end of the time the timer counts. But, it is nothing complicated or confusing. If it doesn't wind smooth, then You have to determine where the obstruction is, as it can be in winding the timer spring, or the alarm spring. So You should separate one from another and try them one by one. This will be possible if the big steel wheels on the front are removed, then the arbors turned in winding direction to check resistance. The construction of spring wheels (first wheels) contains ratchet and click that allows the arbor to be turned in winding direction without the wheel rotation. This is the place where the resistance should be. Have in mind that waiting for the timer to stop in end position doesn't mean the spring is unwound, as the steel wheels limit the rotation1 point

-

I have found this little youtube where a timer is taken apart and reassembled. The first part looks at the movement before it is taken apart. Part 2 he takes it apart and reassembles it. The winder not only winds the timer spring but also the alarm spring. Maybe it is catching there. It's an interesting puzzle. Sometimes what should be simple turns out to be more challenging than at first glance. Are you going to attempt to take it apart to see where the problem is?1 point

-

This runner is for long pivots - the ones of the 4th wheel, where the sub seconds hand sits.1 point

-

So, I finally finished my picture service walkthrough for this ETA calibre 2472. Here it is!1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)