Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/24 in Posts

-

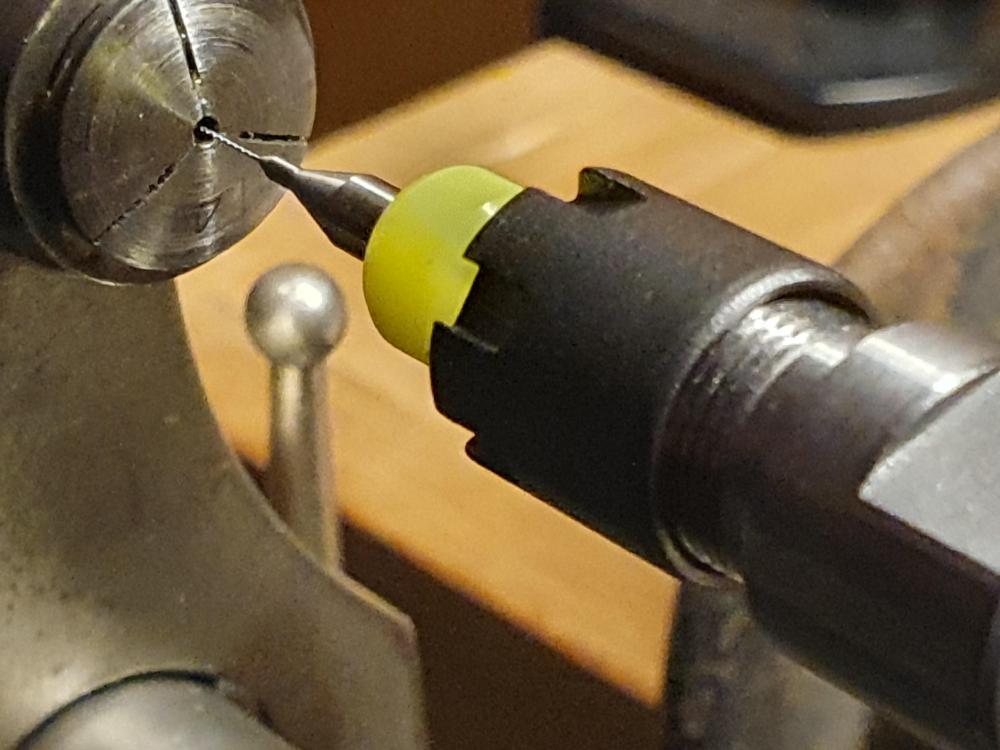

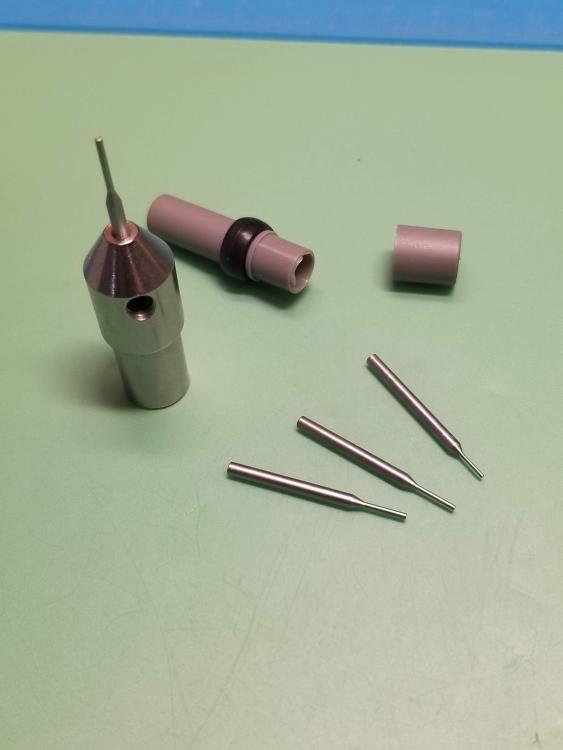

The drilling attachment I got with my recent new to me 6mm Wolf & Jahn lathe works with these classic spade-type drills, but is not big enough to hold the 3,17mm shanks of the carbide drills I also have. Online I found ER collet holders with cylindrical extended shanks. There are also versions available that hold ER8 collets and have a 6mm shank. Combined with a 7mm OD, 6mm ID brass tube, I now have something that works. Turning it doesn't show any wobble under my microscope, so I guess it is accurate enough.3 points

-

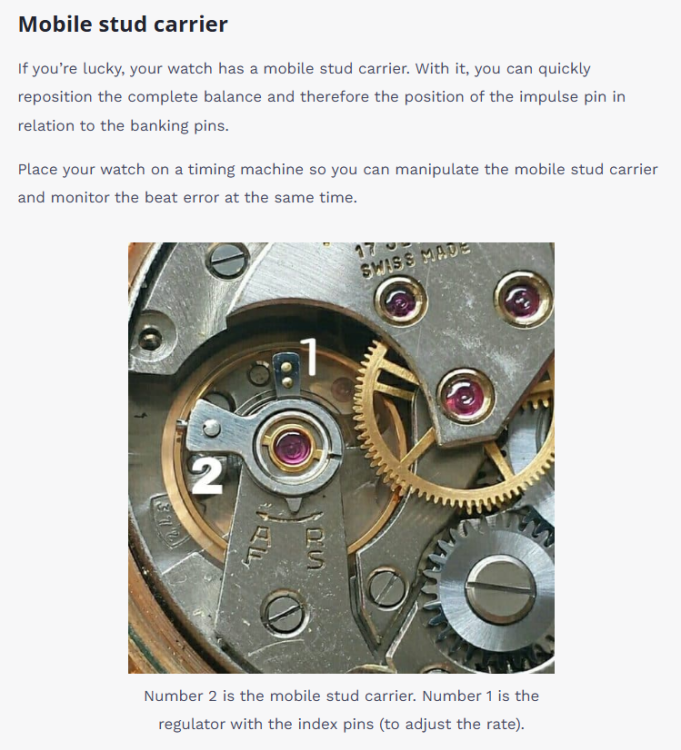

That would entail two trips of the balance/cock out and back in, which is always good to avoid more than necessary. Also, if there is a boot, 99.999% of the time it's a flat hairspring, and the gap at the pin will be a bit larger than with no boot (overcoil spring), so no risk if the spring's regulating curve is properly centered.3 points

-

Thanks for the ideas fellas, this sounds like a good plan that I feel comfortable with. I'll need to get in some practice sessions with making the bush ( very small compared to anything I've turned up before....i may be a little while with that....maybe a week or so...as I'm back in school till next summer...along with work and taking care of mum some days, makes my time limited at the moment. But that idea of the back plate added to bush from you both sounds like a solid plan . I've used bismuth low melt solder in the past a few times to repair dial feet, its fairly solid stuff .2 points

-

To limit the amount of heat needed as opposed to silver solder. Good one. Time to give your lathe another airing Rich!2 points

-

2 points

-

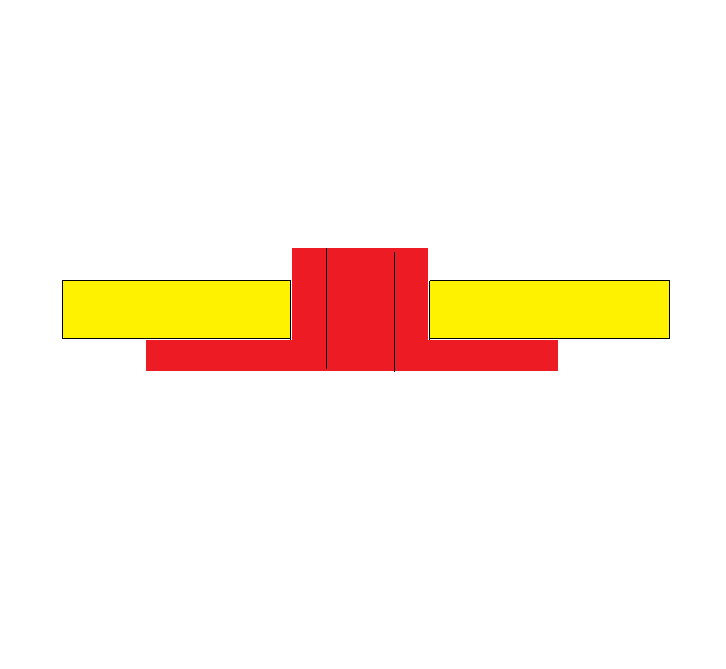

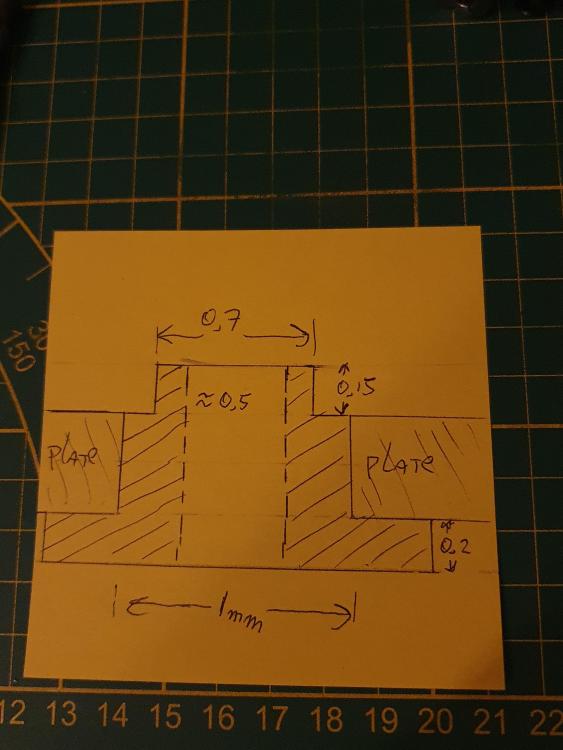

Hi Nev. My last suggestion in the pm's to Rich was to make a bush like this because he suggested that a bush could probably protude out of the top end of the plate by about 0.2mm without interfering with anything. One could consider using some loctite. If part of the wider shoulder protudes out into the plates cutout, that could be trimmed off. Do you think that would work?2 points

-

2 points

-

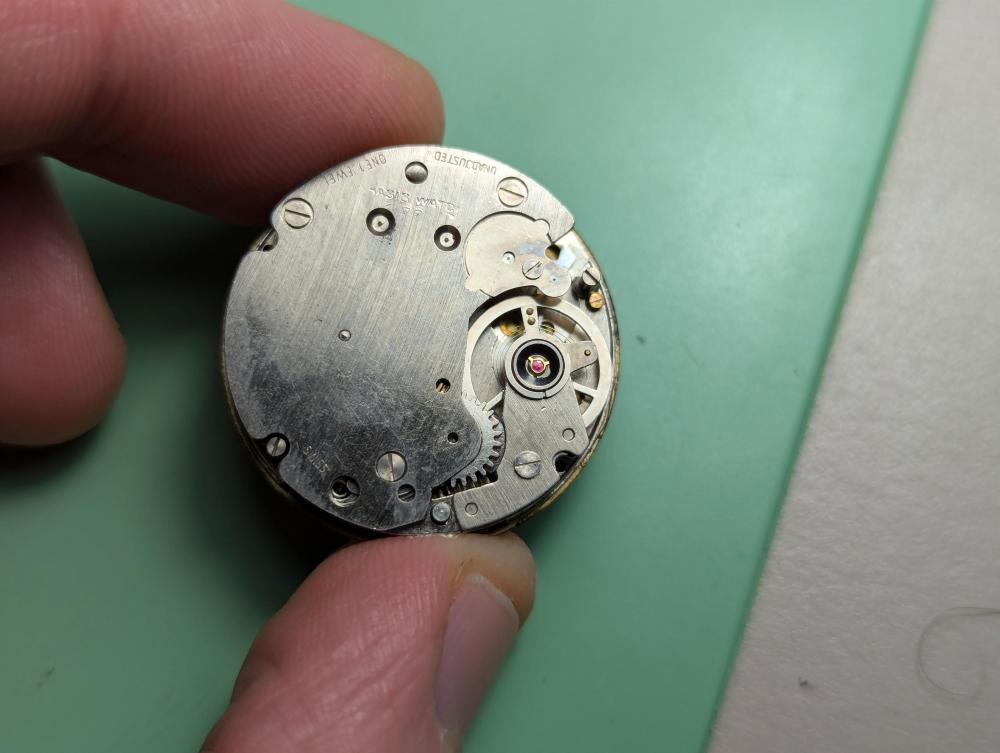

It is correct, confirmed with a slow-motion video and when it knocks it is easy to hear. The thing just has very high amplitude. If I open it again I'll measure the mainspring, but there was no evidence the movement had been disassembled before. Plate screws were factory tight and not a mark anywhere on it.2 points

-

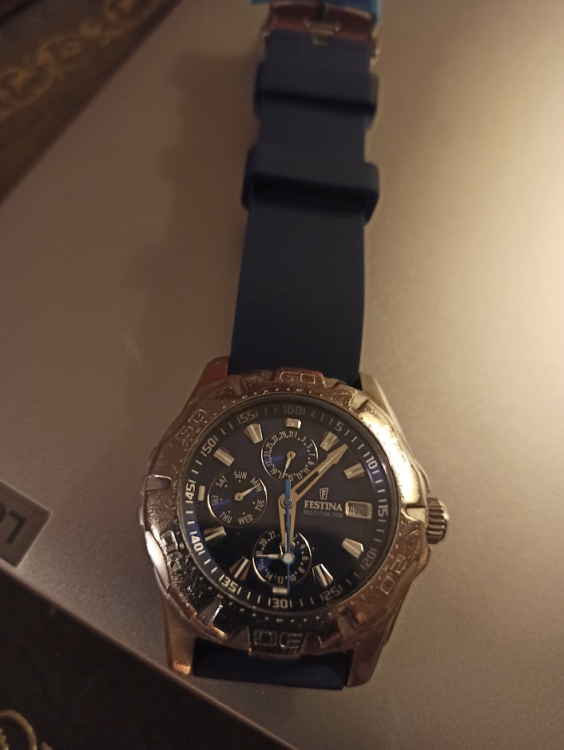

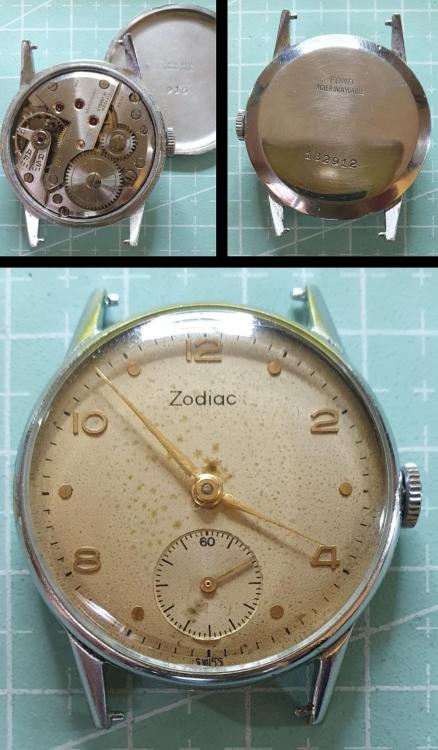

Another contender: So here we have a 1950's Zodiac with the FHF 26 movement. Purchased for £10 buy it now, on arrival, as you can see, condition not too bad, there is some of the chrome plating coming away from the case. Movement was running, but somewhat reluctantly. Full strip down and clean, mainly just dried oil with a few hairs thrown in. There is quite substantial wear on the movement plate in the stem/clutch area, so not much I could do about that. Some fun and games with the hairspring, my fault, managed to slip and distort the spring whilst addressing beat error, but managed to recover from that. Like mbwatch's watch, I was surprised with the amplitude on this one at 290. So nothing spent on the movement and case, everything was usable, however, I don't think the hour hand is correct, doesn't match and a bit too long for my liking, but as it's a £10 watch, I can live with it. What I did have to order was female spring bars, not had any dealings with these previously. It's a small watch from the period and the lug width is 16mm, so ordered 16mm female spring bars. Wrong, I needed 14mm in order to get past the pins on the lugs. Cousins no longer stock these and elsewhere ridiculously expensive, so took apart the 16mm ones, ground down the tube to required length and re- assembled with the help of the staking set to round the ends back over.2 points

-

It's a powerful degreaser, it converts oil & grease to a water miscible "soap" type substance. I'm guessing the commercial L&R stuff it made by adding gaseous ammonia directly to the solvent mix under pressure to saturate it, so no water is added??2 points

-

I see. This is the worst case... Another question: Is dial thick enough as to allow grinding on it's back side of about 0.2mm? I mean, no standard bushing will help here, the bush has to be riveted or at least soldered. It will be easier if part of it protrudes above the plate and it will lift the dial this way, but if the dial can be thinned in the area above the bush, this will be good.2 points

-

We need photos, mainly to look at You hairspring. This is the thing that may have got wrong when moving 'timing pins'. There is systematic way to search where the problem is and it is to do the free oscillations test. It means to remove the pallet fork (first mainspring is to be released) and then put balance in place and check how free it oscillates when some energy is given to it. One way is to rotate it to 180 degr. and then release and count the number of free oscillations to full stop, the other is to just blow air at it with blower and observe how long it will oscillate, about a minute is what is expected if hairspring/pivots/bearings are OK2 points

-

Of course what you are saying makes complete sense, but I see this as more of a challenge, a mountain that must be climbed2 points

-

Post script to this story. The owner of this watch is a good friend of mine, and when I found out he'd inherited it from his dad and it never worked, I offered to take a stab at repairing it. While I was working on it, it inspired him to get into the hobby, and he's been tinkering away. I gave him the watch and he was ecstatic. He can't stop talking about how smoothly the date ring snaps over now. Last night he asked me out for a drink. He started talking about how much he loves the watch, how he knows he owes me money for the parts I laid out, and then he pulls out this box and says he hopes I'll accept it as thanks for all the work I did. He knows how much I love Bulova Accutrons, and we often talk technology about them and the f300. So behind the scenes he found this non-runner DeVille on eBay and fixed it himself (including texting me questions about it!) so he could gift it to me. I am blown away by the thoughtfulness and absolutely love the aesthetic of this watch. It is, however, weird to have a watch I don't have to take apart and repair first...2 points

-

Hiya watch people ........Surprisingly enough this is the first one i have had to do, i usually manage to close arbor holes with ' hammer time ' unfortunately not the case with the movement I'm currently working on. The original bearing had a thin walled shoulder added to it from the inside...which i knew would crumple when trying to reduce the hole size....and it did. So I'm left with the option of bushing a .5 hole to 2mm ( 2mm is the smallest i have with a near enough arbor hole that i need ) Thought a little practice would benefit the outcome. Seems very straightforward but any input that might include something i miss....could be helpful....thanks fellas. So far so good with the practice piece..... but I need to recreate that same crumpled shoulder on the bush.....just less crumpled . Looking for other options before i ream out the plate Take off the damaged shoulder completely from the original plate....leave the hole and add a free floating ring ? Nope...the shoulder formed part of the bearing....so that wont work....ideas anyone ?1 point

-

The only issue I have with this, is that it states it contains ammonium hydroxide, which by definition is ammonia and water. I'm still trying to figure out a way to emulsify the mixture. Canola oil has a very high amount of Oelic acid, so I may try that. That is totally logical. My though process was, I have all of this stuff on hand, so why not try to make it myself! That's correct, my ammonia solution is 5% of total volume. I ran a previously cleaned movement through the solution, and the solution was nearly black when in came out. However, it did remove a small amount of gold paint on the barrel bridge, but I'm not 100% sure if that was already worn off before cleaning, so just a note I'll need to monitor.1 point

-

1 point

-

1 point

-

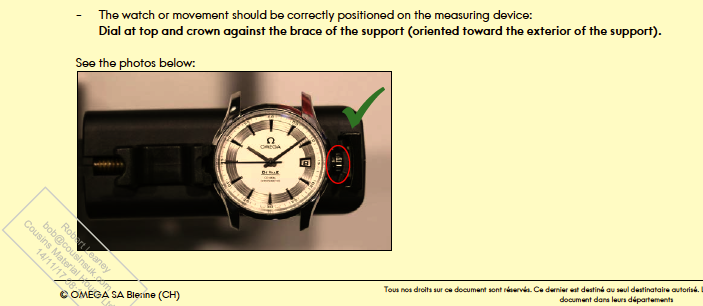

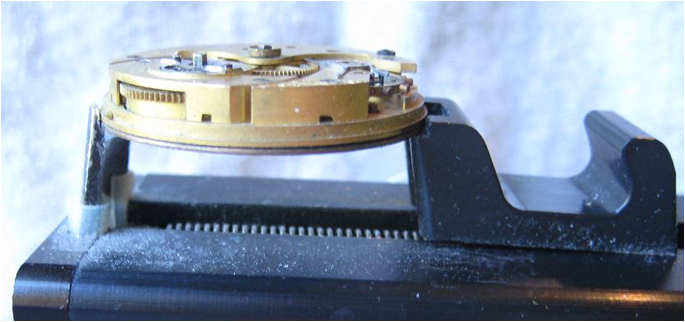

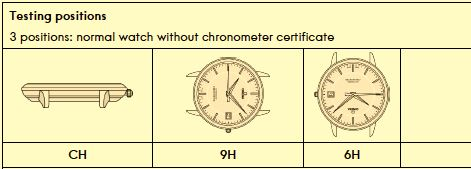

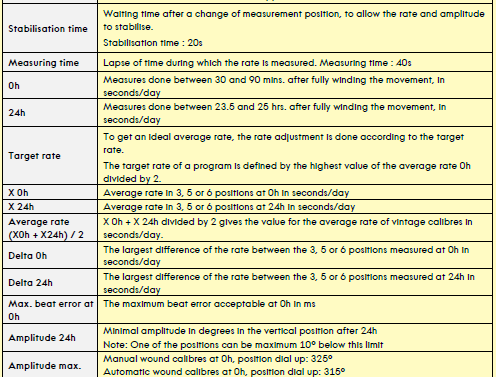

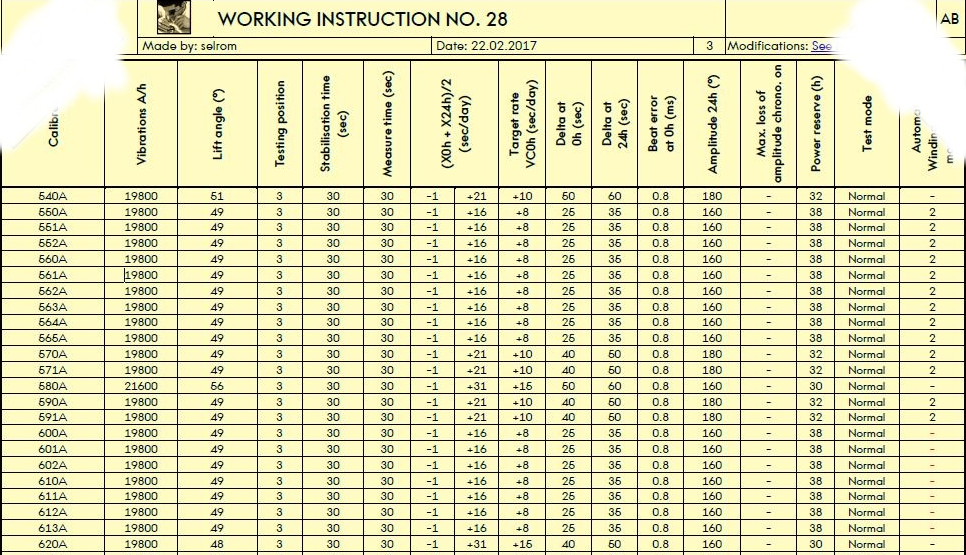

I'm attaching a PDF that you might find interesting and it also shows how a case up watch is to be held in the machine microphone. Although the word microphone isn't technically correct as the microphone is picking up of vibration preferably not audio from the air. So cased up watches are sometimes hard to pick up because the case absorbs things or you have plastic movement rings or heavy cases or variety of issues so you get the best signal out of the watch the crown goes out. In other words it goes against the metal contact as the sensor is found down below. then if you're holding the movement you're supposed to hold it like the image below. Doesn't really matter which way the crown stem goes as you're picking up the vibration from the entire movement. Which is why it's very important that the metal not have tape or other stuff on it. Then it is nice if the stem would go out as it does make a nice reference to keep track of what you're doing. In the case of the watch below there is no stem as this is a key wind setting watch. for diagnostic purposes you should look at the watch in six positions. But if you look at the technical specifications of the various watch companies they will specify the actual positions such as this watch is a standard three position Omega watch and the three positions are found in the image below then in addition to the various positions there are procedural things that you should follow which are mentioned way up above on the specifications although Omega does have some minor variations. To understand procedures I'm attaching an image. yes those crazy people at Omega knowing that the people in this discussion group will probably have a heart attack and die when they see that number. Although it's not just Omega I've seen some of the others Swiss companies will specify bizarrely low amplitudes it 24 hours. Of course the watch still has to keep time 8643_WI_81 BASIC CHECKS AND SETTINGS OF A MECHANICAL WATCH_EN cousins.pdf1 point

-

Simple answer is yes. That is how you put it in beat, just make sure the hairspring is free in the regulator if not you might kink the hairspring.1 point

-

If the cylinder is correct and has no wear then it is the weight of the balance and the length and strength of the hairspring. Be careful because of age these hairsprings can be brittle.1 point

-

I suppose it will depend upon a variety of factors like the containers they come in. Then whatever containers like the cleaning machine jars which have a lot of open space and surface area for evaporation plus the temperature that it stored at so at home when I used to clean watches I was using L&R cleaning fluid and rinse. I was using the method where you have a beaker and an ultrasonic tank and then I would use some plastic 8 ounce containers wide put about 6 ounces of fluid in each. Then from time to time when they were dirty I would change out one of the rinses and the cleaner. So the first gallon of cleaner that I had lasted for my really don't remember how old but will say more than 10 years by quite a bit. What I noticed was eventually the cleaner just wasn't cleaning but as far as I can tell the rinse other than conceivably evaporating doesn't break down at all then I just now checked the replacement cleaning fluids the rinse still looks fine and yes I really shouldn't put dates on these things. The cleaning fluid probably half a gallon left or more still looks the right color but definitely had zero ammonia smell. No idea if it would cleaner not if I need to clean a watch I just take it to work where we ever really nice cleaning machine. then the 8 ounce plastic containers apparently I never emptied those out at all and they eventually evaporated and the plastic lids themselves cracked rendering them unusable. But who knows when the last time I cleaned the watch at home was so my best guess is providing the containers they come in last forever and you never know with plastic the rinse probably would last almost forever. The cleaning product will eventually break down because David has ammonia that will go way. In the cleaning jars don't really know other than there is a lot of surface area. But I'm guessing even a couple of months isn't really going to be an issue. If you are really concerned you could pour out of the jars into some container with a volume close to the fluid level so you have less surface area for evaporation.1 point

-

Thanks Frank. I think I will confine this to my ever expanding 'non operational tools' drawer... Tony.1 point

-

Thats correct Nev a Roskopf pin pallet movement, in private messages with Caseback i did call this small wheel a direct drive minute wheel but i wasn't entirely sure of it's exact name. The shoulder on the plate or maybe more accurately in description the hub Does get inside the hole of the minute wheell. The arbor at this end aslo has a shoulder set back into the hole, the plate hub and arbor shoulder connect to serve keeping the minute wheel from rubbing on the plate. I will add a picture of the arbor sat in the hub. I thought about grinding back the damaged hub and have a free ring in its place.1 point

-

While I appreciate the effort, is it really worth saving 50% minus the work, to have and use a cleaning solution that might be as good as the commercial stuff?1 point

-

1 point

-

Scott, a quick google for “oleic acid uk” returns lots of it. It appears to be used in the food, pharmaceutical and beauty industries. Tom1 point

-

OK, let me see what we have to do here. Rich, I need to see all the pieces. The main plate, the barrel with it's arbor and the ratchet wheel that I guess stays under the bridge. We need to know what is this thin shoulder needed for.1 point

-

1 point

-

You can push them out with a small screwdriver. The pins might be split.1 point

-

Chucked up and ready to go . A quick touch up to graver and we're off Absolutely no way i can do this under a loupe....not today anyway...this difficulty proves to me the shear skill of anyone that can work on pieces dimensionally under 2mm using only a loupe. The added complication that the bush needs a finishing height of 0.3 is not helping.....why would it... ridiculously stupid barrel arbor bearing design with an insanely thin shoulder.....not happy.....not happy at all..... I need a different plan, the maximum diameter of the bush has to 1mm and even that risks breaking out of the side of the plate...think I'm pretty much stuck just now. At least the lathe got an airing1 point

-

I understand you not wanting to scratch the side of the case but the piece of cloth you have wedged in might be interfering with resonance that the tg could be relying on. Not echo....just maybe dampening the sounds that the tg needs to pick up from the escapement to give an accurate reading. The mic should to be close to the escapement or an item that tranfers the noise produced....such as the crown. Take out the cloth and add some sellotape to the metal clamp.1 point

-

On a 'quality' watch like Omega, most would aim for 270° amplitude or more (the last 620 I serviced I got 295°). For a beginner, I would say aim for 240°+. It's not so easy on small ladies watches like this, as the small size means that any imperfections have a bigger effect. Also watches with smaller balances are generally less accurate. A drop in amplitude from horizontal to vertical position of about 40° is expected. DU and CD positions look great, but the -32s/day looks to be Crown Right : which is not a position the watch is usually in. What does it look like Crown Left (one of the test positions)? For the 620, Omega don't show an initial amplitude when wound, but list a required amplitude after 24h as 160° (which is enough to send many who post here in to shock). It also shows the Delta 0h as 40s. This is the difference between the lowest and highest values in the positions tested, which are 3 for your watch : DU, DD, Crown Left.1 point

-

yeahhhhhh...but i dont like where this is going It just heard me mentioning its name.....its now currently shaking in it's draw Shhhhh it's ok.....caseback was only joking. So here's the plan I've come up with.....i tell you want i need making and give you my address and we'll just take it from there .1 point

-

Part of the problem could be incorrect positioning in the holder along with the fact it looks like you're changing it's position between the different orientations. Crown should be located in the black clip for all orientations.1 point

-

I've been sitting on an Autocrat for over a year, it needs a balance staff after I replaced some jewels but the one I installed initially is incorrect and I have not returned to it. Finally a worthy contribution: $10 US, a "Splendor" skin diver in a monobloc case. I was hoping for an EB8800 movement, but could tell by the slow calendar change action that isn't it. I also assumed a 2 piece stem and firmly pulled a 1 piece stem right out! But apparently this is by design? It reinserts and still works correctly. Also expected a tension ring crystal I would have to blow out, but no it is a basic crystal removable with a lift tool. The dial is pretty marked up unfortunately, and the hands don't look great. The movement I expected was a Baumgartner 866, but I'm not sure yet what this thing is. Edit: Ah, the movement must be a Brac 500 series something or other.1 point

-

1 point

-

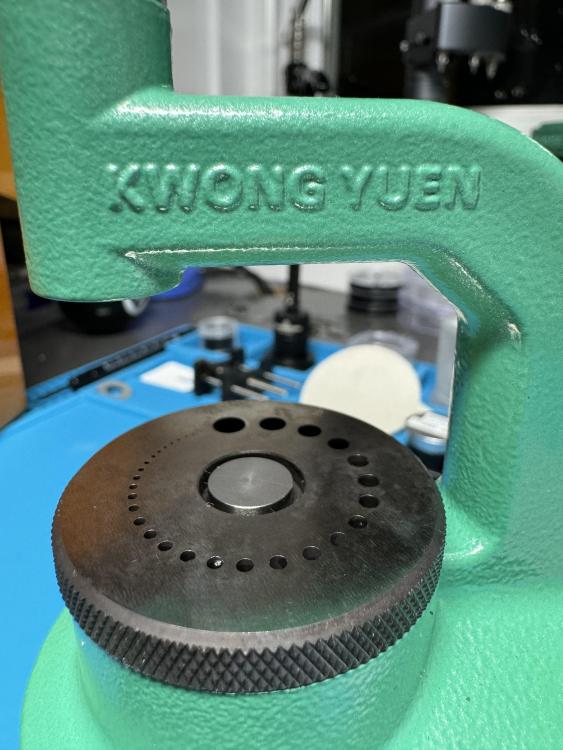

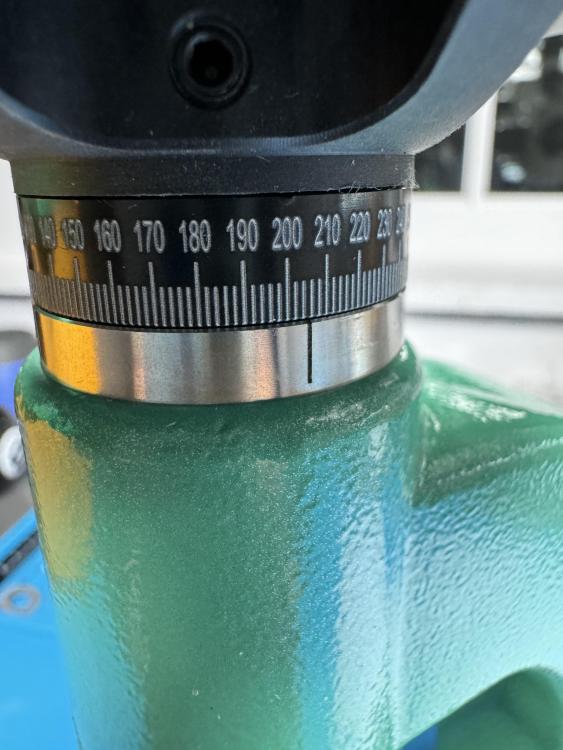

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:1 point

-

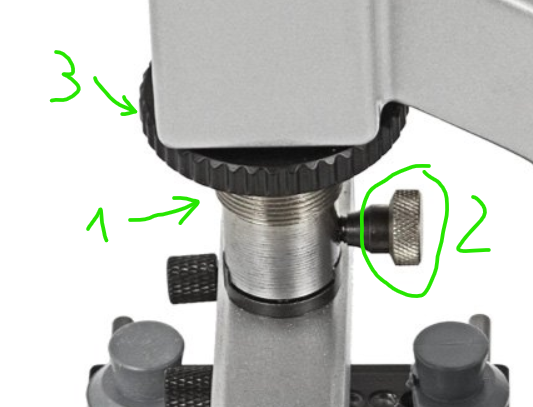

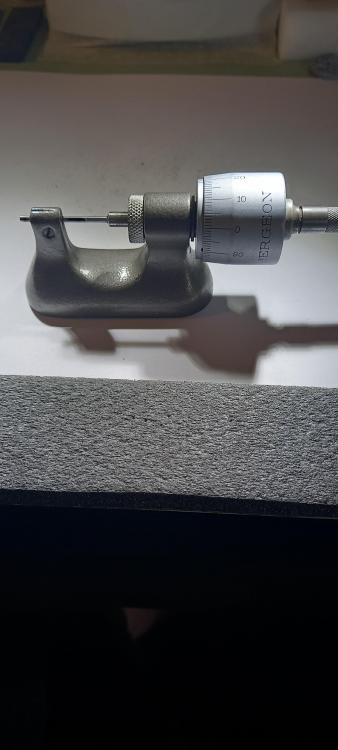

In direct comparison to the one I sent back: 1. The thread here is much finer (this is what you pointed out regarding the Bergeon tool) 2. The tightening knob/screw here seems to be of metal. Min was a very flimsy plastic one. 3. The lock nut looks different from mine (but this may just be cosmetic). That's true. Well, I'll soon see if there's a tangible difference. I'll let you know. The tracking say that it'll arrive on Friday.1 point

-

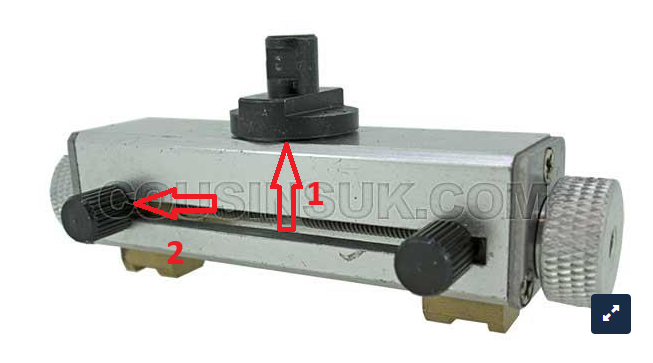

What are the differences? I'd be surprised if there was more than one factory making these. They all looked the same to me so I just bought the cheapest. The one you link to seems to say "Key of Watch" on the side of the base, which is what it says on mine. I've now managed to remove almost all play in the shaft, and by adding washers and playing with the grub screws, most play in the adjustable jaws. EDIT Just an update for anyone with one of these Chinese tools : On mine, there was play in the jaw holder as the screw (1) was lose. The only remaining play was in the brass fitting holders. The locking screws (2) should lock these solidly in place, but I found that they didn't. I fitted a washer under each screw head, and now the brass holders lock solidly in place. I now have a tool with no significant play.1 point

-

1 point

-

At the risk of inspiring you guys who have to have one of everything (like me) to spend money on one of these, I thought I'd show a photo of a Chinese-made tool I jut bought. It's not a watchmaker tool but rather a tool to make tools which can easily include many watchmaker things. The first applicable thing that comes to mind is... screwdriver blades. My back story here is that I have some 3/16" and 1/4" titanium rod that's been sitting around for forever, and I got to thinking that since I could use some really nice screwdrivers, rather than blow a bunch of money on a set, I'll just make my own... out of titanium. The blades can be made from whatever, and though you can easily enough just hone some stock into good tips by hand, this machine could dang quick whip out a set. The titanium shafts and delrin knobs are another project, but also another whole story. Just an idea I had and plan to implement coming up. I'm a machinist by trade so my newly accepted tangent into watchmaking is adjacent. Anyways, I wonder what you other guys can dream up that this machine might be handy for in the watchmaking realm. Behold, the cutter grinder: These run around a grand delivered, give or take. A full complement of decent wheels is another half that, but you can get by with what it comes with for a fair while. Anyways, any thoughts?1 point

-

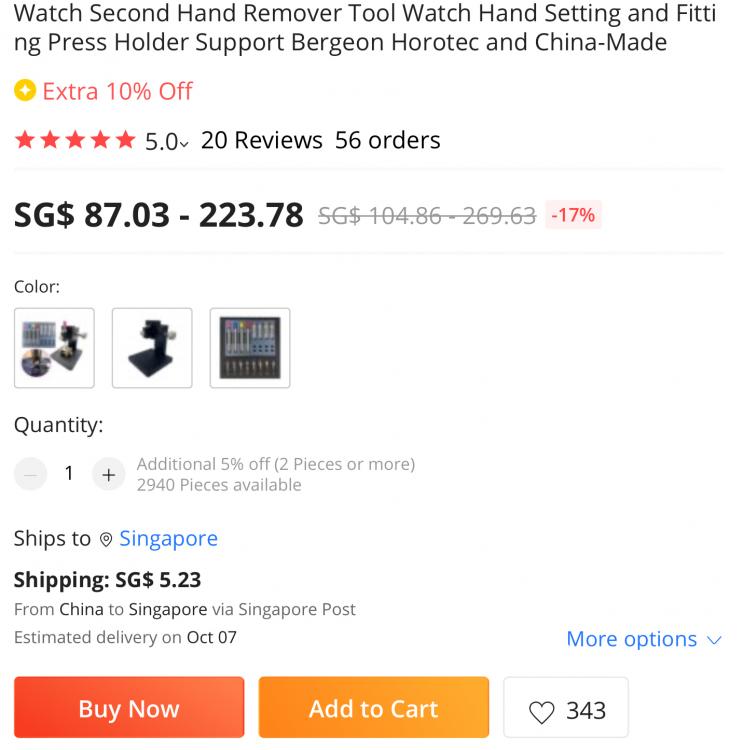

I don’t normally post about Chinese tools, because I am apprehensive about supporting direct copies/clones of existing tools. However, I recently came across this hand remover press on AliExpress, which looks quite distinct from the existing Horotec one. In fact, it’s design looks quite good, with a movable rack supported head (with Vernier scale) to allow you to adjust the height of the hand remover on the go. Any of you guys interested? The price is also much less than the Horotec one. https://www.aliexpress.com/item/1005004261155255.html1 point

-

1 point

-

Hi all Time for the next tool in this series and this time we introduce a little controversy Yes we are now talking Chinese Watchmakers Screwdrivers, could there be such a thing as quality watchmakers screwdrivers from China, I think so. I had in the past tried some low cost drivers from China and to be honest after a little bit of work, hardening and tempering and honing the blades they worked quite well, although in the end I settled on the French (A*F) set that Cousins sell, these were an excellent set but my only gripe would be that the thinner blades where a little to bendy and it was quite easy to bend them if applying pressure on a tight screw. This led me to these. https://www.aliexpress.com/item/1005002528364614.html?spm=a2g0o.order_list.0.0.56751802D1Kqw7 These turned out to be a very high quality set with very rigid hard set of blades. Replacement blades are also available from the same seller should you need them. For £23 plus VAT & P&P they are quite a bargain. Again like some of the other tools in this list their similarity to some well known Swiss drivers may or may not be totally coincidental . I can highly recommend these, so much so I have just bought a second set, just in case Stay tuned there are some more controversial tools to be added to this list soon.1 point

-

Hi all. Its been awhile but now time to introduce the next tool in this series. This time I introduce my Watherproof Watch Case opener, which is clearly based on the much more expensive Bergeon 5700. I went with this one https://www.aliexpress.com/item/4000394753607.html?spm=a2g0o.order_list.0.0.7c8018028gGu7h Which at £63 was quite a bit less than the £535 the Bergeon version is Comparing the two side by side, there are a few differences most being cosmetic, like the measurement scale on the adjustable tool on the Bergeon version, on this version there a no scale markings, but in reality they are not needed, the only other difference is possibly the support spring, on the photos of the Bergeon one it appeares to be a little longer. The Chinese one had one issue out of the box but it only took a few seconds to correct, out of the box the two raws (for want of a better word) were not quite the same difference from the center line of the tool, so with one lug in its slot in a case the other lug was out by about a millimeter. This only took a few seconds to cottect by unscrewing the two locking grub screws in the Alluminium adjusters and sliding the threaded rod a millimeter to the correct position thenlock the screws gives an accurate possition. One other difference that is first seen is the use of black plastic for the base were its wood on the bergeon tool, well it was wood on the Bergeon tool, as can be seen in the picture below even bergeon now sell their tool with a Plastic base. Is this tool made in the same factory that Bergeon use for theirs but with less QC applied to keep the costs down, I would not be surprised, I worked in production engineering for years and seen the practice of having stuff made in China but boxed in their country and then claiming on the box to be made in the the boxing country before so would not be surprised if the reason so many Bergeon and Horotec tools look identical to some of the Chinese tools is because they all came of the same production line just with different finishing touches. Still if its the same or not it does exactly waht it says it does on the tin (as they say) I comes with a useful selection of tools and adaptors to hold the case with or without a stap and different size and shape lugs in the case back. If you only encounter a few divers watches with a super tight back this tool will pay for itself in no time at all. pictures below, first is the current version of theBergeon tool, then a couple of the Chinese one I got from the link above.1 point

-

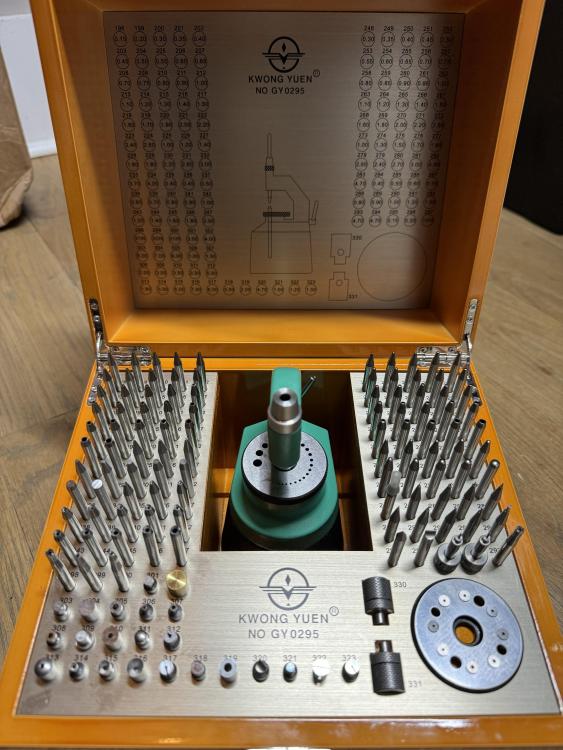

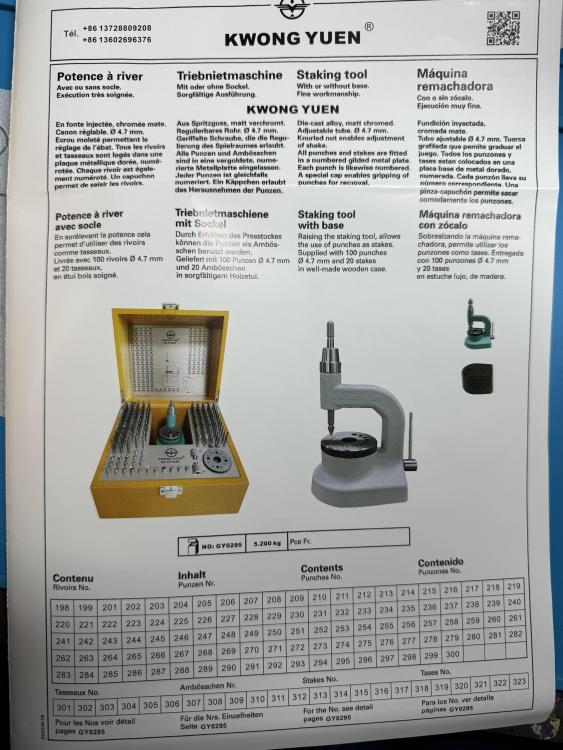

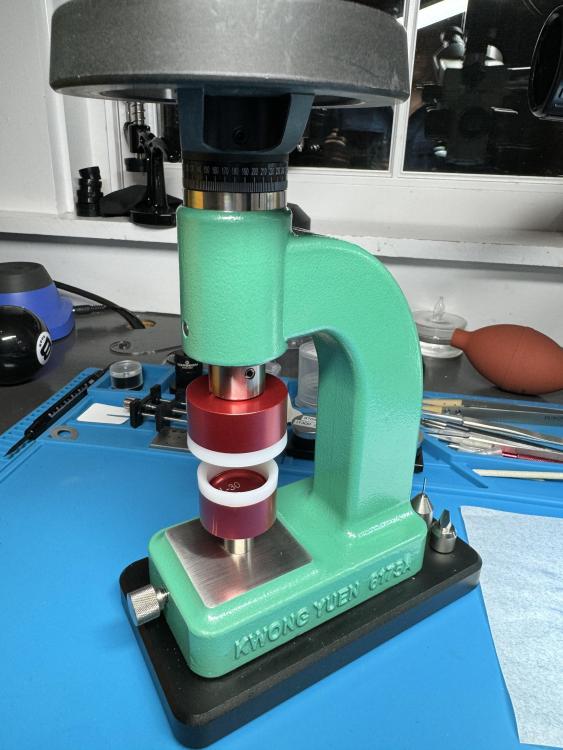

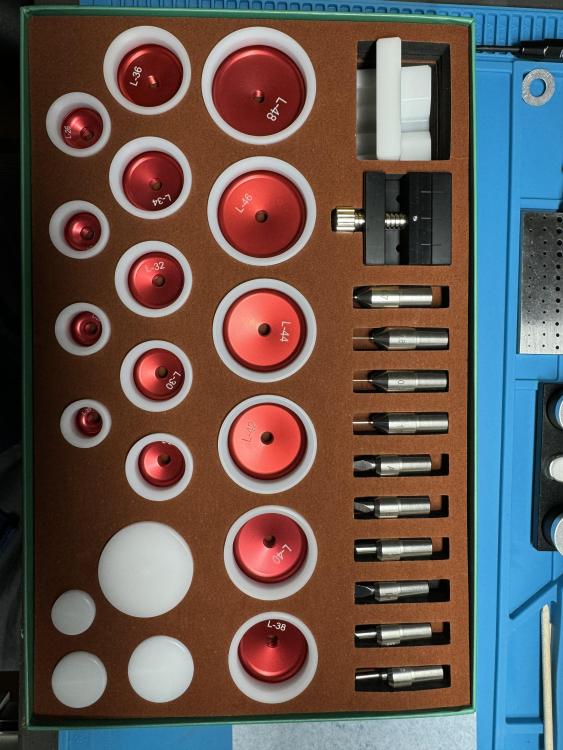

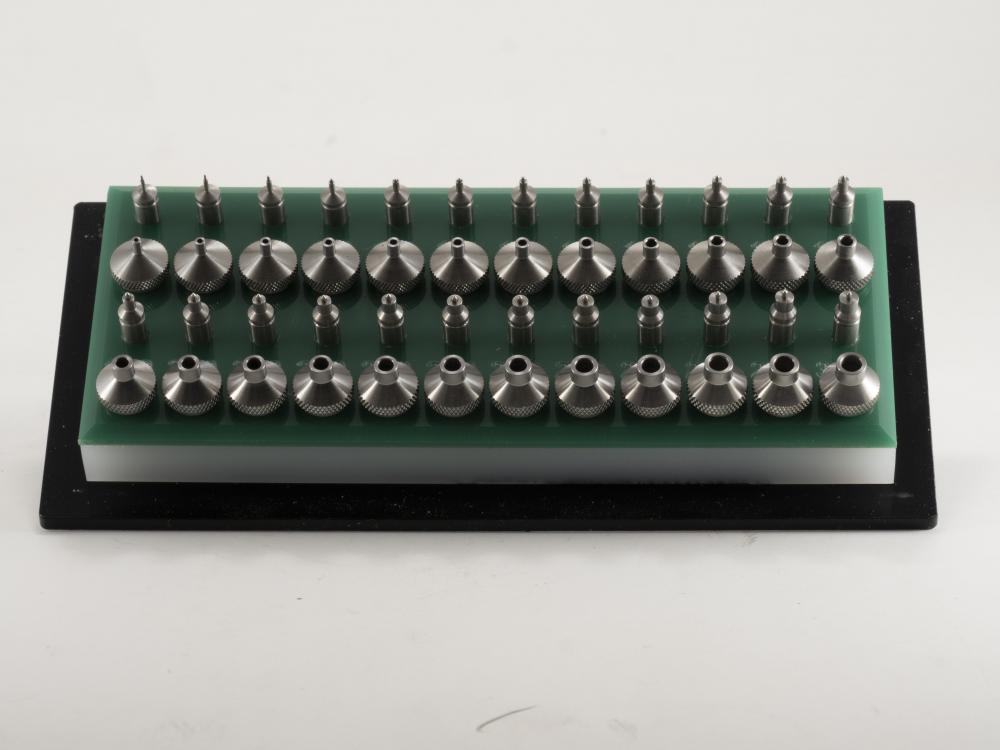

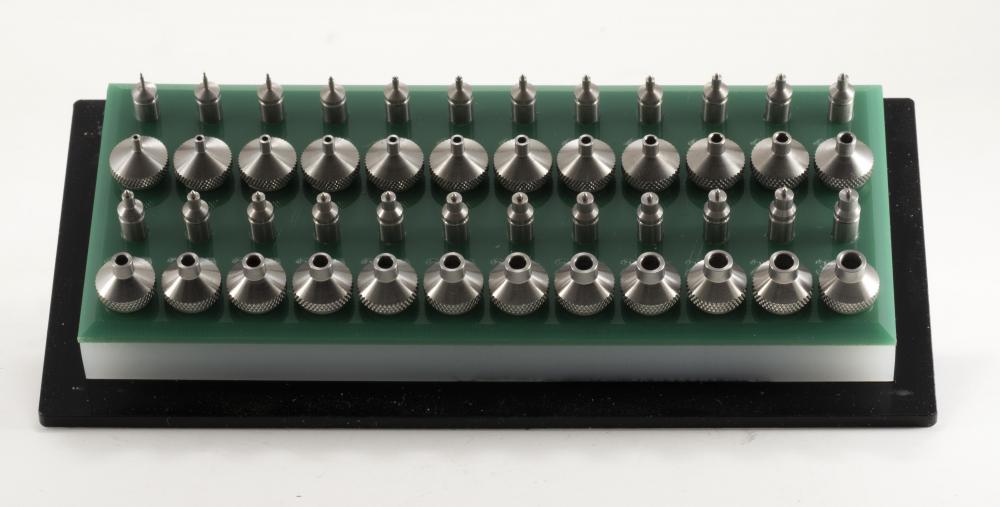

Hi all Time for the next tool in this series This time is the good old Jewelling tool Seen before on the forum but still well worth a second look here. Again from Aliexpress for £117 for the tool and a nice selection of 24 pushers and anvils which are all well made and seem to do what they are supposed to do, https://www.aliexpress.com/item/4000261581571.html?spm=a2g0o.order_list.0.0.119c1802OtQ8wu Obviously a clone of the well known Horia tool but a well made tool none the less and at a fraction of the originals asking price. Not used it in anger yet but have used it a couple of times to adjust end shake and that function was performed faultlessly so doubt a jewel replacement will be an issue for this tool either, once a replacement jewel has been found that is. Thanks for following this thread. Paul1 point

-

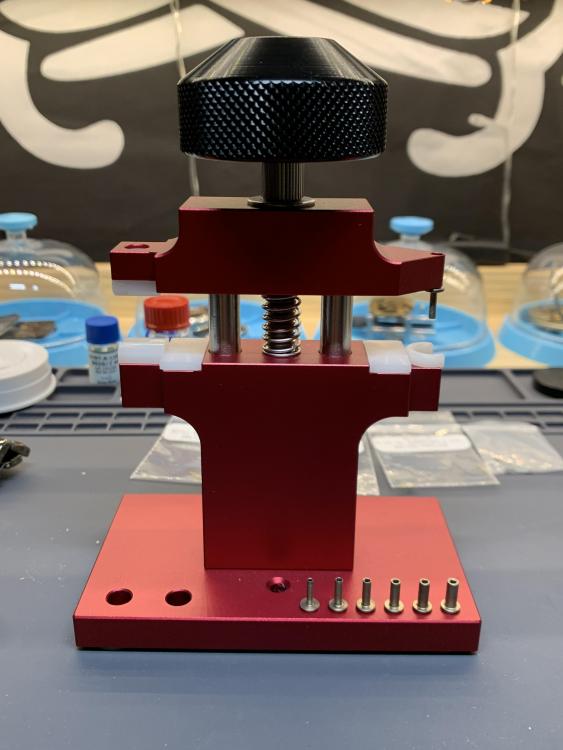

Hi all Time for the next update in this series. This time we have Hand Press tool but not the cheap red ones often found comming out of china, this one is a serious bit of kit and at £102 it sould be https://fr.aliexpress.com/item/4000316385317.html?gatewayAdapt=glo2fra&spm=a2g0o.order_list.0.0.21ef5e5btCjVvv This tool is night and day better than the cheap red ones and makes hand fitting a real brease. Its similarity to the almost a grand Bergeon tool is starting to make me think Bergeon are pulling a fast one and also having their tools made in China and just packing them in their own boxes and hiking the prices. OK I have my tin hat on after that comment but I would not be surprised if it were true A few pics of the actual tool1 point

-

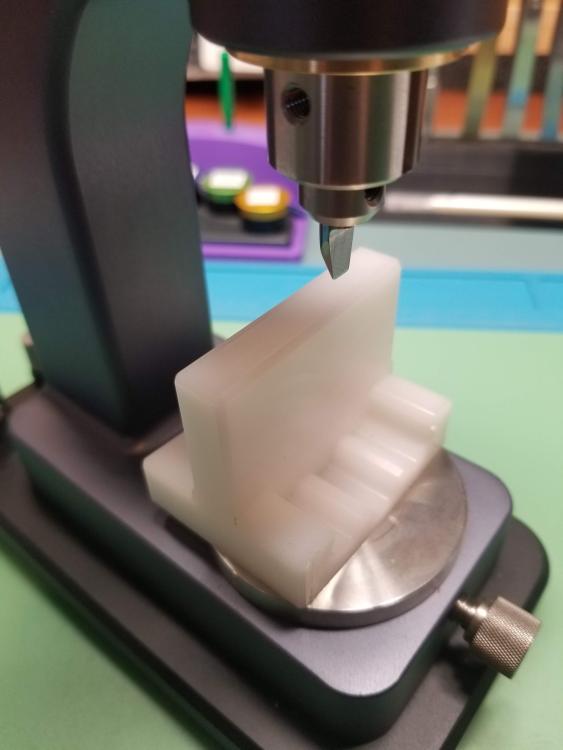

To go with the dial feet repair theme shown in the welding machine shown above a cheaper option is the brass replacements that are glued into place, the downside to this is if just glued to the back of the dial the head of the brass foot can raise the dial enough to give fitment issues, so whats needed is a tool to mill a flat bottomed hole into the back of the dial, just deep enough for the head to be flush with the back of the dial. Prices vary so look around for other deals but this one is £63 https://www.aliexpress.com/item/4000539391167.html?spm=a2g0o.detail.1000023.1.254a6e72zaGioL Another well made tool that does what it is designed to do Kit includes the tool & Cutter, replacement cutters are available if you break the supplied one, 2 plastic movement holders and an assortment of feet in the common sizes1 point

-

My favorite so far has been this watch crown pusher tube remover. I technically didn't purchase it from China because it was on eBay with quicker shipping and actually cost less too, but its definitely this one from Ali: Iron Watch Crown/Friction Tube Removal Pusher Punch Press Watchmaker Tool With 7 Bits(1.55/1.75/1.95/2.15/2.45/2.65/2.95mm)|Tool Parts| - AliExpress1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)