Leaderboard

Popular Content

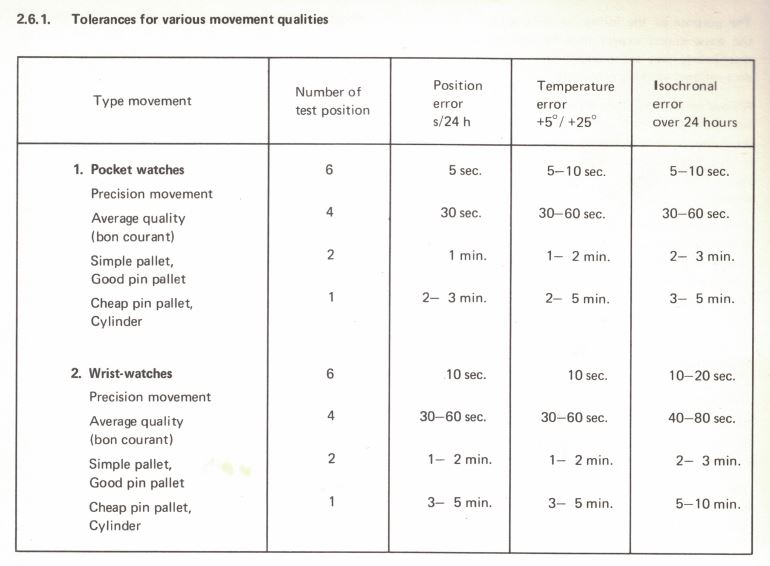

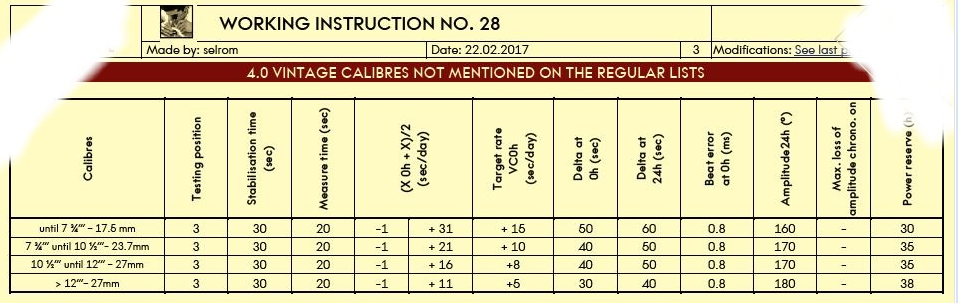

Showing content with the highest reputation on 11/19/24 in all areas

-

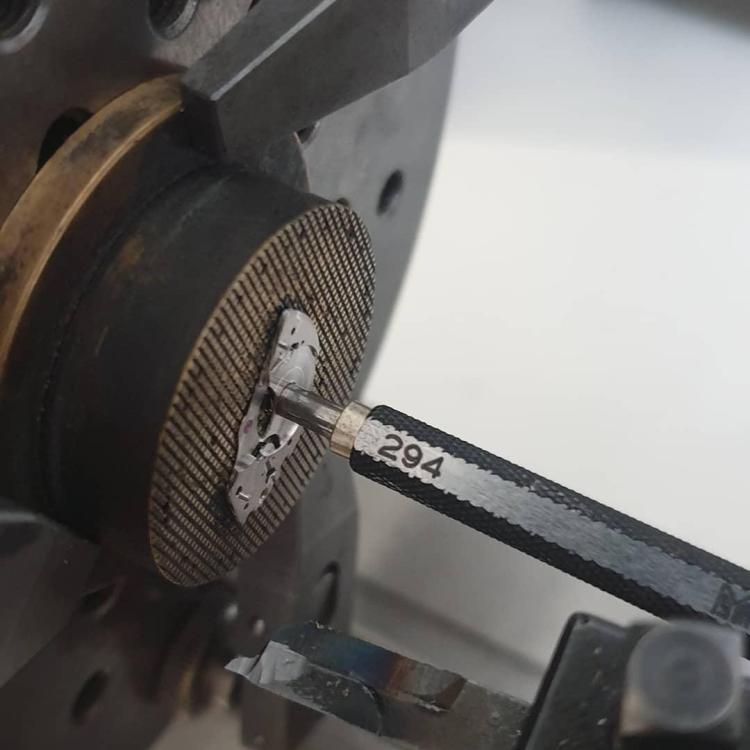

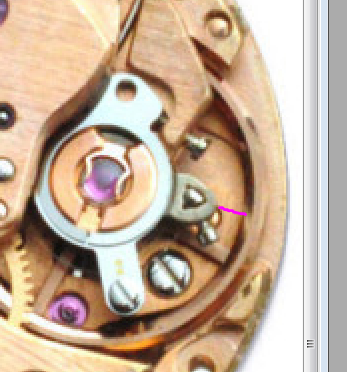

If you can make a stepped hole in the bridge you can avoid the need for solder. Here's a fix I did on a JLC 838, this has a suspended barrel, so 100% of wear is on the bridge and there's next to no material to work with. The worn portion protrudes down toward the barrel a bit and up toward the ratchet wheel. I did the bridge work in a faceplate, the stepped bushing was all lathe work. In the last pic the the barrel arbor looks low but it pulls up when screwed to the ratchet wheel.7 points

-

Anyone close to Hull? If so can you nip over and reset Rich, looks like his algorithm has jumped into verbose debug mode Tom5 points

-

Back in school......Just my first step in getting to Uni mate. I have no school records so I'm having to start from scratch, I'd like some qualifications under my belt besides my building apprenticeship before next years intake. Access to learning can be hit and miss for us 'old uns' and I didn't want to rely on a Uni's clearing process to scrape in. So I'm studing English , Maths and IT.....inbetween bits of work.....absolutely loving the refresher learning.5 points

-

As you have a original Omega balance complete you should never be rotating the collet to adjust the beat. This is because this watch has a movable stud holder and yours is currently at its maximum of one extreme. I've pasted image down below see you can see approximately where the stud holder should be. Then down below I have a link as we recently discussed the movable stud holder I'm giving you that link also.4 points

-

The screw heads of the ratchet and crown wheel screws look the same. This in some movements (Usually AS ones) is a sign that they both are lefthand threaded. Did You try tho turn the screw clockwise? Using Evaporust is totally wrong, throw it away.4 points

-

Too complicated ( complex : synonym ) for me ( pronoun ) to attempt (verb) ) Nicklesilver ( proper noun ) Besides ( conjunction ) I ( personal first person pronoun ) dont have ( auxiliary verb ) the ( definitive article ) tools ( collective noun ). But ( conjuction ) Wow ! ( interjection ) thats fantastic ( adjective ) work ( noun ) matey ( pronoun ).3 points

-

Lucky for me it's only in the old print catalog. I think for safety reasons they removed it from the online so you'll have to find somebody with one of the older catalogs. Then there probably won't take your order again for safety reasons.3 points

-

Shock is one of the best things to release a rusted together part. If you have a staking tool, rest the barrel arbor in a stump, and come down with a flat face punch on the screw, good contact, then one sharp smack with the hammer. If you don't have a staking tool, you can try with some other means of support and punch but would be less ideal. Then work the screw, putting pressure in both directions, until it starts to move. As said, there's a chance it's left hand thread, but sometimes going the "wrong" way a little helps loosen things up.3 points

-

I know I shouldn't say this they will get their Tar and feathers and burn me at the stake. On this group there is a magical amplitude that you must hit or your life will be terminated in a slow painful fashion. But if you look at the Omega specifications for your watch all they care about well really all they care about is timekeeping. Then for a lot of vintage watches the minimum amplitudes are actually very low at 24 hours with the specifications still being timekeeping within specifications. Then the reality is the most important of all is what does the watch do when somebody is wearing the watch. I remember a while back where somebody had a lady's new old stock watch that he wanted to give to his aunt. There was a several page discussion of its problems and the problems He had with timing it. All of which I'm going to skip over because in the end he gave the watch to his aunt and she was happy as can be. So that really is the most important thing that the owner is happy with the timekeeping.3 points

-

I've just completes a nine hour long-soak test with the EDTA rust remover, to see the effect on small parts; I've posted the result separately in the walkthroughs and techniques section, rather than confusing this thread.2 points

-

This is the 3D printed platform that I use. https://www.printables.com/model/234556-platform-for-watch-hand-setting-tool?lang=en That does give the flexibility to use any type of movement holder that you wish. I usually use the holder in the 2nd photo just in case I need to support the center jewel when pressing on hands. You need an Allen wrench to adjust the center pin, though. I leave the pin flush usually, as a flat platform will provide some support to keep the main plate from flexing when pressing on the hands.2 points

-

That's a FAIL Rich . Good luck with the courses. I was never that great at Maths, which is ironic, as I spent my working life using it in aero engineering. Now I've retired I'm learning stuff I always wanted to better understand, like Quantum mechanics (where the maths isn't as hard as you would imagine).2 points

-

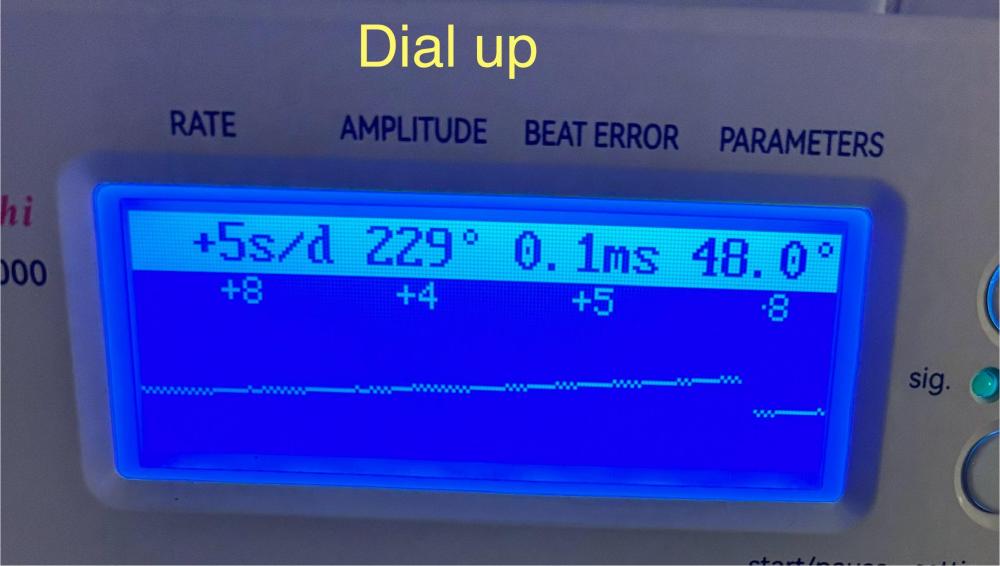

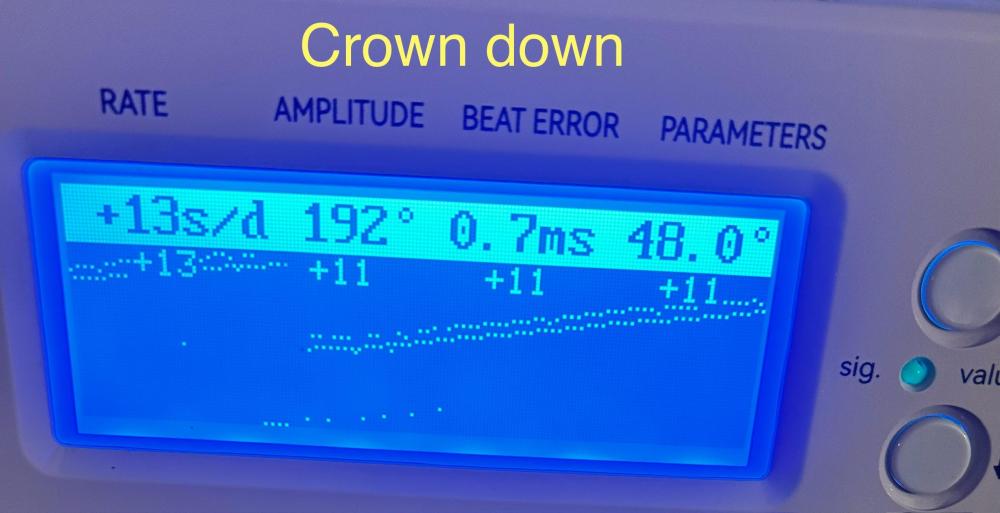

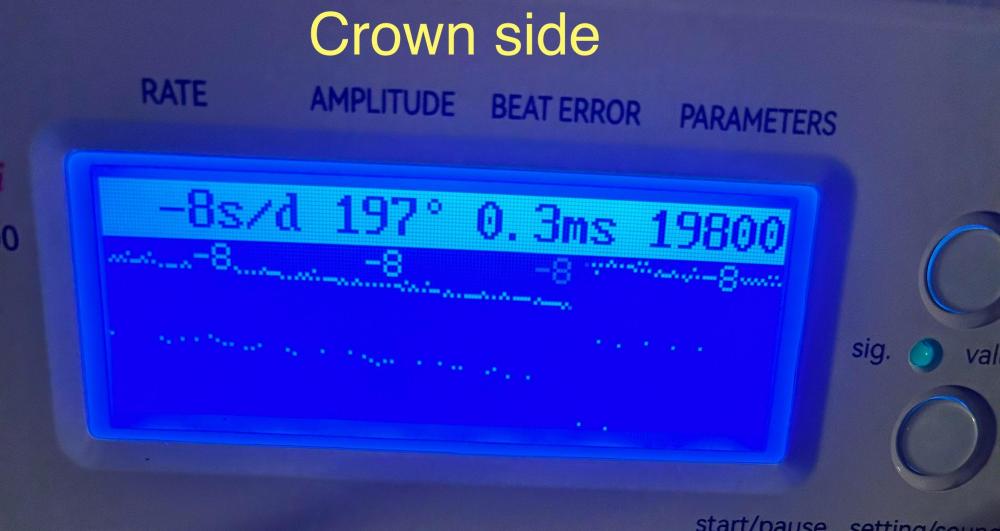

Just closing the loop on this thread with readings post 24 hours (on what I believe is a 30 hour power reserve). My wife wore it al day and it has worked fine. The amplitude has dropped as expected. The rates are above the factory specs, and in dial up it’s above what many experts suggest as the minimum for a healthy vintage watch (210 degrees). It’s not great, but having re cleaned and re oiled as meticulously as possible, I feel like I’ve run out of ideas. So I’ll leave it at this for now, considering this was technically my first watch service/restoration. I have a few more vintage watches on the bench at present, so maybe I’ll come back to this one after some months of practice and experience if my wife has complaints with its functioning. Thank you everyone for your excellent suggestions and advice! I truly appreciate it! And I look forward to talking with you over the other watches I intend on servicing.2 points

-

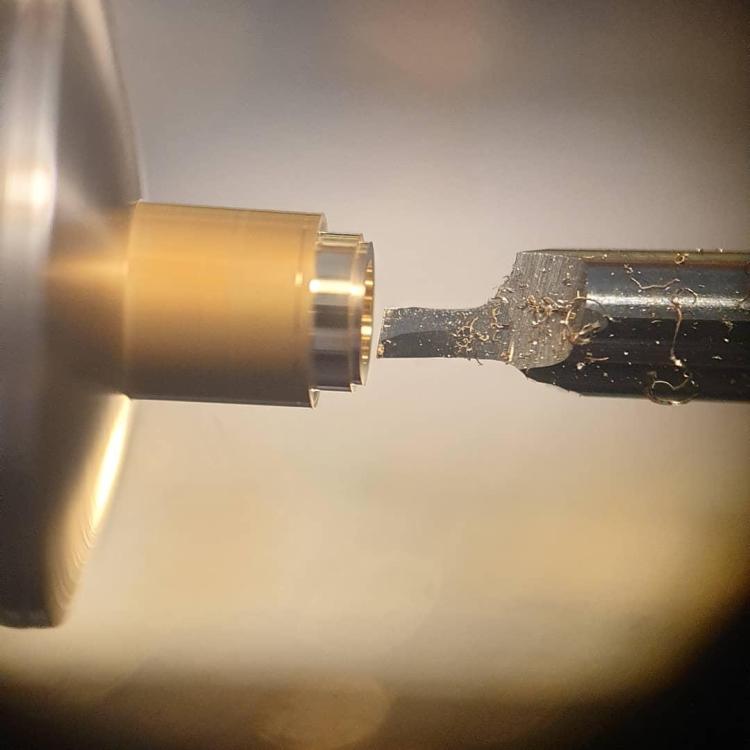

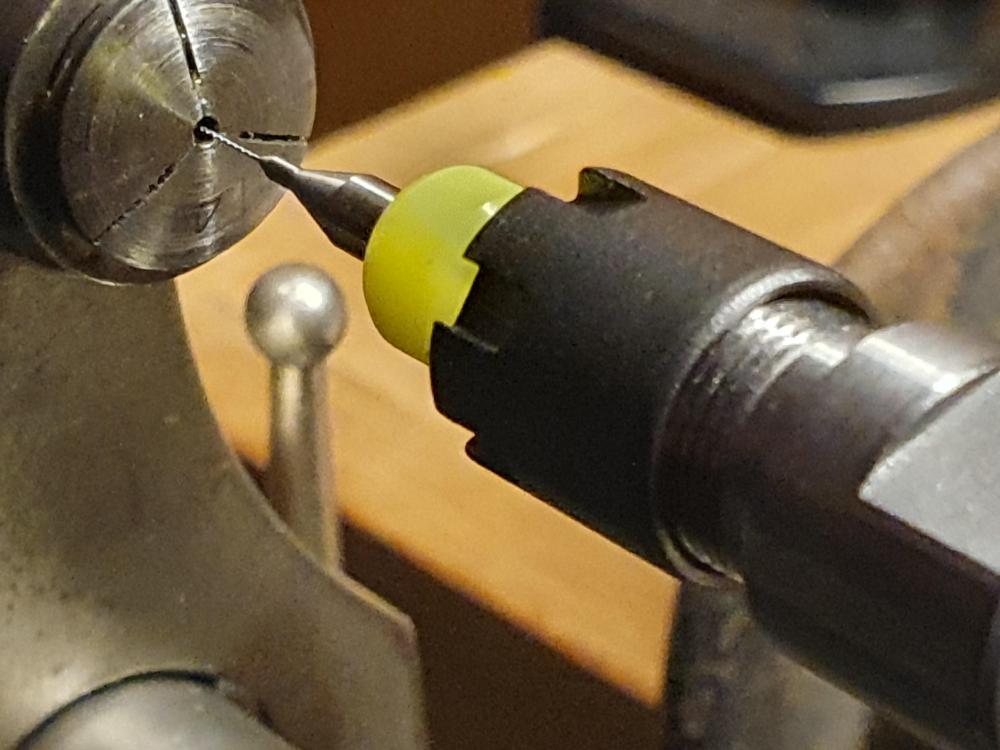

The drilling attachment I got with my recent new to me 6mm Wolf & Jahn lathe works with these classic spade-type drills, but is not big enough to hold the 3,17mm shanks of the carbide drills I also have. Online I found ER collet holders with cylindrical extended shanks. There are also versions available that hold ER8 collets and have a 6mm shank. Combined with a 7mm OD, 6mm ID brass tube, I now have something that works. Turning it doesn't show any wobble under my microscope, so I guess it is accurate enough.2 points

-

The penetrating oil mix is 50:50 Acetone and automatic transmission fluid; it's a common mix used by many mechanics and engineers. The only commercial penetrating fluid that works better, from what I've seen is something called "Liquid Wrench". Heating, when the parts are compatible, works best of all - but with delicate parts you can't use much heat without risking damage. Re. the usage of the rust remover - it seems to have very little effect on clean metal, though I have not tried soaking small parts for long periods. The penetrating mix should be totally safe as long as it's only in contact with metal, in a glass container - acetone breaks down many plastics and adhesives.2 points

-

In my day job, particularly removing screws that have been in for years, I always tighten the screw a tiny bit before undoing it - breaks any bony ongrowth and if the screwdriver slips in the screw head and rounds it off a bit you can still unscrew it ok. There are other more extreme techniques for getting out stuck or broken screws from bones. None involve soaking in coke2 points

-

I know that some commercial rust removers contain acids and as @Neverenoughwatches states they attack all of the steel indiscriminately, other substances with acids in it eg coke will do the same and who knows what the other ingredients are doing. Other rust removers do not contain acids and only remove the iron oxide (rust), the side effect of this reaction can be blackening of the steel in some cases, but for light rust and short exposure this is often not the case - a little often is better than a long soak in my experience. I know some users on here advocate using coke, but there are much better alternatives out there so it blows my mind when they come on here advising it as some kind of panacea. We are so methodical and cautious in other aspects of watch making (reference the other discussions on lubrication, cleaning fluids and use of epilame for example) and then we are blasé about dunking parts in a soft drink?!?! Rant over!2 points

-

What what do you mean by crap I continuously see references on this group that Coca-Cola is the ideal solution to everything although I don't recall if anyone recommended drinking it? You really don't want to look at the fine chemical details of a lot of the things we eat they have a lot of amusing substances. Then thinking of natural organic products like Coca-Cola I think I've seen recommendations of using tea As that probably has some mild acid in it also. Then the classic problem of a little is good but a lot can be bad in particular with rust removers. Yes I've seen screws that turned black not good at all and no they still will not come out. Or worst-case you can start dissolving the screws with whatever the acids are.2 points

-

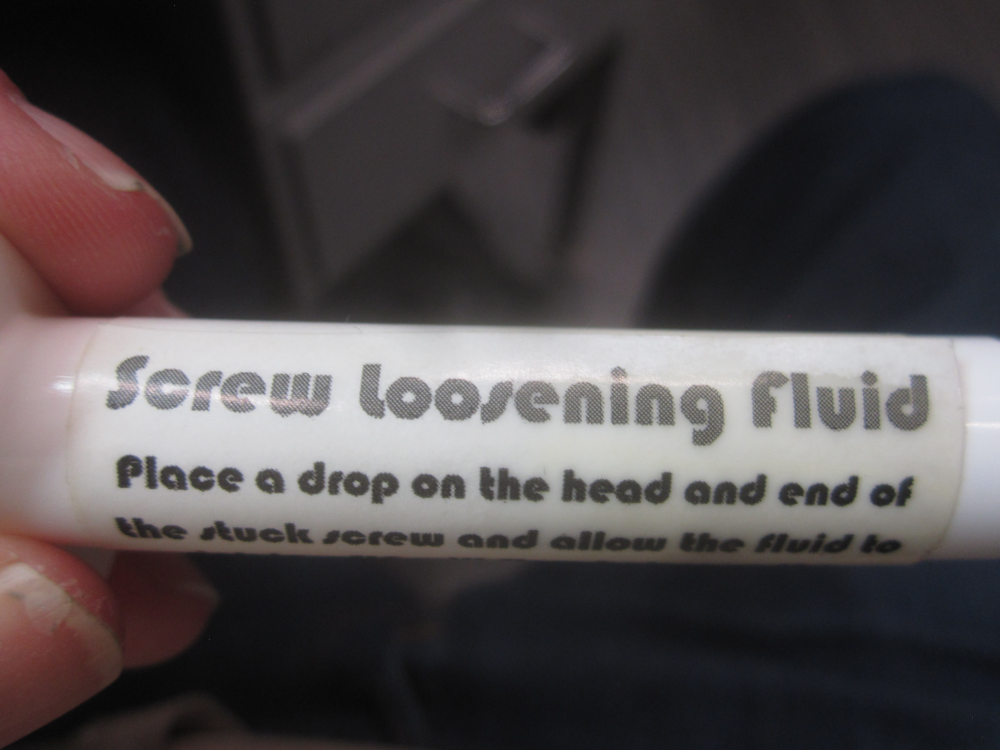

Just as a reminder with your enthusiasm of trying things. With the watch cleaner do not elevate the temperature use it at room temperature and Longer for cleaning is not better. Usually around four minutes works may be five but do not leave it in the cleaning solution as bad things will occur. Then you really need a different solution like something designed for screws like something like this. I find that work a drop or two on the screw and wait a little while and I've never had a problem. Then I have a link to the company manufactures This product but I do know there would be other penetrating fluids for screws this just happens to be the one we have at work and it does work really well https://westernoptical.com/products/screw-loosening-fluid Then the unfortunate classic problem In watch repair left or right handed Screw? Made considerably worse by turning it in the wrong direction and yes this can be quite a nightmare. Then unidentified movement I don't suppose you have the dimensions? Like what is the diameter of the dial side plate. Then a picture of the setting components found on that side as we may be able to identify the watch from that information.2 points

-

Thanks to all of the information gleaned from this post (and a couple of excellent YouTube vids), I took the plunge today and ordered a Microscope from AmScope and camera from AliExpress. Here's what I ordered: AmScope SM-3TPX Simul-Focal Zoom Trinocular Stereo Microscope 3.5X-45X Magnification on Single Arm Boom Stand (includes 0.5X Barlow lens) AmScope 144 LED Intensity-adjustable Ring Light for Stereo Microscopes with White Housing HAYEAR HY-3307 Digital HDMI USB Microscope Camera 16MP 1080P HAYEAR 0.35X C-mount Adapter AmScope started a Black Friday 15% Off Pre-Sale today (enter PRE15 coupon code at checkout), so that was a pleasant surprise. AliExpress pricing was also lower today. The two videos I found most helpful were from: Alex Hamilton - The One Tool That Will Make You a Better Watchmaker Kalle Slaap - Microscope special Part 2of2 - My personal set-up and why I'll follow up with a brief review once I have some bench time with the new gear. Cheers! --Rick2 points

-

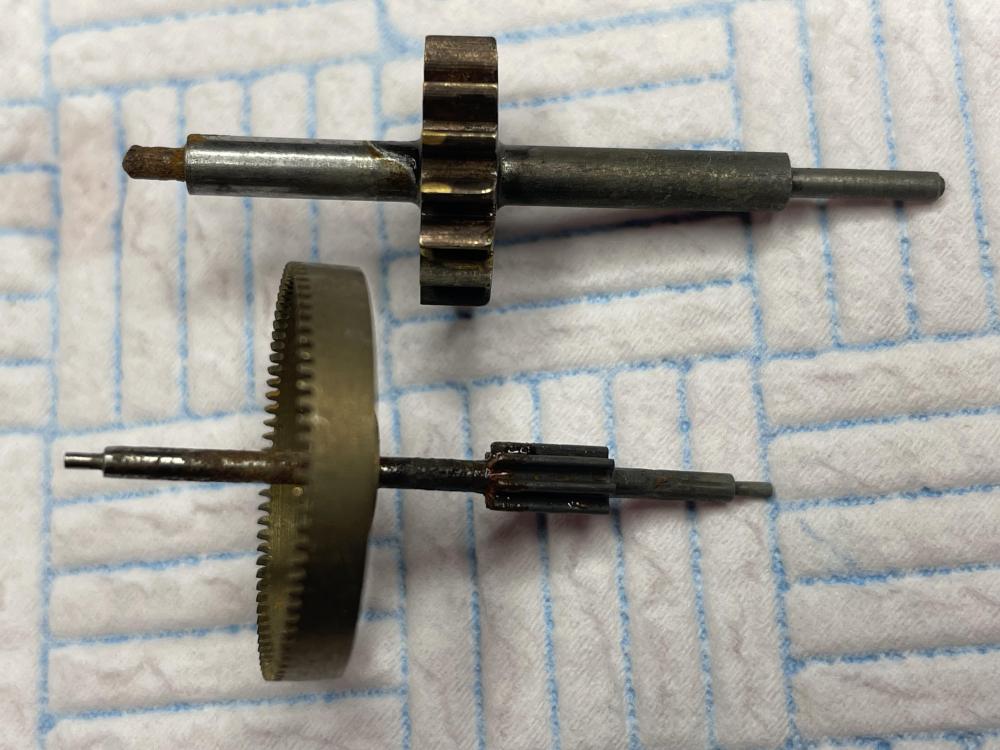

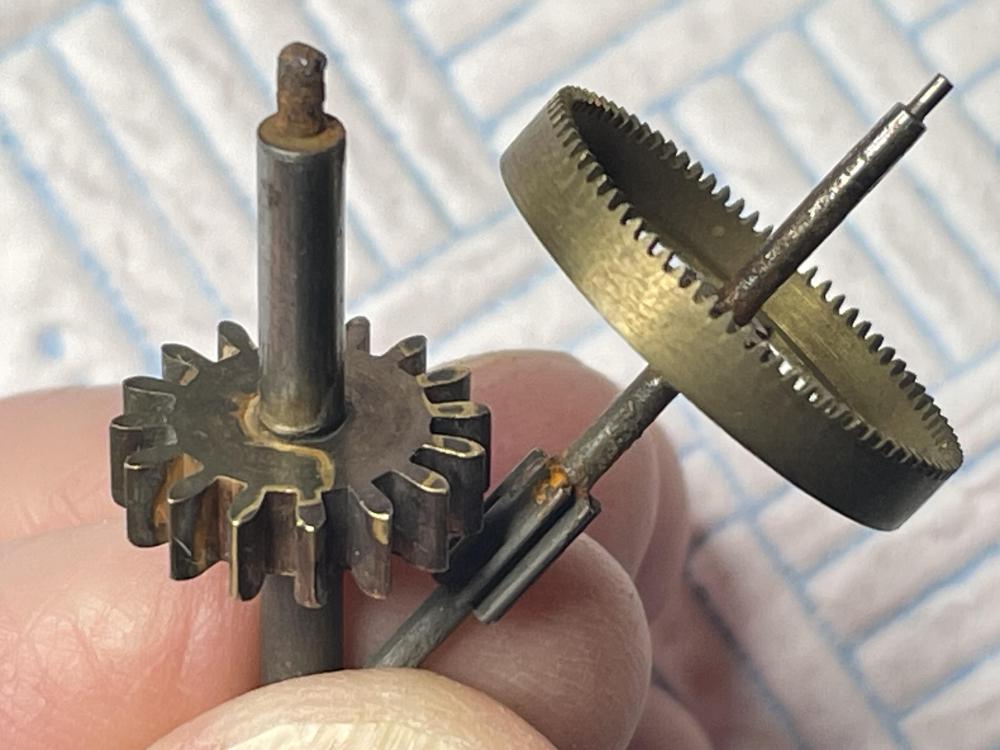

This rust remover solution was mentioned in another thread, and I thought I would do an experiment to see what effect it had if metal parts were left in it for rather longer than required. The mix is five grams of tetrasodium EDTA per 100ml of deionesed water, plus a tiny amount of citric acid to bring it to around ph 6.5 - 7 I've also used disodium EDTA, which seems to work pretty much the same; these are used in such as cosmetics, so not toxic, though I'd not inhale any dust, on principle. I normally soak parts in it for between 30 mins and a couple of hours, depending on the level of rust - and generally use it for tools and such as keyless mechanism parts, rather than movement train wheels. For this experiment, I used a couple of items from a big clock part collection I got a while ago. They were suspended part way in the solution; the one with the single thick wheel was at roughly 45' with the wheel half in the liquid, and the other was vertical with around 3/4 of the pinion submerged. This is the result after something over nine hours; the first two photos are the parts straight out of the solution, with just a rinse under the tap: And this is after drying and removing loose residue with a paint brush. They were in quite a bad way, rust scale and pitting in places, which is why I used those parts. You can still see the heavy rust on top of the small pinion, where it was not in the liquid. The pivots and steel pinion leaves do now have a matt surface; I don't know how much the size would change after re-polishing them. The brass wheel has obvious colour changes, more coppery where it was immersed, but still shiny rather than matt. This was using a fresh mix of the solution for this test & I may have added a bit too much citric acid. For comparison, this is a more normal use - a lathe bed from ebay, which had significant surface rust. Around one hour in the solution and it looks vastly better! The slight "marbling" is probably due to me initially trying to use a cloth wrapped around it & soak that; once I realised that was not working evenly I made a crude trough from cardboard lines with a bin bag, so it was fully immersed. And after; dried then oiled and thoroughly cleaned off, to avoid further rust. The stuff does definitely work very well, under appropriate circumstances.1 point

-

Hello everyone my name is Andrea and I'm writing from Livorno (Italy), I'm a mechanical engineer and I signed up to this forum to discover and learn as much as possible about watches. In particular, I own an old Enfield striking clock (1945) that belonged to my aunt's father (English) which, with the sound of his gong, accompanied some beautiful moments of my childhood so I decided to put it back into operation. I got some basic tools and a set of bushings, I dismantled and washed the mechanism (F3) which appeared destroyed by years of running without maintenance, I rebuilt one of the ratchet springs and replaced eight bushings. I was satisfied with the work but unfortunately I broke the escape wheel pivot and to date the clock is unusable, so I would like to ask if any of you have this replacement. Thanks for your hospitality.1 point

-

1 point

-

1 point

-

Exactly @Knebo. 99% of the time I don't need more magnification, but for instance today, I was oiling the pallet jewels on a small ladies movement, and the extra magnification makes it much easier. There's even times when I put in the 2x Barlow to give me 90x mag if I need a really close look at balance pivots.1 point

-

I think what @mikepilk and I are referring to is where you can benefit from even more zoom. He said: And it's the same here. I think 0.5x barlow, 10x eyepiece and the 4.5x maximum magnification of the main lens add up to 22.5x total magnification. That's more than enough for 99% of the time. But I do sometimes want that full 45x magnification (i.e. 10x eyepiece with 4.5x mains lens, but no Barlow). For example, when I want to really see the surface smoothness/roughness of a pivot to determine if my work on the Jacot tool was effective.1 point

-

Yeah, I thought the same. I think more likely it was a design improvement to add slightly thicker screws on later movements. It might simply be a total coincidence, who knows. I did a lookup in the old Bestfit catalogues based on the setting lever and yoke shapes you posted.1 point

-

Thank you and don’t I feel like an idiot. I do know what’s a moveable stud holder is. I was so distracted by thinking about the “welded collet” and what challenges that presented for fixing the hair spring that I couldn’t see what was right in front of my eyes. I corrected the beat error in like five minutes. To date most of my watch projects have been on older, less expensive vintage watches which did not have moveable stud holders so I have had little opportunity to use them. Obviously a huge improvement in design. Thanks again! Pic of new adjusted position1 point

-

Don't need to look any further than the movement to see it's a fake and should just go in the bin.1 point

-

1 point

-

Welcome to the forum. You're besting starting another post in the clock forum and provide as many photos of the movements as you can.1 point

-

I don think it needs to be wider than the barrel arbour, ideally the arbour needs to just rest on a stump, right? The shock travels through the screw, through the arbour, and directly on to the stump.1 point

-

Only downside pivot of the arbor must get in a hole, the arbor itself should be supported on the stump. Heat/cool method doesn't work in small objects like watch parts. They have small mass and the temperature spreads very fast.1 point

-

You can try that way. Why not? If you can generate some relative expansion and contraction between the threaded parts, so much the better. I would just alternately heat and cool the screw head and expect that to eventually break the bond and draw in any penetrating oil.1 point

-

1 point

-

I think its a Gruen 240 movement. Very similar to this one - https://www.ebay.co.uk/itm/286073258459 Hmm, on second thoughts maybe not. Similar but not identical. For £15 though, I'd be tempted for spares. You might even get lucky and be able to use it as a replacement movement.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

If I could find the Bergeon part numbers I'd be on my way over there now!1 point

-

The problem I see in this case with rust removers is how to get them to where they are needed? Soaking has the unfortunate side-effect of damage to all other surfaces. I would use penetrating oil together with alternating heat and cold. You can get freeze sprays which shock-cool parts to enhance the effect of your soldering iron. Sooner or later, with enough cycles, it will come loose. Knowing which way to turn the screw would be a big advantage too.1 point

-

@rjenkinsgb posted a rust removal recipe a while back, I think he also posted one for penetrating solution too but I can’t find it right now. 5g tetra sodium EDTA (the rust chelation component) 100ml deionised water citric acid to bring the ph to measure 6.5PH Rob, if you see this can you repost the other recipe please and any advice for use of both? Tom1 point

-

Meandeanman I would start another post because it will get more attention in its own thread. Dell1 point

-

I'm tempted to give that a go. The original look is for a mirror polish with frosted numerals. I may revisit the bezel and improve the polish, as there are still a lot of scratches, but I don't want to over polish it and flatten out the numerals. I'll wear it for a bit and see if its current state annoys me enough to do some more work on it.1 point

-

Chemical rust removers usually contain acids that eat away at the steel oxide, problem is.... it also attacks the good steel. Coke contains phosphoric acid ...hard to believe that folk drink this crap..... it gives our Calcium such a hard time. If i were doing this, my first thought would be to determine which way that screw has to turn to come undone. Do as John suggests with identifying the movement, at least then you ask ' does anyone know LHT or RHT ratchet and crown wheel screws ?'1 point

-

Timekeeping specifications are always interesting and now that people have nifty timing machines that are affordable amplitude is now number one at least on the discussion groups. Then timing things PDF is attached with how to do all the nifty calculations if you really want to get obsessed with nifty calculations. It's so much nicer feel the timing machine that does this for you but typically there very expensive especially if the microphone rotates around to all the various positions. Here is an image out of a vintage timing machine manual for timing specifications. Notice no amplitude as cheap timing machines that measured amplitude did not exist. That's also why you cannot find listings of lift angles for vintage watches unless somebody today measured that which is easy to do because they didn't have a nifty timing machine that could do amplitude Then while some of the Swiss companies do have timing specifications for their watch most of them are Swatch group which means you'd not going to see the entire sheet at the best you might see a snippet. In the case of Omega I think almost all the watches have been time except they do have a generic category. So this would basically be timing for a nice all of the watchThen of minor amusement depending upon which version in other words they kept updating this the Stabilization and measurement time seems to very. With no problem with their longer if you go too short on these you can end up with timing issues. Like moving the microphone really fast and not allowing it time to stabilize that will be an issue and usually if you run the timing in a position longer things will stabilize and be better plus of course you can change the averaging time in the machine to longer time interval to smooth things out. X-D-DVH-Di-Im-N_EN witchy calculation of numbers timing.pdf1 point

-

Thanks for the ideas fellas, this sounds like a good plan that I feel comfortable with. I'll need to get in some practice sessions with making the bush ( very small compared to anything I've turned up before....i may be a little while with that....maybe a week or so...as I'm back in school till next summer...along with work and taking care of mum some days, makes my time limited at the moment. But that idea of the back plate added to bush from you both sounds like a solid plan . I've used bismuth low melt solder in the past a few times to repair dial feet, its fairly solid stuff .1 point

-

I had put it in benzine for the last 2 days and I was just able to move it. Still quite some force needed, but it's ok now. Thanks for the advice @Nucejoe!1 point

-

Some penetrating oil on the post, let soak over night. Best to hold it in a long nose pliers & turn about the post, so you wont exert any force on post, so to avoid breaking it off. This is one instant that slight damage from Coca Cola can affect reverses. Screwdriver in the slot wont work if its stuck, perhaps some rust. Good luck1 point

-

If you have a 3D printer you can print one out for each movement. That's what I do, takes about 10 minutes on my printer.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)