Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/24 in all areas

-

Cant see the wood for the trees (idiom)......too fixated on a particular small fact that the big picture problem has become invisible. Thats nice to know......that we have a group that understands, cares and takes the effort to help another member. Unlike some facebook groups that belittle with sarcastic, condescending remarks with gatekeepering tactics. We are literally the best watch forum on the planet4 points

-

A pic of the assembled watch for anyone who’s interested. It’s my friend’s grandfather ‘s Omega watch and it hasn’t run in about 30 years. To me, there’s nothing about watch making that is more satisfying than fixing a watch that means a lot to a family member. Again, thank you to everyone who helped. This forum is literally batting 100% in helping me solve my problems.4 points

-

Yes, heard back from Cousins (they respond within an hour). That's definitely the 3.25mm cannon pinion, they have updated their website.3 points

-

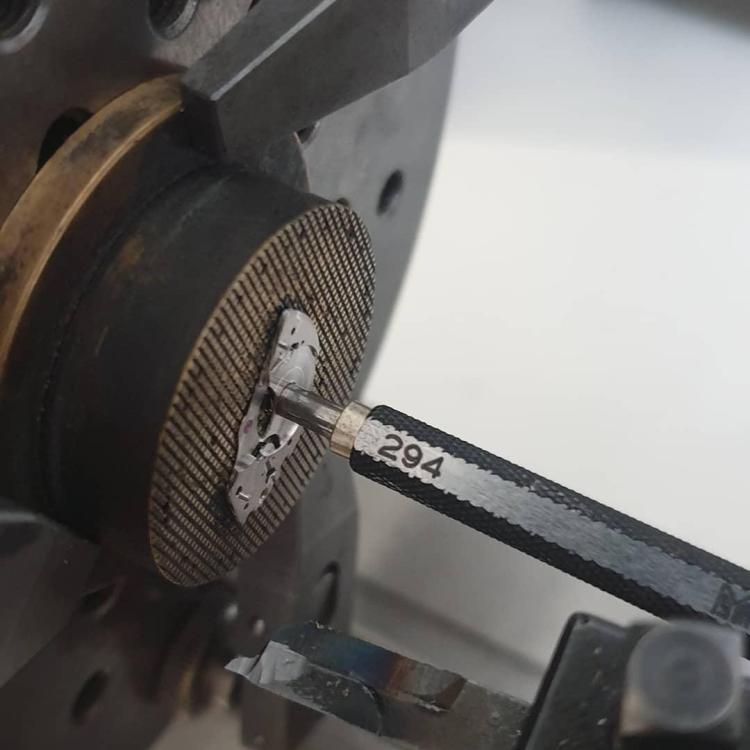

Well I have successfully drilled out the pivot on the impulse gear on the quartz movement, used the fixed collet holder, made a new 0.6 x 8.5mm long pivot which I then glued into the impulse gear. Put it in the movement cover with just the coil to check it all worked ok. Clock is now ticking away quite happily and hasn’t missed a beat. Actually quite pleased that I worked out that the piece of the pivot that was in the magnet side of the pivot was to engage the spigot on the respective movement cover. Just mechanical fitting on a completely different scale.3 points

-

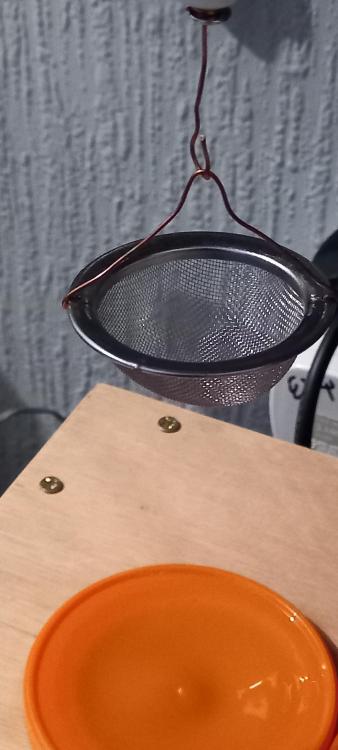

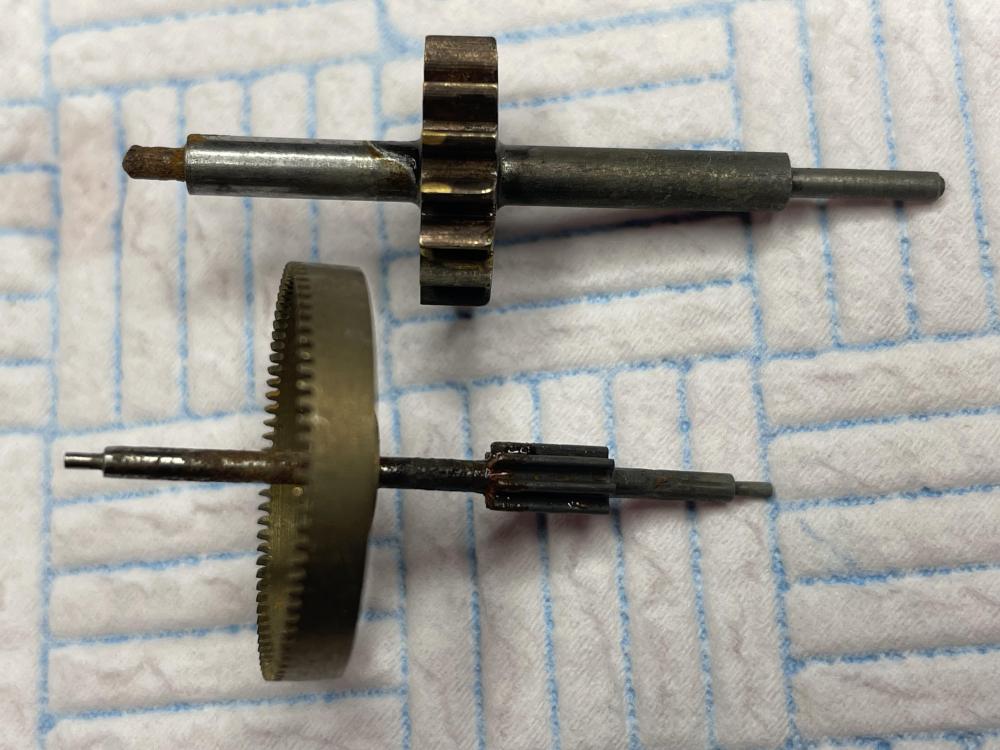

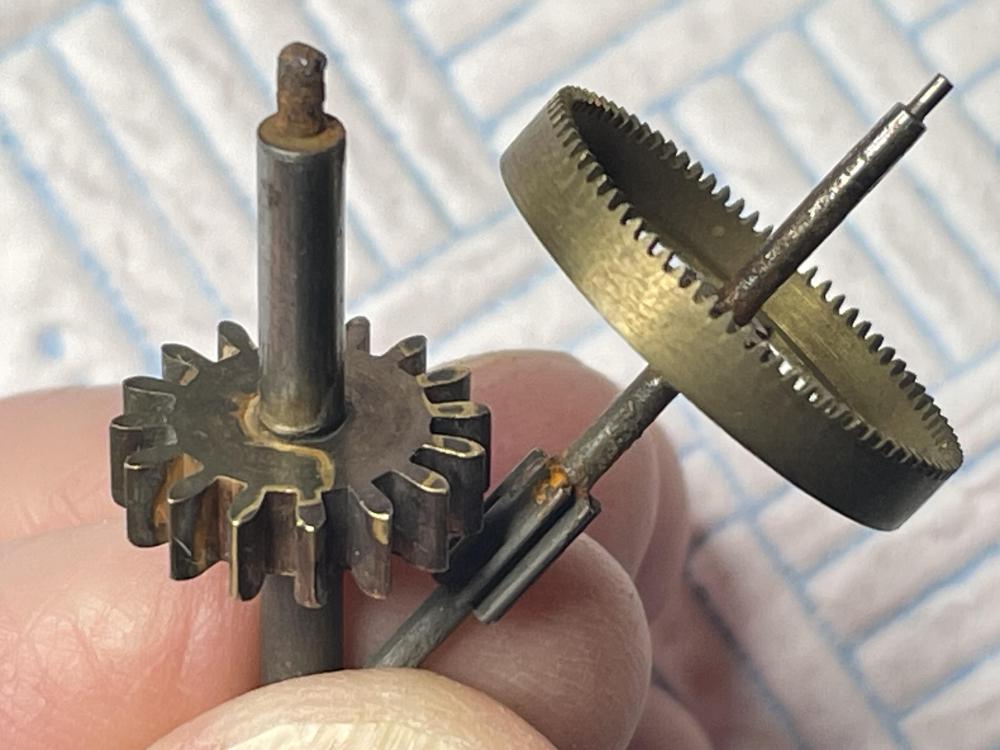

This rust remover solution was mentioned in another thread, and I thought I would do an experiment to see what effect it had if metal parts were left in it for rather longer than required. The mix is five grams of tetrasodium EDTA per 100ml of deionesed water, plus a tiny amount of citric acid to bring it to around ph 6.5 - 7 I've also used disodium EDTA, which seems to work pretty much the same; these are used in such as cosmetics, so not toxic, though I'd not inhale any dust, on principle. I normally soak parts in it for between 30 mins and a couple of hours, depending on the level of rust - and generally use it for tools and such as keyless mechanism parts, rather than movement train wheels. For this experiment, I used a couple of items from a big clock part collection I got a while ago. They were suspended part way in the solution; the one with the single thick wheel was at roughly 45' with the wheel half in the liquid, and the other was vertical with around 3/4 of the pinion submerged. This is the result after something over nine hours; the first two photos are the parts straight out of the solution, with just a rinse under the tap: And this is after drying and removing loose residue with a paint brush. They were in quite a bad way, rust scale and pitting in places, which is why I used those parts. You can still see the heavy rust on top of the small pinion, where it was not in the liquid. The pivots and steel pinion leaves do now have a matt surface; I don't know how much the size would change after re-polishing them. The brass wheel has obvious colour changes, more coppery where it was immersed, but still shiny rather than matt. This was using a fresh mix of the solution for this test & I may have added a bit too much citric acid. For comparison, this is a more normal use - a lathe bed from ebay, which had significant surface rust. Around one hour in the solution and it looks vastly better! The slight "marbling" is probably due to me initially trying to use a cloth wrapped around it & soak that; once I realised that was not working evenly I made a crude trough from cardboard lines with a bin bag, so it was fully immersed. And after; dried then oiled and thoroughly cleaned off, to avoid further rust. The stuff does definitely work very well, under appropriate circumstances.2 points

-

Acetone for Superglue, heat for Loctite. Can you separate the auto bridge from the rest of the movement?2 points

-

Noooooo..! The Black Country is west of Birmingham. Where the Yamyams come from. Hull is on the East Coast. Where the sexy sounding people come from. With celiac, or is that a swiss village as well as a disease?2 points

-

That as well .....Nicklesilver has it correct....impact will crack the theaded bond.2 points

-

There's a term for it, I can't remember the what, but it's human nature. I asked a similar question, again can't remember what but after a coffee and a ten minute chill, I realised that I knew the answer, I just couldn't see it. Sometimes asked a question can focus your mind.2 points

-

The wheel with the pin that is engaged with the fan or flywheel is in the wrong place it should be just before the pinons on the fan or fly wheel when it is locked.1 point

-

At school I was crap at English. Running a business, i think you just automatically learn how to communicate with people. Then with all the paperwork you pick up other bits and pieces, I knew before starting studying some of the word types and clauses in my post, the rest i have been taught this month. I think writing structure is a fascinating subject, but Maths and the Sciences are stlll my favourite, i see more logic in them whereas English has tons of grey areas and has never become fully refined. Thaats cos wi sexi peeps art wi Even Jack Black and Kyle Gass said we're sexy people1 point

-

Hi as previously mentioned by. ANDY pictures please. I have pivoted wheels with nothing more than a pillar drill so even with minimum tooling it can be done.1 point

-

1 point

-

1 point

-

Is it still under guarantee? Are you sure the lever is in the correct position to chime and strike and not part way for silent. Has it got a shut off for night time from say 11pm to 7 am. Can you get back to me when you have checked this out.1 point

-

The jewel you need is more complicated / specialised in its form than a simple "Lochstein Flach, zylindrische Bohrung mit Ölsenkung". (That's an intersting blog, by the way. Thanks for linking to it.) You might get lucky with the Cousins set J47496. I can't find any documents identifying the jewel itself, but the bridge is part 1134 Framework for automatic device. If you have to buy 1134, some sellers have them without jewels, so beware of that.1 point

-

1 point

-

1 point

-

Thank you for bringing the Bestfit catalogues to my attention. I have downloaded them now and they are a superb reference for a beginner like me.1 point

-

1 point

-

This is why the pivot should be mostly ground off before you start punching the staff out....you can't have a stuck pivot if there's no pivot to become stuck.....and do you really want to punch the staff out anyway ?1 point

-

Old engineers say "it can't be stuck if it's liquid," but that seems a little extreme for horology.1 point

-

Thank you and don’t I feel like an idiot. I do know what’s a moveable stud holder is. I was so distracted by thinking about the “welded collet” and what challenges that presented for fixing the hair spring that I couldn’t see what was right in front of my eyes. I corrected the beat error in like five minutes. To date most of my watch projects have been on older, less expensive vintage watches which did not have moveable stud holders so I have had little opportunity to use them. Obviously a huge improvement in design. Thanks again! Pic of new adjusted position1 point

-

Anyone close to Hull? If so can you nip over and reset Rich, looks like his algorithm has jumped into verbose debug mode Tom1 point

-

Don't need to look any further than the movement to see it's a fake and should just go in the bin.1 point

-

Welcome to the forum. You're besting starting another post in the clock forum and provide as many photos of the movements as you can.1 point

-

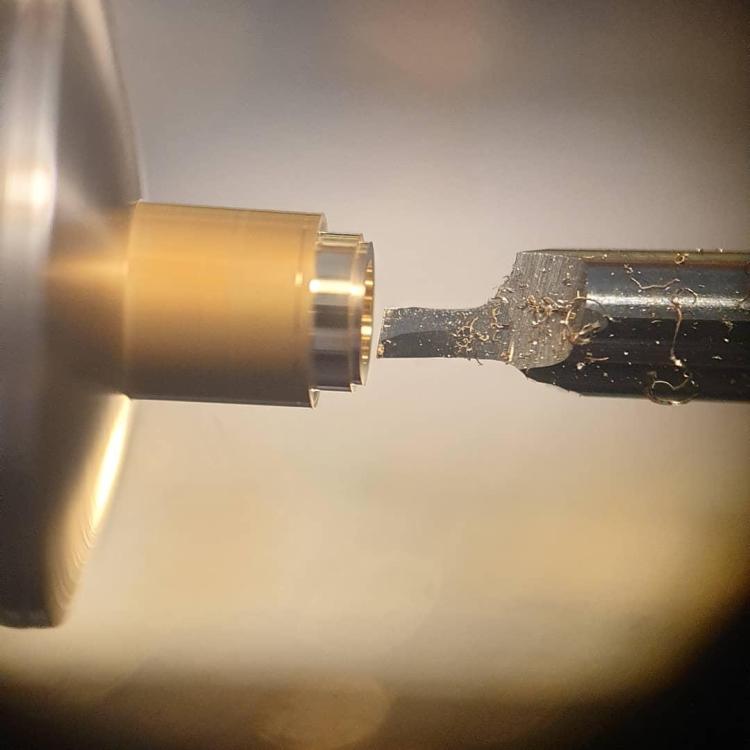

If you can make a stepped hole in the bridge you can avoid the need for solder. Here's a fix I did on a JLC 838, this has a suspended barrel, so 100% of wear is on the bridge and there's next to no material to work with. The worn portion protrudes down toward the barrel a bit and up toward the ratchet wheel. I did the bridge work in a faceplate, the stepped bushing was all lathe work. In the last pic the the barrel arbor looks low but it pulls up when screwed to the ratchet wheel.1 point

-

Hello Michel and welcome to the forum. Pictures accompanying questions is greatly appreciated. TZIllustratedGlossary.pdf1 point

-

Hello and welcome to the forum, sounds like you are on the way down the rabbit hole. You can re drill the escape wheel and re pivot it , getting bit means finding a donor clock. Re pivoting is do able.1 point

-

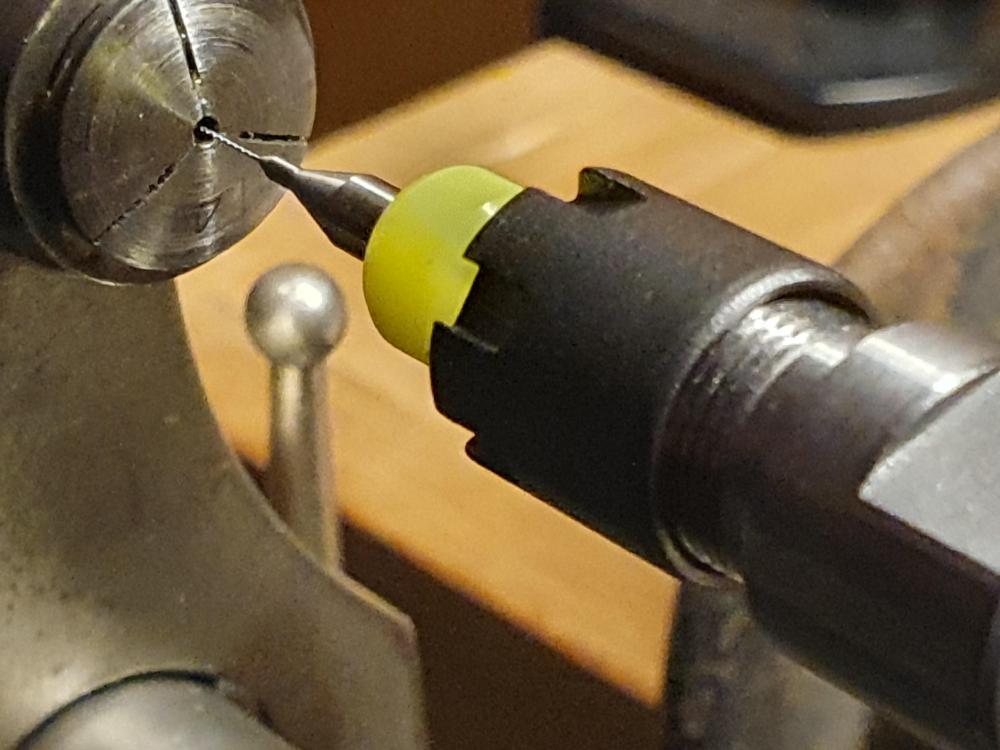

The drilling attachment I got with my recent new to me 6mm Wolf & Jahn lathe works with these classic spade-type drills, but is not big enough to hold the 3,17mm shanks of the carbide drills I also have. Online I found ER collet holders with cylindrical extended shanks. There are also versions available that hold ER8 collets and have a 6mm shank. Combined with a 7mm OD, 6mm ID brass tube, I now have something that works. Turning it doesn't show any wobble under my microscope, so I guess it is accurate enough.1 point

-

1 point

-

We need photos, mainly to look at You hairspring. This is the thing that may have got wrong when moving 'timing pins'. There is systematic way to search where the problem is and it is to do the free oscillations test. It means to remove the pallet fork (first mainspring is to be released) and then put balance in place and check how free it oscillates when some energy is given to it. One way is to rotate it to 180 degr. and then release and count the number of free oscillations to full stop, the other is to just blow air at it with blower and observe how long it will oscillate, about a minute is what is expected if hairspring/pivots/bearings are OK1 point

-

Because it is matey, my knowledge of electrical and electronic devises isvery limited. All the parts I mentioned are bought as a whole and only need wiring together......just a few wires to connect power to programmer to motor. The programmer comes with instructions of how to input it's functions which are merely time delayed clockwise and counter clockwise set speed rotations with gradual increase and decrease of speed between them. Lol SOME, predictive text that I failed to notice, i do it often.....just found out i have dyslexia.....quite bad actually. I have read reread and reread again. You dont need one. Thats bloody brilliant Frank, i would just need to get the missus involved to turn the handle while i disappear to make myself a cuppa, it'll keep her quiet for 10 minutes so thats a bonus. " oy sweetheart do you wanna come wind me up " she'd jump at the chance to get her own back.......yes i annoy the hell out of her I'm not 100% keen on the whole idea of the jar , carrier, baskets thing. I say this lots and it still question's my brain, " what about all these barriers " how effective are the cavitations at penetrating them ? When i use an ultrasonic, i like to cut out as many barriers as i can.....this idea doesnt lend itself well tk the convenience of dropping your full rotary basket into a jar of fluids in the USM I hang the plates and bridges from wires and the train wheels etc from little wire trees.....only the very small parts go into an open basket. Doing it this way means that there is barely anything to spin off. With conventional baskets..... most of the fluid that remains is trapped within the baskets themselves. The heater does also need to penetrate those same barriers we talked about. The little wire trees and open basket allows for direct airflow and heat for drying. On the naked parts.........yep i said naked parts........grow the hell up1 point

-

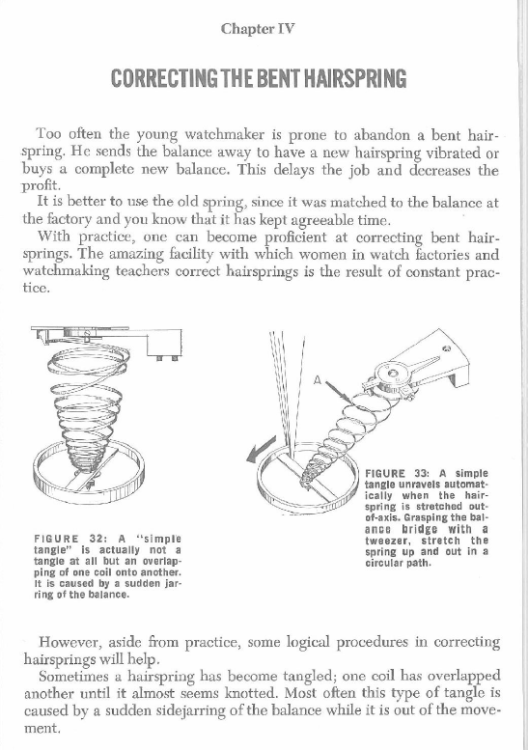

The problem isn't so much that he showing large springs the problem is that he has a incredible amount of background knowledge and experience. Basically he's going to make everything look so easy and it is for Henry just not for us. I suppose we can flip a coin and make a choice remove it or leave it on? For now I would tend to leave it on because when it's removed as my experience with omega hairspring is our that their butter soft would be that with both ends free they are free to make things worse. It's a lot easier if only one thing is free than both of them of the balance wheel will give you kind of a reference. Then the next fun thing to do is proper evaluation of what exactly is the problem? Yes I know it looks bad but how bad is it really? Yes that really is the collet and conveniently I can't remember the name of it. They started going to other designs like this especially when they got away from using a pin to hold the spring in. Ideally you should find something disposable to practice with as opposed to practicing with this. Then take some time to study this because. In addition to the video Henry did lots of magazine articles several books and was basically just an extremely interesting person. Who strangely enough I had actually met and talked to on several occasions so yes very interesting person but unfortunately we don't have his experience. Then in one of his books he has an interesting section on hairsprings. Somewhere in the group we discuss the book because there is a minor problem of it came in various additions and I can't quite remember and not every version has the section on hairsprin's BENCH PRACTICES by Fried chapter fixing bent hairspring1 point

-

This is a Fried interview, it shows how he unravesl , straightens bends and flattens springs working to bigger scales than this tiny Omega. Personally i would want both ends free to work it, the balance would be obstructive. This depends how safe the spring would be while attempting to realease the collet.1 point

-

Don't try removing the hairspring yet. I know it looks bad but if you think carefully, both ends of the hairspring were fixed, one end to the stud and the other to the collet. So it couldn't have wound itself into a knot. I remember watching a video where a hairspring was detangled just by "spiraling" the stud around. I can't remember if it was by de Carle or Frick. Found it. Don't do anything to your hairspring until you watch this.1 point

-

I'm attaching the parts list so you can see what the parts look like it looks like from the parts list it's not the third wheel 201/1 which is labeled large driving wheel. then it's part number 240 which I'll let you read its own peculiar name. So yes their separate components we should build a separate and possibly there is a way of typing them because they are separate components. I've expanded the image of the parts list and snipped it out so you can see the parts better 939_AS 1906, 1916.pdf1 point

-

Yes. Sounds like it's a loose cannon pinion problem. Does the crown feel very loose when adjusting the time? Cousins has stock for two different heights of the cannon pinion. You'll need to measure the height of the original cannon pinion. Most cannon pinions can be tightened. Can you post some photos of yours, so that we can advise you further.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)