Leaderboard

Popular Content

Showing content with the highest reputation on 11/22/24 in all areas

-

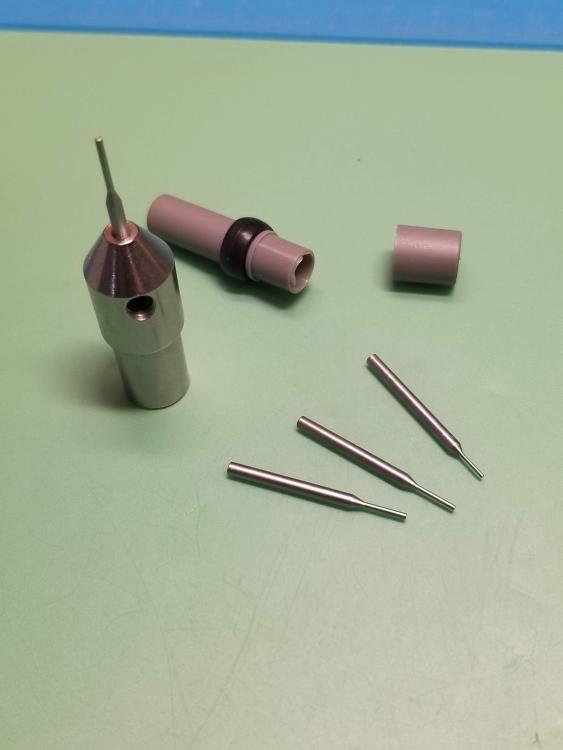

Thanks Andy, this one has Glardon stamped on it with a little fish symbol Thanks Nev,It has a nice round edge on the base that glides on the rest. Thanks guys, I also found a chunky graver that I sharpened up, I think its carbide.....just reduced the shaft of this carbide drill to fit in the drilling sleeve of my lathe, it cut it like butter as it did also some blue steel.3 points

-

2 points

-

If it gets too dark when you zoom in you should be able to increase the exposure/brightness using the remote or menu. When I was using one of these types of cameras I would have to increase and decrease the exposure every time I zoomed in or out. Annoying but doable. I switched from one of these dedicated microscope cameras to a Sony A6300, a mirrorless camera. The image quality is much better but one of the biggest benefits comes from the larger image sensor; the larger sensor captures more light giving an increased sensitivity and an increased dynamic range. What that means is that when I zoom in and the image is perfectly exposed, if I now zoom out the image isn't blown out, like it would be on the dedicated microscope camera. Also, when you set the exposure (how bright you want the image), if you zoom in or out the camera automatically adjust the brightness to keep it where you set it.2 points

-

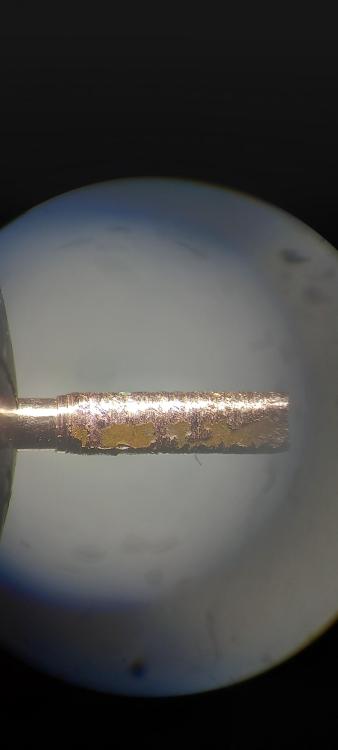

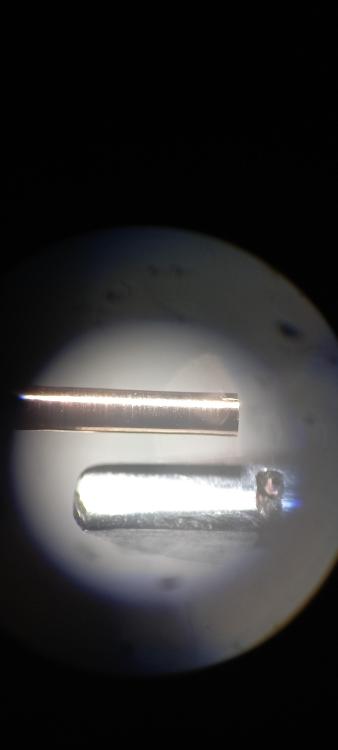

I gave up on the carbide i was using, thats even if it was carbide and went back to some lozenge shaped gravers I have. Used just a simple roller sharpening jig, 2000 diamond plate and a Washita stone....pretty good result....and the brass shavings come off either very fine or thick depending how deep i go.....the edge is lasting much longer and I'm getting a good smooth finish on the brass....I'm happy now . One trial make of the bush and fitting into an old plate will do me before the genuine job. I was inspecting at x40...that made me a bit critical. The piece even though quite small is much easier to make at x16......you can pick up the square shapes much better with a lower magnification.....too close and you lose the overall shape of what you're making.2 points

-

So far the ones that I have tried on it lay flat. I suppose that maybe an old bumper movement without the oscillating weight would be an issue. Having the 3D printed platform option gives the flexibility to use any movement holder that you want.2 points

-

I expect the spring has lost it's tension and isn't pushing the crown out enough to engage with the stem. To remove the crown try gripping the crown tube and then rotate it anti clockwise.1 point

-

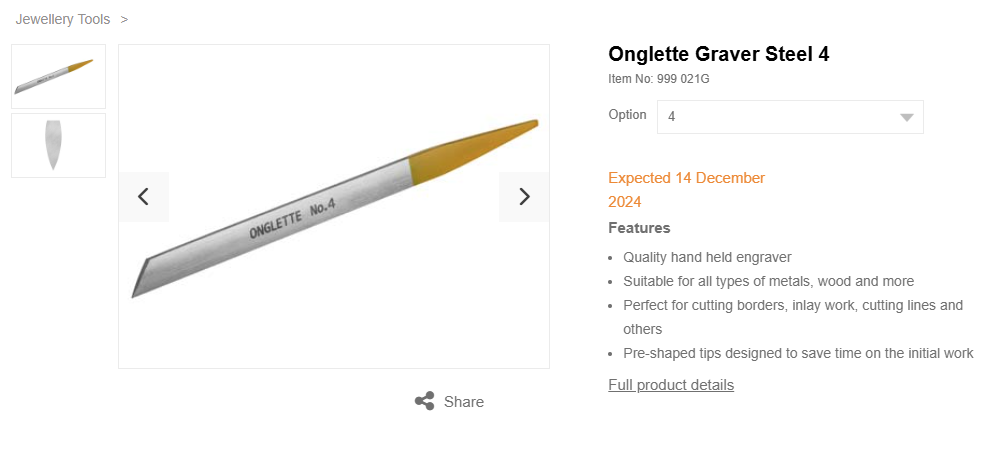

Yes, as far as I know the dimple never disappears. I was playing with it a bit more, and it seems like I can insert the crown/stem fully now - but despite the fact that it's fully inserted, it's still moving the hands as if I'm adjusting the time (position 1 I believe?). I think this continues to point to a keyless issue, like watchweasol suggested. I have a few potentially silly questions: I have a 2E20a. Is it clear what differentiates the "a" version from other 2E20s? Page 4 of the guide that watchweasol linked shows multiple hour and minute wheel combinations. If I purchase a new movement, will it be likely that I cannibalize the parts from the current movement to ensure they're the same? How would I know something like this before I purchase the new movement, or try to set hands? Thank you both so much for your help/engagement here. As I build my knowledge, I hope to do the same for other new folks in the future.1 point

-

1 point

-

1 point

-

1 point

-

Hi Ruffass. Ther are also A.G.Thomas ( Bradford). And H.W. Walsh who are also material houses who deal amateur’s.1 point

-

1 point

-

There is a limit to benefit of more and more MP's. Basically, 2 MP - 5 MP is sufficient. Anything above that will not provide better image quality.1 point

-

Thanks Tom, I've just had a look and it turns out I've successfully obtained an account with Cousins. I'll try them for the relevant parts. Thanks, Ruffass Cool, cheers for that Richard. Sorry just seen this edit! Yes it is Andy, and there's an F in a box next to this Number.1 point

-

I think I was asked for a business address and vat number, if I remember correctly, I left it blank and I was allowed to join.1 point

-

I haven’t done the conversion myself but have seen plenty of info online in doing this. Happy to help if I can though. I echo Andy about cousins, there are also HS Walsh along with Gleaves. Worth checking all three for price as sometimes one can be cheaper than the others. i wasn’t ask for a vat number when I signed up for cousinsuk, it was fairly straightforward. Tom1 point

-

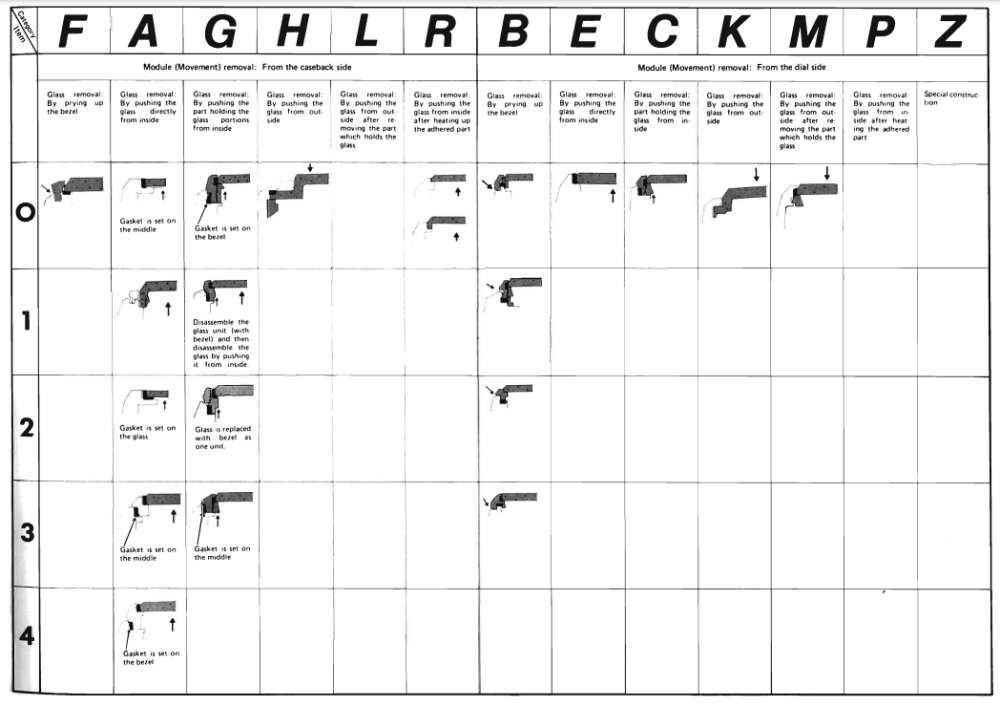

The C to CS mount spacer is what I use for my camera. I also use a mount adapter with a focus adjustment to fine tune the focus.1 point

-

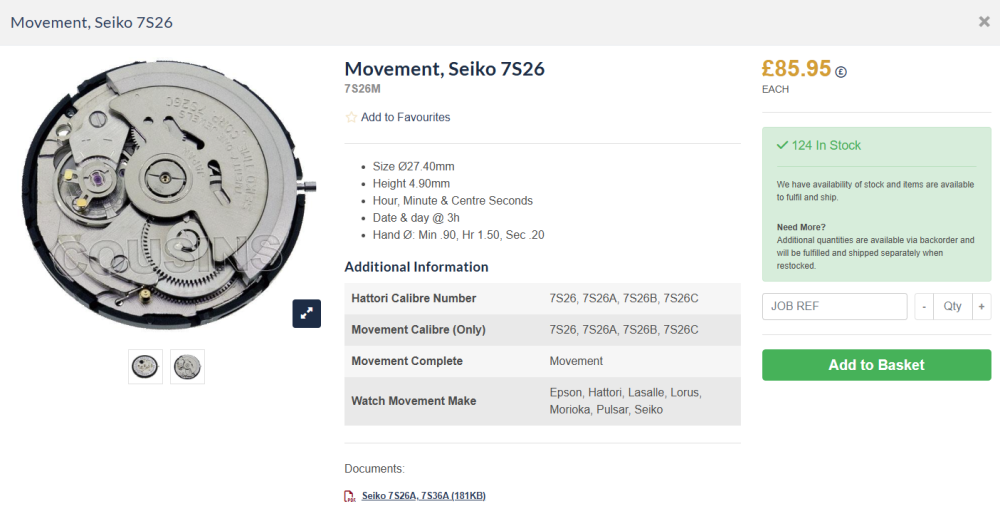

Cousins will deal with anyone but as Trade (so you don't get the same customer rights or something) but it's never bothered me and I've only ever had 1 issue that was resolved without question. I you looking at genuine parts for replacing on the 7S26? Edit Is it a 7S26-0480?1 point

-

My lathe is a Wolf Jahn it came with mostly all of the cc collets also with the 2807 code. There were a few wj with it. So my lathe wasn't something just floating around Ebay, i picked it up from Leeds, the seller's past father was a watchmaker and his grandfather as well. I turned up at his father's home as the seller was clearing out his old man's possessions before he put his house on the market. The old boy had a full watchmaker's and jeweller's workshop in his converted garage. If i had known i would have taken a big wad of cash with me and bought the lot. So my lathe either belonged to an 80year old watchmaker or a 100 year old watchmaker....so i figure the collets are correct. The only lathe collets that are an exact match for the WJ that i know of are Bergeon and Hinchcliffe. So the cc could be from the two C s in Hinchcliffe .......possibly? 8mm that is.1 point

-

Spot on @spectre6000. I tried holding the camera just above the Barlow, and I could focus and zoom and keep focus. As you suggested It seems about 5mm would do it. The thread on the camera can be screwed out, but not quite far enough. There's plenty of cheap spacers on ebay - I guess one of these would work?1 point

-

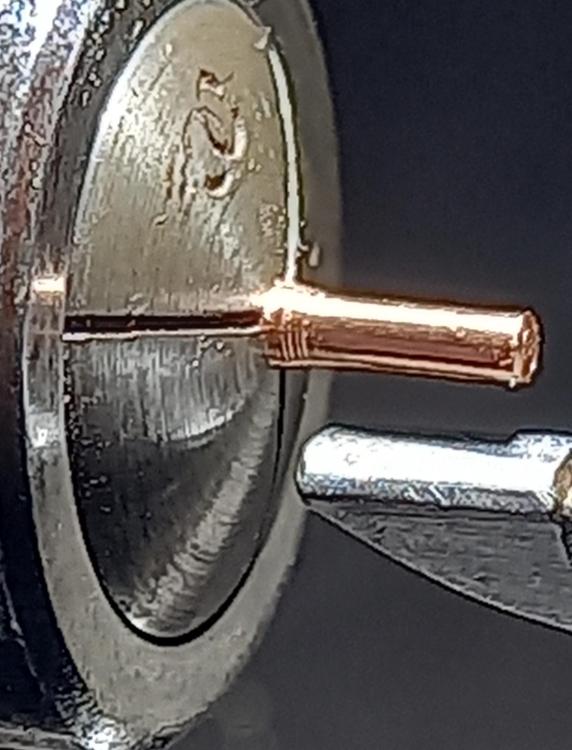

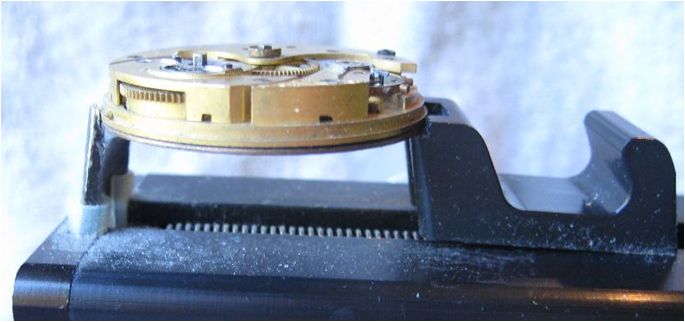

I didn't have any brass bar....so a two pence piece provided me with some material to make a mild bronze bush. Hopefully i have enough diameter left when its rounded up. It bloody well is just now, the previous owner cut two slots in it , god knows why . Dont ask why i have it back to front, its just giving me a better tool height to get in close....it might actually not be for this lathe. Its not big enough and it looks way too coppery to be as durable as bronze. Nice little practise though, I don't think I've ever seen anyone on youtube turn a cylinder the right way, all the ones I've watched in the past use the whole of the cutting edge held flat on the rest instead of running off meat from the middle of the cylinder using just the center of the cutting edge..nice to see the shavings curl off, yesterday really peed me off lol.1 point

-

Rich, whats going on with your tool rest? That missing chunk would drive me nuts! Good turning though!1 point

-

I believe you need a spacer. I forget the exact whys and whatfors, but it's something like a 5mm spacer for going from one standard to another... Hopefully someone else can weigh in on the reasoning or provide a link. I looked through my orders on Amazon and Ali-X, and don't see it. Might be @gpraceman had a spare to throw my way or something, and he knew the reason and solution, which is why I'm not coming up with it. Could also be lack of coffee...1 point

-

Don't sweat it. It's brass and you're shearing it off. No matter how perfect you polish the tool, under magnification you'll always see some imperfections. What matters most (OCD aside) is: will it work? (Answer: yes it will..). I've looked at some of the brass bushings that came with my Seitz set under 22x magn. and see some marks on those as well.1 point

-

I think a better use of the a clever way of figuring out how to send the outside temperature into the jar and send it to me so I could release it where I live. As we are heading into our winter months and I would enjoy some warm weather.1 point

-

iirc you’ll likely have to swap the plastic ring that comes as part of these movements, black ring on the 7s26 and grey on the NH36 as well. Tom1 point

-

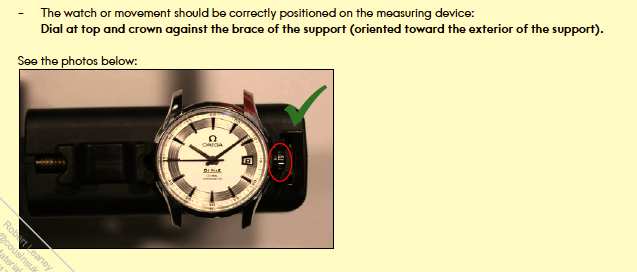

When using a timing machine is very important how you hold the watch to get a good clean signal into the machine. For instance I've attached a PDF that talks about that and I snipped out an image if the watches case dump The reason for the specific orientation is two separate purposes. The signal itself wall in the audio frequency range in reality is a vibration and usually the easiest way for a case stopwatch to get the vibration out is by way of the crown. Then the secondary purpose is that the sensor itself is located at that and attached to the metal piece. Now the problem with this can be large heavy cases just do not transmit the vibration good at all no matter what the orientation. Or some watches like Seiko it has to of how it's mounted in the case perhaps a plastic movement holding ring so basically sometimes cased up watches just will not time at all and they will have to have the movement removed and placed in the microphone. Then the microphone itself is actually been designed to hold movements like this Ideally it's nice when you have a watch in the microphone that you not have the dial on. This is because having the dial on without having a case to protect it can lead to unfortunate problems. So when you're servicing a watch once you get the watch running before you put the hands style automatic etc. on it and place it on the timing machine like in the image above and get a good signal but depends upon the timing machine and other factors you may not deal actually hold the watch in which case you could try putting it in the movement holder. You want to make sure it's a metal movement holder because that's better at transmitting vibrations and its placement in the microphone is critical so that you can get the signal to touch the metal at the end. 8643_WI_81 BASIC CHECKS AND SETTINGS OF A MECHANICAL WATCH_EN cousins.pdf1 point

-

As you said, some older Swiss movements just aren't meant to hit those high marks, and Seikos seem to be more relaxed in that sense. I’ve found that with a good service and proper cleaning, even the lower amplitude watches can keep great time, though!1 point

-

1 point

-

Yes, but it's not more than a suspicion at this stage. Neither the barrel nor the lid appear to be convex, and the only other way for the end shake to increase, as far as I can see, is by a reduction in the height of the hubs. (I'm assuming wear, but it could be compression at the hands of a previous repairer.) Thanks, I'll bear it in mind.1 point

-

Hey Tom, yep i completely agree with you, whats 3000 for one brand might be 1500 for another. I think i tried just about every grade of everything i have but could get the edge i really wanted . Yep normal proceedure of removing burrs from sharpening......honed and polished the four sides of a lozenge graver for the first inch or so from the tip and the carbide i also used had a mirror finish on the top edge. Ive heard a few say that they use the graver straight from a diamond grinding wheels...a low grit grade.1 point

-

That how I always mounted a bare movement Andy....in a movement holder. The sprung clip on mine has a load of tension and i worried that it would press up too hard on the barrel or bend the plate . I think it can make a difference with some watches. I few times has happened to me.....a completely bizarre reading....then reposition the holder on the tg to find that the trace is almost perfect. I guess it depends how well the movement design, case etc transfers the ticky tocks through the movement to the mic.1 point

-

Yes, You are ready to make the bush needed. You don't need measuring tools. The hole must be 0.1 mm smaller than needed - just use the drill bit with such size. Ream and prepare the hole for the bush in the plate and use this hole for measure when turning the bush. Then, You can cut the bush longer. After soldering it in place, it will be easy to file it to acceptable height above the plate and ream the hole to fit the arbor pivot. Only the hub should be turned to right size.1 point

-

Looks great! Working under a microscope like you do now, you'll have no trouble making the actual part after this tryout. Your lathe will be smiling as well and won't like to be put back in it's drawer..1 point

-

Easiest way to do this is not to destroy your lathe by playing with them. As others have said they normally do not come out and you do not want to re-grind them. It really just looks like surface something like cleaning should solve the problem. The lathe itself doesn't exactly run on that surface anyway it basically runs on a film of oil. To just clean up whatever that is without modifying the surface if you can do it and make sure you have good oil and add oil from time to time. One of the most interesting problems I've seen of watchmaker's lathe is the failure to grasp that you need to add oil. So typically end up with people running their lathe's dry which is definitely not good at all.1 point

-

Ok so its not ideal and a its very " builder's rig " set up......milk crates..actually....newkie brown crates....solid lightweights...batterns and scaffold poles omitted for this small simple rig . And i just need to change my slippers for Rigger's boots. But its got me sat in front of a lathe so how about a round of applause for motivation and initiative fellas . Fully set up with a cuppa and a proper builder's size slice of homemade tea loaf, Archie wasn't available today so Donald has offered to chip in with his input .1 point

-

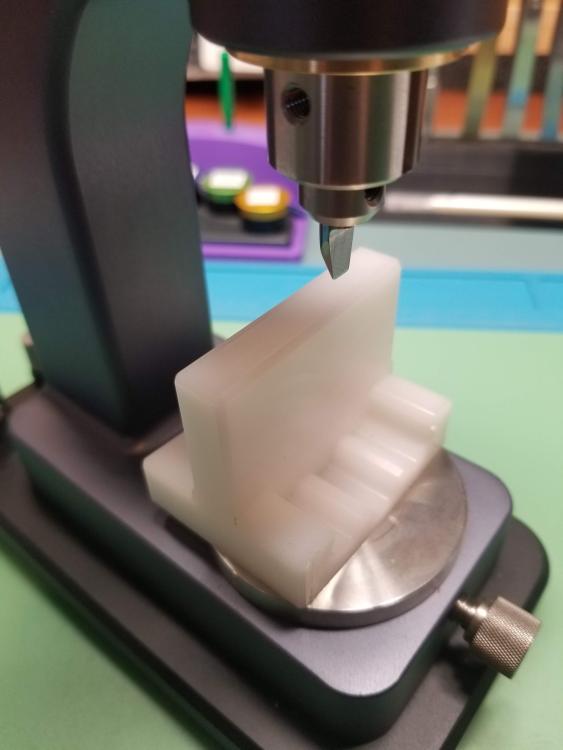

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:1 point

-

The Seiko crystal code for your watches is 315W02AN0, and the Sternkreuz equivalent is XS317.407. Very nice watches BTW.1 point

-

0.02mm is a bit too much. But, where did you measure? The pivot there is tapered normally, so it will be smaller at the end and larger a mm or two back from the tip. When I make tubes I usually drill 0.01mm smaller than the smallest part of the pivot, then use a tapered broach to bring it to final size. When broaching check often, and when the hand fits about 1/3 of the way it needs to go with normal pressure (you can still pull it back off with tweezers), stop. That should be a good friction fit for a chronograph hand.1 point

-

Operation to get rid of a trigger finger on my middle finger. And an issue with my index finger. Sigh.0 points

-

0 points