Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/24 in Posts

-

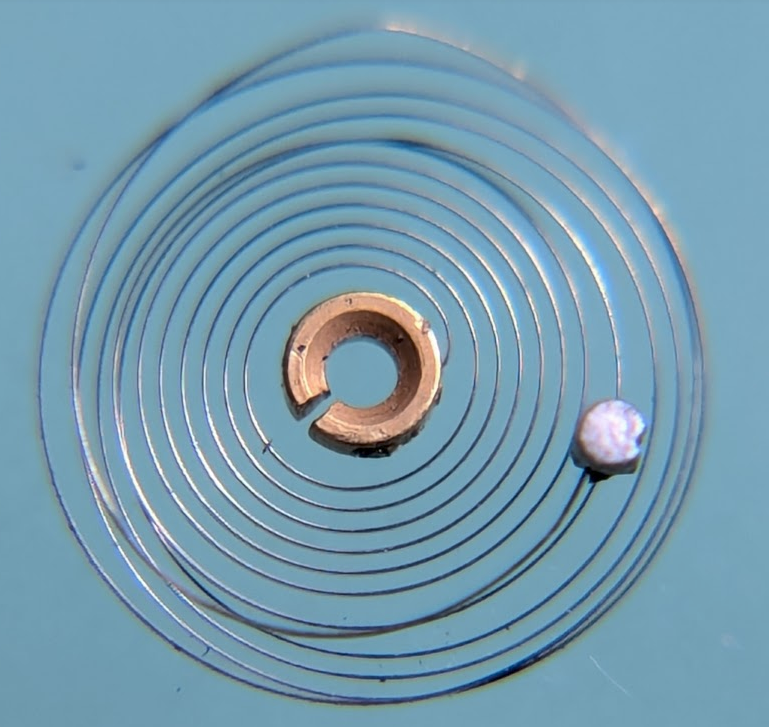

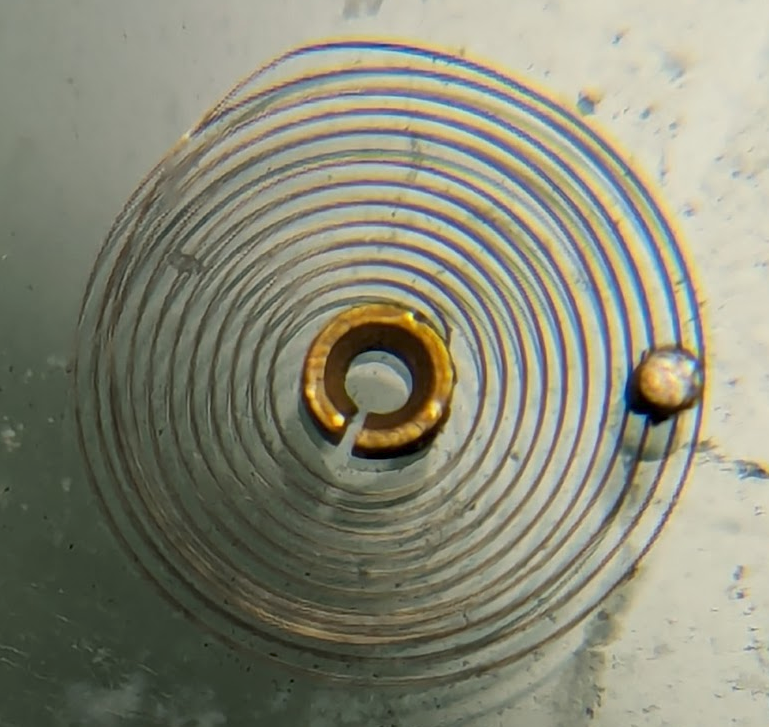

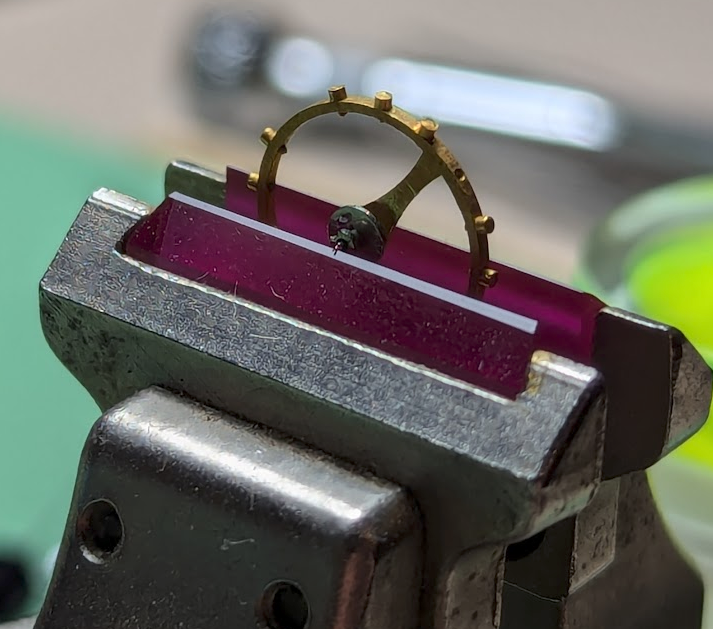

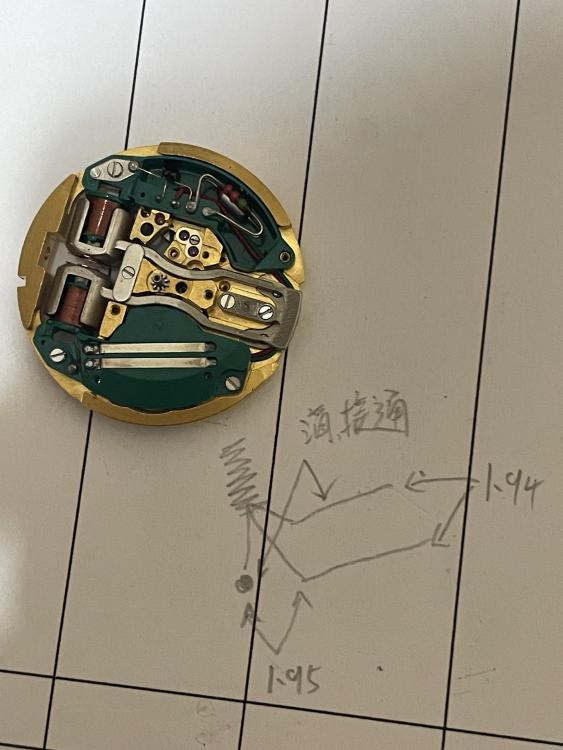

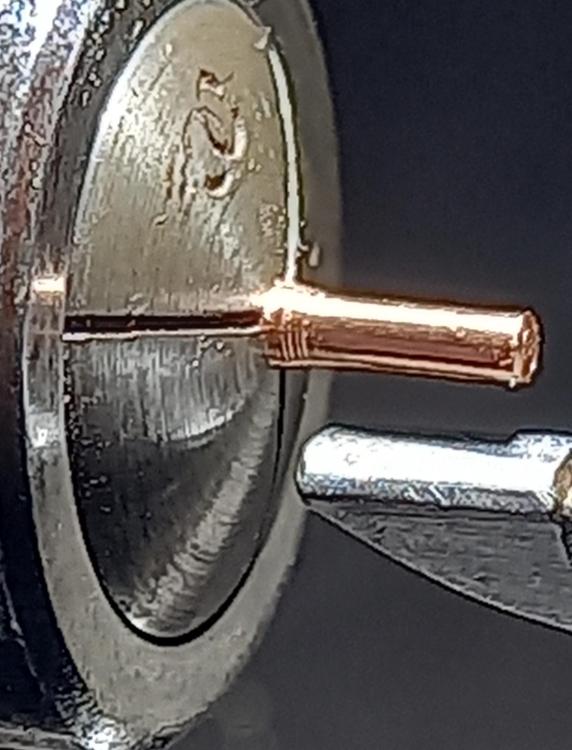

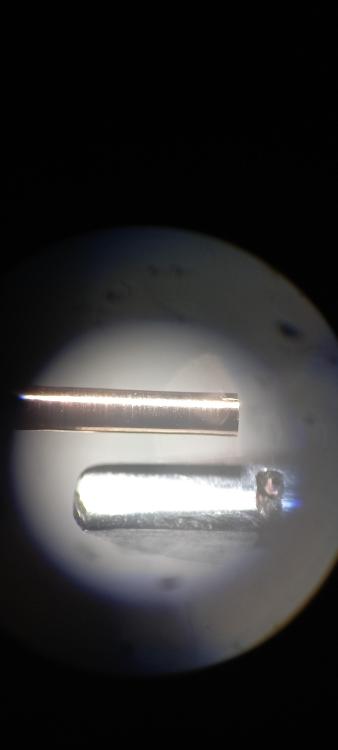

Well my friends, it is a Friday-Before-Black-Friday miracle. I have got this watch running again. This is my first significant hairspring repair and I feel like I just leveled up. When I removed the balance complete from the cock, I found it had 2 coils swung underneath and looped around the roller table. I might have made things harder for myself by lifting them over in the wrong sequence. But when the hairspring was removed, it didn't look that bad. The overcoil had several issues but no kinks. Concentricity looked very decent and flatness was a little out, but I discovered while fixing the flats that what looked like concentricity defects were actually tangles. There were two tangles which I could not see well under a loupe (have no microscope) without a 3D view. The first two photos are what I started with: I did not know the strategy for removing a tangle I first did one in the outer 2 coils by manipulating the stud through them - which worked but was very challenging and probably dangerous. The second tangle was much farther in and I didn't see any feasible way to pass the stud through there and have it pop out untangled. I figured I could maybe get some oilers in between and just push tangle around and around until it made its way out to the stud where I could lift it through. This worked. With the tangles out, I was left with not too bad a state, 2 or 3 minor concentricity issues and the overcoil pointing down a little. Also the collet was twisted at a slight angle. Because I don't know any theory on forming overcoils, I decided I would just try to wing it. I mounted it back to the balance cock and pushed here and there until it was pretty well centered. Any additional adjustments to the overcoil I have to make while the whole balance is in the watch, because I can't work out the 3D relationship. Someday I will learn to do this the right way but for now, it's just YOLO and poke at the running balance until it looks right. I took the opportunity to check its poise, which was fine on this tool. I probably won't go to the trouble of dynamically posing this watch. And now it's running in! I have it at 1.4ms BE and honestly, I think I may leave it here. After my first service attempt from a year ago, it was at >3.0ms BE but running flat in all positions. How I got myself into this mess in the first place was by going back in to dial down the BE and reclean the balance jewels, then my ocillations test and my tangled up hairspring. Right now, the verticals are very good (>250°!). I'm okay with the BE since there's no mobile stud carrier (and this is a vostok not a patek which has already caused me a lot of trouble). The horizontal traces are noisy a bit irregularly wavy. I will go back in to clean those jewels once again, because at one point before messing up the hairspring I swapped the lower from a spare movement while end shake seemed too high. I can swap that back and I expect to see some improvement. Thanks for all the encouragement. I didn't expect I would actually fix this one rather than toss it in my "USSR box"8 points

-

2 points

-

I'd use naphtha as IPA isn't good at dissolving oil and grease.2 points

-

Lol yes I have Case, this time around it has unleashed the turning beast in me .....soon be time to have a go at my first balance staff......after I've aquired some brass material to finish off this project that is .2 points

-

2 points

-

I don’t why but I have found with Seiko watches certainly vintage amplitude always seems low..,However despite this they run well and keep good time.. Maybe they were designed this way..2 points

-

1 point

-

1 point

-

Is it a regular cycle between the two extremes? Show us the timegraph trace, and time the period, if it's regular.1 point

-

I'll press one in a piece of clay and use that to check the taper angle and get back to you on this.1 point

-

Hi. If you are going down the donor route I suggest you have a look at the one you have first and see what’s the problem. Remove movement , dial and hands , date and calendar wheels ( if fitted) and expose the keyless work, perhaps the setting lever /spring is either broken or dis lodged that way you have gained knowledge and a little experience. All the best1 point

-

Try soaking it in IPA and see if you can get any debris to come out which maybe restricting its movement. If you've got an ultrasonic tank then put it in a little bottle of IPA and leave it to soak before putting the bottle in the tank for 10 or 15 minutes.1 point

-

If you pull the crown while holding the stem does it move our further and can you get it to lock in both directions?1 point

-

Thnx. I received that book as well this week, but haven't found the time to read it1 point

-

Yes, I think the main lesson I just learned from HB Fried's demonstratoin is that next time I work on a 16 or 18 size pocket watch, I can twist and yank and pull on the hairspring with abandon and nothing bad will happen1 point

-

I did the 7S26X - NH family swap a few years back. First time I had done such a thing, so I was likely in a similar state of skill as you are currently. I had an old gray market 5 that bit the dust in a particularly nasty car wreck (fun times). I intended the resurrected watch to be a shop watch that would take irregular wear (and absolutely unconscionable abuse), so I went with a non-date version (NH39?) and didn't have to deal with any date complication complications. I also replaced the crystal and dial with aftermarket units. I don't recall any particular challenges related to the movements themselves save a vague recollection that I wasn't entirely comfortable with how tight the fit was getting the movement into the case. I don't have any clue if I used one movement ring or another, and it may not have even been the same watch I'm thinking of. Whatever the case, I went ahead with it, and I'm a famously cautious person with that sort of thing (me and torque specs are a running gag with the car club guys), so it couldn't have been that bad if I'm even remembering correctly.1 point

-

1 point

-

I found this videos so useful, I bookmarked a link. It's the man himself : Mr Henry B Fried ! The first part is untangling - he is quite "robust" with the spring! Then he goes on to removing kinks and bends. Sometimes a hairspring looks a total mess, but if only tangled, just one simple manipulation and it's fixed.1 point

-

1 point

-

Yes good practice indeed. However when you re assemble make sure every part is spotlessly clean and check and test as you go..1 point

-

1 point

-

It's got to lock both ways if it's got Day & Date Quickset. Did you try holding the crown tube instead of the stem and then unscrew the crown?1 point

-

1 point

-

Cheers Andy. Yeah I got the 3.8 NH36 coming from Ali Express. Only cost £25 in Black Friday Sale. Supposed to be Japanese but you never know. Hope it performs like a couple of my other NH35 Japanese movements which I've got in Addiesdive and a Cestrian watches.1 point

-

I found this on occasion as well. On many a Timex, the spring tension flexes the plate enough that it actually stops the movement. I have found this if I mount the movement oriented such that the plate cutout that exposing the balance and regulator is receiving spring tension across it. Unfortunate too, because that is the safer and easier orientation to setup a Timex.1 point

-

1 point

-

I expect the spring has lost it's tension and isn't pushing the crown out enough to engage with the stem. To remove the crown try gripping the crown tube and then rotate it anti clockwise.1 point

-

1 point

-

1 point

-

No cutting required but if you do go for the NH36 you're best going for a NH36-3.8 so you don't have to mess around with the Day Dial.1 point

-

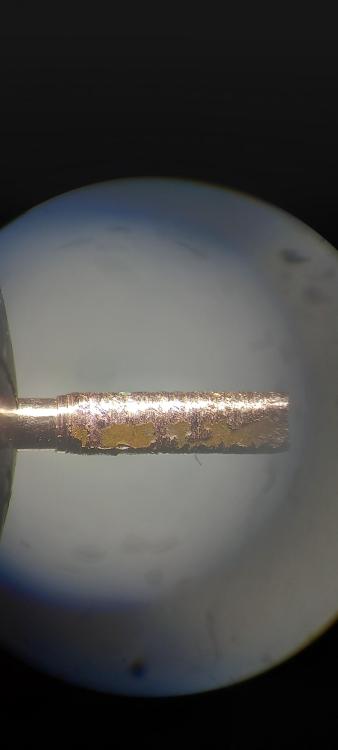

I didn't have any brass bar....so a two pence piece provided me with some material to make a mild bronze bush. Hopefully i have enough diameter left when its rounded up. It bloody well is just now, the previous owner cut two slots in it , god knows why . Dont ask why i have it back to front, its just giving me a better tool height to get in close....it might actually not be for this lathe. Its not big enough and it looks way too coppery to be as durable as bronze. Nice little practise though, I don't think I've ever seen anyone on youtube turn a cylinder the right way, all the ones I've watched in the past use the whole of the cutting edge held flat on the rest instead of running off meat from the middle of the cylinder using just the center of the cutting edge..nice to see the shavings curl off, yesterday really peed me off lol.1 point

-

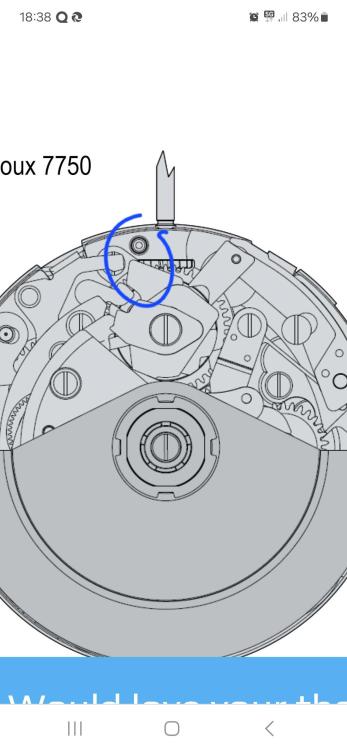

For the last couple of days, I've been giving this big cat some exercise Citizen Leopard, 1972 with the 28 jewel 7230 movement full of springs. I've had this for quite a while and must be over a year ago it was serviced and repaired. The rotor weight was adrift on one rivet and that all tightened up nicely. When I finished it, was running excellently, the cannon pinion a little on the loose side but coping well with the day date change so left it alone. I won't attempt to tighten these unless absolutely necessary, I'm still on the lookout for one for a different watch that I over tightened. A replacement for this movement I would imagine would also be hard to find, and it's coping with the day date change. Until recently, I never got to wear this after the service, when I did want to, and went to set it up, discovered it had developed an issue where the hands would lock up when passing through the midnight change over. By this time, another watch all stripped down and taking up the bench, so this got sidelined. Well I've eventually got round to it and I have eliminated the persistent niggle in the back of my mind to get this sorted. Very simple fix in the end, and a basic mistake on my behalf. Found the date ring retaining plate / quick set rocker spring (circled in picture below) was not fully home on the left hand stud causing the right hand side of the plate to dip down enough for the date ring teeth to catch on. Lucky escape for me, if I had tried to force it then the plastic day date cam would have been damaged, again, I reckon they won't be easy to find.1 point

-

I wouldn't put heat anywhere near it. If it is a Tube & Pin arrangement then I think looking at your photo the punch size is possibly too big and you're just hitting the tube and not the pin inside.1 point

-

Well I am very pleasantly surprised. The 3am communications in imperfect English were not indicative of a ruse. I got 3 watches, all runners, with beautifully hand painted dials. The Statue of Liberty is missing a caseback and is a very thin model, possibly a Luch slim. I'll see if I can find a replacement case but I'm excited about these. The cosmonaut is a total surprise, as it was not visible in photos.1 point

-

Just reading it made me more scared than any event around Halloween ever did! This is probably the most important tip: Allow yourself to relax as much as possible. Holding your hand in the air and thinking you can keep it still is doomed to failure. Another possibility might be to put the balance on a clean staking block, put the roller table in a hole just big enough, and then hold the balance with tweezers. That's what I do when adjusting the collet position. That was a tip I got from @nickelsilver some years ago: "For everyday work, from the smallest ladies' movements to the marine chronometers, I set the balance with the cock on a bench block so the roller table is in a hole, balance on the block. Lift up the cock and move it over not flipping it, just moving laterally, until I can see the slot in the hairspring collet, get in there and adjust (for tiny watches this is usually with an oiler, larger, a small screwdriver). I hold a balance arm of the rim with tweezers while moving the collet. Go back in the watch and check on the machine." Now downloaded to my Onedrive for future use and as a reminder. Many thanks Jon, much appreciated!1 point

-

The material of the tweezers isn't important, it's how you grip the balance that is. You can adjust the screws without a pair of tweezers holding the balance still, but it is a bit risky. The shockproof will give a bit, but the last thing you want is to hear that noise no watchmaker wants to hear. That 'SNAP'; you know the one I mean. When you hear that, you know you're in trouble. Also, it might be an idea for a first go to take the balance out of the movement and place the balance on a balance tack that has a supporting table for the balance. You can then hold the balance from the sides with your finger and thumb whilst turning the screws equally. That is probably the hardest part in getting the screws to turn evenly and not put it out of poise. You'll know if you have when it goes on the timegrapher in vertical positions. This will give you a feel of the Microstella screws without the risk. Once you feel confident, put the balance back in the movement and finish the last bit off in situ, using the tweezers this time. The trick is to relax, which is hard to do and the more you see your hand shake the more you're telling yourself to relax and the more pressure you're putting yourself under. Eventually muscle memory will take over and it'll be like an out of body experience of watching yourself adjusting the screws to perfection. There will be no more worry, only confidence in what you are doing. I found a vid I did a while ago on a 2135, so made a GIF. The hand with the supporting tweezers is resting on a block just out of shot, so my hand is totally steady. Here's a link to my cloud where the original video is, but it won't be there for long. https://drive.google.com/file/d/1CJUCz846vvgf6uUNIK7m9CWL7j5fxjSW/view?usp=sharing1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point