Leaderboard

Popular Content

Showing content with the highest reputation on 11/24/24 in all areas

-

4 points

-

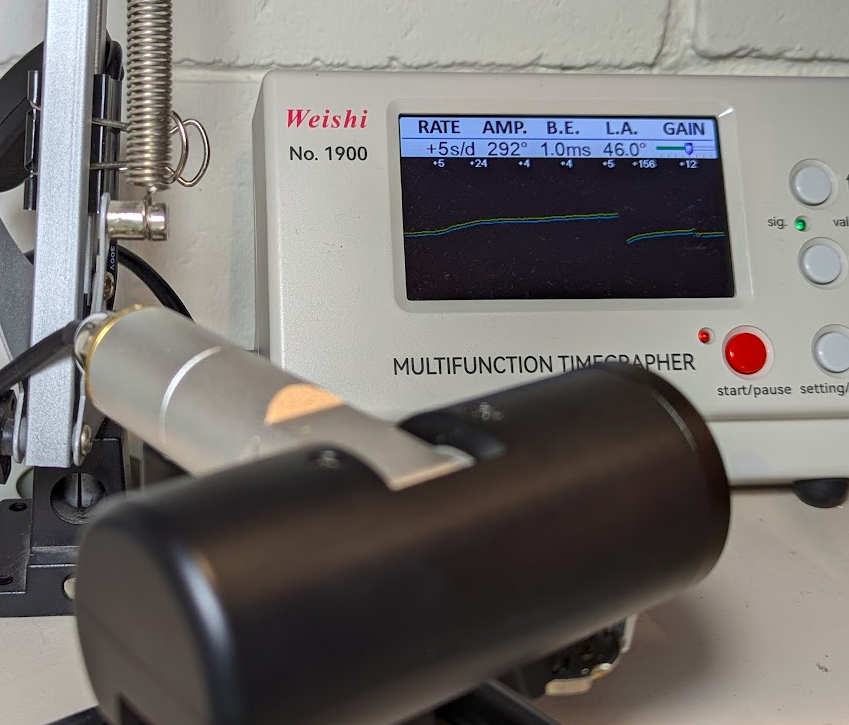

Examining the horizontal positions with the best magnification I have (which is not good at all) I could see there were times when the overcoil was rubbing at high amplitude. I could see that was because it was angling slightly downward near the stud, which pushed the Breguet bend up where it could touch the balance cock. I was able to fix that and it took all the noise out of the traces. Of course I could not let it stay with 1.4ms beat error... It took way too many tries to get it down below 1ms but now it is as low as 0.3ms (or as high as 1.0ms, which I think is an imperfection still in the terminal curve). Final product: a Vostok 2214 from the scrap bin that now runs like a demon. I had to redo the shellac on the pallets, and ultimately my only mishap today was dumping my container of shellac flakes into the carpet. Pictured DD, while the verticals are a little faster but narrower at +30/255°/0.3ms. I had planned on selling this but now I may have to hold onto it as a trophy.3 points

-

3 points

-

I've made point of topping up the oil wells everytime i use mine. Thats the nature of a watchmaker....in fact any tradesman that considers aesthetics .3 points

-

I'm reading Donald de Carle's " the watchmaker's and model engineer's lathe" and found something on page 15 that made me think about this thread: "Without exception, watchmakers are almost as concerned about the appearance of a lathe as they are about its precision. In no other field is plating used on precision equipment."3 points

-

Since posting this 5 years ago, my hairspring fixing has improved a lot. I recently posted this in another thread, but it's worth watching (it's Henry B Fried)2 points

-

It all depends on who the final person is in the chain. My Evri delivery person is great. Yodel are a disaster, and my Royal Mail guy is fantastic. Others will have totally different experiences from the same companies.2 points

-

Easiest way to do this is not to destroy your lathe by playing with them. As others have said they normally do not come out and you do not want to re-grind them. It really just looks like surface something like cleaning should solve the problem. The lathe itself doesn't exactly run on that surface anyway it basically runs on a film of oil. To just clean up whatever that is without modifying the surface if you can do it and make sure you have good oil and add oil from time to time. One of the most interesting problems I've seen of watchmaker's lathe is the failure to grasp that you need to add oil. So typically end up with people running their lathe's dry which is definitely not good at all.2 points

-

Hello all! Sorry for those members clicking here and expecting actual content from me (yet!!) I'm planning to service this Jaeger-LeCoultre Master Geographic, reference 142.8.92, with the calibre JLC 929/3. It's also used by Audemars Piguet as AP 2329 (base)/2847(dual time module). The base calibre the JLC 889/2, which was also used as an ébauche for IWC 3253, Audemars Piguet 2124/2224/2329 and Vacheron Constantin 1126). I found the (succinct) service sheet from JLC for the 889/2 base calibre and the travel time module 929. See attached! jlccal889-2.pdf JLC 929.pdf Below some pictures of watch and movement. Does anyone have any experience with these calibres and hints/tips for me that I should know to avoid mistakes?1 point

-

Right, Re-edited now: added ( with respect to the feet). We are describing the same thing only from different view point . I think.1 point

-

Lovely watch. Nicely detailed service sheets. Lots of bits, but it looks pretty straight forward. Good luck1 point

-

1 point

-

The windows are all at 3 (all the ones I've seen are). The feet are at different positions as shown in my pics above.1 point

-

1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

The problem with nos springs is that you don't know what you are getting, besides the fact that they are unused old stock and probably have little chance that they have anything new about them. A rusty looking spring is just that and should never be used, a spring that has micro fractures again is just that unfortunately you wont know that without looking at it under high mag or until it fractures under tension in the barrel sometimes spectacularly and possibly at any given moment during winding. To summarise a nos spring is an unknown quantity of age , quality and consistency. You can narrow down those risks by buying from a reputable supplier but still not remove them entirely.1 point

-

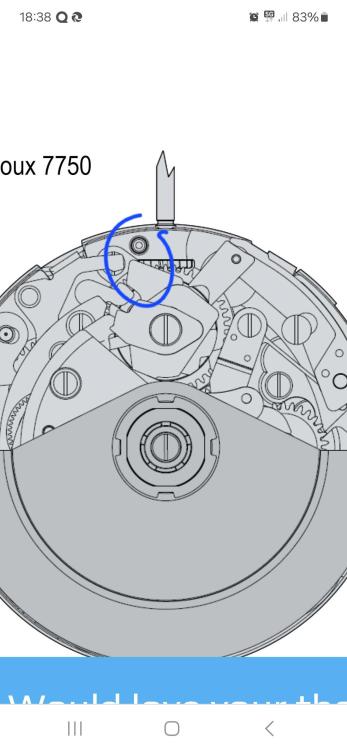

The 1916 is day and date. In the video you can see where the finger on the Calendar Driving Wheel is when the date changes, which looks to be where the teeth on the day wheel would be, so it is odd why the finger is so far off in the OP's photo. You idea of the rivet being loose and it shifting makes sense.1 point

-

After reading about the delivery guys you have, it makes me feel like I've been taking the delivery guys I have for granted. For parcels too big to fit into my dropbox, some of them would even open my front gate, leave it on my bench and ring my doorbell. Looks like I have to get them some Christmas presents in appreciation. For your horrid delivery guys, you can leave a lump of coal for them at their usual dropoff. PS My latest big value item was an Atmos clock from the US. The delivery actually rang my doorbell and handed it over to me persnally.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

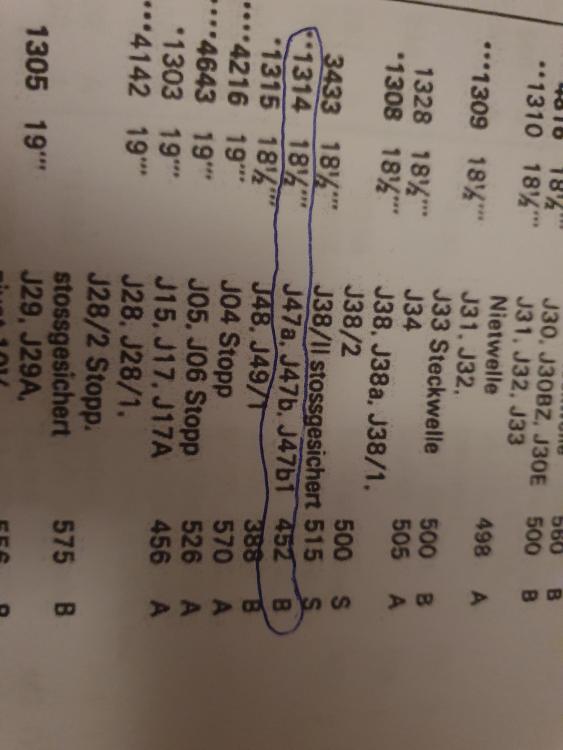

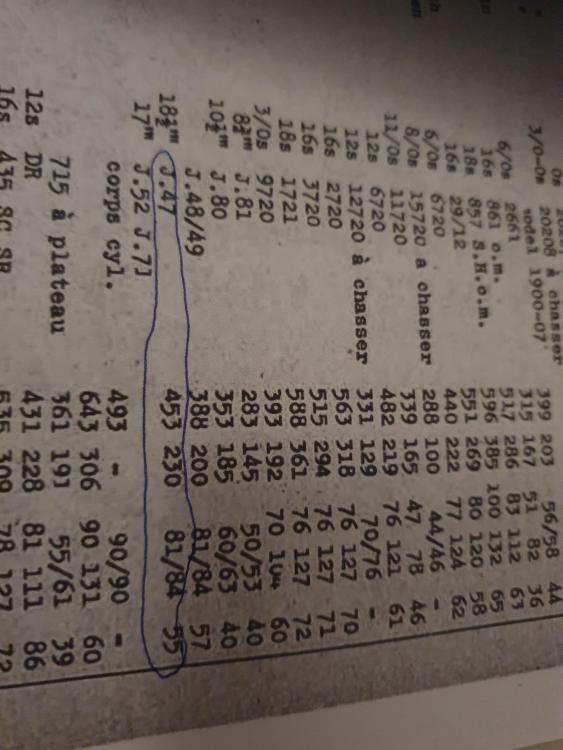

I believe but I'm not 100% sure that the Ronda catalogue has a column "mod" and code "B" is used for non-rivited staffs. My printout doesn't have a legend explaining the different model codes.. The dcn catalogue apparantly shows a "/" between de F and G value to indicate there is a taper. Mind you, the Ronda and DCN dimensions are not always the same as you can see in the photo's.1 point

-

1 point

-

Hi as previously mentioned by. ANDY pictures please. I have pivoted wheels with nothing more than a pillar drill so even with minimum tooling it can be done.1 point

-

If you just took it to somewhere that replaces batteries then they don't normally have much of a clue what they're doing.1 point

-

Finally got this little Oris tank back on my wrist ( after fiddling with the Westclox) with a half decent strap. I went with Frank's ( praezis ) idea of drilling a hole in the top of the cannon pinion so i could then tap the broken cw arbor out from the top end, thanks for the suggestion Frank it seemed like the safest option. And Nev's idea of gluing an iron tapered pin to fill the hole, in fact it was a stainless steel panel pin that i shaved down with a mini sanding disk on a low powered rotary type tool. Filed down and polished up, the join is visible but only under good light and magnification . Running solid up to now , 28 hours and it doesn't appear to have lost any time. This watch goes back around 2 years to my initial attempts at restoring it,this cannon pinion with jammed cw arbor inside it, broken hairsprings a balance staff , a dodgy overpowered mainspring, a new crystal that i put off buying then aquired a big stock of fancy crystals that was just over the cost of the one i nearly bought for it. And last night closing the minute hand hole, it still needs the hands restoring , bluing and luming but I'm happy to wear it for a while as it is, luming is something i haven't even tried yet, mostly because i enjoy originality, a watch's history, it's age , its life and its deterioration unless something is needed to protect and prolong it. Just as we should embrace growing old gracefully , the aching back, the dodgy knees, hair loss, hair growth in the wrong places , stiff hands, failing vision, I'll stop now before we all get depressed about the inevitable . Time can be short ,so make the most of what we have, grab any opportunities that come our way to make life more enjoyable. Signing out people, have a great day and make the most of it. Rich X1 point

-

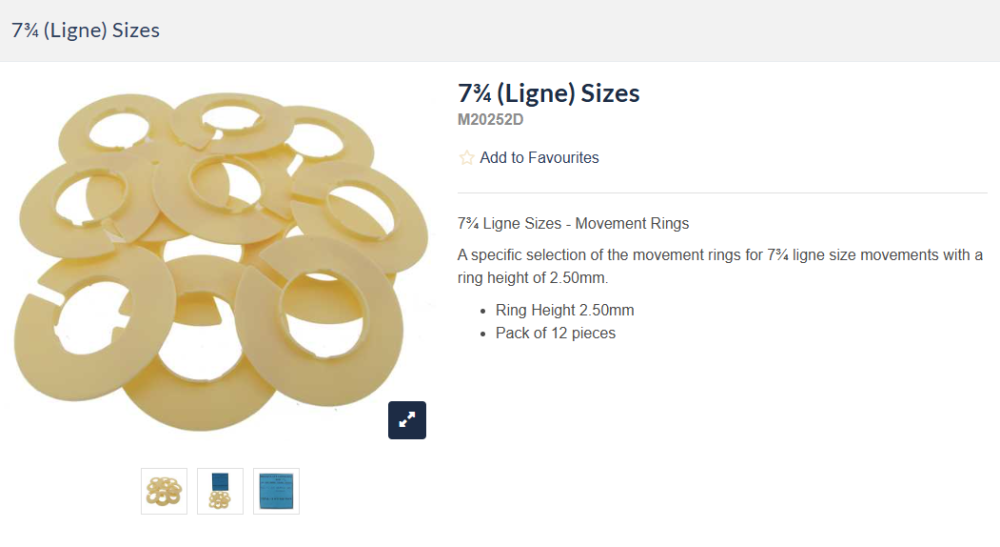

I enquired again regarding the tension ring and was informed that 0.9mm is the height and the ring thickness is 0.75mm.1 point

-

Well, Cousins in the UK were no help as usual. I had to go back to Sternkreuz after they first passed me onto Cousins. DIA – C 320 Outer ø = 320 ±0.02 Inside ø = 305 External height = 3.6 Inside height = 2.1 Ring = 305 * 0.9 DIA-CF 320 Outside ø = 320 ± 0.02 Inside ø = 310 External height = 2.1 Internal height = 0.9 Ring = 310 * 0.91 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)