Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/24 in Posts

-

Woohooo! The screw is out. It came out completely intact, nothing left behind in the arbor, and YES, it is left-hand thread. The parts are all OK apart from some surface blackening from the coca cola. I applied screw loosening fluid to the screw head and left it to be absorbed for three days. The final result came from heating the screw with my soldering iron at 450C for one minute, then squirting the screw head with a tetrafluoroethane freezer spray. This was quite spectacular, with the whole ratchet wheel becoming instantly covered with frost. I tried the screw both ways as usual, but this time it came free on the clockwise turn. Thank you everyone for your helpful advice. One more question: I think the black carbon stain can be removed from the ratchet wheel and the click with a very light polish on a lapping plate, but what about the barrel arbor? Should I try to polish away the black from the bearing surfaces of the arbor, or is it better to leave it alone?6 points

-

3 points

-

My master told me put in a couple of screws put don't screw them down tight as you will break off the pivots, it helps to keep the plate in place while you fiddle about with the wheels to get them in place, as you go you can screw down a little more each time a wheel is in place.3 points

-

3 points

-

The barrel arbor bearing surfaces need to be smooth and shiny. Has the cola eaten away at the surface, or just left a superficial stain? Try with some jeweler's rouge or similar first. This won't remove hardened steel, and you might be lucky and get a nice finish. You can get rid of some roughness with a harder abrasive, without removing too much metal. A few 100th mm are not going to be as critical here as they would be on a balance staff. If the surfaces are badly pitted, you probably need a replacement.3 points

-

3 points

-

Patience and practice, practice, practice... There is no shortcut. When I first started out, it could take me 45 mins to get all the pivots in, now it takes me less than a minute. I made a tool for nudging the wheels out of brass wire stuck into a short handle. Something like an oversized oiler. Brass does not scratch the wheels. Then I start by making sure all the bottom pivots are in their holes before dropping on the top plate. If you are lucky, you may get a hole-in-one. If not, then use a woodstick and press lightly on the top plate and nudge each wheel into the hole. Start with the biggest first and end with the escape wheel, or in your case, the pallet fork. Sometimes putting in a few of the screws but not exerting any pressure on the pivots, helps to prevent the top plate from see-sawing and getting displaced. Good lighting and a microscope helps. Take your time and take breaks before something breaks. Good luck.2 points

-

1 point

-

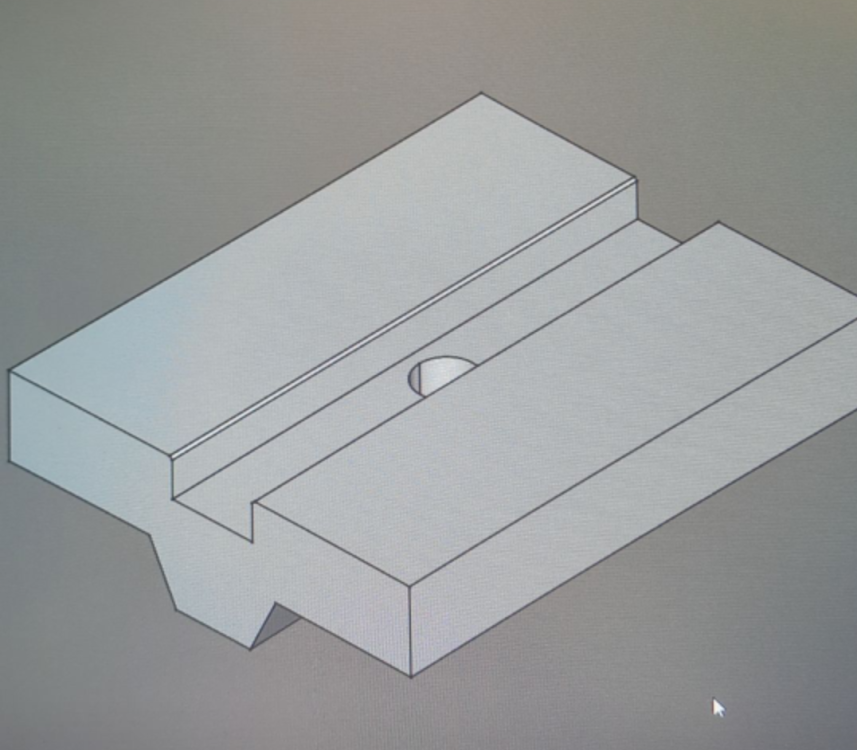

Well I figured the silence on this post meant everyone knew as much as I did. So I designed this part in CAD to attach to the rest and the lathe bed. I don't have a CNC mill, so I sent it out for machining. I'll update this post once I receive it. I'll have to make a new locking pin for the cam lever to accommodate the added length, but that won't be hard.1 point

-

I also have a Mosely and a Taig lathe. The Taig is my "big" lathe. I use that one mostly for tool making. The Moseley I use to actually make watch parts like balance staffs and screws. IMO, its best to have both lathes. The Taig is acceptable for making some tools, but it has too much run out for turning a balance staff. I think mine has 0.15mm with the 3-jaw. And that's after I re-ground the surface of the jaws. The collets you can get from them are pretty good, but very limited in size. I ordered mine without the motor, and put an adjustable speed industrial sewing machine motor on it, and bypassed the foot switch. I have a pretty large range of speed now, from I think 200rpm up to 4500rpm. I haven't taken it past 1200 or so. Keep both I'd say1 point

-

Jealous of that lathe, but the table looks about to sag at the knees!1 point

-

Hopefully the arbor's surface is not too damaged, pivot to bearing tolerances surely allow a little more here than with something like a balance pivot. Some amount of burnishing woukd be better than none, the OP would be in a better position to decide once he knows how poorly the arbor is. I really like pollinum for polishing or autosol which has a bit more bite to it. I'm sure we discussed this ages ago about what effect an abrasive can have on spinning metal watch parts....the possibility of charging it with compound compared to a pivot file or burnisher. The OP does have the option of reducing the arbor bearing size also.......not an ideal situation just an option. For the rat wheel and click I would just try a dab of autosol on a chisel ended piece of pegwood to clean them up.1 point

-

Congratulations, how closely can you inspect the arbor's surface ? The pivots should really be polished just like any other train or balance pivot.1 point

-

1 point

-

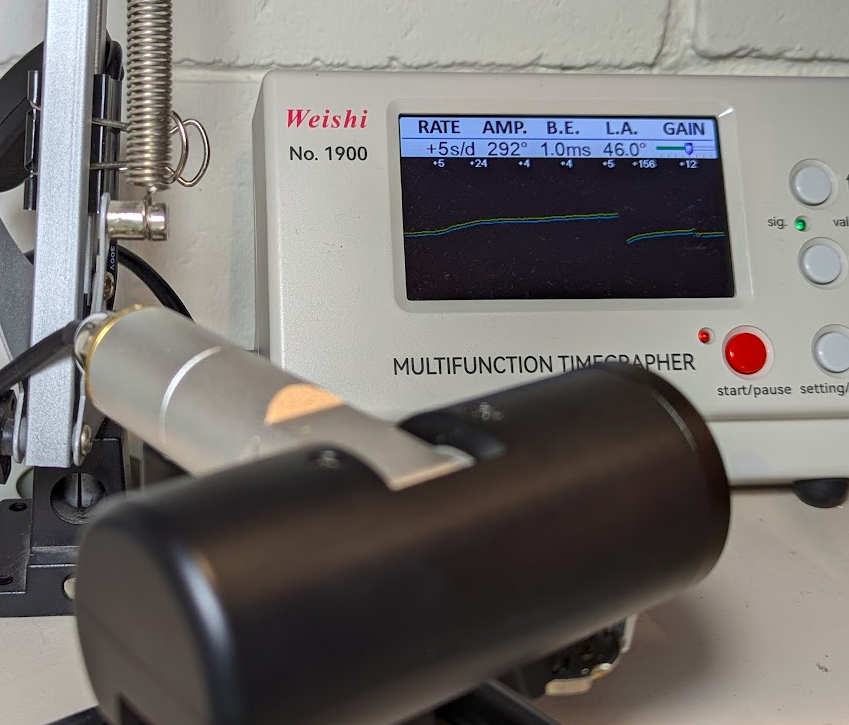

Examining the horizontal positions with the best magnification I have (which is not good at all) I could see there were times when the overcoil was rubbing at high amplitude. I could see that was because it was angling slightly downward near the stud, which pushed the Breguet bend up where it could touch the balance cock. I was able to fix that and it took all the noise out of the traces. Of course I could not let it stay with 1.4ms beat error... It took way too many tries to get it down below 1ms but now it is as low as 0.3ms (or as high as 1.0ms, which I think is an imperfection still in the terminal curve). Final product: a Vostok 2214 from the scrap bin that now runs like a demon. I had to redo the shellac on the pallets, and ultimately my only mishap today was dumping my container of shellac flakes into the carpet. Pictured DD, while the verticals are a little faster but narrower at +30/255°/0.3ms. I had planned on selling this but now I may have to hold onto it as a trophy.1 point

-

Welcome @jao! You found the right place for your hobby. Don't hesitate to start a thread when you have questions. I didn't know you're in Stuggi! I studied in Tübingen1 point

-

I attempted to measure the distance between the cap jewels and came to 2.78 mm. Some of the DCN staffs in stock at Cousins do come close and are marked "à chasser" with F/G measurements, which I'm now convinced means they are tapered and friction-fit like you suggested @caseback. I'll order a couple different ones and see how it does. Thanks everyone!1 point

-

There is a dedicated tool for this...an offset cannon pinion remover. This has two thin platfoms that slip between the two pinions and seperate with an reverse plier action .1 point

-

Well I am very pleasantly surprised. The 3am communications in imperfect English were not indicative of a ruse. I got 3 watches, all runners, with beautifully hand painted dials. The Statue of Liberty is missing a caseback and is a very thin model, possibly a Luch slim. I'll see if I can find a replacement case but I'm excited about these. The cosmonaut is a total surprise, as it was not visible in photos.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)