Leaderboard

Popular Content

Showing content with the highest reputation on 11/26/24 in Posts

-

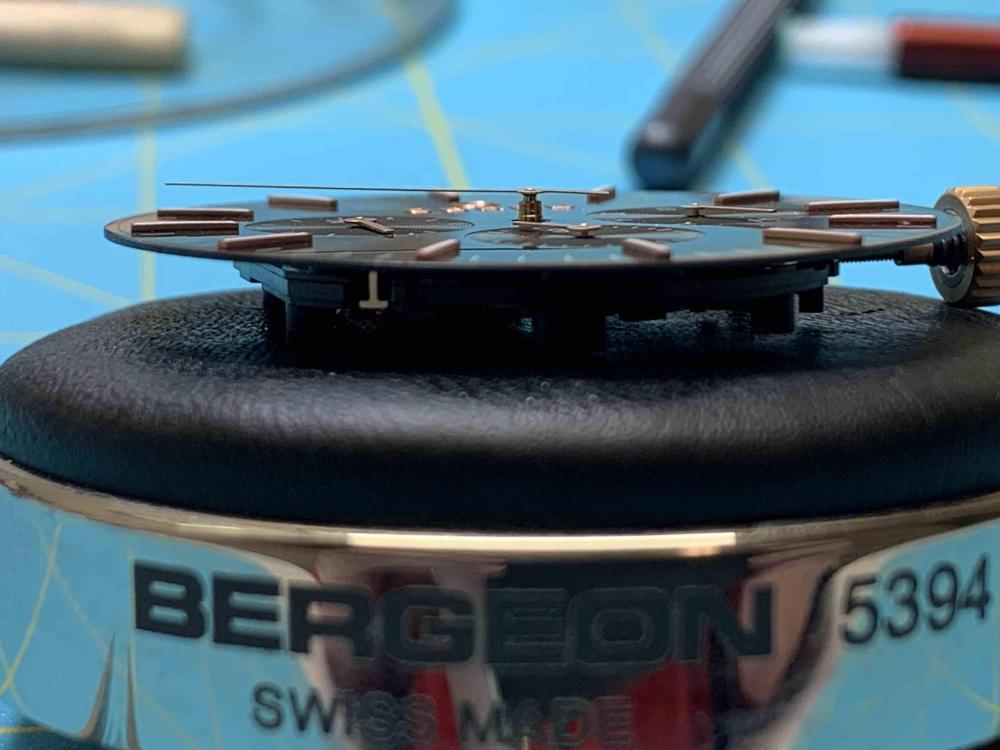

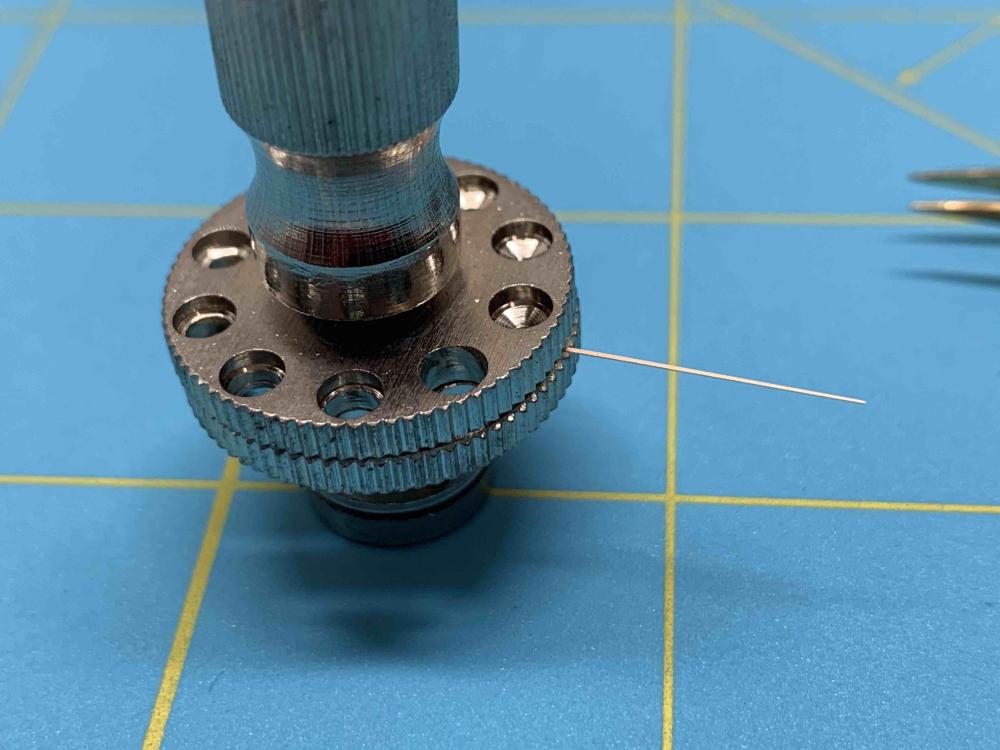

The lathe bug has grabbed me firmly by the danglies ....my first attempt at cutting away the staff hub from the balance wheel using a lathe. Its off a pocket watch...but a clean cut with no damage to the wheel....took me around 3 minutes....overall I'm chuffed. I throughly believe if you have a lathe and can handle a graver this is the kindest way to treat the balance wheel...no more staff punch outs by this chappy. Pictures 2 and 3 , work related thumb damage7 points

-

Today, I used my Elma Super Elite for the first time to clean a movement (I had been waiting for the cleaning fluids to arrive by road from Cousins for 1.5 weeks). Seriously, what BLISS compared to my previous setup! Now, I'm actually looking forward to the cleaning, while before that was always the task I was dreading. Still super happy and excited3 points

-

I'd say the Velocite 6 would do just fine. Your machine already has a larger bearing surface to cope with the heavier machining.3 points

-

a number of things we need to know to help you identify the watch. It would be helpful to have the size this is measured on the dial side of the movement not the dial itself. then I'm attaching a PDF for you can convert your favorite measurement into ligne which is how we identify watch sizes. then if the number isn't under the balance as you observed the next place to look is as quoted above under the dial. Which will be helpful for variety of reasons you can then measure the movement and give us the size. Also there's a system of identifying movements from the keyless component so if you get us a really good picture of the backside of the watch we may below find the movement. Or you may just be lucky and the movement at that a vacation will be under their where it often is on some watches. from the picture it looks like a little bit of the stem is sticking out? This is good because if we cannot identify the movement we can measure the dimensions on the stem and find something probably equivalent. Ligne millimeter inch diameter watch size chart.pdf3 points

-

2 points

-

2 points

-

2 points

-

Filing this story under Watch Case Issues, but only because there's no section on the forum for really bad judgment... A friend of mine calls me the other day and says "Can you get the back off of my watch? It needs a new battery and I just scratched it trying to get the back off." I tell him no problem, bring it over. The case back is a press-fit and pops right off for me. I even have the battery he needs. So far so good. I make sure the case and case back are spotless, and clean and lube the case back gasket. I'm feeling very good about things at this point after investing about 5 minutes and enjoying some banter with my friend. Then I try to pop the case back on. Nope. No way with my all my strength is this thing popping back in place. No problem I tell my friend, happens all the time. That's why I have a little hand press for case backs and crystals. Heck, I've even installed a case back on one of my old grumpy watches using the bench vise in the garage once... So I choose a flat die for the case back and a concave die that will touch only the watch case and not the crystal. So far so good. Get everything lined up and give it a squeeze. Nothing. Take a deep breath and squeeze harder. Still nothing. Recheck everything is aligned the way I like and try again with all my strength. Nothing. Grumble. My friend (who has bigger hands than I do) offers to give it a try. I give him the press with the watch in place all lined up and tell him to give it a go. He does and we hear a satisfying little 'pop,' which I assume is the case back snapping into place. Great! He hands the whole thing back to me and I extract the watch from between the dies. Oops... Looks like the die on the dial side flexed so much that the centre pin the die sits on breached the crystal. Adding insult to injury, the case back still had not seated. Good grief! But it was worse than just the broken crystal (and my damaged ego). Two of the hands were bent and some glass must have worked its way into the movement which was now seized. Deep breath. Sent my friend home with no watch. Lucky for me the movement was relatively easy to get and not very expensive. Same with the crystal. Hands came back to shape well enough, and things went together well. The movement front-loads on this watch, so the first thing I did during reassembly was press the case back in place. Then the movement went in, crown installed and finally the crystal. I guess it all ended well because I had the watch back together, running well and in my friend's hands a week later. And at least he scratched it first! What a crazy ride.2 points

-

Where abouts have you looked for the brand and calibre? Something this young will almost certainly be marked up. Quite often any of the Ebauches SA brands will be marked up just under the balance. Often under the dial there is a maker's mark. Try these first before we start looking at the keyless works for the identity.2 points

-

well those are all nice suggestion but, there is no plastic movement holder for this model. Rather it is a front loader and has a dial ring the fits between the dial and crystal. This hold the assembly in place.2 points

-

I have some other books will have a chance I'll look to them now that I know exactly what I'm looking for.1 point

-

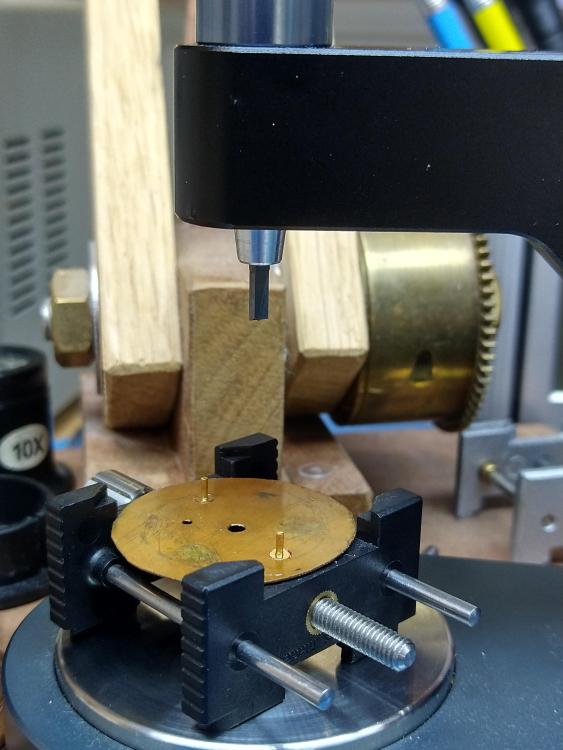

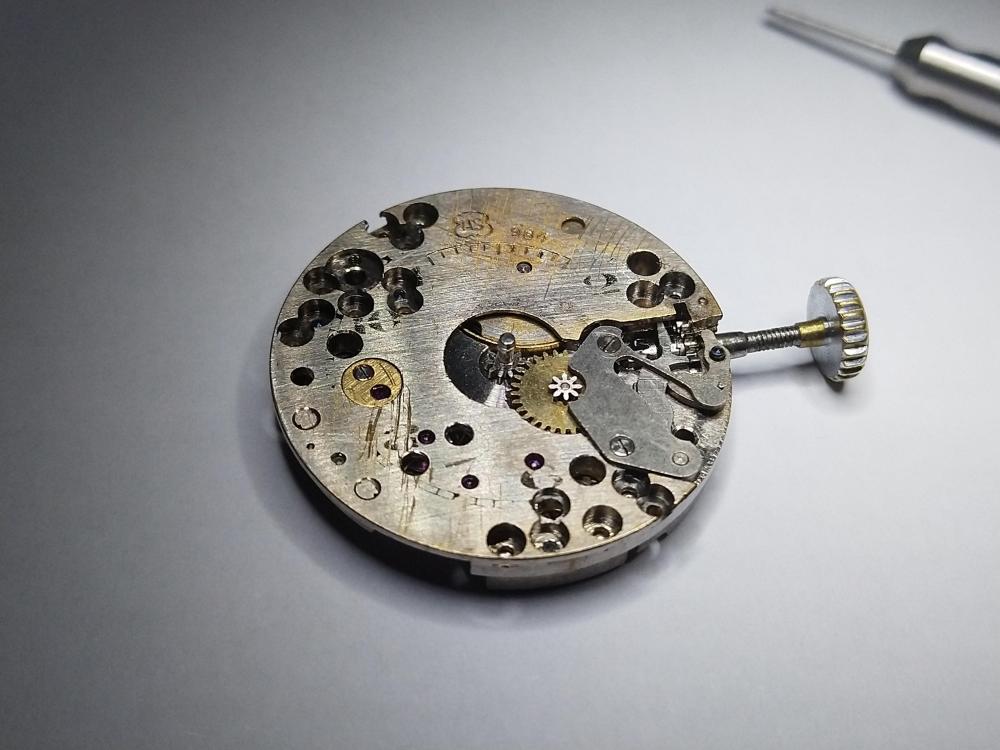

HWGIKE#30 AS 984 Afra Watch One of my most difficult repair. Dial is not made for AS984 so it is not possible to add a second hand, there is no extended pivot for it anyway. The hole should be only 1 or 2 mm be closer to the center. ( i consider to larger the hole and buy a 4th wheel with an extended pivot) New crystal, stem & crown. Holes for the barrel arbor tightened, both upper and lower one. (the second one was tightened after the assembly, with full power the arbor wedged so the movement stopped.) Setting lever did not reach the stem, was worn, ordered another but i knew before the new one arrived that it would not work... i am not sure if the case is original to the movement or not... i had to file the setting lever down a bit so the little thing on the setting lever would catch the stem. This was a very challenging repair/ service and I am very happy how it worked out at the end. Dial was originally big someone cut it around so it would fit and had no legs. I added new legs, but with difficulties, even if I marked their position using the holes on the movement it was not accurate enough had to replace them several time. I also learnt that adding a tiny drop of the oil to the cutting edge of the tool makes an enormous difference. It cuts and does not try to twist the movement holder out from your hand making the hole oval. I made a mistake and went too deep so it is visible on the other side a bit. AFRA stands for Dr Alex Frankel from Vienna, but it also happens that my daughter is also named Afra. I am going to wear it as promised 4 years ago when I bought it.1 point

-

No, but i do have a little clock collection. I only collect clocks that show time in a special way .1 point

-

Welcome to the dark side. You'll find more and more excuses to use your lathe. Mine gets used multiple times a week. Now you better start making tools. Mount a burnishing wheel to it to dress your screwdrivers and gravers. Mount a pivot polisher to it to quickly polish pivots. make a superglue arbor for mounting various parts. Polish screws. The list is endless!1 point

-

I think $500 is too much for this, since for that price you can typically get a larger and more complete K&D set that includes tools like roller & balance staff removers. The condition of what is here looks good, but it isn't a particularly expansive set. In this condition, $350 sounds better. If it was dirtier/rustier, $300. Be sure to filter the ebay listings by "Sold items" to find out what people have actually been willing to pay. Quite a few Boley sets of different sizes and conditions have sold within the past month.1 point

-

1 point

-

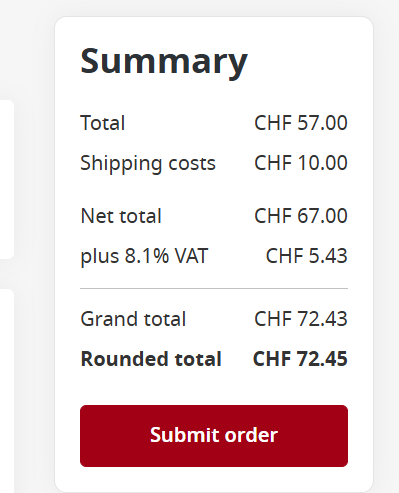

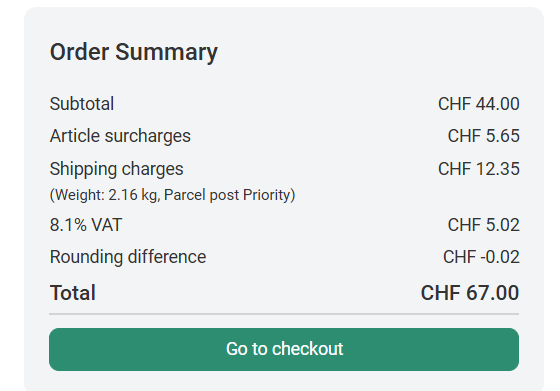

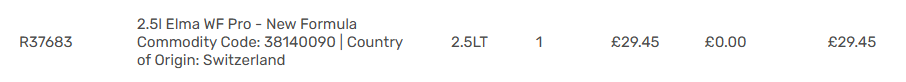

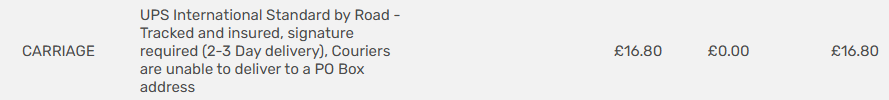

Thanks @nickelsilver, I just checked out Brutsch and Bijoutil. here's a price comparison for a 2.5l canister of Elma WF Pro, including shipping within Switzerland: Bijoutil: Brutsch: NOW Cousins with international UPS road shipping from UK to Switzerland: SUM: (29.45 + 16.80) + 20% VAT = 55.50 GBP = 61.90 CHF. Crazy, no!? Cousins is still cheaper!1 point

-

I also order fairly often from Cousins, it's just hard to beat their selection and price- but- for stuff like cleaning solutions I definitely buy them here. You can order from Brutsch-Ruegger, Horotec, and Bijoutil (and I'm sure others) without a VAT number or anything. I use Greiner solutions and get them from Brutsch. On that page is also Greiner's concentrate to mix with water that's a great all around cleaner for the ultrasonic.1 point

-

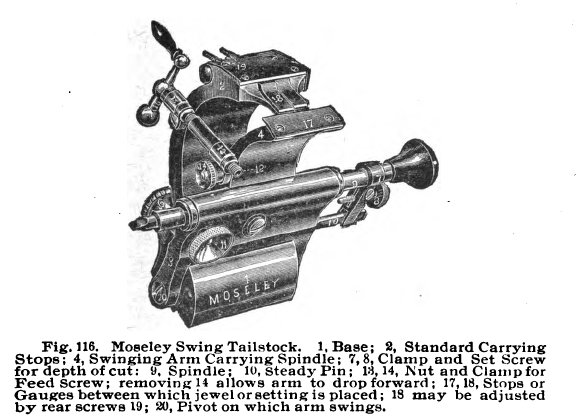

Yes that is the tool I have. I even emailed Tony over at lathes.co.uk to see what info he had. I haven't heard back yet. All the books i have seen that mention this, don't really explain how to use it. I seems self explanatory, but im struggling to see how setting the jewel opening makes a difference when there is 2 stops, and they are both on the same side of the device. This is just for making a jewel setting or opening a hole in a plate, or really whatever you wanted to make a hole in. Apparently some even use it for light milling.1 point

-

I used to use this. I set the temperature to 80°C and leave the basket on it for 15mins. But now I just leave the whole basket on top of my air cleaner and leave it for 1-2 hours.1 point

-

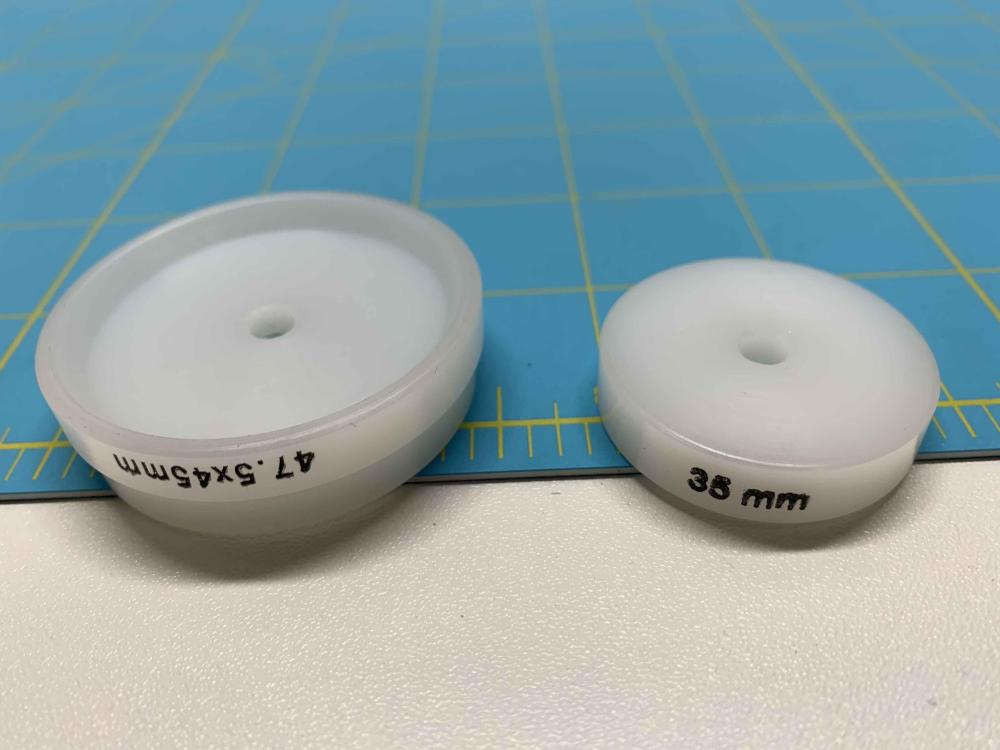

This doesn't tell you much more but it does look like they're some sort of moulds possibly resin casting?1 point

-

I dont know but i hope you didn't want it....ahem.... just kidding, I already have way way too many tools. I need a bigger house if I want anymore.1 point

-

They look like molds and some sort of press or frame for forming acrylic crystals. Though I assumed that was a vacuum process and this does not look like a vacuum tool. It's a shame the listing does not have better photos of the metal molds, to see if they come in upper/lower pairs.1 point

-

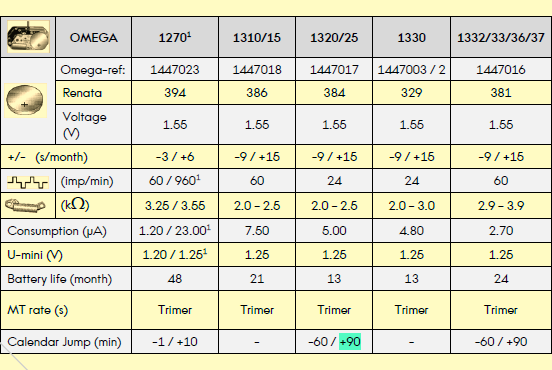

I have a link searching for the word working and you get a interesting list of Omega working instructions. Number 18 may be of interest to you but while you're there download all the rest of them they're all interesting and worthy to download https://www.cousinsuk.com/document/search?SearchString=working then looking through number 18 you'll come to the page that I snipped image from we get technical specs for your watch this is where it be nice to have some test equipment because unfortunately circuits without test equipments are basically black boxes that there isn't a lot we can do with. then your measured coil resistance is within the specified range. then why you're on the cousins website you can change the word working to 1337 and you get the parts list for 1337 which only has two parts? Notice the reference to 1332 that's the base caliber and searching for that the get the parts list for that. Which then brings up the amusing problem of watch repair where's the service bulletin? Most vintage or most documentation was scanned solely for parts and not for servicing. Sometimes for a lot of watches there never was any servicing as the manufactured perceives that whoever is working on their watches didn't actually need servicing. Although there should be something for this? I did find you a servicing document but it's more just the test points and a few helpful tips on servicing because once again they expected you to know what you're doing. did you figure out any reason why the teeth through broken? and typically for a quartz watch everything has to be super super clean and properly lubricated anything that sticky is going to be an issue. Then you want to use the lightest oil possible on the pivots if you're doing more than one quartz watch the 9000 lubricant for quartz watches works really well then we can only go so far but let's follow the testing procedures. With the battery in place they give you test points ideally for the plus you would like to put it on the plate someplace and not on the battery even though it shows contact with the battery. The reason for this is you want to make sure that the battery power is actually going into the watch and there isn't a short or something else somewhere. Then yes analog meter supersensitive one would be preferred. You can then check for the impulses to the coil. With a digital meter you'll probably see something as opposed to just sitting there and doing basically nothing. With analog meter on the most sensitive settings what you typically see as the output polarity changes each time the stepping motor steps you would see the alternating movement of the needle by a little bit. So you might build a sort of possibly see that with the digital may be but there should be some sort of change their then we basically come to the end of the testing that you can do with what you have. Ideally it be nice to have a variable voltage power supply and the ability to measure microamps including fractional microamps. Personally I prefer an analog meter over a digital meter here. Because then we can see what's going on as opposed to we can't at all then the Chinese do make some inexpensive diagnostic things and somebody will come along eventually and tell you about their nifty device that does nifty stuff. otherwise the Swiss make a whole variety of test equipment but it's hardly worthwhile unfortunately for one watch. Although? One of things you do is take out the wheel next to the stepping motor. The stepping motor rotor is only turning itself and see if that will turn. You might have to put a Mark on the rotor because when it steps it may actually look like it didn't step would off. So sometimes a small mark on one side than you can tell but it actually rotated. In other words you just trying to get the stepping motor to step if that works you can start to add the rest the gear train in. omega 1332_complet_4217.pdf1 point

-

or? Typically when I come to the group I ask for new discussions or things that I haven't seen before. But I've noticed for variety reason sometimes discussions are not there. Then a lot of times people are probably only looking at specific sections which means they're not going to see it either. then what helps if a few people responded say just about anything at all and then the group will notice and we might get an answer perhaps. Although the problem is that is a specialty tool with so many people on the group not even having a lathe at all. then in one of the lathe books I have a think this is what you have? but even better yet I found a link with pictures looks the same as yours? https://www.lathes.co.uk/moseley/page4.html1 point

-

Yeah, if he's that brave then I will be too (and I'll hopefully also be a little wiser). No offence taken. Some of my best lessons have been learned through pain.1 point

-

Not all faceted backs are screwbacks, some don't even remove at all. So anyways what do we see on the case at the left hand lug ?1 point

-

Its a lovely lathe......haha the table is very deceptive...the legs aren't wood... its a fully welded box steel one piece frame ...more than boss of the job...but still a tiny wobble under the 80 odd KG load of the lathe and motor.1 point

-

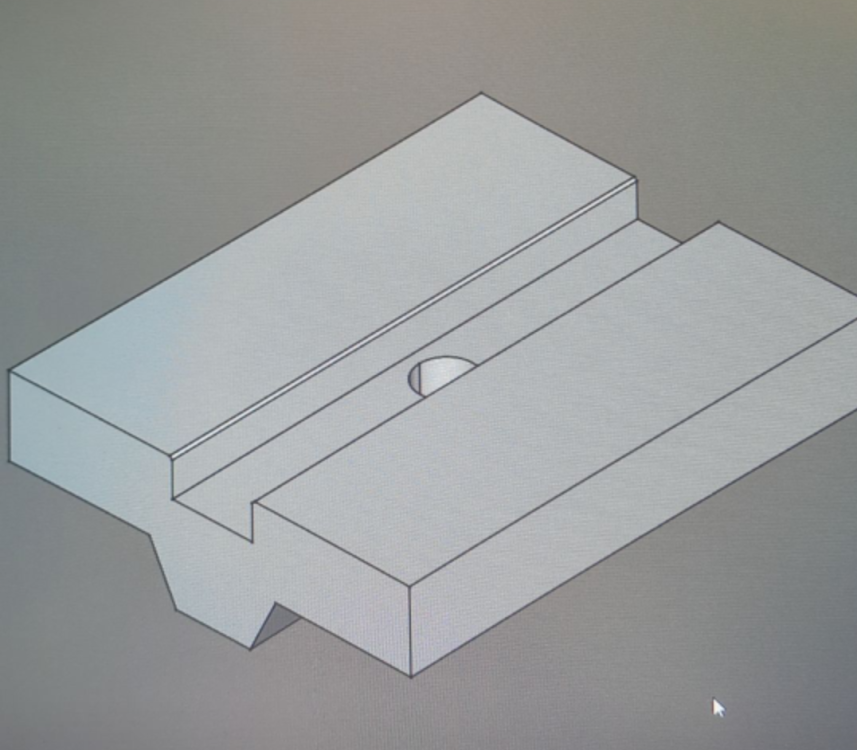

Well I figured the silence on this post meant everyone knew as much as I did. So I designed this part in CAD to attach to the rest and the lathe bed. I don't have a CNC mill, so I sent it out for machining. I'll update this post once I receive it. I'll have to make a new locking pin for the cam lever to accommodate the added length, but that won't be hard.1 point

-

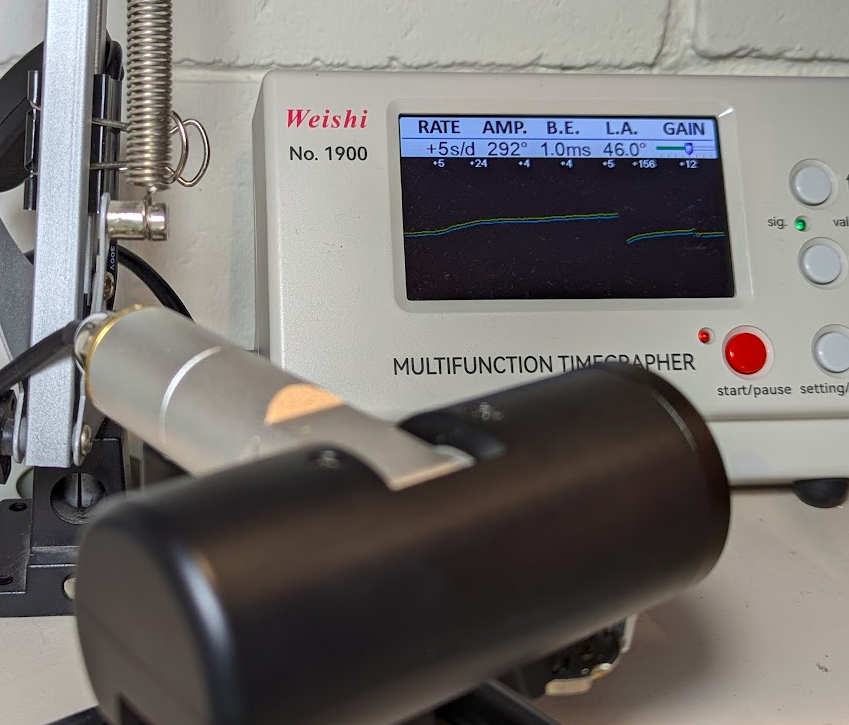

Examining the horizontal positions with the best magnification I have (which is not good at all) I could see there were times when the overcoil was rubbing at high amplitude. I could see that was because it was angling slightly downward near the stud, which pushed the Breguet bend up where it could touch the balance cock. I was able to fix that and it took all the noise out of the traces. Of course I could not let it stay with 1.4ms beat error... It took way too many tries to get it down below 1ms but now it is as low as 0.3ms (or as high as 1.0ms, which I think is an imperfection still in the terminal curve). Final product: a Vostok 2214 from the scrap bin that now runs like a demon. I had to redo the shellac on the pallets, and ultimately my only mishap today was dumping my container of shellac flakes into the carpet. Pictured DD, while the verticals are a little faster but narrower at +30/255°/0.3ms. I had planned on selling this but now I may have to hold onto it as a trophy.1 point

-

Hi Guys, Today I have a huge sense of accomplishment and relief after finally finishing restoration of this Ball 999B 16s 21 j railroad grade pocket watch. I started it in April, so it only took me five months to complete; as life got in the way. It also had a lot wrong with it. Broken jewels, broken staff, bent wheel, broken hands, well, you get the picture. It's running great in my estimation. The fact that it's running at all is proof, not of my workmanship because heaven knows it's lacking, but of the high quality of workmanship that went into the watch's manufacture. I feel very lucky to have gotten it back into shape. My only regret is that you can see some of the glue used to adhere the crystal. I thought it was supposed to dry clear. I might retry with some UV glue to see if that's better. Thanks to all the people who gave me input along the way. I couldn't have finished without all their help. Arron.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)