Leaderboard

Popular Content

Showing content with the highest reputation on 11/28/24 in Posts

-

4 points

-

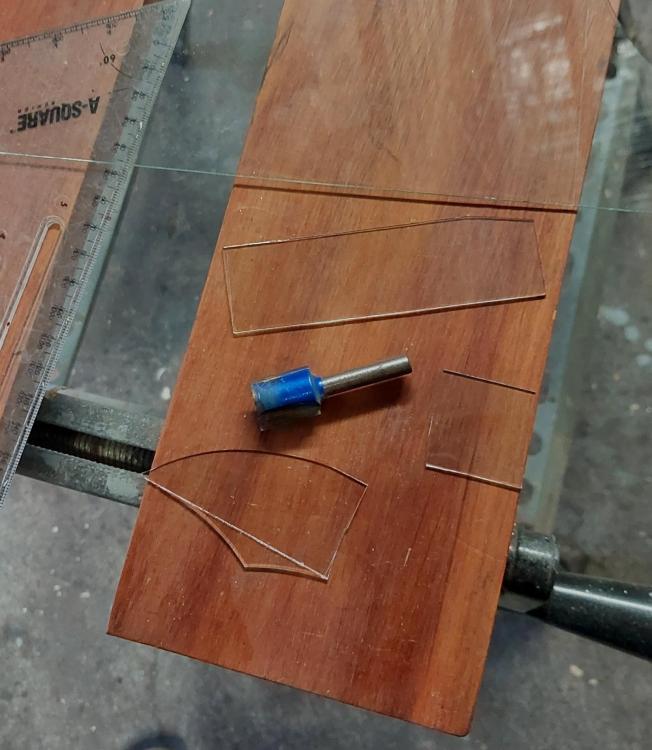

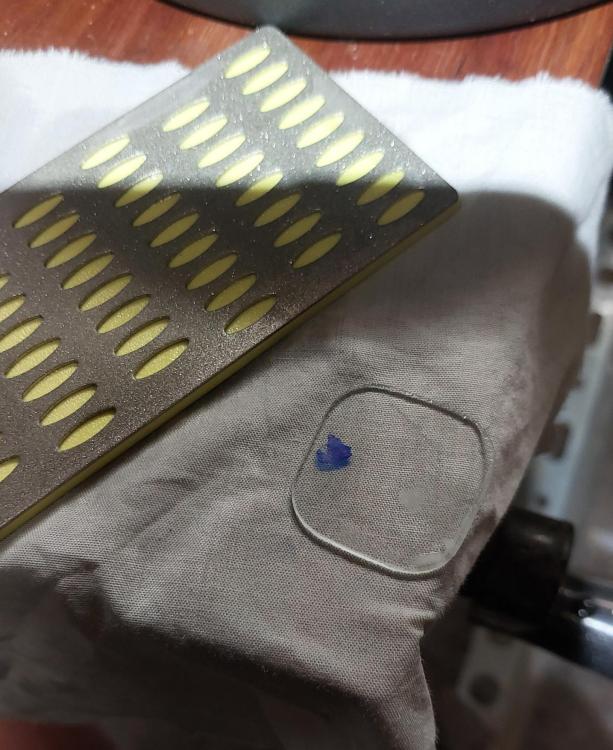

Had an Oh Sh#t moment this week when I cracked the crystal on my nephews Tissot. As Im sure you well know finding a replacement for a 1970's square case is next to impossible so this necessitated a deep end dive into crystal manurfacture.. I found a cheap picture frame with the correct 1mm thickness and went at it with a routing bit. The original plastic gasket was in good shape luckily so I taped this to the glass and traced it out with the router bit.(forgot to photograph this step unfortunately). I then roughed it out with the dremel (with a whole lot of test fitting) the tidied it up with a cheap diamond whetstone with a 45 degree bevel. If you look at it closely you can definitely tell its home made but Im very happy with the result, and honestly it wasn’t as hard as I expected. Well worth giving it a shot on your old obscure watches! Cheers3 points

-

I'm afraid I have no experience with the "859 + PTFE" grease, but if JLC recommends it, I'd be inclined to get it just to make sure. If, on the other hand, we could tell for sure that 8217 would do the job just as well, then why not save the money? Here's a quote from @nickelsilver that I've saved: "Moebius 8217 is the standard grease Kluber P125 is also a standard if a bit more high tech grease. Then there is 8212, also known as Glissalube B, for aluminum barrels, and 8213, Glissalube A, for brass barrels. Easy to remember as the letter code matches the opposite metal."3 points

-

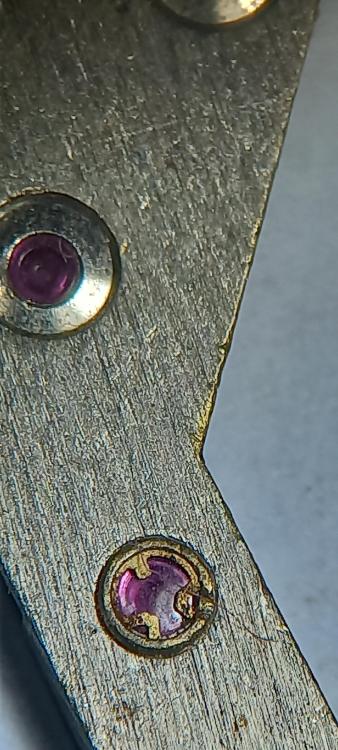

Correct It is just a cap jewel retainer not a shock spring. I release just one arm then the other and gently lift them out. But yes they are fragile, so ive seen lots of them broke in half. You might want to use a blob of rodico on a stick to lift them out. Dont try squeezing both arms arms at once, this is how ive seen many broken ones. I was remembering why they are frigile so i pulled out a big bunch of Soviet plates and bridges i have, they're really prone to rust. The rusty one took free flight, i had to give it some extra help to come out as it was part rusted in and the rodico stick had been neglected . So here's another more friendly one that has come away by releasing just one arm and the rod stick lifted it away nicely So as you can see they are plated steel, try a little light magnetism instead of the rodico you might prefer that invisible sticky steel substance, just a light brush over some carbon tweezers or a probe with a small magnet. Slow predictable move see it back home safe. Problem with this is.....the cap doesn't get a good clean, and after going through a wash might be in a worse condition with residue staining than before washing. Thing is you have no idea of how clean the cap really is unless you take it out and buff it up.3 points

-

I'm not sure where he said it, but @Jon always uses 8217 and without any issues. (please correct me if wrong). And same for me. Always used 8217. So far no problems. But I've always wondered if Kluber P125 was better... but it's so expensive. Now this 859+PTFE popped up and I'm wondering if it's like P125 at lower price. PS: when saying "better", I guess there are two factors: 1. Later slipping (i.e. higher amplitude) 2. Protecting barrel walls from wear. For me, I don't care about losing 10 degrees of amplitude (@JohnR725 would be proud of me) if the barrel wall is protected better.2 points

-

One arm is a tad shorter, that's the one that should come out first and go in last.2 points

-

Consider rs-winder https://github.com/vishnu350/rs-mainspring-winder especially if you are equipped for 3D printing. I have a cheap Chinese set that has never yet proved useful but my 3D-printed winders work fine. They work a bit differently from the Chinese clones of the Swiss tool but for me they're just as good and a tiny fraction of the price. There's a fairly long thread about them here:2 points

-

They're not that expensive. https://www.ebay.co.uk/itm/135353225104 I expect they had good old fashioned books to look at.1 point

-

not only do you need to get pictures but you really should explain to people what this is? Like for instance I don't see the crown anywhere what happened to the crown? plus usually given photos the front has more than likely most people in this group haven't ever seen one of these. Then you're going to have problems because this is definitely a vintage watch. I have two links below the first link somebody asks the same question you have and you'll see lots of confusion. but if you scroll down you'll finally get to the answer there is a article in the horological times magazine. otherwise it just isn't a lot of information on this is for servicing it goes. then for those that don't know what this is the second link gives you the history of talks about it until blame of the title first automatic wristwatch. https://mb.nawcc.org/threads/harwood-automatic.21429/ https://www.fratellowatches.com/tbt-john-harwood-and-the-worlds-first-automatic-wristwatch/1 point

-

Well, these are product of bad design. Good sharp needle is needed to lift from one side, while the other is held with wooden stick in place. When the first side has popped enough to insert sharp tweezers tip under it, grasp it with tweezers and take the thing out. One of the legs is shorter and may be it is to be taken out first, but no one knows which is the short leg when the thing is in place. May be there is rule which way to insert it as to know which is the short leg, but once the movement has been disassembled, it can be put both ways.1 point

-

Job done. It is difficult to tell which is the shorter arm. And I think these were more difficult to remove than install. My lower one came out and went back in easily but I broke the upper and had to take one off the next movement in line for service. I'll order a batch of spares today. I expected the clip to fly right out once one arm was pulled free (like an inca spring or like the other Soviet shock spring) but it really wants to hold its circular shape in the groove. It takes some pulling to get it free and that's how I broke one. Reinstalling, as long as they are laid in position just a light pull against one arm and the whole thing jumps right into place.1 point

-

Looks like a front loader so yes the bezel would need to be removed. Need photos showing around where the bezel joins the case.1 point

-

The problem with this type of tester is that it doesn't tell you how accurate the watch is.1 point

-

No reason at all not to. That's really the only way to fix them.1 point

-

Its diameter is close to my 1.2mm screwdriver blade. I will remove it in a bag - haven't had to do that in a long time. Good to know. For a long time I had assumed most shock and retainer springs were brass, until some presumed lost in the carpet turned up weeks later during a magnet sweep. So it looks like there is a fine groove milled all the way around in there to accept the clip, and its radial direction probably does not matter (though I expect it has a top and bottom side preference) I hear you have some particularly bad ones in Australia1 point

-

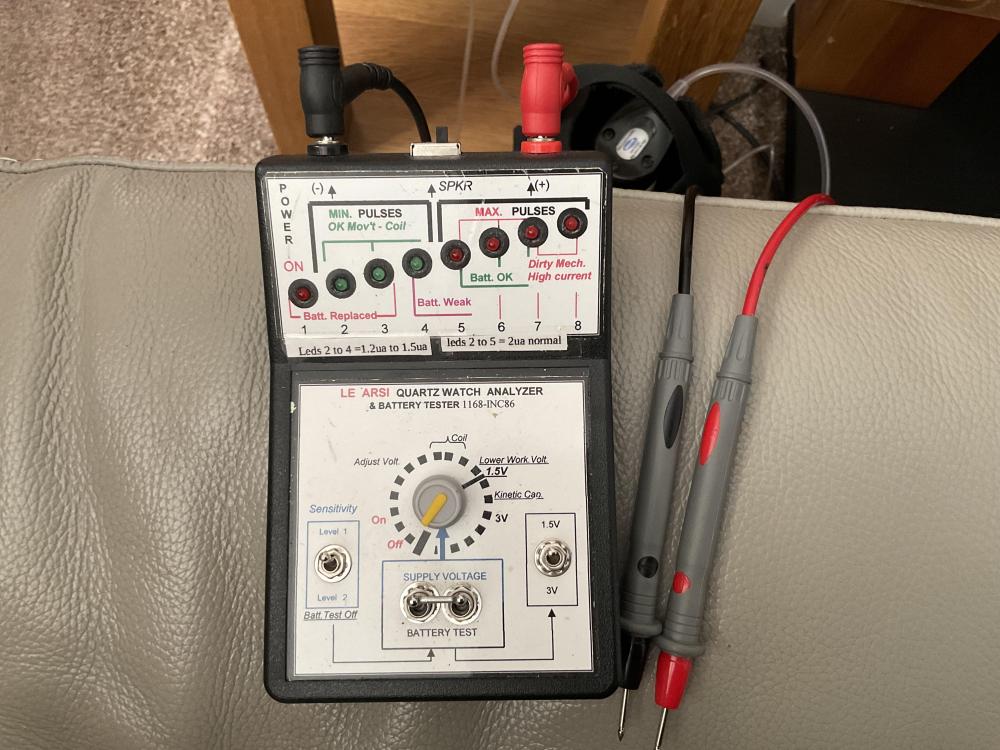

In my experience repairing /testing quartz watches the likes of the Horotec are good as is the quartz watches analyser which I use by Le Arsi. 1168-1NC86. The Le Arsi one being a bit cheaper with all the functions. I did have one of these Indian made pulse testers which broke and when I took it to bits to repair it was cobbled crap so binned it. basically you get what you pay for. If you want information on the analyser give me a PM. .1 point

-

Completely agree, it's why I persevered with removing the pesky little blighters. I have seen it suggested so I thought I'd mention it. I found putting them back in even more awkward than taking them out. They have a tendency to just be pushed around in a circle in the recess for them without the spring going back in. To the OP: One end of them is slightly different than the other. That's the end you want to play with. Good luck.1 point

-

Well I was close, but take the advice from the people that have done the job before and forget what I said. I shall now go and sit in the corner. Ooo. Spiders. This is nice.1 point

-

Some are called quartz pulse testers but not all show the actual time and then there's the Hortec Flastest. Not all Quartz watches have a trimmer for adjustment. https://www.aliexpress.com/item/1005006099270185.html?spm=a2g0o.order_list.order_list_main.139.1ed21802dxhmIh https://www.cousinsuk.com/product/horotec-flashtest1 point

-

They are a pain. I used the chisel end of peg wood to stop them flying and a cheap oiler to get under the spring end. Using a tweezers on both ends at the same time to compress can apparently break them. They have a tendency to be old, so are prone to breaking anyway. I bought a small number of Raketa watches for parts after breaking a couple. I believe I saw a suggestion as well of leaving them in place, cleaning the movement as normal, then oiling with an automatic oiler or oil the chaton with a standard oiler and push the oil through with a hair from the back of your hand, or a special tool for the job. Good luck1 point

-

I would suggest a fine pair of tweezers. Put the points of the tweezers in the two angles on the shock spring and squeeze to get the spring to come away from the gap it is sitting in. I suggest the tab is to assist when putting the spring back in. Again, squeeze the two angles toward each other and with a second set, push the tab into the gap in the movement and then work the rest of the spring in. What size are we looking at? Diameter? I would expect it to be potentially quite fragile as well. I'd be trying to remove it inside a bag. The potential for this to go flying off into the wild blue yonder would be very high.1 point

-

I think you're best getting the old mainspring out and then deciding if it's useable. If not you've 2 option 1) New Mainspring that can be just inserted without a winder 2) Barrel Complete (which isn't much dearer than the GR2377X mainspring). If you're going to be working on the likes of the 7S26 then try looking for a Bergeon Left Handed No6 winder.1 point

-

Thank you Spectre6000, for all your help and your work. After doing some (more) googling myself its now clear to me that even a very small space heater would be consuming 0.5 kWh. The power density of even the most advanced springs lies in the order of 8 kJ/kg (gravitic energy density) meaning a weigth of 10 kg spring would harbor about 80 kJ = 0.02 kWh. In conclusion, for building an off-grid space heater i'll really need a more energy-dense power source than springs. Thank you again for setting me straight on this!1 point

-

Yes. In a binary true/false sense, this is 100% possible. It's far from practical though. In a pure energy transmission context, you're not wrong. However, you seem to be neglecting the energy requirements and source thereof. Energy has to come from somewhere. In a clock, that's a spring (typically, and for the sake of simplicity in this context). The energy from the spring is passed through the gear train to oscillate the balance, and en route turns hands to indicate the passage of time. If you have additional complications, a chronograph say, you have to increase the strength of the spring to accommodate the additional work being done moving additional hands or dials or what have you. In this instance, the complication is heat generation. You need a commensurate increase in spring strength. Heat energy is pretty intense, and the energy used to power a clock is, by comparison, infinitesimal. The oven will operate in terms of kilowatt hours (typically 2-3 kWh/hr according to google), where the watch spring will be measured in microjoules; 1 kWh = 3,600,000,000,000 uJ. A quick google says the mainspring in a 2824-2 (an extremely common modern movement) stores 33,000 uJ. By the time you got a spring significant enough (at least 8 orders of magnitude) to make a dent in the heat generation requirements of a stove, it wouldn't be in any way recognizable as a clock (edit: actually, the 2824-2 is a watch movement. I do watches, not clocks, and those are the terms I think/operate in. A clock spring would be bigger/stronger, but not meaningfully so in this context, and I'm not going to go back through and redo the math for this sort of thing). The spring would be easily the size of a small car, and winding it would either take massive mechanical reduction or massive force from the winder. So let's say you did it. You set up a watch with all the gear reduction in the world to some sort of heat generation device. You wind the watch up and... The full wind of a 2824-2 mainspring will get you an increase of .008°C in 1 mL of water. Extrapolate that to a turkey (Thanksgiving is tomorrow in the US). Say a fairly average 15 1/2 lb turkey, which we'll round to 7 kg for simplicity, is 70% water (ignore the rest for these purposes), and you want to raise the temperature from 20°C to 70°C. You've got 7,000 grams X 50°C / .008°C per wind of the mainspring. If you could wind the spring fast enough to keep it in continuous motion, and it wasn't also powering the clockworks (which would use all the stored energy in addition to slowing its release beyond the point of the turkey's decomposition; assuming a 36 hour wind down time for the watch, and all of the energy goes to heat generation instead of clockworks, that's 103,561,644 years), and could release the energy of the spring extremely quickly and without any internal friction, you'd have to wind the mainspring 43,750,000 times to cook your turkey. More googling says to expect 13 minutes per pound of turkey, so you'd be winding your spring 3,365,385 times per minute, or 56,090 times per second. A mainspring barrel typically holds something like 5 full revolutions (I'm picturing a Maltese cross whatever it's called limiting device), so you're looking at 16,826,923 RPM just on the winding side. Double that since you ALSO have to unwind to release the energy... Never mind that the spring would explode, I honestly can't think of anything that's running 34 million RPM for any length of time... In summary, it's POSSIBLE, just not practical, and probably not feasible.1 point

-

if you go searching for something like the term above in case ranch you will find something like this it's one of the interesting problems of watch companies there are lots and lots and lots of variations of stuff including how back's on. It's like the picture above of all the various case wrenches typically if you require old watchmakers stuff you'll end up with a huge supply of those it typically you'll never use almost because it was a limited for one company and that was the end of it. the alternative to using the wrench on the case back itself is epoxy a large nut to the back and unscrew that. Although the word unscrew is not quite appropriate as it only needs to move a little bit the free the tabs. Then the epoxy is really easy to get off you just dropped the thing of boiling water and usually not that much pressure is required and I will pop off. That's also really nice way of removing glass crystals and have been epoxy into watch cases is you just boil them and they will just push out. Then the other probably may be facing is that a lot of times the gaskets disintegrate and become super sticky like glue which is one of the reasons you may be requiring so much forced unscrew it1 point

-

I think we would need some more operating parameters to really properly answer your question. So for instance how much power does the stove that you would like to power consume and then we can work with this and work out how to generate the power.1 point

-

I have a full set of those Chinese winders and none of them fit a 7S26. A better bet is this other Chinese design. 1Pcs Watch Mainspring Winding Winder for ETA Movement 3135 2836 2824 2892 46941 7750 2824-2 NH35 7120 2000-1 8200 8205 2671 8500 https://a.aliexpress.com/_mPVysEr The NH35 model also works for the 7S26 and many other Seiko movements. It's much easier to get the spring on the winding arbor and to release the spring from the arbor after winding.1 point

-

You're going to need to produce a lot of energy to power a stove with any real heat so that is one big clockwork generator. Energy is not free as such, besides harnessing what the planet can provide.....Tesla suggested it...if it can self produce we certainly dont have access to it.....yet ..........in which case who's going to wind up this massive clock ? That would be a chemical to kinetic to thermal energy conversion. Intersting idea that my old boss once put to me....a clockwork generator to power a house. I think you're better to invest in letting nature produce your free energy....wind turbine ?1 point

-

1 point

-

well those are all nice suggestion but, there is no plastic movement holder for this model. Rather it is a front loader and has a dial ring the fits between the dial and crystal. This hold the assembly in place.1 point

-

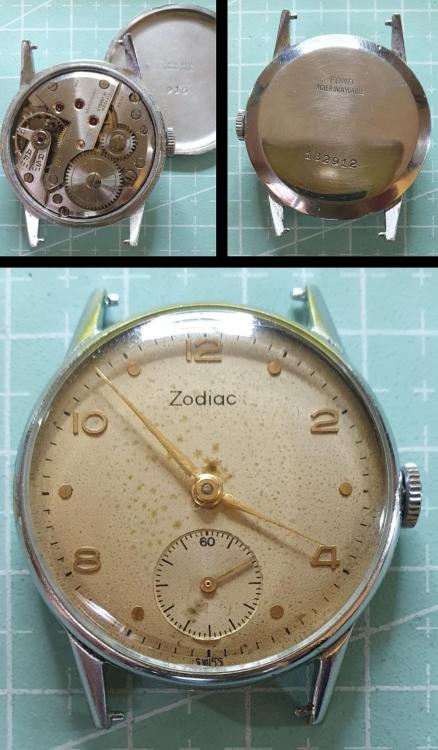

Another contender: So here we have a 1950's Zodiac with the FHF 26 movement. Purchased for £10 buy it now, on arrival, as you can see, condition not too bad, there is some of the chrome plating coming away from the case. Movement was running, but somewhat reluctantly. Full strip down and clean, mainly just dried oil with a few hairs thrown in. There is quite substantial wear on the movement plate in the stem/clutch area, so not much I could do about that. Some fun and games with the hairspring, my fault, managed to slip and distort the spring whilst addressing beat error, but managed to recover from that. Like mbwatch's watch, I was surprised with the amplitude on this one at 290. So nothing spent on the movement and case, everything was usable, however, I don't think the hour hand is correct, doesn't match and a bit too long for my liking, but as it's a £10 watch, I can live with it. What I did have to order was female spring bars, not had any dealings with these previously. It's a small watch from the period and the lug width is 16mm, so ordered 16mm female spring bars. Wrong, I needed 14mm in order to get past the pins on the lugs. Cousins no longer stock these and elsewhere ridiculously expensive, so took apart the 16mm ones, ground down the tube to required length and re- assembled with the help of the staking set to round the ends back over.1 point

-

1 point

-

Make an ultrasonic lid to hold your solution containers....it gets them out of the mesh basket and floating in the bath.....the cavitations dont need to wriggle their way through it. This little set up is great if you just want to quick clean half a dozen or so parts . Beans tins with cousins plastic and mesh basket for full movement cleans the over motor slowly rotates anything from one revolution to around 20 per minute. Yaa I've considered the marine ply will probably deteriorate in time with condensation over the water tank, i thought about yacht varnishing it......I mean boats last for a long...... long time in water . But then i realised that I really could not be arsed, when the ply is dead I'll make another lid from pvc.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)