Leaderboard

Popular Content

Showing content with the highest reputation on 11/30/24 in all areas

-

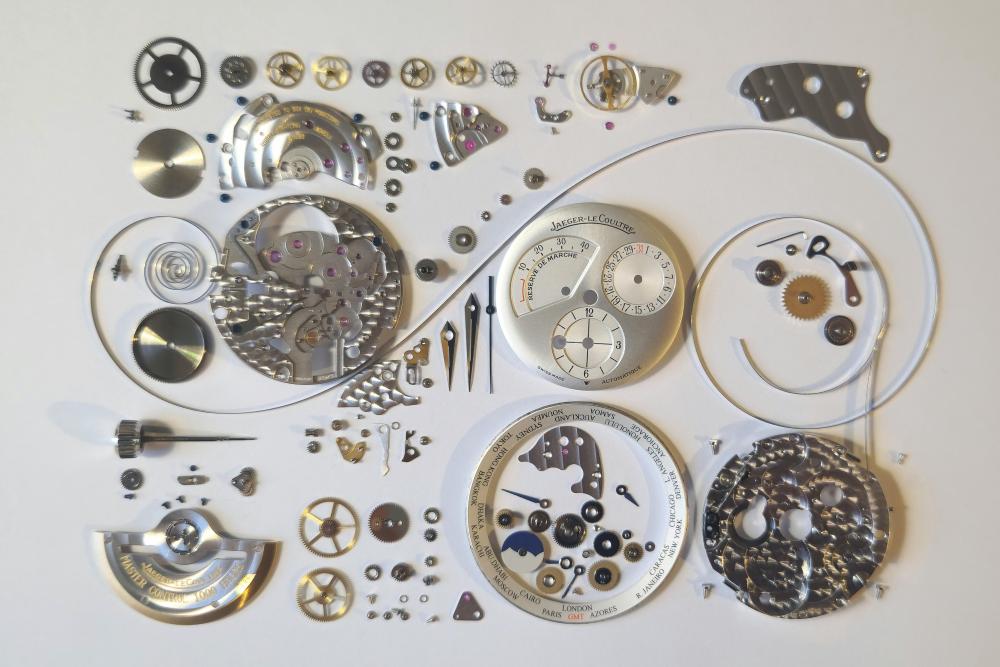

When you start putting things back together, begin with a check of the barrel assembly before putting the gear train in. This is where amplitude originates, pop the lid off and see that the mainspring is properly seated and has some light lubrication. If the mainspring is tied up inside the barrel from incorrect sizing then the balance is never going to receive enough energy to run with a decent amplitude. When you are happy with the mainspring's ability to provide enough power then inspect the end and side shakes of the barrel arbor in the barrel itself and between the plate and barrel bridge. Please yourself that the barrel can operate with free motion within the movement without rubbing anywhere. When you're happy with all this then progress to the installation of the train, checking, pivots, pivot bearings, wheel teeth for damage, end and sideshakes, wheel and pinion meshing as you go, and finishing with the free motion check of the entire train up to pallet fork....looking for exhibits of friction. If all is good...a good sign will be the escapewheel giving a few seconds of backspin.....install the crown and winding works to give you a better feel of the energy you are winding in...no pushing the barrel .4 points

-

My grandaughter that just got married has a musical rotating porcelain bear in a clown suit that had seen better days. It plays a short part of 'Send in the Clowns'. To wind it, it should have been lifted up and the plastic base that attached to the winding arbor of the music box turned to wind it up and then ireplace it on its base to rotate while it played. What had been done is people had pushed down on the bear while it was sitting on a bedside table etc to wind it. The result of that is the base centre that attached to the winding arbor had completely broken out of the base and the cover of the mainspring barrel on the music box had completely broken from the pressure of winding. All the bits were there so I took it apart as much as I could as it is riveted together so cleaning was going to be difficult. I put all the parts of the music box into the ultrasonic cleaner which has done a great job of cleaning it. I was able ro remove the mainspring which was quite set. I spent some time running the spring over a piece of round in my vice. I was able to increase the diameter of the spring and finally got some of the coils to come away from others. Allow had to fiddle around with the centre coil as it was not grabbing the arbor very well. Lubricated the mainspring and wound it back in by hand. Then worked out a way to clamp the broken part of the cover to the main part and used some 5 minute Araldite to glue the cover as well as the plastic base. Got that done before I went into hospital so the part stayed clamped for about 3 days before I took the clamp off. I should have taken more photos, but I want to get it done and sent back to Sydney before Bec & Jarryd's baby grows up. I have to make a new wooden cover that the music box is screwed to which is in turn glued to the porcelain. Hopefully get the base cut and drilled tomorrow and get it all back together. The click for the mainspring is a molded plastic setup on the arbor underneath the mainspring in its barrel. Nothing I could do with it after the damage sustained from the incorrect winding. It still works, but I will be telling Bec that if it fails again, it'll be unrepairable. I'll take some phots of it all tomorrow. Ok. It's not a clock, but principles are the same. Hey, I'm working my way up to a clock. It'll be my grandmothers Hettich first as that has been in bits for years now. A bit embarrassing really.3 points

-

With ultrasonic cleaning, you want the minimum time which gets everything clean. I cut down the times I use to 4 mins clean, 2 mins for each rinse. I've found it's enough to get things really clean. Documentation for Elma WF Pro cleaner says use for "2-10mins", and Suprol Rinse "about 3 mins".2 points

-

2 points

-

1 point

-

Can we have more details here please, like what parts did you run through ? and what solutions did you use ? Absolutely, there's something about using ultra light tweezers that makes your touch softer. They scratch no more than brass and are tougher, no worry over magnetism.1 point

-

1 point

-

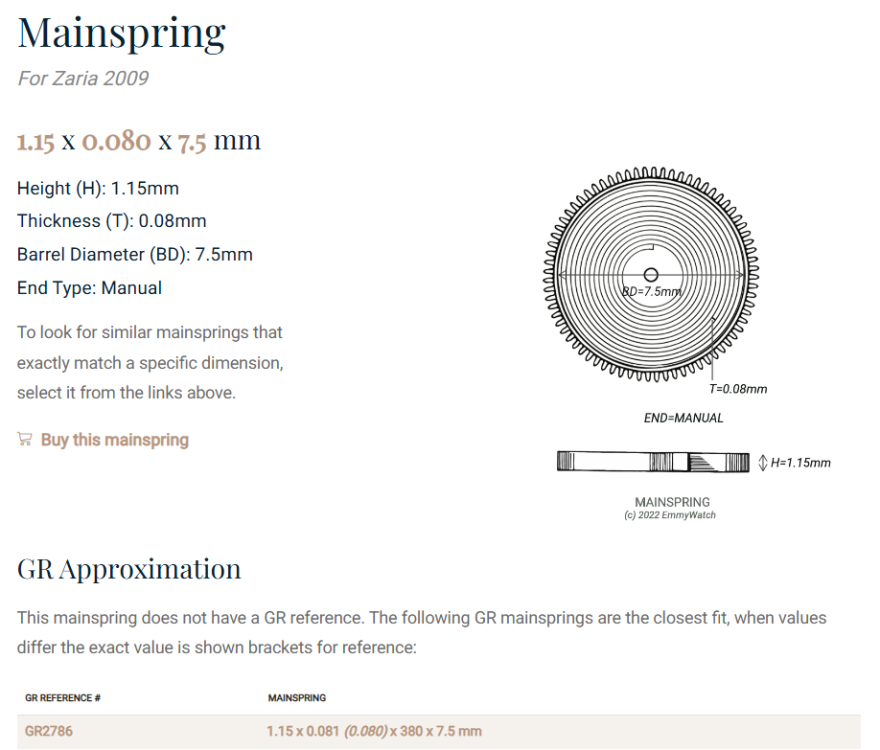

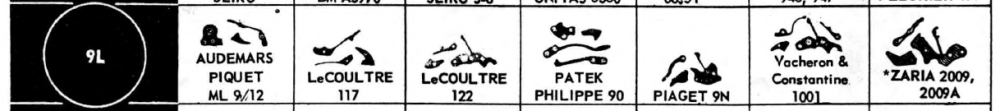

Zaria 2009B is completely different movement, it is released 20 years later than 2009. The problem is that I have never seen data about russian movements springs, and even have no such movements to measure the spring. But I will ask in the russian forum, probably will get answer. I used to repair such watches but it was before 35-40 years, so I have only pail memories. http://forum.watch.ru/showthread.php?p=7113015#post71130151 point

-

From the brands you listed, if you put new movements in, I would be surprised if you could make a profit, or break even. Not if you make a statement in the advert that the watch may not have the correct movement.1 point

-

Keeping the crown turned adds more power to the clockwise unwinding of the mainspring resulting in increasing the amplitude, which you noticed.1 point

-

Got enough watches there? A bucket of dead Ruskies like that requires an explanation. Be careful! Those are Australian spiders! The internet says they can fly, and kill you with a glance!1 point

-

Trying getting some titanium tweezers.1 point

-

Plastic tweezers are not fine enough. You need to demagnetise your metal tweezers. Get a cheap demagnetiser. Make sure all jewels and pivots are spotless and not damaged. Check end shakes - especially side and endshake on the top of the barrel arbor. It's common for wear allowing the barrel to touch a plate or wheel losing lots of ampitude.1 point

-

I have an old Seiko AGS watch, which I inherited from my father. This was the precursor to Kinetic watches. It uses a gold capacitor to store electrical energy, unlike modern kinetic watches that use a rechargeable lithium battery. The downside is that a gold capacitor only stores enough energy for about 48 hours. I'm not sure if the generator of my watch is wirking properly but the movement from normal everyday activities is not enough to keep the capacitor charged up. Regular automatic watch winders just don't have enough speed to wind a Seiko Kinetic watch. A special charger for the Seiko Kinetic on eBay costs around $350. I wasn't going to spend that kind of money just for charging Kinetic watches. I managed to use a wireless charger from an old electric toothbrush for charging my Kinetic but it was rather fiddly. The coil of the generator had to be placed in a sweet spot over the coil of the toothbrush charger for it to work properly. If it wasn't placed properly, the watch just wouldn't charge. Then recently, I discovered that a cheap charger from AliExpress had enough kinetic energy to charge a Kinetic. The plate swings 'violently' enough to charge up the capacitor. An hour of violent swinging is enough to give the watch a full charge. So far I'm happy with this winder. It lets me enjoy my Kinetic again. A short gif to show how violent the swinging gets.1 point

-

Doesn’t sound very safe to handle without really good ventilation. From Wikipedia: Short-term exposure to high levels of hexane can cause dizziness, headache, nausea, and giddiness. Long-term exposure can cause polyneuropathy, which can lead to numbness in the extremities, muscular weakness, blurred vision, headache, and fatigue. Hexane is a toxic substance that can cause severe nerve damage.1 point

-

I put quite a bit of 8217 around the barrel wall of a 7S26C, but not paint it on and use a 0.95 x 0.115 x 380 x 10 mainspring and get this. The thing with Seiko's is there so many variables that have nothing to do with the mainspring, just because of the movement and the amount of wear in these movements. One of the biggest wear being the barrel arbor hole in the bridge or mainplate. I would look at braking grease lubrication technique, rather than looking to change your grease, but that's just me, as I've found what works for me. As they say, 'the proof is in the pudding'1 point

-

1 point

-

OK, what is important when replacing cylinder is the diameter of cylinder, overall length and the height of the mouth. Diameter of course can be judged by the hole of the old balance - the new one must fit there tight. But, if You replace the balance completely, then You need to check 2 more things of greatest importance: one is that the outside cylinder diameter is small enough to get free between wheel teeth, and the other is that cylinder inside diameter is big enough that the tooth can get in with small free play. Of course, if You movement works flawless, then all this for sure is fulfilled. 2 min/day is not much. For replacing the entire balance from different unknown caliber, this is rather perfect match. Of course, the movement needs to be adjusted as the regulator to be able to make movement slower as well as faster than 0 sec/day. In You case, You can check if it is possible to decrease the depth (the distance between cylinder and the wheel) and still have enough drop lock. This will make the movement faster enough. If the depth can not be reduced without loosing the drop lock, then You always can shorten the hairspring to make the movement faster. If You have moebius 8200, then wash the wheel and the balance and apply just a little grease on the cylinder surfaces where the teeth touch. Then compare the amplitude.1 point

-

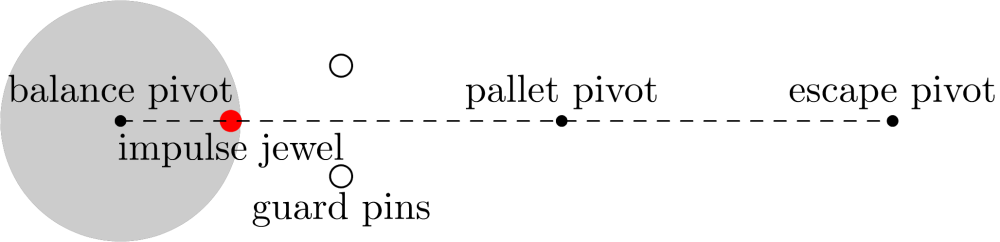

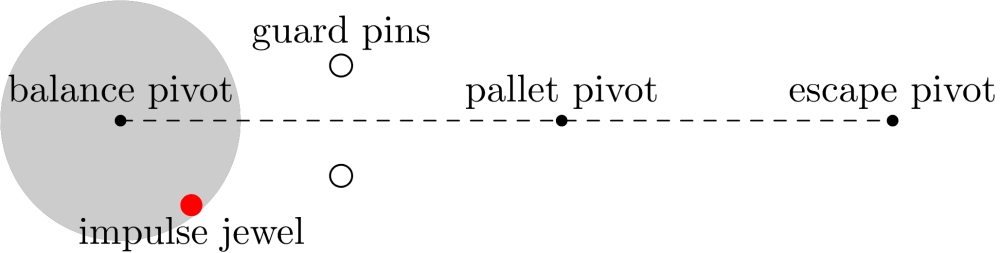

As @caseback pointed out, the stud carrier is way out. The impulse jewel should come to rest on the line that joins the pivots of the escape wheel, the pallet fork and the balance wheel, and that line should run right through the middle of the two guard pins. Something like this: From your diagram yours looks to be more like this: To fix this you should gently turn the stud carrier anticlockwise towards the balance cock with the balance installed, until the jewel comes to rest on the correct line.1 point

-

https://youtu.be/YF-Rf1Cxx94?si=9uXa39qyiRBCHv1O I came across this some time ago, it's very old and the quality isn't great but it's certainly watchable. It's also quite long and I hadn't intended to watch it all, but I found the whole process fascinating and saw it through. Apologies though, I can't seem to inbed the video ftom youtube, says youtube won't allow it. I'll submit this post anyway, might be a case of copy and paste the above link.1 point

-

I don't see this video in the topic's past history to my surprise. Watching George Daniels work and listening to him philosophize is completely fascinating. Watching Daniels handle a fine handmade tourbillon and silver engine-turned dial without any finger coverings and quickly mash the minute hand onto his masterpiece with the back of his tweezers makes me dizzy. (Hoping to prove the timekeeping superiority of a mechanical watch over an electronic one was a lofty goal)1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)