Leaderboard

Popular Content

Showing content with the highest reputation on 12/02/24 in all areas

-

3 points

-

Instead of solder chips, try using low fusing solder paste. Although I have a similar carbon rod soldering machine, I prefer to use a microtorch to do dial feet soldering. From my experience, brass wire and brass dial feet do not work. It has to be copper for good heat conduction. I use a 0.8mm copper wire as my dial feet. Some downward pressure on the copper wire must be applied so that there is good contact for heat to conduct to the brass dial. Heat the wire about 1.0cm above the dial surface and let the heat travel down the copper wire and melt the solder paste. The heat will conduct down to the dial and solder will flow. All this happens quite quickly, so watch carefully. Practice on some old dials first, for you are definitely going to scorch a few dials before you get the hang of it.3 points

-

I have half a dozen versions of this tool with different centers and have used them for pulling both rollers and hands. The one with the through hole with the adjacent hole i use for roller removing , the staff pivot can run through and if breaks can be cleared out. Personally i prefer this for removing the roller table, the jaws need to be kept free of damage .3 points

-

I use my heaviest tweezers all the time, carefully. And I have not had a problem with a bent arbor or seconds pinion or broken center wheel jewel. I do know that these are possible bad outcomes, but again I am slow and careful to pull straight up. The one exception to this was a brand new ST36 movement which had such a tight cannon pinion that I ended up having to use hand levers - tweezers were not strong enough. Some particular youtube guys make a Really Big Deal of the cannon pinion removal tool, but it is a luxury you can get on without for a long time. In truth, breaking a center wheel jewel is probably the thing that would go wrong most readily when pulling a cannon pinion with tweezers. Maybe on a chronograph with a very long 4th wheel pivot it would be easy to bend if you don't pull straight.3 points

-

The Bergeon is fairly useless, I'm not really sure how they sell them. The design is based on an American design, and those work just great. I pull tiny cannon pinions on the smallest LeCoultre and Patek movements with them, as well as big honkin cannon pinions on pocket watches. The original brand was "M-C"; that is stamped into the lever along with "Pat. 2271945". Looks just like the Bergeon, except it actually works.2 points

-

The vintage ones are pretty much that magic wand Bill, these days though you’ll likely be paying well over £100 to get one! Tom2 points

-

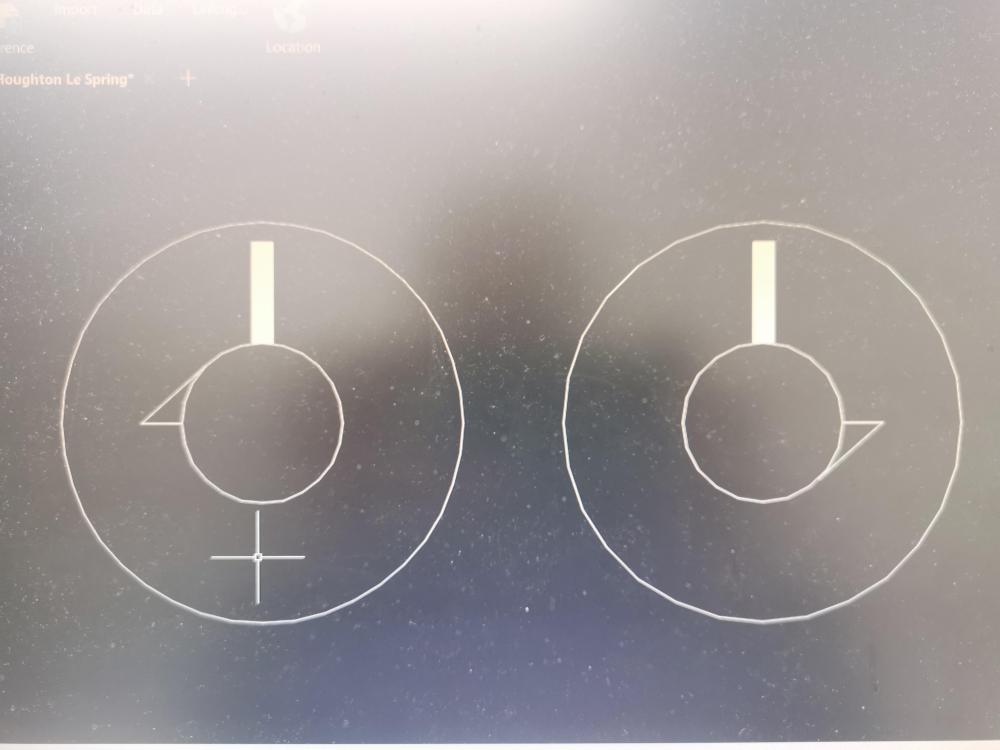

OK so yes the operating lever for the date is on the left hand side and with the day finger up your date finger is to the right so 180Deg out. The only thing that confuses me now if the date lever looks like it would operate with the finger rotating clockwise, not anti clockwise as it is. Edit Just knocked this up on the Cad with mine being the left and yours the right with the Day finger at 12 and on the front. Double Edit God I must clean that screen tomorrow.2 points

-

2 points

-

If you’re wanting to work on wristwatches the Burgeon 4854 is not really useful as it cannot grip below 1mm. The presto tool will work fine, for the copies we unfortunately get back to varying quality at the £10 end of the market. Certain types of tweezers can be used and often are, I have also heard of pin vices being used but have not tried that. Tom2 points

-

2 points

-

I use an ancient Burgeon tool passed down to me from my dad. I have since acquired several more by accident (maybe I bought one on ebay...cannot remember). In all my use, never had a failure. So, I love the tool. But, I am an amateur. Update: the two that I can lay my hands on right now, are both marked M.C. as noted by @nickelsilver. I have another somewhere...???1 point

-

1 point

-

it looks like word of the Chinese machine has spread to cousins as they have one for sale. Also early English or two separate English manuals are available and a video. Visually the machine looks beautiful video is interesting I would be curious about exactly how the ultrasonic works as it's a bit vague. Along with apparently things can be programmed for the ultrasonic but even the manual although I was really excited when I saw it and didn't have time to read the fine print so maybe it's in the fine print like the various frequencies etc. But no matter what the price totally beats out everybody else if you want a fully automatic machine. https://www.cousinsuk.com/product/biao-jiang-watch-cleaning-machine1 point

-

Unfortunately dial size is not the only parameter you have to take into consideration. Depth of movement, Depth of the stem etc. Your best bet is to find a donor, with a decent case but broken movement. Modern cases are available but probably not for your movement.1 point

-

1 point

-

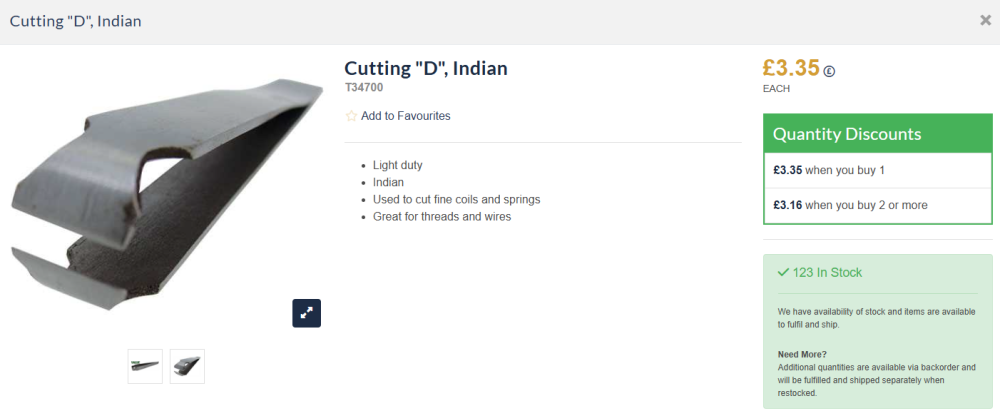

How do you go about maintaining yours? I have both the Indian copy of this tool and the real Bergeon/Bradux and every time I use either of them the blades get further chewed up. I've used them on pocket watch roller tables. Eventually I bought good staking tool accessories for roller removal and have not gone back to this type.1 point

-

From this photo's vantage point it becomes clear these are basically nail clippers without the thumb lever. So I might also experiment with the same blunted clippers I already use as cannon pinion tighteners!1 point

-

1 point

-

I haven't messed with one of these machines very much, but I agree with Hector, copper is the way to go for the feet. I tried German silver and brass, both terrible, while copper was almost a guarantee of success.1 point

-

I have only ever used my standard tweezers. Just be sure to pull straight up.1 point

-

It does take practice and care. To do it with levers, they have to be thin but sturdy and still you need to be cautious to apply the same pressure from both sides. Most of the time with vintage watches, the cannon pinions will tend to be worn inside such that they are not holding on very tightly. Tweezers are easy on those. New movements with brand new or newly tightened cannon pinions can be more difficult with tweezers.1 point

-

I would say its middle 1850's going by the style of the wheel collets and the thickness of the plates.1 point

-

Its for pulling watch hands off. The center piece which is adjustable presses on the top of the cannon pinion. The two side pieces fit under the hands and by turning the adjuster at the end it will pull the hands off. I had this very tool in my workshop.1 point

-

That looks like a cannon pinion that has perhaps cracked and been repaired by sleeving it. I think they made a tube that fits between the pinion and the upper seat for the minute hand; no way to adjust it now. A new CP should be easy to source.1 point

-

That looks odd. All the pics I've seen of a 7040 show a 'normal' pinion with indents. It looks like it should pull apart1 point

-

Hello nameless 1st time poster, is this a promotion for your mentioned link?? I am afraid, steel technology for use in watches is far beyond your imagination for many decades already. Frank1 point

-

1 point

-

1 point

-

It was an original 'Nivaflex' spring from Gleave and Co. which I don't think they sell that anymore and instead the GR spring. I fit a lot of mainsprings. One thing I came to realise from experience and seeing the results of those mainsprings is, you can get information about the size of the mainspring from several good sources and they may all give the dimensions as slightly different. One source I generally look at first is the GR catalogue, but I can find that a spring is either too strong or clearly too weak for that movement, even though the catalogue says it is correct. I may have to go up or down one strength. Now, I would start to think it was the wear of the movement, etc. for me to up the strength of the spring, but most of the time it is having to come down in strength to stop the knocking (re-banking). I've found this to be the case with some vintage JLC's, Tudor and a Rolex 1200, so maybe it's the makers of the mainsprings that make them slightly stronger or weaker, even though the pack says the correct size.1 point

-

Just looked at the photos and the first thing you need to do is get rid of that terrible wire which is strangled and kinked. You will need to take the movement apart in order to do this. It originally had a chain as I can see the marks of a chain on the barrel. That wire will also leave terrible marks on the barrel and on the fusee. Replace with synthetic gut or better still coated wire with nylon.1 point

-

Welcome to the forum If the ring overlaps then it looks like you've got the wrong crystal. I presume the ring is from the original crystal so how does the new crystal fit in the case without the ring? Details on the case and what crystal you've bought would help.1 point

-

1 point

-

Hi here’s few pics, I know that the wire on the fusee barrel should be straight and aligned -it’s almost impossible to keep it on the barrel-I was hoping it would sit better when it ran when I got the clock the wire was loose and all over the barrels -not wrapped. When I wind the mainspring barrel the wire is tight between the two ready for the spring to slowly pull the wire over-but it doesn’t move. The fusee barrel appears to be stuck-it will wind the wire up but won’t rotate the other direction to allow the main spring barrel to pull it. Apologies for the poor description A little bit about the clock for those that haven’t seen one before.. The pic is of the clock without its glass hood-it looks nicer than that . It’s a Congreve rolling ball clock. The ball rolls from one side of the platform to the other every 15seconds instead of a pendulum. It hits a lever which then tips the platform to allow the ball to roll in the opposite direction. They are notoriously difficult to set up and don’t keep good time it has lots of little weights and rods to adjust the levers and platform, and a little spirit level at the front as it has to be completely flat to work. It’s a lovely item-I just wish I could get it to work!! Sorry-there’s more.. The clock doesn’t have a click spring to keep it in place and the main spring is about 2”” wide-the ratchet whelk also doesn’t have anything to keep it in place. I’ma little nervous about completely winding it as all of that power will be on the-not great click and it’s screw1 point

-

Just to close this thread, I got the book so happy days, a little disappointing as it doesn't have the expected drawings of the workings I was expecting to help me with my clcok0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)