Leaderboard

Popular Content

Showing content with the highest reputation on 12/03/24 in Posts

-

I recently paid US$85 for a vintage tool from eBay before which I was using a pair of hand levers that I had thinned the ends of on a stone. It's much easier to be confident it's coming straight off with the right tool. I tried with tweezers but never felt I was properly in control of the process. Maybe I don't have the right tweezers.3 points

-

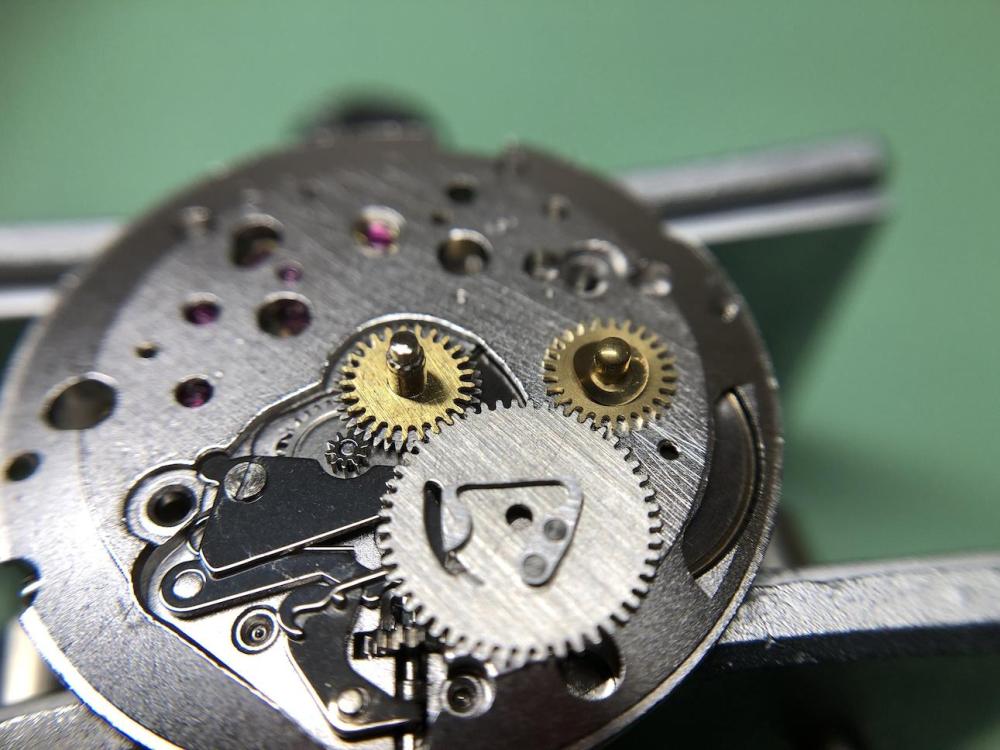

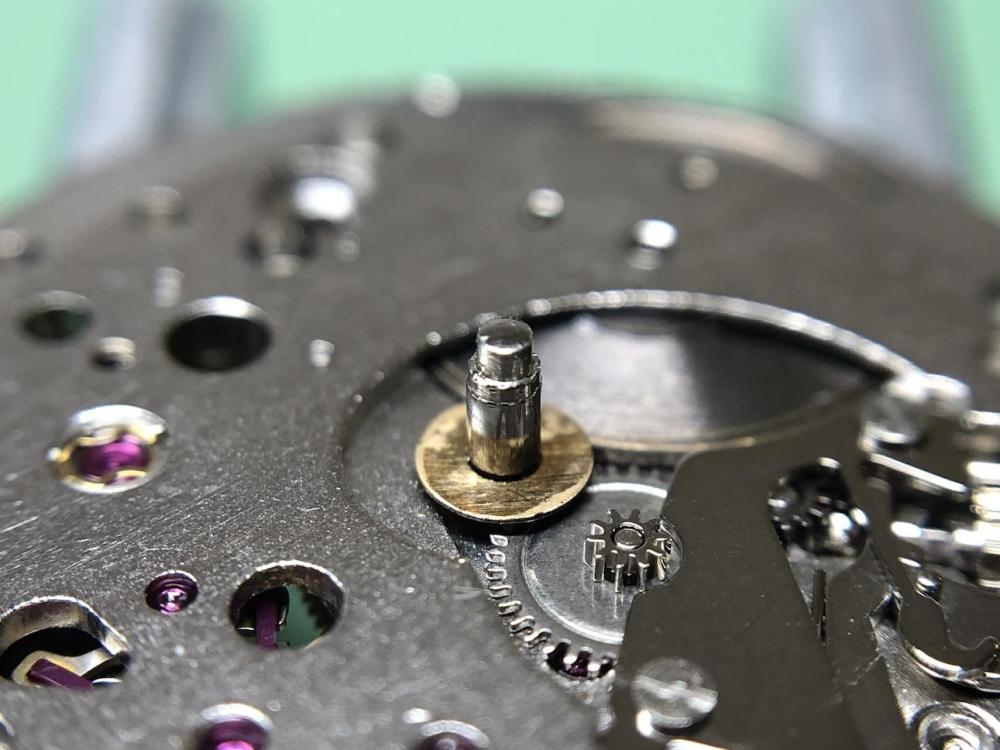

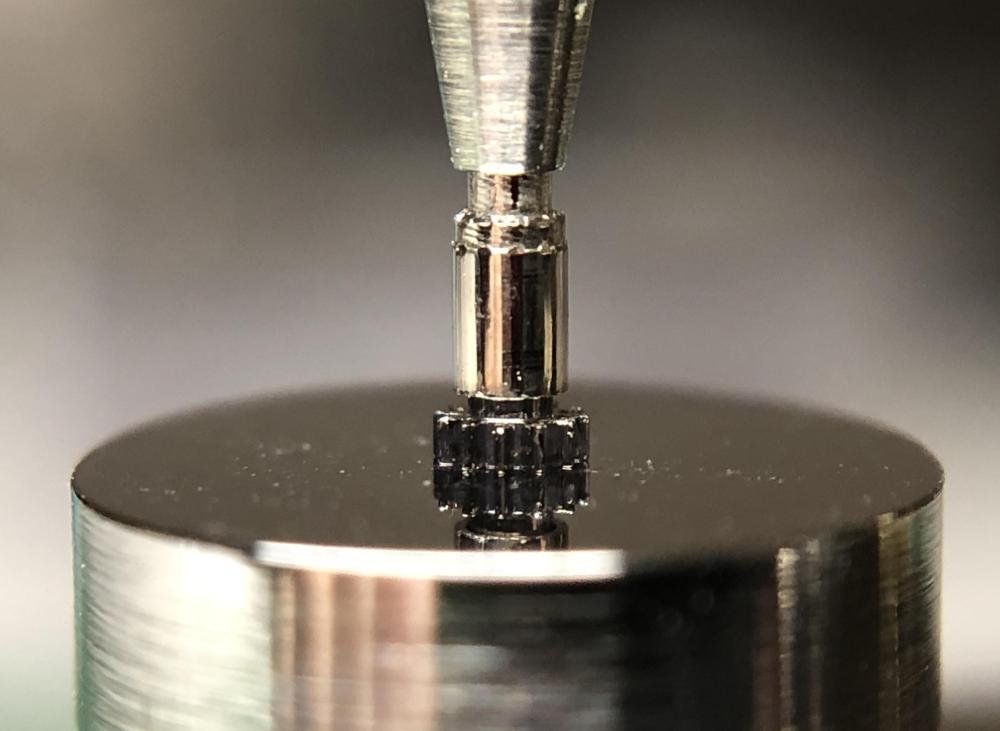

You were absolutely right, so thank you very much! The manufacturer needed to make the CP thicker to accommodate the gear that drives the hour hand and date hand on this regulator watch. I managed to split the tube and the CP by prying with hand levers, at least a bit. Then I attached the tube to a vice and pulled the tube off by holding the CP with brass tweezers. Then, it was just to adjust the CP's friction as usual, which in itself can be quite difficult. The friction got an ounce too big, but that's better than the CP not rotating or rotating only sporadically, as in my case. At some point, I'll try to reduce the CP friction in the way @nickelsilver described in this post . To reattach the tube to the CP, I used my staking set and a concave punch. I almost managed to get the tube on by hand alone, but to get the tube down the last little bit I tapped very gently with a brass hammer. I kept a small gap between the tube and the CP because it looked like that when I pulled the tube off, but also because there is a washer against the CP that I assume should fit in the gap (without really understanding why it would be needed or if it was intended). After this, it was just a matter of reassembling the parts and the watch is now sitting on my wrist doing its thing, ticking away to Christmas day.3 points

-

There is also the method of putting the cannon pinion in a pin vise and pulling it off. But a vintage cannon pinion puller still works best.3 points

-

To others that are looking at this and wondering if its worth the effort, only you can answer that question. But, I have written some basic code to build one of these machines, for fairly cheap, with a stepper motor, driver, and an arduino. Whole thing can be built for around $100-150. I can start a new thread if interested. The plus side, is it can be expanded and updated to whatever you might like it to do. Right now, I have it set up to have 3 buttons, one for starting the cleaning, one for a spin cycle, and one for a drying cycle. I am working on adding a linear Z-axis, so that the cleaning and spinning are automated. Eventually, ill have a turntable axis as well, so all the cycles can be completed with the push of 1 button.2 points

-

I just tried one using some of these cutters. I didn't even blunt them, just held gently. They work well. I assume everyone does as I do, and just push crown pinions back on with tweezers, and not use a staking set? If so, what's wrong with using tweezers to pull them off?2 points

-

I ordered one of those years ago when I was new to this, and you're right, it's pretty useless. I even got Cousins to refund me and that tells how useless it is. Eventually, I got myself an old "M-C" and it works like a charm. It never fails me and I love that tool. Hand levers seem like a good idea. Why don't we use them more often?2 points

-

Presto tool works well. And it’s useful for getting hands off too. I almost got a specific Bergeon cannon pinion removal tool but decided it was unnecessary.2 points

-

It's probably why the machine is so much cheaper than the Swiss were the knob is already attached. In other words it's a cost savings feature.2 points

-

This method works for me too, I can get the cannon pinion off most Omega pocket watches easily, But it can't get the cannon pinion off a brand new st36 for me.2 points

-

That is to give you the sense of accomplishment that you had a part in the build of the machine.2 points

-

There will be more, don't see is as a ... you missed out ....but as a potential.....lucky escape. If it was meant to be then you would have got it, everything happens for a reason. There'll be more coming your way for sure.1 point

-

1 point

-

1 point

-

1 point

-

Hi transporter, I picked up 3 weights with chains and a pendulum on eBay and now have the movement working on my test stand, it seems to be running well, so fingers crossed. I bought a cheap music box on eBay, and swapped the prongs over, it works, but it isn't great so I bought a second one which should arrive later this week, this one looks closer to the original so hoping it will be a bit more tuneful. I bought the paper to repair the bellows, which looks simple enough so that's my next job when it arrives. I also found a back with the gong attached which I had to modify slightly but that now fits. It has been an interesting project so far. The wooden case needs some TLC, its covered in paint splashes which I have tried to remove but I think I am going to have to repaint at least some of it, it looks like a chocolate brown matt emulsion so I thought I might buy some tester pots to see if I can find a match.1 point

-

It was the cannon pinion. Further testing I realised that there was very little resistance when hand setting, so I swapped it for one from another Landeron 48 I’m working on. And now it seems to be keeping time, no slipping.1 point

-

That looks like a modern plastic replacement level as can be bought on amazon (exactly like the one I have mounted on my Bergeon/Vigor poising tool)1 point

-

https://archive.org/details/watchmakerslathe00good and The Modern Watchmakers Lathe And How To Use It Hardcover – January 1, 2003 by Archie B. Perkins (Author)1 point

-

Could you recommend a good site for watch makers lathes? I have no idea what you are talking about, hehe. Joking apart, I know the basics but would like to learn more.1 point

-

@SwissSeiko that sounds really interesting, would love to see the design and it working Tom1 point

-

Interesting! That's the fun in buying a used watchmakers lathe. Trying to figure out what the last guy was thinking in his tool making adventures. I'm sure when my kid sells my stuff, the next guy will have so many questions.1 point

-

My suggestion would be to rewire from scratch. You're best just using 3 core mains flex and then use this type of connector in the base. https://www.amazon.co.uk/lever-splice-connector-221-413-terminal/dp/B0744BG6FR?crid=Z9OCYHATWX61&dib=eyJ2IjoiMSJ9.li-z2OlSrWEmL8WFRdSZWq51-SCkLY1U3s5NZfnMDRJPeu9A7tKHPvNBLEID1ZzWlHlkf-tqangnjIfvxKs3tg4u0ayjqdLJce2-_eKE87GzWqSZBvPe6a1TkuiZ9PqW41Fqk6hKZ8NazXdPw776_9iFPBTvXo68wo10yPOu9fzElkfEoKnwLOEqGhTK9QvAID8sD_d8lmFld2XZ2Tc5rJapCJUP9T6d3jtADR5YigtvLjd3Uvyf1jkkdYbIPTCPtuJ5VoQjtPuvoNl-ceUS3HcIYX-ATiSEd8BjjvRFkm0.pvOGRr6_3pv6r-zhPl_EwgntlIkZIye-e2egc4UWHQw&dib_tag=se&keywords=wago+connectors&nsdOptOutParam=true&qid=1733241483&sprefix=wago+connectors%2Caps%2C119&sr=8-7 I'll see if I can knock up a bit of a sketch but not sure where you'll be able to connect the earths?1 point

-

1 point

-

Ha....Just figured out what the notches in my lathe rest are for....possibly.....but what I'm using them for. Sharpening a graver with a diamond wheel in the lathe...the lathe came with a number of accessories, burrs and the like and a small diamond wheel. These bend easily when pushing the graver upto grind...the notch act as a stabiliser....not in the case I show, as the wheel is two sided . But in the case of a one sided wheel it will apply, may not be exactly on the nose but i think its on those lines with my lathe.1 point

-

JLC used thin washers under some crown/winding wheels in many movements. I think both to take wear, and to take up play. Does it logically fit under one of the winding wheels?1 point

-

Let me add that separating, cleaning and lubricating this canon pinion setup seems to be important. My movement had a binding canon pinion when I sent it to JLC for the first service. They replaced the whole setup. Years later when I did the service myself the canon had started binding again (setting the hands got stiff).1 point

-

1 point

-

I pulled one stubborn cannon pinion with some peg wood leverage1 point

-

I presume you've gone through your pictures in detail as I would expected it to still be visible and can't be many parts with that size hole in them.1 point

-

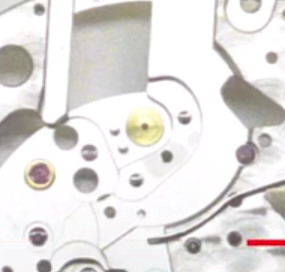

I used my Presto tool and a racor blade. The canon pinion with the small wheel is pushed from below through a suitable hole in the blade while the bigger wheel is held back by the blade. The plastic legs of the Presto tool push against the blade during disassembly (Hope my words make sense…). I just worked on the 889. No idea where the washer comes from. Here a picture of the canon pinion unit for reference:1 point

-

I have read it somewhere that the balance staffs on American pocket watches were much harder than those of Swiss watches. I'll guess mine are all dinged up from the mighty Elgin & Waltham staffs.1 point

-

1 point

-

I have 2 bradux which I seem to think is Bergeon. On both the jaws were a liitle chewed up when i got them in some joblots. No idea if they are hardened but maybe not as roller tables are soft, unless a heavy handed someone has been chopping balance staffs with then .1 point

-

I too hope to someday acquire highly sought-after tools by accident.1 point

-

Things are slightly more complicated with yours due to the domed dial so you also need to consider the lens dome and height.1 point

-

I use a presto tool that i bought on Ali years ago, very cheap and work grate to extract the canon pinion.1 point

-

I use my heaviest tweezers all the time, carefully. And I have not had a problem with a bent arbor or seconds pinion or broken center wheel jewel. I do know that these are possible bad outcomes, but again I am slow and careful to pull straight up. The one exception to this was a brand new ST36 movement which had such a tight cannon pinion that I ended up having to use hand levers - tweezers were not strong enough. Some particular youtube guys make a Really Big Deal of the cannon pinion removal tool, but it is a luxury you can get on without for a long time. In truth, breaking a center wheel jewel is probably the thing that would go wrong most readily when pulling a cannon pinion with tweezers. Maybe on a chronograph with a very long 4th wheel pivot it would be easy to bend if you don't pull straight.1 point

-

If you’re wanting to work on wristwatches the Burgeon 4854 is not really useful as it cannot grip below 1mm. The presto tool will work fine, for the copies we unfortunately get back to varying quality at the £10 end of the market. Certain types of tweezers can be used and often are, I have also heard of pin vices being used but have not tried that. Tom1 point

-

Hello nameless 1st time poster, is this a promotion for your mentioned link?? I am afraid, steel technology for use in watches is far beyond your imagination for many decades already. Frank1 point