Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/24 in Posts

-

4 points

-

I think what Andy is suggesting is that a lot of us here...a real lot....repair watches just for the love of it and the mechanical aspects of it. With a mech watch there is so much that can be achieved and knowledge gained from restoring it. Money and value doesn't exactly have a place here, in fact the opposite applies. We have age old threads here dedicated to aquiring and repairing watches bought at minimal prices. We repair and make stuff for next to nothing for the hell of it, we dont move on when some worthless trash nugget looks beyond repair, we dig in and get that sucker fixed and working again. Not many repair to sell, if so we dont state what was profitted,or ever quote the value of our collections...because...thats not why we do it...and to be honest imo it kind of disrespects what we do. No offence intended if thats your game...just mine and a lot of us...our view. It doesn't make you any less of a member if thats how you think...everyone is different, and your knowledge and contributions are just as valid and welcome. It was just the money bit like Andy said it was kinda off putting...sorry. And as for Tom's thoughts...I would compare that to...me in the 80's caked with oil and grease...in my element surrounded by tools and car parts...to me in the 2000's with the bonnet of a car up looking at sealed black boxes...scratching my head and wondering what the frig to do with a modern car. There's just not enough to keep my interest with a quartz watch, something electronic with an oscillator maybe a bit more. I always have that feeling when I start to take the back off..that in there...there is a part that I know just can't be made or fixed by just about anyone. Thats going to require a complete movement swap or just about. I dont like swapping parts at the best of times...but a full movement...noooo....to me that isn't a repair.3 points

-

I struggle to see the value in using a piece of test equipment built around a quartz crystal oscillator to measure the rate of a watch built around a quartz crystal oscillator. Unless the test equipment is calibrated and certified by an accredited measurement lab you'd have no way of knowing how much of any difference measured was from error in the watch or in the test equipment itself.3 points

-

No, beat error has nothing to do with it and is already fine. Nev already told you what happens. Amplitude is too high! Frank2 points

-

I think that is about as good an answer as we are going to get Rich and in line with what Andy said. The contributers vocabulary has it nailed. You both said " is it " you both said " not sure " and Andy threw in a " I dont think ". So " I think " that just about wraps it up for now. So upon reflecting with myself ...lets tackle this another way...Mr. OP...forget everything you know about what you've bought and seen, and imagine you are us trying to figure what you have....could you come up with a clear detailed answer with what you can see from these pictures ? No of course you can't . Come on chucklebuns give us a few clear close up images of what you're talking about and a bit more information and then we can help you in a more helpful way to getting it sorted. I'm trying , i really am . My old mum used to say to me " Richard you are very trying " . She wasn't wrong.2 points

-

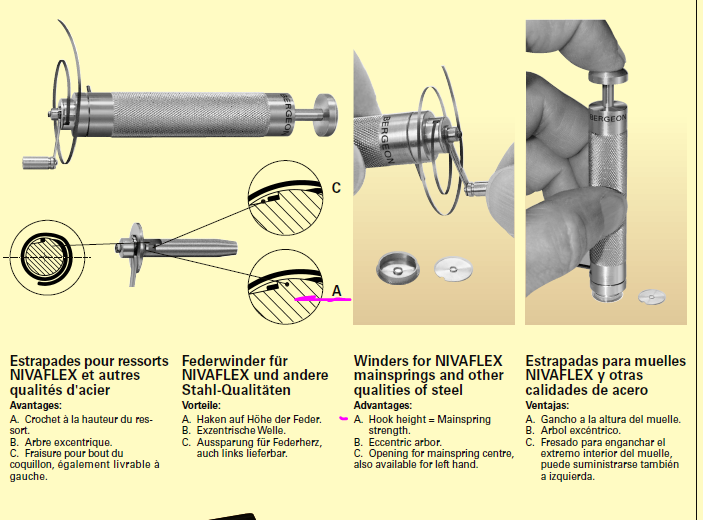

I have filed all my K&D arbor hooks down to just about the thickness of an average mainspring and have no problem getting the hook out by back winding the arbor. I didn't file the hook at an angle and it works for both left and right windings. But modern mainsprings are lower than vintage springs and I had to pound the arbor into the handle to lower the height, to reduce the amount of space between the winding handle and the mainspring, so that the spring doesn't twist and get stuck under the coils of the spring.2 points

-

Ah, the whole reason I have that set is to be able to wind either direction. In practice any time I work on a lefthand spring I either end up hand winding it, or using a trick to flip it from one of my C&E Marshall winder barrels into another before it goes into the watch barrel (rarely workable). I don't really work on vintage Seiko or Orient movements so my left wound springs are mostly in pin lever Roskopf barrels. But your directional filing gives me an idea to watch for the extra K&D arbors that are often floating around tool lots without their adjustable handles. Then I could make a right and a left.2 points

-

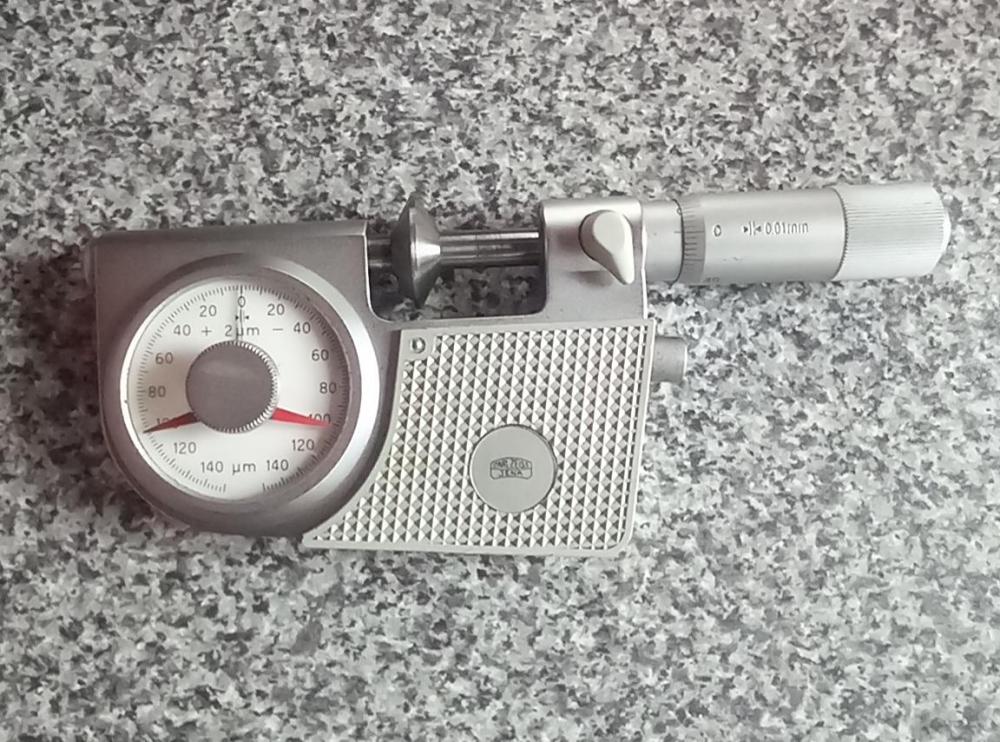

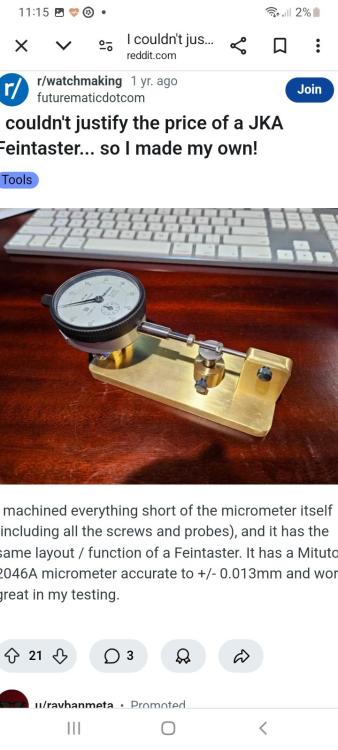

Thought I would post this up . It just came in the post this morning. As we can see a micrometer so no mystery item today, but a nice quality measuring device I picked up on Ebay, I was drawn to it, as it had a feintaster feel about it. Wether I can apply it to watches I'm not sure yet, but I could probably make a holder and a part platform for it. This will measure to single microns, so thats pretty cool, and as it is, it's right on the money with the gauge zeroing down to 1 micron. Below that is a guy thats copied a feintaster design and made his own with what looks like a dial gauge. Correction not single microns, as the dial markers increment to 2 microns, still pretty cool though2 points

-

2 points

-

This goes double for the smallest of the Omega automatics. Kalle Slaap in the video I linked above mentioned that many professional watchmakers refuse to service these, because it requires such meticulous work to ensure they run well. They are not forgiving. Unlike some tiny movements, they can keep good time, and some were sold as certified chronometers. I find it very rewarding to return these tiny mechanical marvels to good running order, but if I’d attempted one of these movements as a beginner, it would’ve been a miserable experience. Tina, if you don’t know much about watch repair and are unsure whether it’s something you’d enjoy learning, I’d encourage you to check out more of the content on the Chronoglide YouTube channel. That channel is run by one of the best watchmakers on YouTube and his enthusiasm for watchmaking is contagious. I do hope you stick around and enjoy this fascinating hobby/profession. Best Regards, Mark2 points

-

Hi Tina welcome to the forum, as Mark has mentioned this is not a watch to start learning with, the repair itself is also not something a beginner would attempt overlooking the fact that some specialist tools are also needed . So as you can now understand, watch repair is not really a one off thing unless it is something very simple and some level of commitment is required. The hardest thing for folk with no watch knowledge to grasp is the sheer miniscule scale of the parts that have to be handled. Hand and eye co-ordination, finger dexterity and tool manipulation must be good if not perfect to be successful at repairing. Please join us and start your journey.2 points

-

Another tip I have for easier winding into the barrel is to lightly lubricate the mainspring with grease.2 points

-

I do not intend to become a YouTuber, but if I ever did my channel would be called "Mistakes were made" and would be principally about my stuff-ups, what I learn from them, and how I recover.2 points

-

2 points

-

Why not try watchmaking naked, just make sure your workshop is well heated and keep away from the windows.2 points

-

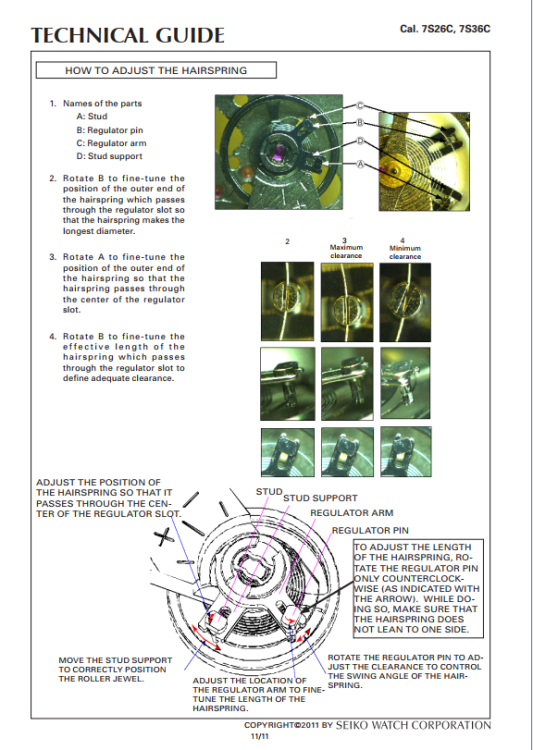

He may have just turned the regulating pin too far. Check that before attempting to bend the spring1 point

-

This little beauty is on its way. It is apparently "working", which is always a bonus. It just didn't quite make it into the 404 club, but easily qualifies for the 1010 society. I have no idea what is in it, but it does at least claim to be Swiss and 17 Jewels. I'm going to guess its an EB880, but place your bets ladies and gentlemen. EDIT: Well 'aint that curious in light of the current situation.1 point

-

1 point

-

@TKM3RD, please take the advice everyone is giving. It's "classic rebanking" as @mikepilk said. Textbook. One could say you did "too well" on this watch. It's cleaned and lubricated so well that it has too much amplitude. Which oils did you use on the train wheels? Using HP1300 on the whole train (even escape wheel) would kill a few degrees of amplitude and might just make it run perfectly.1 point

-

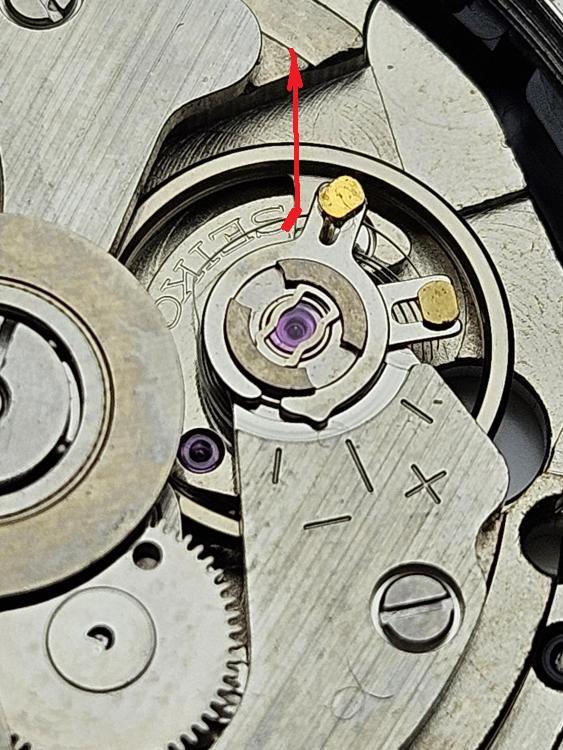

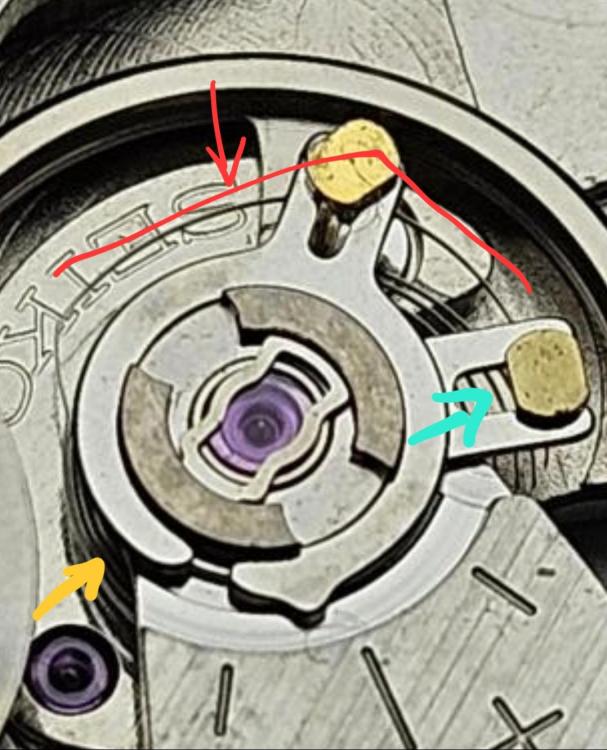

Welcome to the forum, @jakeoid. I fear you must have accidentally bent the hairspring indeed. If you look at the picture below and follow the outmost coil of the hairspring and my exaggerated red line (symbolising the hairspring as it is now, as opposed to a nice round shape). It seems as if the hairspring has a bent right at the regulator pin. You probably pushed where the red arrow points. It compresses the coils too tightly where the orange arrow is and spaces them out too much where the green arrow is. Coils are probably touching when it runs. To properly assess, you'll have to take the balance cock out, though, and turn it over to show the hairspring fully.1 point

-

I doubt if I could make the collets, just the hardening alone would be a task, but i get what your saying, its just a tenner a year . Yes Case I definitely got something wrong, thought I had the sizes right, i also used the hole in the plate but gauging 10 microns extra on a bush for a friction fit isn't easy...not for me anyhow just yet. Could be that the reamer is worn and is cutting under 0.99, I more or less assumed the hole to be correct at 1mm. I only used the 1mm pin gauge as my 0.99 was missing from the set . Pressing in the bush is also tricky the wide hub obscures the vision to see the fit happening . Pleased that I did the trial first, there might be few more attempts to go Smooth broaching out the hole would be an answer to it.1 point

-

Classic rebanking. I just had the same problem - the trace looked just like yours. Try running it vertically - the amplitude will drop and the plot should look OK. An easy fix is to try some HP1300 on one, or both pallet fork pivots. If that doesn't work, then a weaker mainspring.1 point

-

Based on these dimensions and allowing for slight inaccuracies I think the easiest option would be a 28.2mm x 0.6mm I-Ring and then the corresponding 27.5mm x 0.8mm Lens. I've now got a large selection of lenses but when I started in cases like this I'd also have bought a 28.0, 28.1 & 28.2 lens along with what's called G&S Hypo Cement. Edit I should have added that if it's an I-Ring you'll also need a Crystal Press and if it's glued you'll need a steady hand and some pegwood to remove the excess before it sets.1 point

-

1 point

-

1 point

-

I'm affraid your photography skills are pants or maybe you're using a potato for a camera lol. You're going to have to get in a lot closer than that and cut out the pointers. You might know what's going there but we dont. Get zoomed in fella and lets have something that folk can work with please. Too much ? I'm not in the mood for nonsense today Can you tell ?1 point

-

This guy , posted me one out to try, and it was a perfect fit, the collet locks into the keyway as it should. 15mm collet body with a 13mm thread , i just need a thin walled draw bar making, so as to pull it in. The spindls bore is 16.5mm. I'm in that dilemma now wether to buy, I doubt he will drop his price when he knows they fit and I wont find another set like this. Bugger its nearly double what the lathe cost .1 point

-

Kind of abandoned. There would probably be market for a good adjustable winder but nobody makes them anymore. Many people new to watchmaking don't even know they exist. I guess there are enough calibre specific winders and replacing the spring is the easiest option but a hobbyist could really use one.1 point

-

1 point

-

Not always, John. Some buy just a GPS receiver, using the 1-pps signal directly (<< $50) without paying W… prices . Link (German) Frank1 point

-

No expert, but here are a few things I'd be looking for. Perhaps the balance is coming into contact with the centre wheel. Is it worse when you turn it dial up? Or perhaps the extended fourth wheel pivot is not straight. Are the hands and dial in place? If so, perhaps the seconds hand it touching the dial.1 point

-

It didn't go well, so good job it was a trial run. The middle section which formed the interference fit with the plate...crumpled when I pressed it in. I was sure i had the diameters right and I added a leading edge to the pressing side of the plate. So I don't know what happened yet, maybe the bush wasn't quite aligned when I pressed it in, maybe the rod is soft brass. I still did the soldering, because i wanted to see how that would go, and that went just fine with adding flux to the bush before fitting and placing two pieces of solder at the join. Heated from below and the solder sucked straight in. Think I'm going to make a few tougher steel bushes next.1 point

-

Wow! I had been reading that as "Cornhill", but when I compare it with the second "i", I can see what you mean. Now you've pointed it out, it is impossible to unsee. Probably ruined his whole day, or worse. I wonder if it was an apprentice, and if he tried to cover up his own mistake, or perhaps someone helped him. I do wonder what life would have been like in that workshop, 40 years or so before my grandfather was born. Like something from a Charles Dickens novel perhaps. I don't suppose they would have imagined that 170 years later, their watch would end up in Australia, with an amateur wondering about how to repair it.1 point

-

Keeps clothes fibres etc trapped inside the coat and not floating around landing on your work.1 point

-

1 point

-

I have a couple that I wear. I have a cheap one I got on amazon, and a much nicer one my wife ordered me with my business name and my name on it. The cheap one works well enough, but the buttons on it are snap buttons, and they come unsnapped if you get out of your chair often. Maybe my belly is just too big. The nicer one has actual buttons, and its a bit thicker. I prefer that one. But its good to have 2 for when 1 is in the wash. And yes, it does help you see parts that ping off your tweezers. But that happens less and less as the days go on.1 point

-

Its not actually your problem mate, you don't own the patent Andy does . Think I've wet myself laughing so much1 point

-

You also could use such simple speed adjustment as Elma did: A variable resistor (rheostat) in series with the dc motor: slow speed in the fluid, high speed over the fluid for spinning, without further adjusting. Frank1 point

-

Thanks OH, I know you were right about it being a novelty clock, but taking it on as a bit of fun has been quite enjoyable. Thanks transporter, in the interest of maintaining domestic bliss I need to be careful, what was 'the weaving room' has now become 'the clock room' the matter is still under discussion but the fact that the shelves are full of clocks and the windowsill is going the same way speaks for itself I think. The spares department is currently located in a wardrobe in the garage, once that's full I'm going to have to be really inventive - back of the sock drawer maybe1 point

-

I didn't even know this was a thing, thanks for the correction Frank, can actually see the difference now that you've explained it . Machine stamped ? Must be , you can see the circular pattern quite clearly, still beautiful and skillful .1 point

-

Honestly the adjustment of speed is so useful, in that wash, spin and drying cycle speeds can vary. Handy when you're making something that may not be as stable as a commercial machine. If you have a wobble somewhere thats proving difficult to cure and a slower speed can address that problem, so then an addition of speed control can give you that fix.1 point

-

Someone's posted a table of speeds and times for wash and rinse cycles in this forum, i can't find the post but from memory i think it was 200 rpm. You should include a dc speed controller to your set up i have one of these in my homemade cleaner, inexpensive and you have more choice of 12v motors as it lets you adjust the motor speed to get the best results in your set up. This as a switch for manual forward and reverse, i have the output of this that goes to the relay input of an automatic forward reverse circuit set at ten seconds, the forward reverse module can be swithched out with a DPDT switch so you can control the motor directly for spinning excess fluids off at the end of a cycle.1 point

-

I'm with praezis on this. That's stamped and painted with silvering. Look at the transitions between the high and low elements; the details shift with the topology, and the color is independent of it. Get too agressive with the cleaning, and you could very well find yourself learning how to silver dials. Resilvering very selectively like that dial seems pretty challenging to me, but I hate painting with a passion.1 point

-

So it ended up about 13 hours out somehow! I thought there was an issue with the hands catching (related to my relume) so I took off to fit another pair, one of which killed the plastic hour gear! Not gone well then, though fortunately I kept the old movement for spares, so I've managed to get it all back together and working today after much messing with the date change... I wonder if the date change gear was causing issues, though might be that I reassembled wrong - it wasnt happy but after changing the gear and plate from the other movement it's all working again. I'm really hoping the hour hand issue is sorted - feel like I deserve so e good luck on that front but won't know for a week or so... I'm likely out of my depth here! A picture to mark the rare occasion that hour dial is more or less correct!1 point

-

Really regret to have to disappoint you all Not this mass produced dial was made by Guilloche but the die was. Guilloche will not produce tiny pits, separated by crossing walls - but the contrary in the die will. Frank1 point

-

1 point

-

am attaching a PDF and here's a image from the PDF. When dealing with modern mainspring is exactly as quoted above the hook cannot stick out very far at all. The mainspring winders set at one time had other types of samples which I'll show in the picture below for vintage blued steel Springs and it sticks out whole lot. So if you have a vintage set you need to order replacement handles because otherwise it's not going to work at all. It's not like one set a handles works for everything. Then the modern handles usually don't work with the vintage blued steel Springs. here's a picture of what the modern handles should look like vintage handle notice that the flux sticks up quite a bit which is really needed for blued steel Springs. than a handful for a different type of mainspring winders which I typically use for pocketwatch Springs. Notice it's a pin and it sticks up quite a bit. If you get the spring wound in super tight with anything that sticks up like this you are not removing the handle. Which is why your mainspring does have to be properly sized for the winder Mainspring winders 7023 A B C.pdf one of the things I find interesting is teaching people in real life versus teaching people by video on YouTube? I wonder if it's possible that people on YouTube forget that they have a live audience and things don't always work as nice and smoothly as they show. If you're in a classroom situation you make a mistake it becomes apparent extremely fast that there is a problem. But And making videos perfect video is because her supposedly perfect you don't get the feedback of if you made a mistake typically. Instead you get all the people praising you for how wonderful things are1 point

-

Just a note- I've filed down hooks on many winders. The hook has to be nominally the same height as the spring thickness, but a little shorter works fine too. Once the first wrap of wind comes around it's going nowhere, and this strength increases as you wind.1 point

-

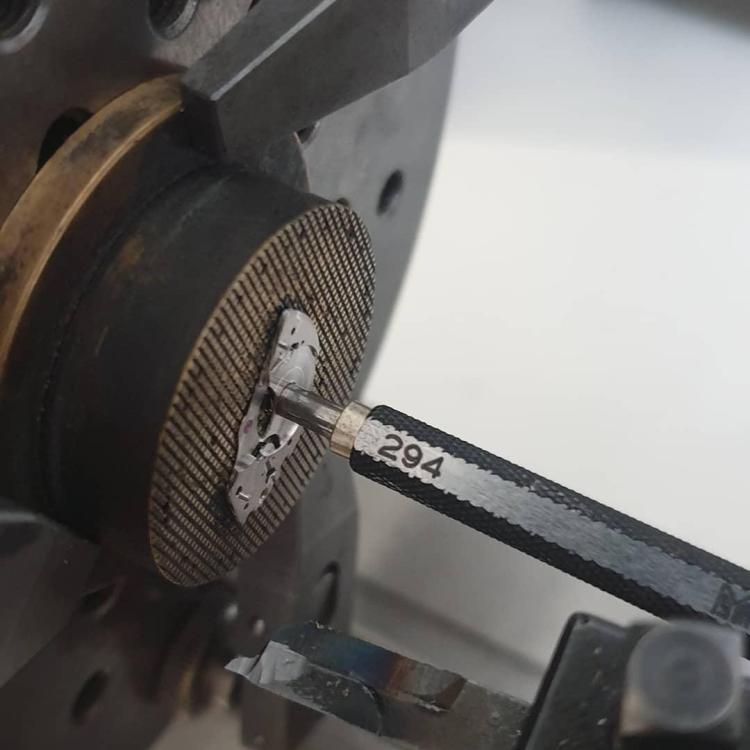

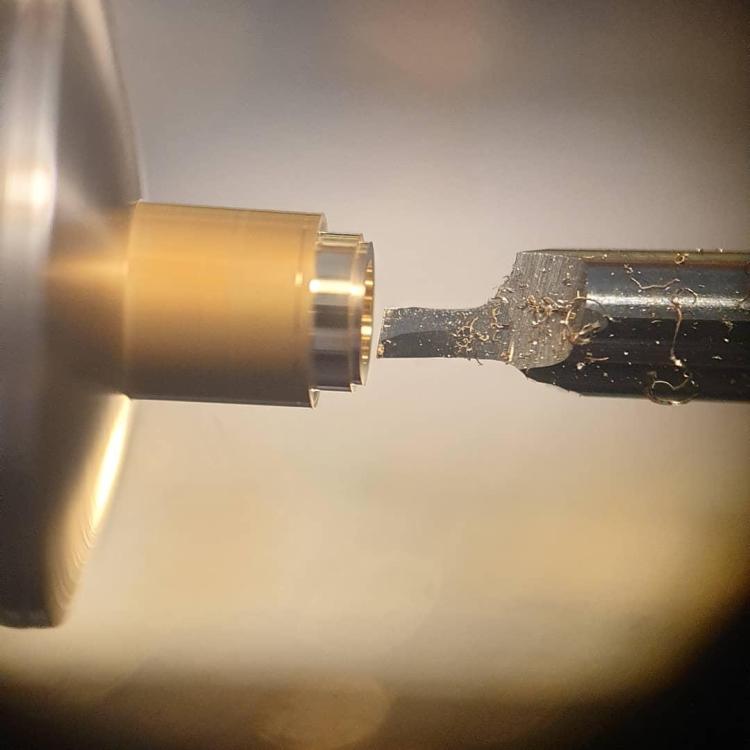

If you can make a stepped hole in the bridge you can avoid the need for solder. Here's a fix I did on a JLC 838, this has a suspended barrel, so 100% of wear is on the bridge and there's next to no material to work with. The worn portion protrudes down toward the barrel a bit and up toward the ratchet wheel. I did the bridge work in a faceplate, the stepped bushing was all lathe work. In the last pic the the barrel arbor looks low but it pulls up when screwed to the ratchet wheel.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)