Leaderboard

Popular Content

Showing content with the highest reputation on 12/09/24 in Posts

-

Just bought another Longines (a 1958 30LS). I'm a big fan of older Longines, especially of the '30' series with the big balance. (There's a thread on here where someone wanted an accurate movement and @nickelsilver mentioned the 30 series Longines). A few months ago I got a 30L (sub second). Spent a while on dynamic timing and got it running nicely. I wound it each morning and wore it for a week (including two round of golf, which is challenging for any watch). Checked it three times a day and it was never more than 4s out, and after a week it was within 2s. This is a 30LS, same as 30L but with a sweep second (the only other in the family is the 302, which is a 30L with adjustable stud carrier, and the mythical 30Z, a movement specifically designed for the Swiss observatory chronometer competitions. If only I could find one). A bit of a polish and new crystal, and it should look nice.5 points

-

This dude Bartosz is amazing. Bit of a renaissance man judging from the breadth of topics on his blog... https://ciechanow.ski/mechanical-watch/3 points

-

Thanks, I'll look into this a bit further. For now, as I'm still waiting for a new mainspring, I started assembly with the keyless works. First, I still need to disassemble the canon pinion A scalpel slid between the parts and it came apart easily. Through the cleaning machine again.. Then 9504 on the shaft and a bit on the base Pushed together on a hard flat surface with hand setting pushers. The excess 9504, I'm removing with Rodico. Oiling posts with HP1300 (wider parts, top and bottom). Canon pinion and minute wheel need to go on at the same time. A bit fiddly. I add a tiny tiny drop of HP1300 on the elevated ring below the minute wheel (red arrow). More posts, HP1300. Note that the elevated ring on the plate has no purpose. The wheel goes on with the bigger side up. Remember that the rounded side goes downwards. Post for the rocking bar, HP1300, small amount, careful spread around the post. Oiling the riveted wheel on the rocking bar is a bit tricky. There's not enough space for even my smallest oiler to really get in-between... so I use a scalpel. A bit messy. Rodico for some cleaning. The three positions of the rocking bar. 1. Time setting, 2. Winding, 3. Setting the hour on the second time zone. Cover plate on. On now moving to the train side of the keyless works (interesting and unusual design). 9504 greasing of sliding/winding pinion and stem Positioning is straight forward 9504 also here. Distributing it by turning the stem. Lubricating edges of rocking bar and setting lever spring with 9504. Honestly, positioning the setting lever was very fiddly. I tried various positions of the rocking bar and I'm not sure which one finally worked.... Securing setting lever with screw and then the stop operating lever. Greasing (9504) the touching points with the hacking lever, then removing excess with fresh Rodico. Placing seat for yoke. Note that there's a top/bottom side. If it doesn't place easily, don't force it, just turn around. Carefully spreading 9504 around the hole of the yoke (since this doesn't turn 360°, I make the effort to spread it out). After positioning and securing the yoke, I also observe and grease the touching point between yoke and hacking lever. That concludes the keyless works.3 points

-

2 points

-

Two things come to mind. 1 is the steel soft or 2 has someone been hitting the stakes with a 2.5lbs lump hammer. Seriously I would look for something better after all this set is small.2 points

-

What do you mean by "light action"? PS: thanks for engaging in this question! Small correction on above oiling plan: the contact point between click and click spring is supposed to be 9415 (yes, the pallet fork oil/grease). I'll follow that. So it's only a question about lubricating the pivots...2 points

-

Professor Jendritzki’s books are available in a few languages, which I feel speaks to their quality. If you search for his name on eBay, you’ll find the watch repair book in English, for sale brand new from Germany. @JohnR725 is right when he says that early editions are the most desirable and contain extra content, but the early editions are much more difficult to come by and tend to fetch higher prices, unless you get lucky. I kept getting outbid for secondhand copies of Watch Adjustment on eBay, and the few secondhand copies in English for sale elsewhere were unaffordable for me. After narrowly missing out on a cheap copy listed as But it Now on eBay, I started searching eBay for this book at least once a day, every day, and it paid dividends within a few months. For those interested, there are a few new copies of Watch Adjustment available from the current publisher, for 74CHF + postage, which is less than I’ve seen copies of the same edition sell for on eBay. Best regards, Mark2 points

-

I just can't beleive my luck. A landeron 48 chrono in working order for $10US or £7.83. Picked it out of a box at a swap meet this morning. Seemed gummed up and not working. Messing with it proceeded to drop it on the ground, lucky it hit my foot first and seems to have survived. Only has 2 lugs, but they are on the top of the watch case. Is plated brass so not sure if new lugs can be added or not. Here is what it looked like out of the box. Then I got it home and started messing with it and changed out the crystal and went through it. Appears to need just a servicing and case work. The best for last is the dial is pretty spectacular! No water damage. Anyone hear of Dorex? Is 33.8mm not including crown and pushers.2 points

-

Watch Repair Tool Stainless Steel Crown Tube Correction Tool Shell Tube Adjustment Watchmaker Repairs Watch Parts https://a.aliexpress.com/_mNeimYR There is a tool for straightening the tube. I bought one recently but haven't had the opportunity to use it yet.1 point

-

I find this often, however not always so extreme as yours. I use to clamp stem with crown tube in a collet of the lathe and tap strongly on the protruding edge (small hammer and a piece of hard wood between). Not always really successful. Frank1 point

-

1 point

-

1 point

-

1 point

-

Hi Bill, You will be not able to wrap the feet, neither to use heat shrinking sleeve. What You can really do is to flatten or squash a little the feet with flat pliers. The squashing will make feet wider in one direction and narrower in perpendicular direction. So, choose the correct direction and go ahead.1 point

-

I wanted to check back in and give people an update on this solution. I decided to omit the dish soap, as I didn't think it was useful and added a strange blue/green deposit to the parts similar to oxidized copper, mostly the plate and bridges. So using just the Naphtha, mineral spirits, ammonia, and IPA, it left yet another strange white deposit on my parts. I was cleaning a Rolex 1030 movement, and it also kind of discolored some of the copper looking wheels. More testing and experimentation is required, but I thought the finish with this was better than what I had gotten with the Liquinox solution in the past. That added black oxidation to some of the steel parts on a Rolex 645 movement I cleaned with it. That was a mistake that took a long time to correct. This was all done in an ultrasonic, heated to 30C and for 6 minuets per cycle. One wash, 3 Rinses.1 point

-

1 point

-

Wow, all joking aside, this has become an awesome conversation. My usual interest leans towards tiny vintage ladies movements (because I can get them dirt cheap, parts are pretty available, and I love the challenge of such a piece of amazing engineering) so when I looked at oils, my thought was the lighter the better. I see that perhaps I didn't take into account using a heavier one when working on a larger movement (and I am always open to the suggestion that I don't have much of a clue as well...) Anyway, it's a moot point. I lost the pallet fork; the shellac in a replacement I had was faulty, the jewel fell out, and is somewhere - really, it is somewhere, I just have no idea where. I also need to get a proper mainspring but my guy is out of town. So, this project is on hold for now. Once I have the parts, I plan to take it apart again, give it a quick cleaning, and put it together again using heavier oil as suggested. I will update the post when that's done. Thank you and Happy Holidays to all! ~~Tom LOL, I drive my wife crazy with Monty Python quotes! You should have heard me when I was working on a Hamilton "Dennis" watch, she about had me committed.1 point

-

Greetings to Hertfordshire! I was in Letchworth for about a year during high-school Anyway, I had a look at the listing and I'd recommend that you steer away from it. Too many broken stakes and also not many of them anyway. The second picture you posted actually shows the backsides of the stakes (where you hit them with the hammer) -- so less relevant. But if you look at this picture (screenshot from the listing), you see that many are broken:1 point

-

The punches are softer at the end that gets hit, and they do deform. These look like they've seen a lot of use, and not gentle use. I would avoid it mainly because it's a reduced set of punches; you will almost certainly be frustrated by the lack of size options. Better to find a larger set and buy once. Star made really good staking tools, if you see one of their larger sets that would be great.1 point

-

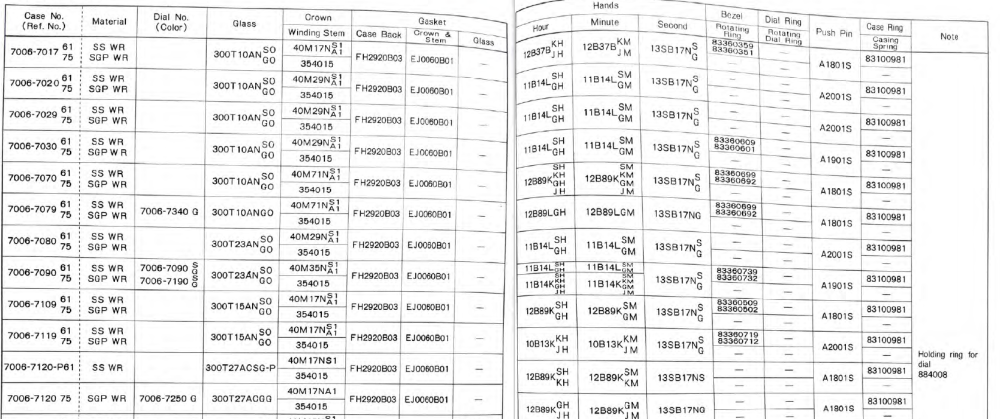

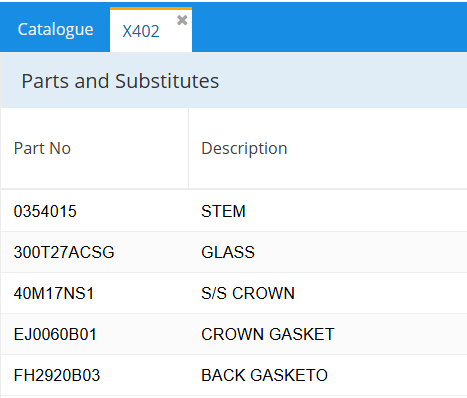

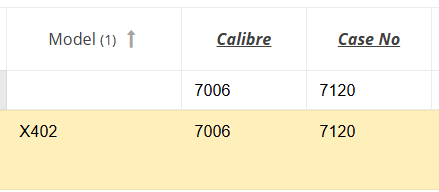

The 7006-6010 is a 32mm Crystal. Be interested to see when you get it if it is faceted or if it's just an optical illusion.1 point

-

1 point

-

My thoughts are that's not enough to be holding the foot, even if the foot was correct. I see 3 options. First is to glue it in place but this is difficult to reverse. Second is to use a small piece of heat shrink sleeve over the foot. Third is to look at the hole & foot size and see if you could replace them with larger diameter ones.1 point

-

1 point

-

No worries about that. We're not judging. We're all here to learn. The title of your thread included "next step". I'd say, this is most definitely your next step. Without any lubrication, it's not surprising that watches don't run, or stop after a little while. Find the smallest oiler (probably black) and work with that one only, for a start. Better to apply small quantities twice, than overdoing it at the first go. Adding is easier than removing. I agree that this is sound advice on the lubricants to get. I got the same ones and they'll last until I die. Don't think about price per gram or ml. Only the absolute price of the smallest available quantity matters. You'll never need more than the tiniest bottle. E.g. CousinsUK sells 2ml of HP1300 for 17.55 GBP and 20ml of D5 for 27.95 GBP. So HP1300 is way more expensive per ml, but in absolute terms it's cheaper. And 2ml will last you a lifetime. You may be partly right with that, but I don't think there's a debate about the 4 essential types of lubricants: - thin oil = 9010. Check. - thick oil = e.g. HP1300 (which, I think, most would recommend) - grease = 9504 is excellent, but not the cheapest (but I think, it's worth it) - special oil/grease for the pallet fork = 9415. Unfortunately, there's a forth. I've heard that some people use 9010, but it's not ideal, I think. ...and when you get to automatic watches, you need a breaking grease. Later.. ..and Epilame/Fixodrop. Well, this may be another debate.1 point

-

Bill, You just need a little big bigger screws. You can use normal screws, just source ones with head that is low (thin) as possible. Then screw the screw to the end (without dial) and mark the head where the hole is, then file the head. The idea is to be possible to insert the dial when the screws are tightened to the end. Then, fixing the feet is by UNSCREWING the screws. The first time some force should be used as for the head to make notch on the foot.1 point

-

As stated by @HectorLooi the flange on the screw doesn't appear big enough. Will the screw not turn any further as it's only just contacting the foot or does it rotate past this point freely?1 point

-

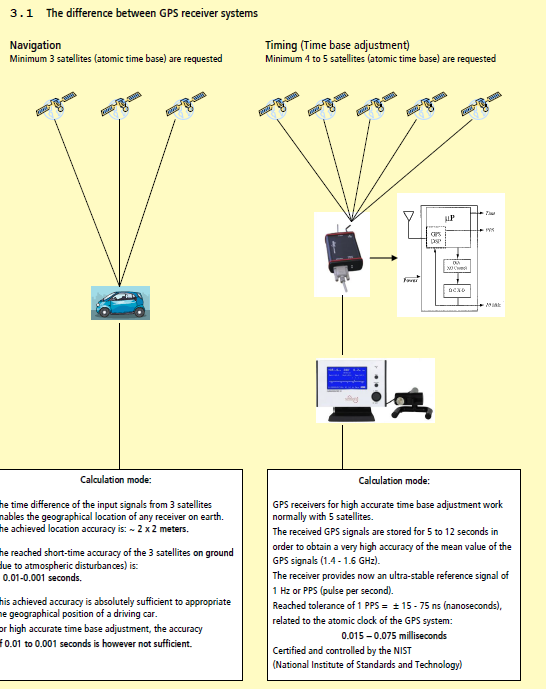

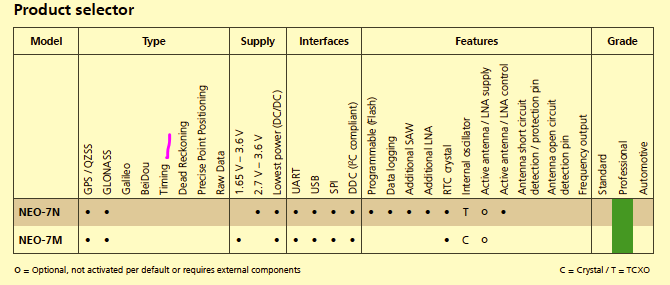

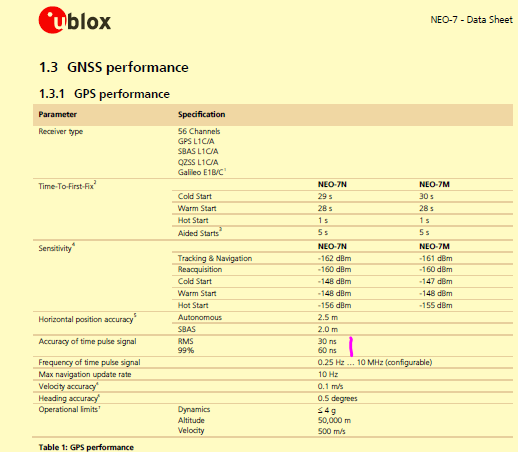

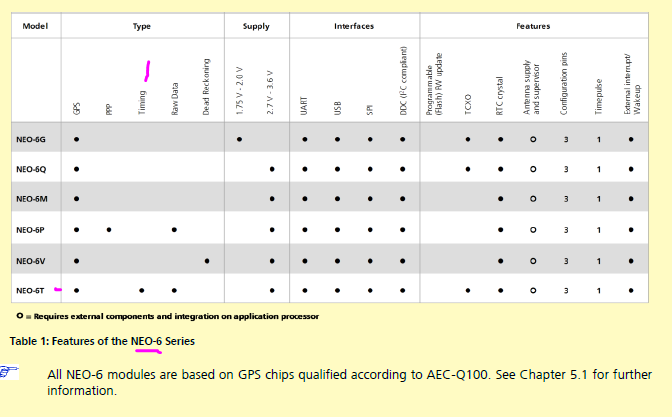

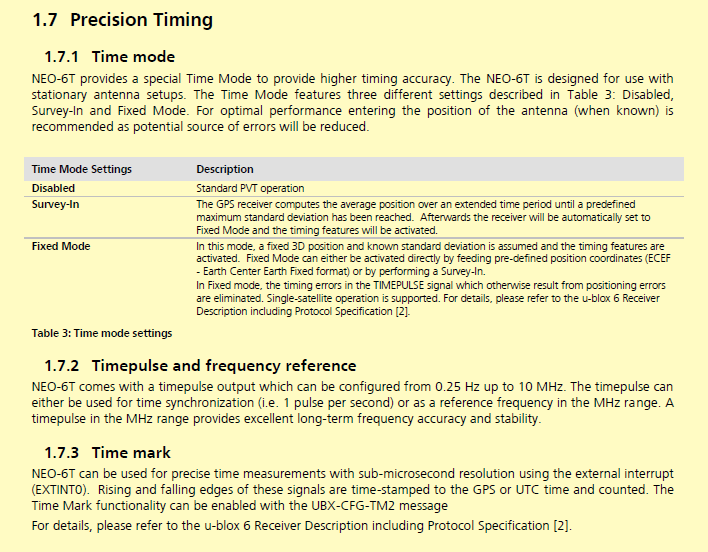

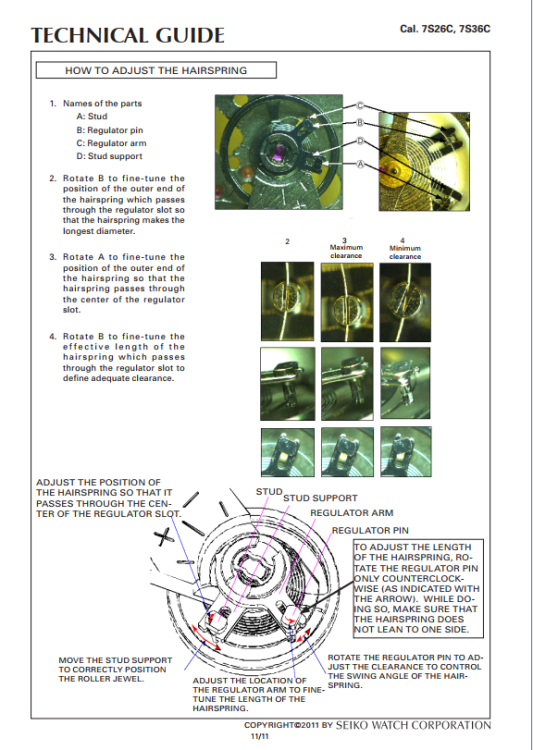

I think what he means are the items in the image that I've circled. I don't think these are actually for timing there probably to select functions or their test points. A lot of times you might have one circuit board for several types of watches perhaps? the problem with slowly doing an answer is I see that already clarified but I will leave this here as it is still a valid answer. by the way that brings up a problem with what is quoted below? the 60 nano seconds is achievable 99% of the time and the GPS can do better according to the spec sheet below. let's look at the specifications sheet and we have a minor problem notice in the features timing is blank? let me quote myself? so the witschi GPS is extremely expensive because who exactly needs one anyway? Most watchmakers never get there timing machines calibrated the vintage paper tape machines existed in shops for basically forever never being calibrated and nobody really ever cared even the modern witschi timing machines how may people ever get them calibrated probably a very tiny percentage and then they send them someplace so the quantity of witschi GPS calibrators are sold is probably extremely tiny which is why it's extremely expensive. But it's still a GPS designed for timekeeping purposes not navigation not that I can't be used for navigation. let's snip out something from the witschi GPS users guide. Amusingly of course they're going to pick and choose and leave out details like the normal GPS would be just fine. At least for normal stuff including normal timing. But they do get things right the timing GPS needs more GPS signals has better circuitry just produces a much nicer timing signal. now let's go backwards in time let's drop back one generation version of Frank talks about and go to the version 6 and snip out image showing the various versions that were available. although if you do look on eBay the version 6 still seems be available even though they considered obsolete. You will note one version is specifically for timing. then let's see what it says about the timing GPS I have a PDF on timekeeping GPS and another one on problems of not having a clean signal. then we get the whole amusement of this silly discussion. Yes there are special GPS receivers for timekeeping purposes capable producing really nice signals consistently or there is the GPS module you can buy on eBay for considerably less than $50 and will work 99.9% of the time. then let me quote freight again worst-case with the particular module he was recommending is outstanding as quoted below. https://www.u-blox.com/en/product/neo-7-series TI_GPS_PPS_Timing_AppNote.pdf Timing_AppNote_(GPS.G6-X-11007).pdf1 point

-

What are you referring to as jumpers? phones have not always had a gps receiver, their time reference would be “network “ time from the cell radio service. The cellular network would reference three or more time servers within the provider network and they in turn would reference master time servers usually referenced to the international atomic clock network. Some ISP’s and companies now use specialised gps receivers within their networks for the time reference, especially relevant if timekeeping is critical. Tom1 point

-

1 point

-

Being an old guy who already had a career I just wanted to know more about this cool hobby. I was not going to watch school but I did think I needed some instruction aside from youtube videos (which are useful.) I paid for two courses which aren't terribly expensive imho. (That will come with buying tools ) 1. Mark Lovick's courses are part of this site. They have great video resolution and Mark's narration is clear/concise. 2. Watch Repair Tutorials. This is Alex Hamilton's site. Like Mark, he's a professional watchmaker. He has a "lot" of useful, free videos and a couple courses. I think he's a bit heavier on theory where Mark's are easier to digest visually. https://watchrepairtutorials.com/ Also, as mentioned above there is a ton of good material on the chronoglide site. Kalle Slaap is a Dutch watchmaker with a good sense of humor.1 point

-

The remnant of the flange is too short. It should cover at least 1/5 of the hole. The dial feet also appear short. Maybe this was intended for movements with dial feet screws on the edge of the plate.1 point

-

You must be right because through a lot of trial and error that's exactly what I found, so thank you. I also confirmed it by pulling up Mark's lesson on winding as well. The other thing I leaned is that once the end of the spring/bridal is inside the winder barrel, then release tension from the handle "slowly" or the bridal can move and pop back out. I probably did 10 tries to get it right and in the course of all that slammed the bridal into the notch and broke two of them. I'm now out of springs for this old ebay beater that I've been practicing on but I think I have a process figured out now...1 point

-

The oiler colors are not really standardized, though I might guess the black one is the finest. Maybe. In addition to your light 9010, get some HP 1300 as a medium oil and Moebius 9501 or 9504 as a heavy grease for sliding and high tension keyless works parts. Or Moebius D5 and Molykote dx as the cheaper alternatives to those, though the 1300 and 9501 will have a longer lifespan in your watches. But the trio of a light oil for the balance and fast wheels, a medium oil for the slower wheels and rotating parts outside the train, and a grease for high tension or sliding parts is mostly sufficient to get started. You should be able to find a service guide for the 6497/6498 movements which will show you exactly where to put those three lubricants on your ST36. Here, I'll save you the effort ETA 6497.pdf1 point

-

With all the good and valuable reading recommended here, I strongly support your spirit of continuing to practice and getting your hands dirty. Keep going! Just a little thing. The lift angle for ST36 should be 44 degrees. So the true amplitude is quite a bit lower. But still good. Does this mean you've never been lubricating your watches when assembling? If not, you should really focus on practicing that. Correct oils/grease, oiling points and quantities are a big and fundamental thing to learn.1 point

-

1 point

-

Getting one's hands dirty. Well, today I decided to tear down and re assemble the ST36. Certainly you experts have both written and read a lot about this Chinese clone of the ETA 6497. All I can say is wow. Timegrapher dial down reports +1 s/d 325 Amplitude .1ms BE and auto detect reports 21,600/52 degrees. HA! If they were all this easy!! I then pivoted to a pet project. My beloved Timex M cell purchased in 1983. Mine has died but I have now a 3rd donor from eBay that seem to stop and start. Just sitting quietly, for a week she will not budge and I lost interest. This AM it was running. So, I used my cheap oilers and my 9010 for the first time and dabbed the pivots I could see. Seems like a front loader so...she was snapped back together and 5 hours later she is still running on my wrist. I added Maintaining and Repairing Mechanical Watches, a Practical Guide by Mark W. Wiles to my ordered books. Three should be a start. The Hans Jendritzki book looks to be a bit harder to source. I added it to my wish list. And yes, the Bulova series and the WWII tech bulletin have been found. The British Horological Institute's Treatise on The Practical Lubrication of Clocks and Watches is also printed and skimmed. But these dang Citizen 0421...perhaps more reading about the balance wheel and escapement. I think this is my area of struggle. Perhaps I should follow the advice, Japanese watches can be hard. Swiss, easier. I lucked into a AS 1586 in a Swiss Caravelle and a ETA 2372 in a Belfonte. They both run but do lose time over 24 hours. Likely gummy inside. I don't tear them down because I fear if I ping something I will be hard pressed to find a replacement. The pocket watch debate. I have a Waltham 1425 movement from 1914 from eBay. Practice movement for my Grandfather's 1425 should I muster the courage. Looks like a lot of parts, screws, pieces. I decided to inventory it and put it away. Await books. Will look for $10 no name Swiss watch movements. Oldhippy. I won't mention my clocks. I have a ST89 waiting as my first test. I have to purchase some spring retainers, build a spring unwind tool, and likely more tools that don't cross over to watches. I have often asked myself if I should start clocks first, then do watches. But....I started watches. And here I am. An ST36 that runs great after three teardowns. And 11DPs that thumb their nose at me. I am trying to keep clocks as a "later" project.1 point

-

1 point

-

Not this type really, It's not something I would attempt, I'm sure there are those that do and certainly did do it without a jeweling tool. Friction jewels do need to be positioned accurately and set to the correct depth required, which is why the jewelling tool is used and was created, amongst its other uses.1 point

-

Great staking set! I have the exact same and love it. Congratulations on an excellent buy. Is the jewel aligning with the metal? If so, maybe you could. If it's not, there's no way you can control the depth of the jewel with the staking set. I've never used a staking set for jewelling, but I think I've heard others do it. But obviously, a Seitz or Horia jewelling tool should normally be the safer choice.1 point

-

What's even more interesting than seeing this is listening to this. In the days the paper tape timing machine work would print the dots on paper when this would occur it would sound like a horse galloping.Then starting on page 9 of the PDF attached which has all kinds of interesting information it talks about it. But when it lists the high amplitude what Omega recommends it will vary by manufacturer so typically don't want to go over 300. Everyone has an opinion when it comes to lubrication. Then 9010 is considered a very light oil typically used on balance wheels sometimes used other places but it is a light oil and seeing as how so many people of asked their probably thinking it's a little too light for the entire watch. Personally because I usually work on bigger watches my light oil of choices 9020 for the most of the watch except the center wheel where I use HP 1300. 8643_WI_81 BASIC CHECKS AND SETTINGS OF A MECHANICAL WATCH_EN cousins UK.pdf1 point

-

Pocket watches can present interesting challenges depending upon when they were made. In other words in the early days of watches they were trying to get around patents so I have clever methods of doing things and clever is not necessarily in your best interest of your learning watch repair. Then Waltham has some interesting mainspring barrels with the word interesting and not really being good for the watchmaker. It means typically after slightly modify the mainspring otherwise it's never going to catch but it depends on which Waltham were discussing. Is actually quite a few things to see on the site including. Basically a U.S. Army training manual of watch repair which hasn't really changed much since 1945. 1945 TM9-1575 War Department Technical Manual Then if you have a choice go for the older editions as it tends to cover things like making stuff where the later addition doesn't. But any addition is still outstanding to have.1 point

-

1 point

-

A new bigger movement would help you to see more clearly a range of the common faults that you can introduce yourself. Sometimes the easiest of issues can be simply overlooked in a small or average sized movement. And viewing those bigger pieces in action will help you to understand how parts can function in a group setting. This helps to pinpoint fault quicker through function group testing. Then also to see how those groups interact with each other to make the movement run as one complete unit. And then read a book about it ,and then read it again and and then read it again until it all sinks in and then like me and others do build a small library even and read all those.1 point

-

1.) Acquire a good textbook on watchmaking and read it fully. 2.) … Frank1 point

-

This one isn't so bad, as you only have to deal with two of the prongs and only one at a time then lift out. There's a shock spring that has 3 notches, and all three prongs have to locate into them at once and then turn to lock the spring in, quite tricky and that one does require a Kif Trior spring tool or a homemade wooden one. But this one just needs a probe to turn it and another placed at it's center to keep it from jumping away. You can use a clear cover over the top if you wish, but I dont think its necessary if you use a center probe. I'll dig one out if you need a demonstration, but i think you'll manage just fine.1 point

-

In my (limited) experience, it usually comes off easily with a pair of tweezers in each hand. After losing one of these early in my journey as a hobbyist, I now work through clear plastic when removing these (or anything else with 'spring' in its name). I can sometimes reinstall them with just two pairs of tweezers (and the clear plastic) but the pegwood turner can be helpful if it's obstinate once the first two arms are in place.1 point

-

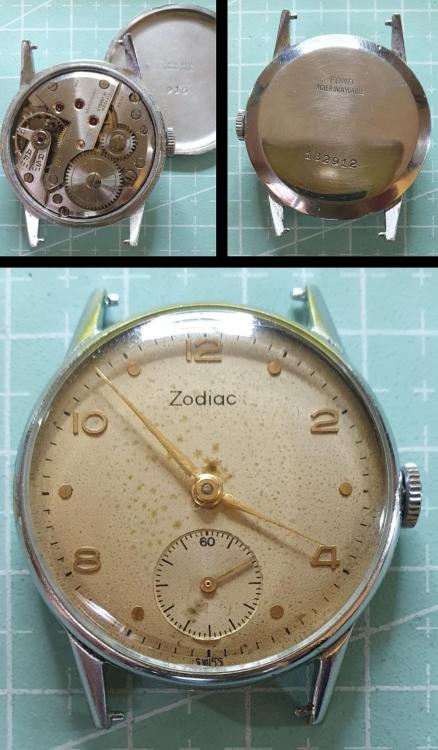

Another contender: So here we have a 1950's Zodiac with the FHF 26 movement. Purchased for £10 buy it now, on arrival, as you can see, condition not too bad, there is some of the chrome plating coming away from the case. Movement was running, but somewhat reluctantly. Full strip down and clean, mainly just dried oil with a few hairs thrown in. There is quite substantial wear on the movement plate in the stem/clutch area, so not much I could do about that. Some fun and games with the hairspring, my fault, managed to slip and distort the spring whilst addressing beat error, but managed to recover from that. Like mbwatch's watch, I was surprised with the amplitude on this one at 290. So nothing spent on the movement and case, everything was usable, however, I don't think the hour hand is correct, doesn't match and a bit too long for my liking, but as it's a £10 watch, I can live with it. What I did have to order was female spring bars, not had any dealings with these previously. It's a small watch from the period and the lug width is 16mm, so ordered 16mm female spring bars. Wrong, I needed 14mm in order to get past the pins on the lugs. Cousins no longer stock these and elsewhere ridiculously expensive, so took apart the 16mm ones, ground down the tube to required length and re- assembled with the help of the staking set to round the ends back over.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)