Leaderboard

Popular Content

Showing content with the highest reputation on 12/11/24 in Posts

-

Hi Bill, Can we see some pictures of that buggered springs? May be it is no so bad. May be with correct directions You will be able to bring them (or at least some of them) back to life.4 points

-

3 points

-

3 points

-

3 points

-

It is possible to use the old spring by folding over a small length to act as the bridle. You need to heat about 6 mm of the end of the spring and fold it over and flatten it. This will catch the stop on the barrel wall.3 points

-

China tools have improved by leaps and bounds in the last 10 years. But the problems are still QC and cheap imitations of imitations. They copy China-made copies. A good example are the "Bergeon" winders. There are some good ones and some total junk. I have an earlier version of this drill press. The runout isn't too bad. Can probably be improved with better bushings or bearings. But the motor is under powered and torque is rather poor at low speeds. If you are using it for wood and plastic, then it's probably ok. Aluminum is a bit challenging and steel would be a problem.3 points

-

I got a cheap non-name one of Amazon about a year ago and I use it all the time. Unless a previous tinkerer did the unthinkable and overtightened the back it always works. One tip I received was to slightly deflate the ball so it's not firm but slighly soft. I was told it allows the ball more surface area contact on the case back, I thought the guy who told me was nutz but i tried it and my ball actually works better. Does anybody else have any experience with this or am I now nutz too?2 points

-

You are right, or course it won't, what was I thinking D'oh. The only option is to move them both.2 points

-

Usually swapping things around desperately searching for the answer will not usually give you the answer. You need to figure out what the problem is and then deal with the problem like here's a problem the picture? It's hard to tell but it looks to me like your hairspring may actually be touching the balance arm. One of the problems of taking pictures of balance wheels out of the watch is that is not where the problem is occurring. When the balance wheel is out of the watch for instance the stud is no longer holding the hairspring up and it will typically say downwards you would have to hold the balance wheel sideways to see if they hairspring is where it's supposed to be because otherwise gravity will take effect. Often times people of the balance wheel out of the watch it will lean in one direction or the other that changes things it won't look right Here for instance they hairspring is definitely touching the balance arms the effect of gravity. But the stud that last little bit looks like it's twisted upwards that doesn't look right at all. Hairspring supposed to come up go over and remain flat this looks like it's been stretched slightly.2 points

-

2 points

-

Hmm, hard to say from the pictures. You're missing a good picture from truly above and one exactly from the side -- both when the balance is installed. It actually looks quite alright to me. If anything (but not sure!), a minor adjustment in the overcoil (here's some basic info: https://www.buzzufy.com/blog/2018/09/24/the-breguet-or-overcoil-hairspring/) Are you sure that your problem is with the hairspring? How did you determine that? Any timegrapher readings or does it not run at all? And please tell us what exact movement this is.2 points

-

2 points

-

2 points

-

I picked this up on Sunday and changed the crystal and cleaned up the dial with rodico and tuned it up to get it working, even the chronograph. Now I am dying to get it on the wrist but the lugs are missing! Looks completely original. Not sure if art deco or the 40s but the Landeron48 was made from 1937 to 1970s so either way this just blows me away...2 points

-

Don't feel like the Lone Ranger. I have buggered up 6 hairsprings in my practice to learn how to handle the balance/hairspring in an NH-35. $14 a pop is fairly cheap instruction cost. Now I have it pretty well down and I have had success on a few removal and reinstall of the balance cock and wheel. But I almost gave up after number 5... Endeavor to persevere.2 points

-

Hi everyone, I am just starting out with watchmaking as a hobby. As an engineer, I've always been intrigued with mechanics and amazed by how these have been miniaturized to make astounding watches. I run an investment fund and live in Monterrey, Mexico. Any tips are most welcome. As I learn more, I hope to also be able to contribute to others. Best, Manuel1 point

-

I've be working on a 1337 recently. It was very corroded and had green, powdery residue all over the battery contacts. It cleaned up very nicely, leaving no trace of any previous battery leak. The coil resistance is 3.5K, which is within specifications. But the movement doesn't move when powered up with my Bulova 700 meter. It shows a short in the circuit. There are only 2 discrete components on the PCB, the quartz oscillator and the variable capacitor. I have desoldered both of these and the circuit is still shorted. So the short must be inside the IC itself. I've also checked the entire internet for a replacement circuit and came up with the same results as @PwrChrdAfcndo. The owner of the watch gave me permission to throw it away for him. I'll probably keep it and try something really unorthodox. I'm going to try an IC transplant from a totally different movement. The only problem is the 1337 uses an unusual method of adjusting the hands. I think Bulova had a similar movement that does that too but I can't remember which model.1 point

-

Cartier used some pretty hum-drum movements in the 70s (80s?), A. Schield, ETA. 30s, they were using LeCoultre stuff. Everything else about it looks cheap, not Cartier. On Edit- for a number of years I did "overboard/load" vintage work for Cartier as an external. I developed a real respect for the brand in that time- no holds barred approach to vintage SAV, and I know they ate much of the cost to provide a good service.1 point

-

Hi Bill, No need to make other pictures, everything is clear. Give me some time, I will explain what to do and how exactly. I will need to make some pictures and put some points and arrows there and in You pictures too.1 point

-

Pivot length may dictate wether to move the hole jewel. Moving the end piece jewel did adjust the endshake for me. To maintain the lubrication But the pivot shoulder/cone still needs to remain free of the hole jewel.1 point

-

I was about the play the 'age card'. I can't blame the wine, as I'm only just about to open the bottle To keep the gap constant, both jewels need moving.1 point

-

Friction only depends on surface area (for a given roughness of surfaces), so you might be nuts, but not in this case.1 point

-

Welcome to the forum. You need to start a new post of your own rather than add to someone elses. You do realise that if you just replace it with an ETA movement the value will be gone. You appear to have done a lot of the hard work so why not continue?1 point

-

I don't have an answer for you, but this will not reduce end-shake.1 point

-

1 point

-

I can't find one similar. I would expect the movement to be decorated and engraved. Definitely wouldn't have screws protruding from the case.1 point

-

sure. Thickness of stainless steel (304 type or V2A, apparently): 0.35mm Width of all the three strips: 12mm Length of all three strips: 107mm The upright strips are bent 90° for 12mm at the bottom to attach to the base strip, in other words, those ones are 95mm upright + 12mm horizontal = 107mm total.1 point

-

1 point

-

1 point

-

Have you considered just getting a new complete barrel and trying that? Edit What's the movement?1 point

-

Yes, for sure. When I do it I will add a side by side picture to this thread.1 point

-

1 point

-

1 point

-

1 point

-

I don’t know if you know, Vintage Time Australia are in Adelaide and specialise in Seiko. They sell parts they have/have had manufactured such as 6309 barrel arbor jewels. They may come in handy for bits here. https://vintagetimeaustralia.com i believe they sell on eBay. @ChrisInOz Tom1 point

-

1 point

-

I was just about to recommend the same as Hector's suggestion, before I saw it. You can do this with just a lighter, but start at a distance. The thin steel can heat up real fast, and hit cherry red in just a second. Aim for only the tip and draw the heat away slowly. Letting the steel air cool to anneal it, so do not make the mistake of quench hardening it. When done fold over around quarter of an inch, flatten but retain the spring's end curve shape. You can also rivet the tab back on if you fancy tackling that. Make a short steel pin, drill the two pieces of steel a fraction wider than the pin's diameter. And then hammer the pin both sides on a steel block to form the rivet with a flat punch, or better a concave punch if you have one. You can make a reasonable estimation of the spring's length by placing glass or persplex over it, then use a piece of cotton to follow the shape, pull straight and then measure the cotton's length. Check the size against the Generale Ressorts data list after you've downloaded it . Always keep in mind what a previous repairer/service guy might have done before you. What is fitted in the movement is not necessarily correct, he/she may have used a different size of spring to the original ! Never assume something is right !!! What is there should only be a guide, a good guide if the movement was performing well before you took it apart. Keep us updated. Re. the polish up, metals can become abrasively charged ie. embedded adrasive particles. These cannot be washed free, this is how lapping plates are made. The softer the metal the more and easily it can be charged. Arbors are generally pretty hard but there is potential for it to become a rotary lapping tool. Depends how hard you had to work to clean it up. Burnishing is better, technically a filing process but also forms a hard outer layer through compression.1 point

-

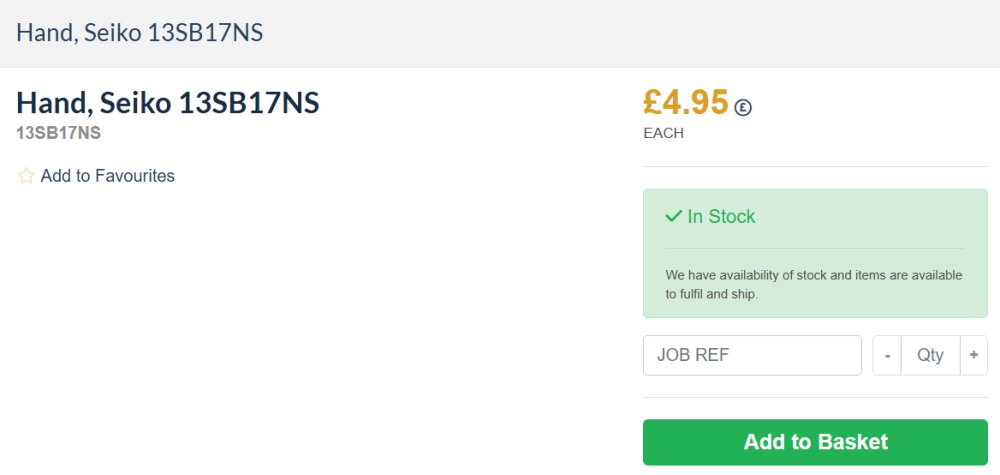

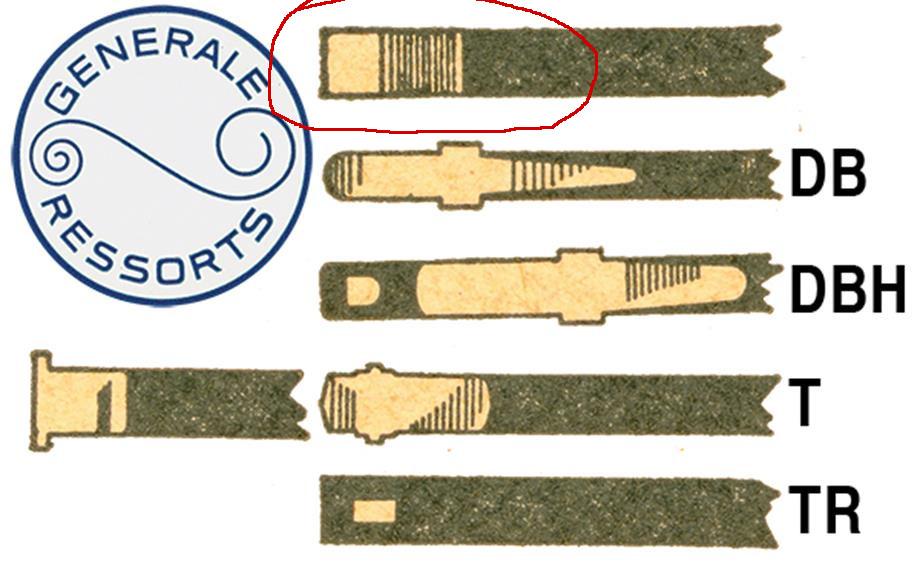

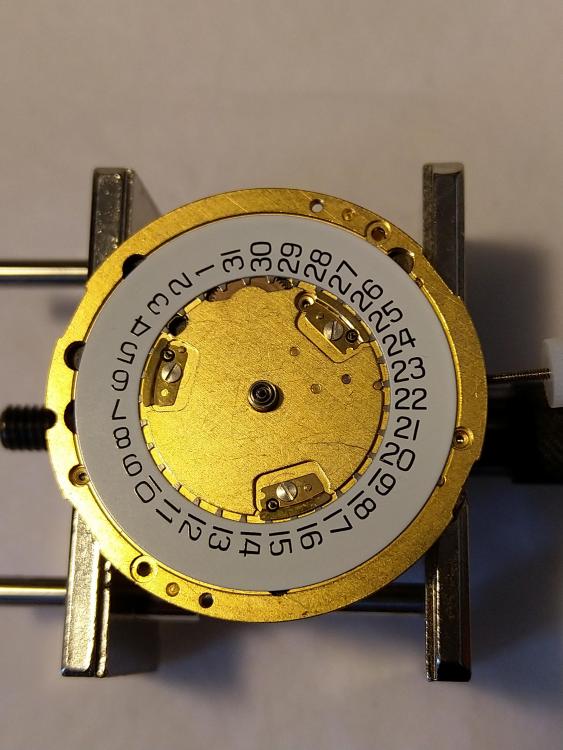

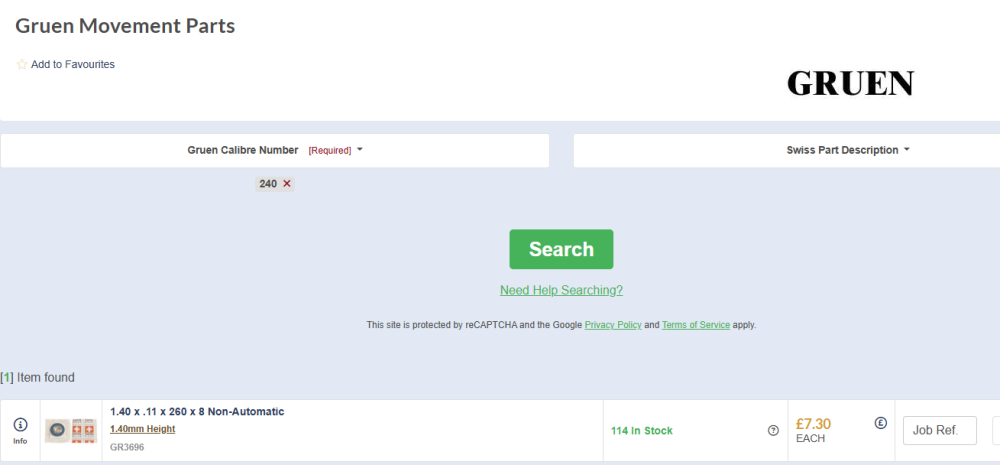

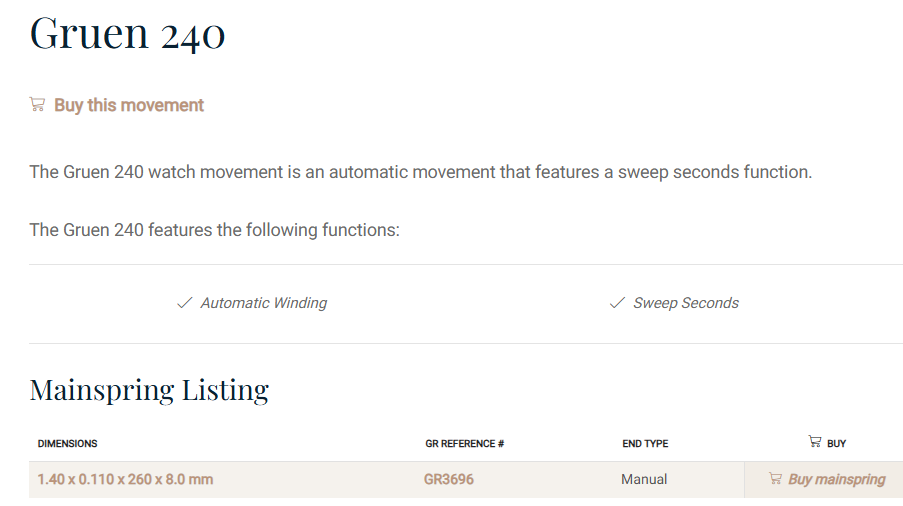

Progress report. I successfully cleaned the arbor, and reassembled the movement, and it now runs, but there is another problem. After I cleaned the mainspring and barrel in the ultrasonic, I found a small piece of mainspring in the bottom of the jar. I'm pretty sure that this was the tab that hooks onto the barrel wall. Now I can put a couple of winds on the spring and get the movement to run, but if I wind it any more I can hear the spring slipping in the barrel, so I can't put on a full wind. (This is a manual wind movement, not automatic.) The answer would seem to be to get hold of another mainspring to replace the original. For those who have just joined us, the movement has been tentatively identified as a Gruen 240, or something very similar, by using the bestfit catalog. (thanks @MikeEll.) Unfortunately, the Gruen reference sites I have been able to find don't list the 240 movement, so I don't know the official specs for the spring. I have a micrometer, so I can get an accurate measure of the height and thickness of the spring. I presume that I should not unroll the spring to measure its length, so I should calculate the length mathematically from the barrel size. I can do that OK. I then hope to order a generic spring from Cousins UK. The problem I have is understanding what terminology to use when ordering the part. The outer end of the spring hooks to the barrel wall by using a very short (~6mm) piece of spring metal that is spot welded to the end of the mainspring. This is the same height as the spring itself. There are no holes or projecting tabs. Is this what Cousins refers to as a "normal bridle?" It is closest in appearance to the circled image below. Am I on the right track with this? Thanks in advance for any advice. The autosol did the trick very nicely, and the bearing surfaces on the arbor came up smooth and shiny with no pitting. Thank you. I cleaned and rinsed the part again afterwards, to avoid leaving any traces of abrasive.1 point

-

WD 40 is not a oil ,it is a water dispersant , Kroil is another penetrating fluid1 point

-

I've been considering the standard drill version from AliExpress but waiting till after Christmas now before I make my final decision.1 point

-

I serviced one similarly rust damaged "blue Pogue" a while ago. Fortunately the critical parts were in good condition and the chrono wheel was good. It made a good beater. Even though there's heavy rust the wheels don't often get corroded at all. I say you service the movement, relume the dial and get the missing parts. The stem with the wheel is hard to find but I think aftermarket alternatives do exist. I even made a video of mine, of course it's narrated in Finnish so it's no use to anyone. It's got almost whopping 300 views!1 point

-

I just had a look and I see they are made in China. I think most members on here know what I think of chinese tools. I think I will stick with the unimat 3 one I have I know that is a proper milling machine.1 point

-

Hey @cor9brg, Don't worry about the missing stumps/anvils. Not so important and you have plenty of sizes (plus the flat stakes that can be used inverted). I actually have more missing ones in those inner rows. The pocket in the front right (69-209) is for reamers. I think these were an add-on option because most sets I've seen (including mine) don't have them. I have reamers in my Seitz tool, so no need for me. Here is the manual: Boley set.pdf (I also don't have the jewelling adapter. My Seitz for that again.)1 point

-

1 point

-

Kind of what i was going to suggest ...placing a holed dome stake or similar over the tube and then rotate. Bit like the rolling action for straightening a pin or a pivot . The generated heat from interference also helps. As Frank suggests..if the tube is soft then it might bend where it comes from the crown using the rolling technique . If the stem starts to give by bending it, then it will probably break or break the tube at the crown from the direct pressure of the stem bending.1 point

-

Great staking set! I have the exact same and love it. Congratulations on an excellent buy. Is the jewel aligning with the metal? If so, maybe you could. If it's not, there's no way you can control the depth of the jewel with the staking set. I've never used a staking set for jewelling, but I think I've heard others do it. But obviously, a Seitz or Horia jewelling tool should normally be the safer choice.1 point

-

Only downside pivot of the arbor must get in a hole, the arbor itself should be supported on the stump. Heat/cool method doesn't work in small objects like watch parts. They have small mass and the temperature spreads very fast.1 point

-

So for anyone who is remotely interested in how my Slava 2428 power reserve test went, the results are in. It actually performed far better than I was expecting, the stated power reserve for this movement is 47 hours, my watch achieved 40 hours and 20 minutes. I don't think that's too bad considering the mainsprings are very probably the original from manufacturer. As previously stated, I had my doubts to the results being great as winding is very easy all the way to the stop, not like some movements where you dont even try to get to the stop, you feel that much tension you just think no, that's enough. But I do have a few watches with this movement so I compared the winding, and they are all the same, wind easily to the stop. So perhaps that's another benefit of the twin smaller barrels, and if you then consider the automatic version of this movement, would it be easier going on the auto works? Well as it's now run down, it can have a rest. Recently I repaired and serviced this early Accurist quartz which uses the 7 jewel ESA 9632 movement. I replaced the quartz oscillator and with it's new battery has been running well, so this can have the rest of the week getting worn. Time keeping is excellent, I use a radio controlled clock to set watches, and this is still to the second from when it was repaired.1 point

-

For years, since I didn't know how much further I would take "watch-repair", I've been "scrubbing" my watch parts in Zippo lighter fluid........ Recently I decided to "up" my cleaning game. Bought a 2nd hand Elma S15H ultra-sonic and the "official" chemicals (in my case Elma WF pro (cleaning), Elma Suprol (rinse) and Isopropyl alcohol (IPA). That made a world of difference ! So, if you are serious in continuing this hobby, fed up scrubbing with lighter fluid and want to "up" your cleaning game to near professional levels; get the decent stuff1 point

-

Even though the garden is screaming for attention one has some spare time to continue my magical journey through the heap of quartz movements. This time it is the ETA 251.262 Chronograph which can be found in watches like Breitling Colt Steel, Certina DS FIRST, Longines Hydro Conquest and so on.. I'm quite surprised of the amount of quartz movements which are getting a new life after a good clean and service. As usual all the files are in a PDF format, and all pictures are original. ETA_251_262_Dissasemble.pdf ETA_251_262_Assemble.pdf1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)