Leaderboard

Popular Content

Showing content with the highest reputation on 12/14/24 in Posts

-

A good writeup, thanks for that. The one thing to remember is that when you read reports on the few of these machines that have supposedly over heated, in every case it's the owner doing something wrong that resulted in the over heating, so for those people some form of thermal protection would have helped. For those who don't do stupid things like place them upside down on the desk or putting books on them so the button is constantly pressed there is no real issue or need to panic. There are loads of electrical items that don't have toc protection that get too hot when incorrectly used, but are fine when used correctly. So no need to panic4 points

-

2 points

-

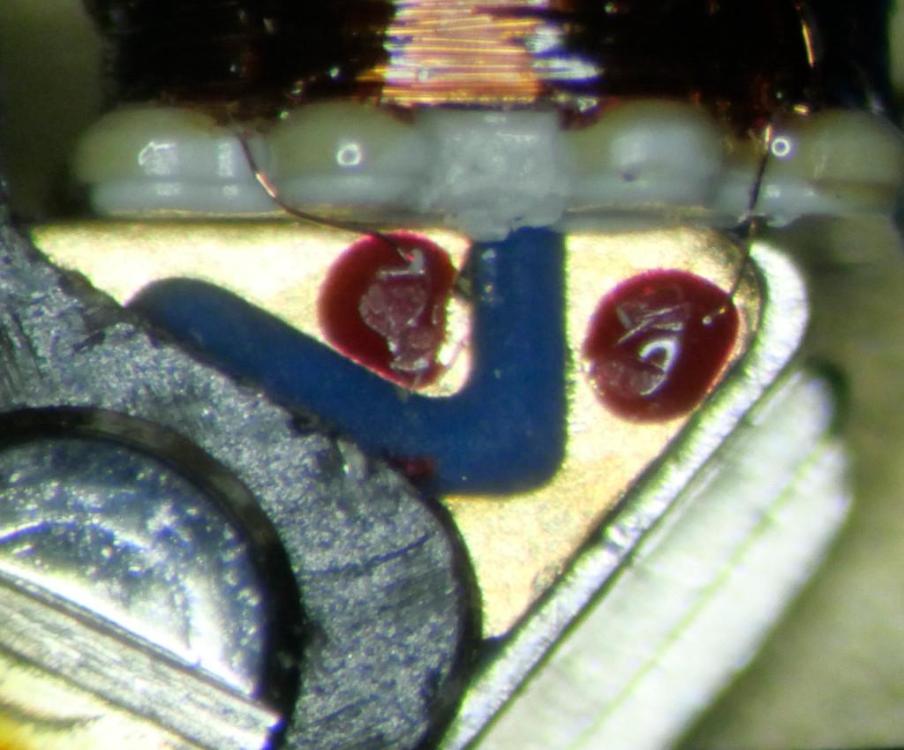

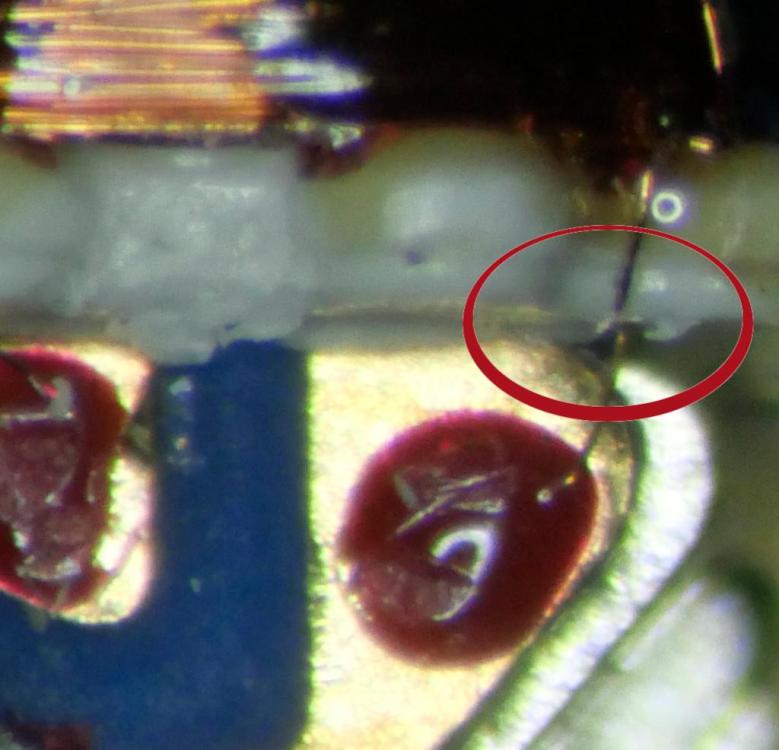

Actually, the problem in the video is hairspring pressed on the balance arm. See the white circle. You can see small amplitude oscillations with high frequency, this is because the hairspring is 'shortened', only small part of it acts as spring. The way to solve it is to twist the spring near the stud as to lift up the place where it is touching now. This can be done in place, as the tweezers can grasp the spot and in the direction of twisting the tweezers movement is not limited by anything2 points

-

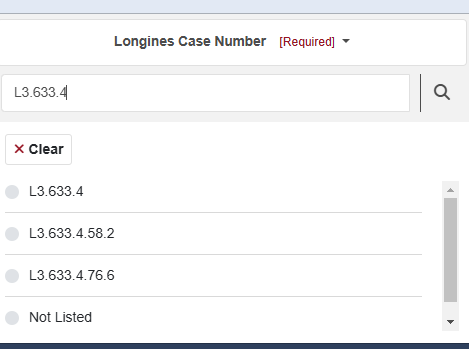

My cheap Chinese 1.3L ultrasonic is similar to the one in @AndyGSi's pic, but with knobs in place of touch buttons. After looking at the specs of the ultrasonics in pro cleaning machines, I decided on 40kHz and 60W power. I think people who complain of stripping shellac from pallet jewels etc may be using machines with more than 60W. Using Elma fluids, 4 mins clean, 2x 2 mins rinse gets the parts clean for me.2 points

-

Yes epoxy and heat is rather interesting. Sometimes what I machining parts I will epoxy because it has really nice holding power and then I will put the thing in a pot of boiling water wagon just tap off the object nice and clean. Also if you want to take out watch crystals and up epoxy Danube oil level in water and I'll just pop out. But it does seem odd that manufacturers would use Epoque see and have a heating system so they may be using a higher temperature E epoxy or something else I had a small ultrasonic machine that I used for cleaning watch parts that actually came with a glass beaker and recommended putting it in the tank With water between the tank in the beaker. This would of course cause in discussion groups of people telling me how stupid I am because you must never do this even though it's the way it came. Then the cheap little ultrasonic ran about 20 years of occasionally cleaning watches and worked perfect until it finally died. But I've also seen larger ultrasonic machines were people put metal clock plates or other large metal objects and shattered their transducers. So yes it usually is recommended not to have things directly on top of the transducer. One theory I heard was if it's solid enough feel reflect back into the transducer which really bad I do not know if that's true or not I do know they look really bad when the shattered. I was trying to find another picture of the bigger machine that I was using when the little one disintegrated. But I did find a picture the little one purchased from the drugstore when they're on sale or there were just really cheap. In other words newfangled ultrasonic cleaning machine with beaker worked really well. Even if I did get schooled in the discussion groups Okay that your machine somebody didn't want it and gave it to me. So it to prevent the beaker from sitting on the very bottom not that it hurt the little machine as far as I get tell I have a piece of plastic with square holes in it and it fits in the tank units up about hard to tell the picture but at least half an inch maybe an inch than the beaker can sit on that and not be on top of the transducer.2 points

-

Most definitely. If I wanted to brighten as well as clean brass parts, I'd use an ammoniated cleaner like L&R #111 or Elma Red. For removing organic matter from watch cas4s and bracelets, I'd use a dental or surgical instrument cleaner.2 points

-

I have one of these. It runs very true, the spindle traverse lever on mine has a small amount of binding, but it doesn't affect its accuracy. I bought it because I wanted a sensitive drill, and this was much cheaper. I didn't get the XY table with mine, but I did purchase the crown holder/hand tube tightener. If you don't have a dedicated space for your lathe, this would be a great solution for drilling since its much faster to setup. But if you have a lathe and tailstock, drilling a crown out would be more precise in a lathe. I plan to use mine for perlage application mostly. I ended up getting mine on sale on AliX for about $50, with the jacobs chuck. I do wish the speed control was mounted on the press, instead of being inline on the power adapter.2 points

-

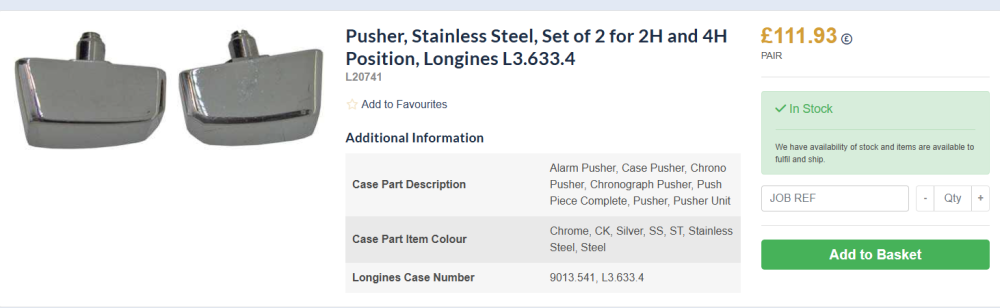

Just noticed you edit above and that's the first time I've ever seen that from Cousins. Edit There's this on eBay that look right so probably worth a message to confirm the size. https://www.ebay.co.uk/itm/1350252435981 point

-

1 point

-

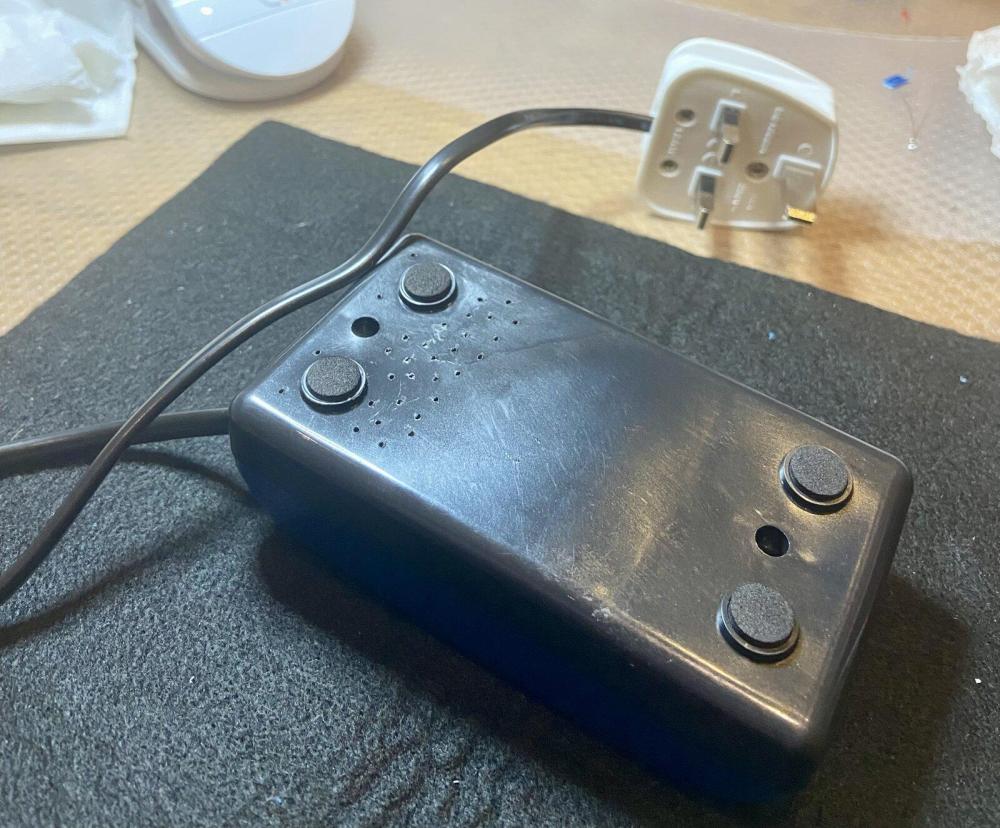

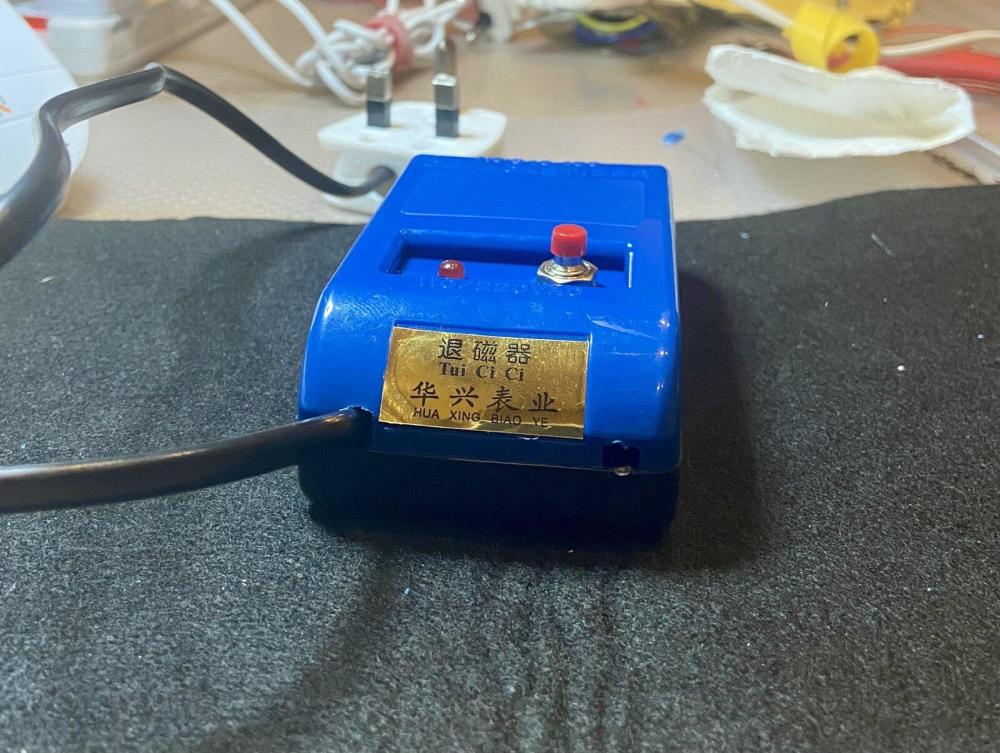

Budget watch/tools demagnetiser modified by incorporating thermal protection. There are discussions within watch enthusiasts, whether it’s a safe and/or necessary to use demagnetiser on quartz movement. I leave this question out of this topic, which aims bringing an awareness of lacking tool’s thermal protection and providing solution. SEIKO memo about magnetic influence Credit to TheHWcave for the research, test and trial on the YouTube link below. Thermal protection based on a PTC (Positive Thermistor Coefficient), the power lead is moved to the opposite side to ensure that nothing is near the PTC as it generates heat (+130 C) when current flows through by increasing its resistance, and I also perforated the back cover to improve cooling. The maximum current of the demagnetiser is around 200mA. The following thermistors were considered and I opted for B755, mainly due to its availability. Note, during operation, the thermistor's surface temperature can be very high. Ensure that adjacent components are placed at a sufficient distance from the thermistor to allow for proper cooling. B755 Datasheet PTCCL05H390 Datasheet Video instruction The demagnetiser is bought on Aliexpress, costed less than €10 PTC B755 5pcs €101 point

-

1 point

-

Well spotted @nevenbekriev Why did we not spot the obvious? I, (and all the others who posted above) hang our heads in shame1 point

-

1 point

-

A lot of the old Russian watch movements had a shim under the balance cock, if that is missing you will have problems. I know the RAKETA 2609 had one.1 point

-

I have the two litre version of that exact one,.they've gone up in price but still cheap. Sounds like the same problem that my second one had. I assumed the transducer had become detached from the tank, as I could still hear it buzzing, but it was not acting on the tank water. I made a lid for my first one with holes in it, and sat three stainless steel cups in them. Works great now.1 point

-

1 point

-

Most transducers are bonded on with epoxy. And epoxy's biggest enemy is heat. I don't recommend using the ultrasonic cleaner with heaters turned on because it will weaken the epoxy and result in debonding. Never put objects directly on the bottom of the tank. This will cause heat buildup because there is insufficient circulation of fluid to carry the heat away. This is also why I don't like the beaker holders that come with the units. With the ultrasonic turned on, the vibrations can cause the beaker to slip down and touch the bottom. I prefer to use smaller beakers and put them in the basket. There are some ultrasonic transducers that are bonded and screwed down to a metal stud welded to the bottom of the tank. These are, in my opinion, the most secure way of attaching a transducer to the tank. But you can never tell the construction method just by looking at it.1 point

-

Interesting problem here is they all looked the same. Any that I've ever seen including if somebody takes the back off there are all identical circuit boards are identical everything is identical. In the case of the 1000 machine the only differences I've seen have been different markings on the case in other words different people selling. Plus there's some minor software variations is a slight difference in how the screen looks and others are some bonus numbers when it's doing the graphical display of telling you what the rate is and at least one variation has the ability to change the gain control but otherwise visually they all look the same. So the problem becomes if they all look identical which one is the legitimate one in which one is not? How do we know that cousins a selling the legitimate one versus the counterfeit one if there even is a counterfeit one? Conceivably maybe if there are counterfeit which side suspicious of maybe they're all purchasing from the same source. So then basically it comes back down to can you get your money back if you're unhappy. As far as warranties go what warranty? True on the back of the 1900 users manual there is a name of a company and a link to a website that no longer functions the company does seem to exist in China but it doesn't list the product on their website The ones I always get nervous of but for the most part I've had success is the tiny Chinese Amazons selling on eBay where if you look at the other products are selling its everything in the universe including your timing machine. But for the most part with things I've ordered from them even that's worked out mostly. Shipping issues can affect all everything. I was trying to think of my bad experiences with the? I can't quite remember all my bad experiences and they typically were watch products there are other things. The little Amazons I have the feeling they toss everything a box and somebody goes the post office and just dumps at a big box and if it doesn't make it into the box doesn't show up in shipping and then when you pester them about that at some point time the refund your money. Because they really have no idea what happened to the product and they really don't care. It's back to finding somebody or purchasing of where you get some sort out if there's a problem you get your money back Then as others have mentioned always look at the reviews. I ordered something I can't quite remember what it is now and it was supposed to be in the US somebody had complained about shipping. So I figured out it was based on the names they had it wasn't really in the US probably it probably came from China and didn't show up for tracking for an entire week I guess was lost in the warehouse that extends from California all the way to China and at material. Which is basically what somebody said in the review and it was some weird shipping company before they handed off to the US mail. Which in itself presents a problem because stuff coming from California tends to be much slower than stuff coming from other places.1 point

-

No, it's not my first. The one (and only) I had (Chinese) worked well for about five watch cleans (like yours). After that, the transducer hardly stirred the water in the tank. It was total junk and the reason I'm hoping an Elma would be worth it. Also, with the Elma, you can get a lid in which you place beakers which would make the processes a lot less messy. The idea is to place the parts in my rotating Elma cleaning machine basket, do the cleaning in the US, then transfer the basket to my cleaning machine, spin off, and rinse (rotating) in distilled water and IPA.1 point

-

I would say if it's cheap it is not the real mccoy.1 point

-

On ebay UK they start at £191 (post from UK) and £159 from China. Many that claim postage from the UK actually get posted from China. Check the feedback to see how people rate delivery time. As John says, they all look the same. I'd be surprised if anyone bothered to make copies.1 point

-

Maybe you’re not comfortable with ordering from China but I’ve found the best pricing for the same items from AliExpress. All my watch tools/parts has been from them and I bought a few machine DRO’s that have been faultless. example: I just found this on AliExpress: AU$439.75 | Weishi NO. 1900 Timegrapher Mechanical Watch Timing Tester Machine Multifunction Auto Calibration Timer Machine https://a.aliexpress.com/_mL7o5oL1 point

-

Don't forget that most of the alleged "Swiss" made tools are actually made in China, then sent to Switzerland for QC and packing, that under Swiss rules allows them to be listed as made in Switzerland. The main difference is the QC aspect, Swiss QC is much better than Chinese QC. You will probably find items that pass Swiss QC get shipped to the Swiss customer for boxing and those that fail Swiss QC get sold via a Chinese supplier in a Chinese box. The unanswerable question is how far away from Swiss Quality is the Chinese version. And is the difference enough to matter.1 point

-

The easier way is to measure the pivot diameter. The other ways need specialized tools. There are gages for holes measuring - this may be set of pins with different known diameters , or tapered things like broaches that have marks for the diameter. Old stones are brittle, so one has to be careful when measures.1 point

-

@cor9brg, I guess one of the jewels is broken, right? Then You can remove it by destroying it. Then You will be able to measure the hole diameter. The other measure You need is the shaft diameter. One option is to make phosphorous bronze bush to replace the jewel. Pressing the jewels out is risky operation, as one of them will have to go all the way through the hole. If one of the jewels is removed (by destroying it), then the other will get out easier. Sourcing such big jewels can be problematic, but big jewels are used sometimes in clocks, so searching among clock parts is some kind of idea. Russian ship cabin clocks have similar big stones.1 point

-

This actually can be replaced without any complicated jeweling tools. Waltham and Elgin and other American companies made these watches to be very quickly and frequently repaired, so the jewels are housed in brass settings which are then screwed down. All you need to do is find a donor, or a replacement for those jewels on ebay. A "parts or repair" 1894 movement will have the jewel you need, and it is also possible to search for new old stock or jewel lots for Waltham 16 size (or whatever size this happens to be). It is MUCH easier than replacing jewels on an old Swiss watch. The same goes for the balance complete - find a donor on ebay that is advertised as having a good balance and you may get a lot of the way there. Now, note that there is likely a serial number scratched onto the balance wheel that matches the serial of the movement plates. It is nice to keep these together and matched so keep your broken balance around until you are ready to invest in a staking set and learn to replace the staff. Then reunite your serial stamped parts. I find working on American pocket watches extremely rewarding, and if you like it, you'l end up collecting a lot of interesting purpose-made tools. Also, familiarize yourself with daveswatchparts.com - He stocks a lot of parts for American movements, and even if something is not listed on his website there is a good chance he has it and can get you exactly what you need. Oh one other thing about the jewels - after removing the screws, you can just gently push them out with pegwood. The whole brass setting will slide out. While it is firmly fit, it won't be "friction" fit such that it takes force and a special tool to remove. Pegwood will do, and there are also vintage brass "jewel pusher" tools which are sort of a star shaped thing with multiple sizes of brass nubs designed to push on the settings without cracking the jewels.1 point

-

WD 40 is not a oil ,it is a water dispersant , Kroil is another penetrating fluid1 point

-

Hey @cor9brg, Don't worry about the missing stumps/anvils. Not so important and you have plenty of sizes (plus the flat stakes that can be used inverted). I actually have more missing ones in those inner rows. The pocket in the front right (69-209) is for reamers. I think these were an add-on option because most sets I've seen (including mine) don't have them. I have reamers in my Seitz tool, so no need for me. Here is the manual: Boley set.pdf (I also don't have the jewelling adapter. My Seitz for that again.)1 point

-

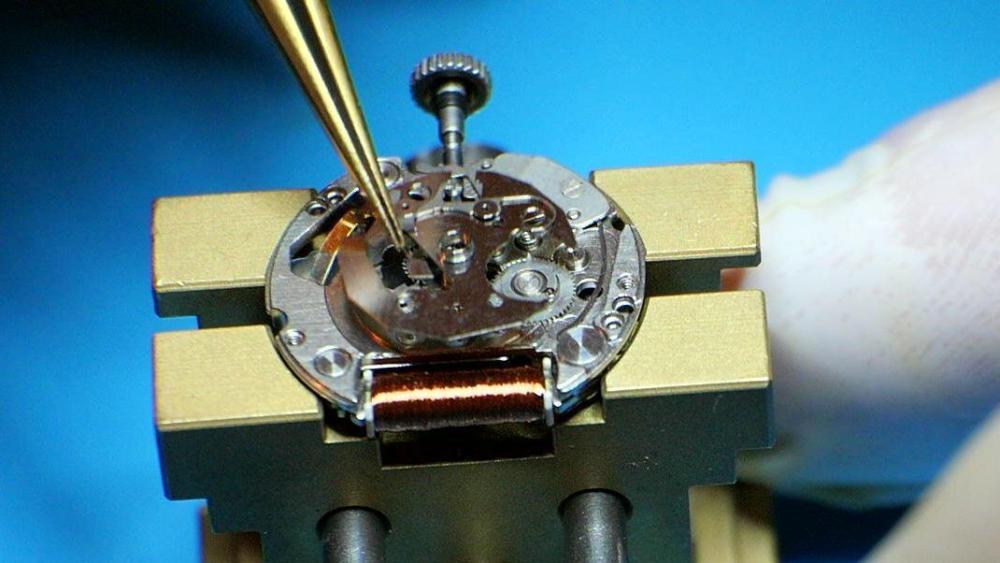

Sorry for not posting so often, I began a year ago, worked on some Seiko 2220 chariot, hi-beat 5740C, more using my little time to practice than to try to write on a foreign language since I'm not so fluent in english. Also my apologies for my cumbersome english As computer scientist, I worked on tools to document and follow my work (a kind of personal and private blog). I plan to publish a simple tool to calculate some data from timegrapher measurements. That said, here is my latest project I finished today. Since I planned to gift a watch to a lady in my family, I searched for a long time a nice Seiko (I'm mainly focused on 1970's Seiko) and finally found a beautiful 2623-0080, with a wonderful blue dial, unworn, from 1978 ! I trained myself on one of this kind of movement, a diver, and knew the challenges. For me, the difficulties resides mainly in the magnetized rotor and the tiny gear train with its bridge. I assumed that the lubrication requires some common sense and I had a look on a quartz ETA oiling chart. So I started doing the service, almost confident. It was an uneventful clean-up. Everything was very clean, the screws were untouched, only some old grease and oil in contained spaces. I could imagine that the oil was just in god proportions, never touched, right from the Seiko's Daini factory. (the gear train on a 2€ coin, the magnetized malicious rotor a bit appart, on the "E" of Euro. It took time to set the scene of this picture) No noticeable problems, until reassembly... When I finished on the back side (côté ponts), I put in a battery... And nothing moved... Not the slightest sign of life... And we're only a few weeks away from the deadline Hopefully I had other movements on this kind, and that's how I started debugging. Quickly I found the issue : Do you see it ? Great ! Yes, just here ! I don't know how I made that, but I'm sure it's my mistake. I (should) always do a thorough diagnostic and (should) take notes on everything I can notice. As I've the continuous improvement mindset, I have to find out how this happened. Not sure, but maybe I screwed the movement holder on the fragile part, or, less tangible, I slipped with my screwdriver on one time or another. This is how I replaced a brand new electromagnet with an old one I encountered some concerns on the other side, since I didn't worked a lot on date/day modules, which I overcame with a bit of observation and patience. Then... Finally, I'm ready to face Christmas holidays ! This is how I finished my (around) 10th project, my second and most important quartz movement... At leas until now !1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)