Leaderboard

Popular Content

Showing content with the highest reputation on 12/15/24 in all areas

-

All the other watches I have so far are broken in one way or another- which is why I got them for free- so I haven't been able to get them working yet (need a staking set, etc). However, I did get a practice movement that I just took apart completely and reassembled. And if runs. I feel like it's a milestone.2 points

-

Always a good idea to take a baseline set of readings before starting on a running watch. Then you know for sure if you made a mistake somewhere. Tom2 points

-

No need to Apologies for the error. We all make mistakes.2 points

-

I'm pretty sure that is not a Swiss movement in the ebay link. They probably say Swiss because it's from a Rotary, but they use cheap Chinese skeleton movements. I tried to repair one for a friend, but the quality was so poor, I gave up and just changed the movement - about £25. I have never seen a stem on a Swiss movement break there - I can't see how you would break it. I think it says something about the (lack of) quality of the metal. Length E is important, but you also need C,A,F to match. Fortunately the Cousins Chinese stems are cheap, so get a couple of the closest.2 points

-

As a novice, take care when adjusting the beat error arm. Normally the regulator pins (arm) will follow the movement of the beat error arm and so maintaining the regulator setting. However, sometimes only the beat error arm moves, and if this is towards the regulator arm it can kink the hairspring between the stud and the regulator pins, as the regulator pins have trapped the hairspring. Moving it away, from the regulator arm, is unlikely to cause any problems unless the movements are large.2 points

-

The right one holds the stud. Moving it will change the beat error. The left one will change the rate.2 points

-

OMG... This is my first staking set. Well, not the actual one, but the same make and everything! It cost me £40 or £50, I believe. It did what it said on the tin, so to speak and I used it for staking back hairsprings to balance staffs and closing up holes. The only problem with Dracip staking sets is the stakes aren't the same width as most others. They are larger at 4.75 mm instead of the usual 4.7 mm. I found a load of stakes that size, so my Dracip set is well stocked and you can use any anvil from any other set. If you get an 8 mm lathe, you could turn your own anvils and even stakes. As a starter staking set, it served me really well until I got the staking set bug and now I've got seven, or maybe eight. As I said, it'll do some basic stuff, which is great. Worth the small amount of money in my opinion and when you want to up your game, buy a better set and sell this one. I've still got mine, as it is my first staking set and I've got quite attached to it, so would never let it go.2 points

-

Well, this is no problem to see something when it is on computer display and actually enlarged 10 times than normal size. Here the balance behavior is misleading as untightenning the screw makes the problem disappear. In reality one would check the axial free play and understand that this is not the problem. May be my eyes are trained and immediately spotted the high frequency oscillations and when one knows what it means, then He will know where to look at for searching the reason. You can see russian watches assembled from variety of different looking parts, buy this is because people assemble movements from what they have and sell them, thus You see mixtures of parts made in different factories and in different time periods.2 points

-

LOL for the last week I've had a Raketa movement sitting on my timegrapher, running dead flat at 280°/245° in 4 positions and it isn't even complete. Missing an escape wheel upper cap jewel but still no real variance in DU/DD.2 points

-

Must be all that carrot juice neven drinks with his breakfast. Lower coil looks good, perhaps spring leaves the stud with wide angle. We best see pic of spring end attached to the stud, before OP ruines another spring. Russians made watch out of parts they had in inventory, so we see variety of makes, not necessarily variant of a base calib, but with all sorts of shock system, hairsprings, balances wheel etc, whats worse is their watches tic , even kept time.2 points

-

1 point

-

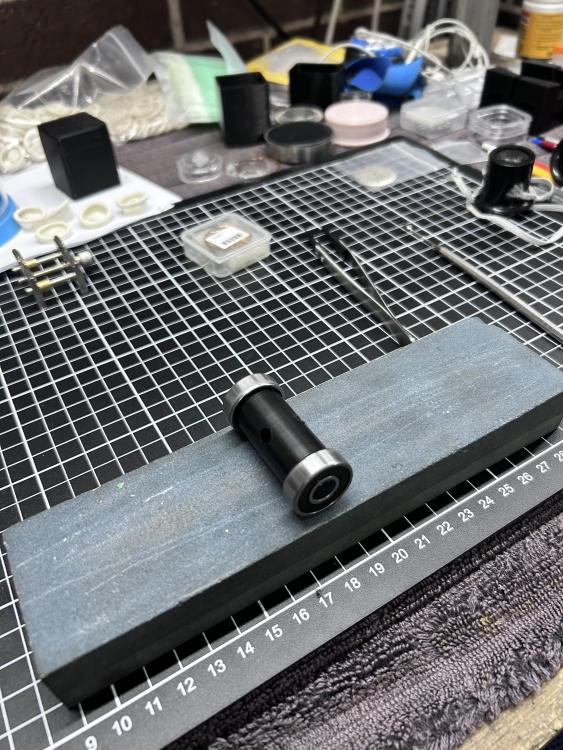

My Omega 565 came in. Wow what a stunning piece of engineering as well as a flat out gorgeous (to quote Marshall) looking piece too. I was taking the automatic bridge off and realised my screwdrivers were not really sharp enough to get on to the screw heads properly. Luckily I have a machine shop so I grabbed some Acetal, a couple of bearings, a set screw and made a screwdriver sharpening jig. I sized it so it would run on one of my non precision stones. It works perfectly.1 point

-

1 point

-

Thanks Nev, as always it's interesting to know the reasoning behind your prediction. There are often many causes for the same issue, it's becoming less surprising to see you pin-point it first time Lol we shouldn't really Mike, Nev holds some of the most extensive experience and knowledge in the group.1 point

-

Anything you're comfortable with. Some regulators move easily and others take some force to overcome initial friction. I like pegwood (cut to a flat "blade") because it won't scratch and is less likely to damage a regulator pin if I slip. I don't find it easy to keep a screwdriver in good contact without it sliding around; feels dangerous to me. But plenty of people do it that way. On some regulators, a closed pair of bigger tweezers makes a good "V" to nest in and push, the ones that want to move more smoothly and readily are easier to do with tweezers. If pegwood, avoid the kind that is sorta crumbly and will shed little bits into the movement. If you are really hoping to dial that movement in, bringing your dial up/dial down rates closer together is the place to start. But that wouldn't be done by regulation; a significant difference there in rate and especially in amplitude is a good indication that one of the balance pivots is less clean than the other, or there is an unequal amount of oil on the balance jewels.1 point

-

For fast/slow, moving the regulator arm away from the hairspring stud increases the rate (by making the spring effectively shorter) and moving it towards the stud makes it slower. So the farther apart those two arms are, the faster the watch. But the movements are really tiny. One tenth mm of movement might change as much as 40 or 50 seconds per day. And the stud carrier is even more sensitive for beat error. Barely perceptible movements cause large changes.1 point

-

Rich, untightenning the screw makes the cock go up, the hairspring goes up with the cock too and this is enough for the balance to be released1 point

-

Front loader but still has access from the back to remove the stem. Try removing the rest of the keyless and see then.1 point

-

1 point

-

Is the stem in the setting or winding position? Looks like winding so try pulling it out to the setting and have another try with the screw. You could also put some penetrating oil on the back of the screw.1 point

-

I have just found my written notes from the last service. Contrary to my recollection, I had lubricated the three springs with D5. I‘m relieved…1 point

-

Thanks everyone! The reason I showed the second video was so that you might be able to see that, because I suspected that was an issue BUT when I remove the balance cock screw it didnt seem to matter that the spring was resting on the arm. But you have now explained that let me try and address this and report back. Thanks again everyone!1 point

-

I have a whole watch that I tried to service, and then I broke the pivot of the pallet fork. So now I have two extra Osco 66 movements for spare parts, and I'm confident that the pallet fork in one of them is fine because it looks like this other movement is actually working.1 point

-

1 point

-

A good writeup, thanks for that. The one thing to remember is that when you read reports on the few of these machines that have supposedly over heated, in every case it's the owner doing something wrong that resulted in the over heating, so for those people some form of thermal protection would have helped. For those who don't do stupid things like place them upside down on the desk or putting books on them so the button is constantly pressed there is no real issue or need to panic. There are loads of electrical items that don't have toc protection that get too hot when incorrectly used, but are fine when used correctly. So no need to panic1 point

-

Well spotted @nevenbekriev Why did we not spot the obvious? I, (and all the others who posted above) hang our heads in shame1 point

-

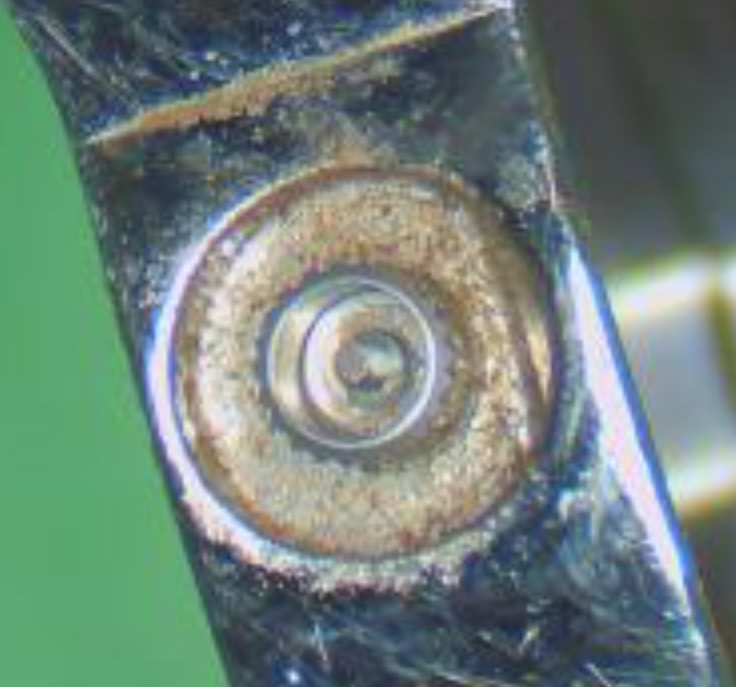

Actually, the problem in the video is hairspring pressed on the balance arm. See the white circle. You can see small amplitude oscillations with high frequency, this is because the hairspring is 'shortened', only small part of it acts as spring. The way to solve it is to twist the spring near the stud as to lift up the place where it is touching now. This can be done in place, as the tweezers can grasp the spot and in the direction of twisting the tweezers movement is not limited by anything1 point

-

1 point

-

I use makeup brushes. The one I've been using the longest is still is perfect condition, very soft, and doesn't shed. I think any brand will do. I stole mine from my wife.1 point

-

Just be careful of cheap imitations. I would stick to a reputable watch tool suppliers. You don't get something for nothing in this world.1 point

-

Hi and welcome to the forum. If the jewels are staled in it’s probably best left alone as trying to remove them may cause damage. Out the plates through the U/s and re check , might take a couple of passes and then peg out the holes and re clean.1 point

-

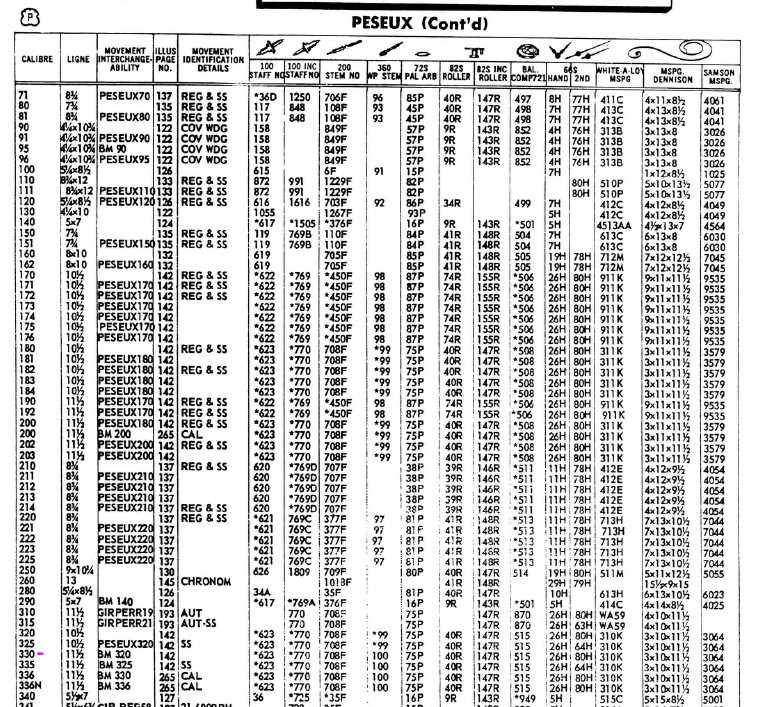

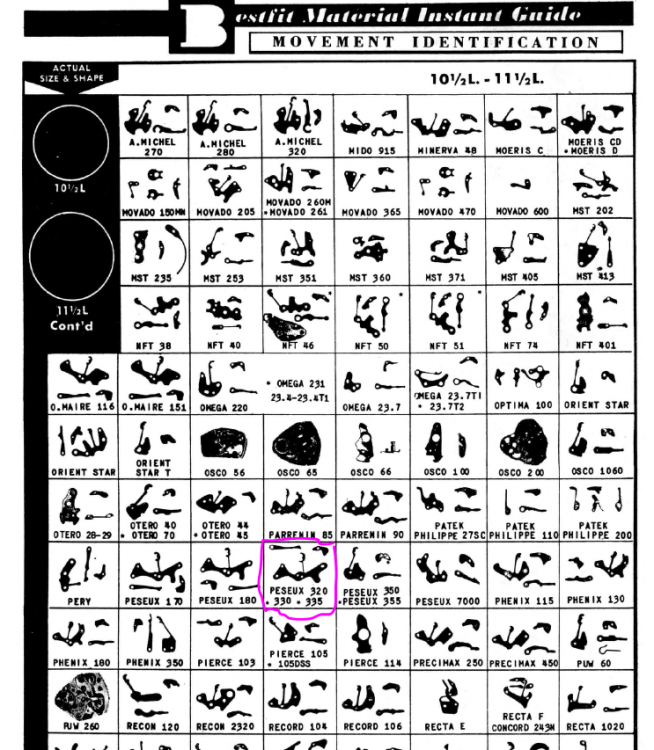

we unfortunately still do not have a picture from the original person who started the question but we will assume that all of our assumptions are correct and legality picture of the dial side. Then because we know the model number and were going backwards. In other words you can go in either direction if you have a diameter size and a picture the setting parts like up above we can look up the fingerprint system or you can go because we of numbers and go the other direction just to verify so here's a page from the bestfit book and noticed that the 330 base caliber is 320 and if you look at some of the other in the 300s they all kind of interchange in fact they all have the same parts so you'll notice in the above example it mentions illustration page 142. then even though I'm looking at a PDF if you have the physical book it's nice because all the parts are exactly sized the size of whatever you're looking for as opposed to we look at the pictures so some of the pictures may look similar but they should be an exact match to the one that I circled. It also see the importance of why I asked for the size because without a size reference you have to go through a heck of a lot of pictures attempting to find your setting components it's a lot easier if you have a reference size1 point

-

1 point

-

If the important bits of the stem are there and in good order they can be measured and matched against a list. This will give us a few examples of what the caliber might be, although it will need to be accurately measured1 point

-

My master taught me with a westminster chime on the quieter past the hammers go down the scale and on the quieter too as it chimes three times the last also goes down the scale. When setting these clocks up when it comes to the warning no hamer should start to lift and after it has chimed no hamer should be stuck. The way to sort this is to unscrew the ratio wheel and adjust.1 point

-

The trouble is not knowing the condition of the movement, if it is worn and dirty adding oil will make little difference and if it is not oiled correctly you could cause more wear. With out taking it out of its case you will only be able to oil what you can see on the back plate this again is not recommended. Never just put it in some sort of fluid as the barrels will be flooded with the stuff and it will not all come out. The movement should be removed from the case, inspected, taken all to pieces including removing the springs from there barrels then appropriate work undertaken cleaned assembled oiled and tested.1 point

-

Ok, so in the end I got this Boley set in really immaculate condition. Can be used in the inverted style and has the ubiquitous 4.7mm sized stakes. 250 Euro (incl shipping). Only a few elements are missing (and I don't need the reamers that could be in the front right - I have them in my Seitz press). I'm happy. Now I just need to find good use for it1 point

-

For the past few months, I’ve been working on a custom dial project. I’m still not ready to show my first production examples, but the project has gotten to the point where I’m comfortable sharing my progress. I’ve been documenting this process, and am committed to sharing my process notes. I believe in open source information, and I’ve benefited immensely in watches (and in life generally) from the wisdom and experience of other people who have been willing to share what they know with me. My hope is that by sharing my process notes, I might be able to encourage other folks to take a risk and try to make something cool. I’ve never attempted anything like this, and even if this project is ultimately unsuccessful it has been a ton of fun. I'm sharing my progress and process notes on this forum because folks here have been incredibly friendly and patient with me. If you have any questions about my notes, please feel free to let me know and I'll try to explain things better. I'm happy to answer any questions, and I'll be sharing more photos as I can. I've received a number of comments from people I've been corresponding with that essentially conclude that "this is too hard to pull off". Bur for the serendipity of finding a source of half-height Seiko dials and having free access to an incredibly expensive precision saw, I would have agreed. If anyone has suggestions or concerns that I'm missing something key, please let me know. Background: Seiko & ETA 6498 Custom Watches My project started with customizing my own Seiko watches, and with assembling several custom ETA 6498 watches using available parts from Chinese sellers on eBay. I greatly enjoyed manufacturing my own ETA 6498-1 based “marine watch” using high quality components, and produced a watch that is nearly equal to the Stowa Marine Original I wanted but couldn’t afford. I could have saved more money using lower-quality components, but instead assembled a watch using high quality components (heat-blued hands, an especially nice 41mm case with a sapphire crystal, an elabore-grade ETA 6498-1, etc.) to build a final product that was high quality but still significantly less expensive than the Stowa. Here's my 6498-based "Marine Watch" On the Seiko side of the house, I’ve built a couple of custom Seiko watches using some of the really amazing dial and hand combinations available from lots of internet sellers. (My favorite seller is called Lucius Atelier.) In browsing the offerings of several different Seiko part dealers, I saw that some suppliers sold higher-end dials made out of meteorite, damascus steel, carbon fiber, and other neat things. Knowing how much I enjoyed building my ETA 6498 watch, knowing how many people enjoy modifying their Seiko watches, and being generally fascinated by exotic dial materials, I realized that it might be possible to design my own watch dials. I enjoyed reading many articles on restoring dials using decals, and thought a lot about using electrolytic-etching or laser-cutting to customize brass dials. It was at this point that I stumbled across fordite and fell in love ... Fordite Several months ago, I ran across a limited series of very expensive TAG Heuer watches that featured unique dials made out of “fordite”. There's no way I'll ever be able to afford once of those £5,500.00 watches, but I couldn't get the idea of working with fordite out of my head. (Here are some quick shots of my first fordite samples, to give folks an idea of what it looks like in unpolished slab form.) Fordite is also known as “Detroit Agate,” and it’s actual industrial waste. Back when car manufacturers used to spray paint cars by hand, they generated a lot of overspray. This overspray accumulated over the years, and hundreds of layers of overspray built up into large chunks of waste material. This stuff was repeatedly heat cured at the same time the painted cars were heat cured, and the resulting chunks of waste are durable and nice to work with. I don’t know the first time it was discovered that cutting open the waste chunks revealed beautiful and psychedelic patterns of paint, but for some years jewelers have been using lapidary techniques to create bizarre and fun jewelry with fordite. One of the things that I find particularly fascinating about this material is that it’s possible to source fordite from specific assembly lines. Consequently, one can obtain fordite in Jeep, Corvette, Cadillac, Peterbilt, and other colors. I’ve even obtained some fordite from the “Cadillac Ranch” in the Mojave Desert. It’s much softer and more fragile than “normal” fordite, but it also has a wider variety of colors and textures. In order to work with this specific soft fordite, I'm going to need to stabilize it using some cool lapidary techniques. Heat-Blued Steel I have been enchanted by heat-blued steel watch components for a really long time. I started researching how I might myself heat-blue steel with an eye towards designing and selling heat-blued steel watch hands compatible with Seikos and other watches. For quite a few reasons, this isn’t feasible (yet?), but I’ve enjoyed polishing and bluing steel pocket watch hands. As my dial project progressed, I realized that it wasn’t practical for me to add applied hour indices, and there are some significant obstacles to using film-free decals on the dials I'm making. I realized that some manufacturers of exotic-dialed watches got around the problem by attaching a short chapter ring directly to the watch dial. This solution really appealed to me, so I set about designing a chapter ring that could be cut out of very thin (0.01” or 0.254 mm) high carbon steel, polished, and then glued to the dial face without risk of fouling any of the watch hands. I worked with an engineer on Fiverr, who converted my really rough sketch of a chapter ring design into a DXF file. My first 20 carbon steel chapter rings are currently in production at a laser-cutting facility. I don't need to share photos of the steel I've heat blued here to prove that it's a work in progress. Temperature control is critical, and I'm going to be switching from a propane camp stove to a precision digitally-controlled laboratory grade Cole-Parmer StableTemp hot plate to get consistent, high-quality results. I know that large manufacturers, including Glashütte Original, are doing essentially the same thing: In this Glashütte Original watch assembly video, one can see them using a $50 digital soldering-station with a brass attachment to blue screws. I'd go that route myself, but my chapter rings are a lot larger and so I want a larger heating area with better temperature control. I'll specifically be using a 1" thick 4" x 4" block of aluminum mounted on the hot plate's ceramic heating element to ensure uniform heat distribution. Chapter ring, from concept sketch to technical drawing to first prototype. Obviously, I'm going to need to do a lot of polishing before I re-blue these for installation! [Continued ...]1 point

-

1 point

-

1 point

-

I agree. I really wish I could get steel Seiko watch hands (either pre-blued or to blue myself). For what it's worth, Vostok actually sells really high-quality blued steel watch hands at a very reasonable price: https://meranom.com/en/amphibian-classic/hands/vostok-watch-vostok-amphibia-original-blued-hands.html1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)