Leaderboard

Popular Content

Showing content with the highest reputation on 12/20/24 in all areas

-

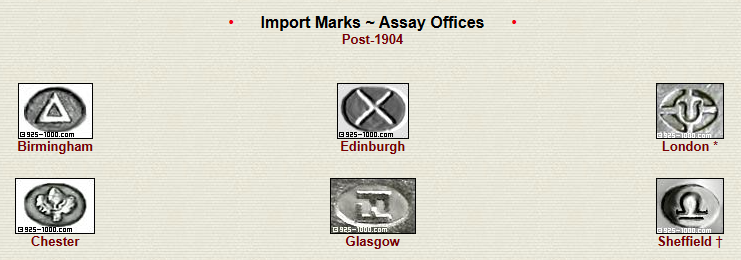

Surprised is not what I think when I think of Waltham mainspring barrel. Then they can get more interesting if it's the Waltham jeweled barrel. What about the hallmarks in the case isn't that more of an English thing also? Both Waltham and Elgin exported oh block of watches especially to United Kingdom where they actually had a distributor. Elgin got even more creative with their exported watches as they sometimes don't look like American pocket watches that are more like three-quarter plate watches. Many times the only have the serial number and on rare occasions the England distributor will actually engrave their name on it hinting that they actually made this watch when they did not. So basically United Kingdom should have a lot of Waltham and Elgin watches if you know what you're looking for. The other thing that makes the Waltham mainspring barrel interesting is the mainspring itself. Yes it has a hole in the end nice and simple except it's not. Rather than explaining I have a PDF which explains the problem. Yes it really is helpful to modify the end of the spring otherwise it's wishful thinking that the hole is going to go where it's supposed to. HT_August2016_MembersOnly The Waltham Hole-p22-24.pdf3 points

-

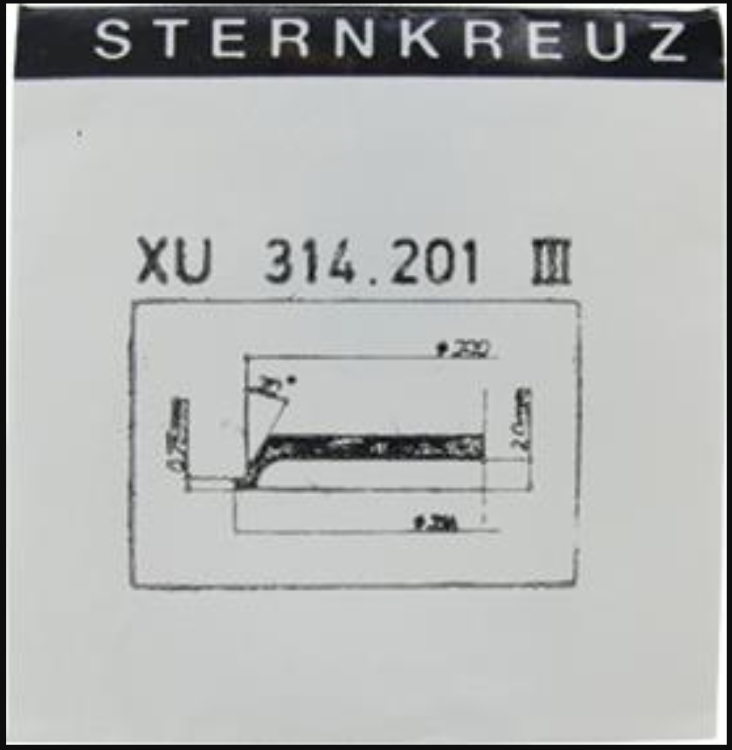

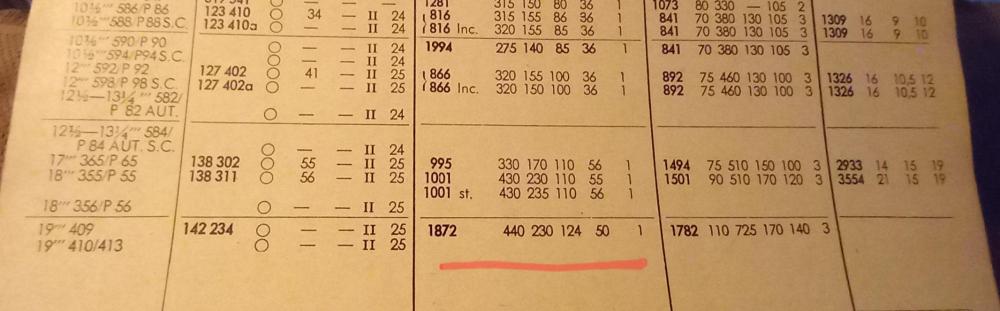

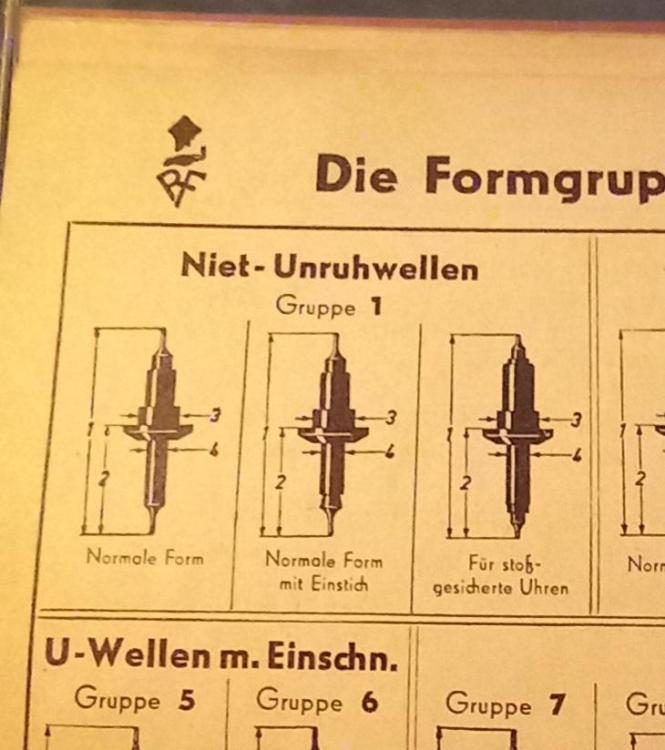

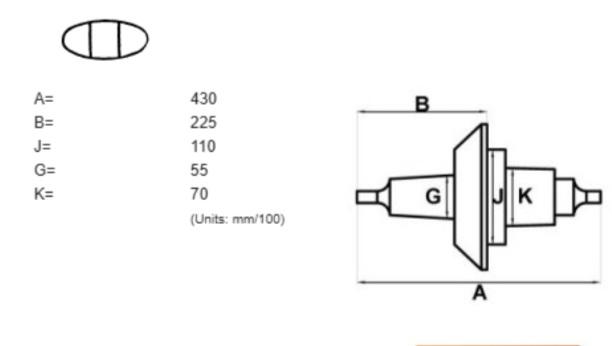

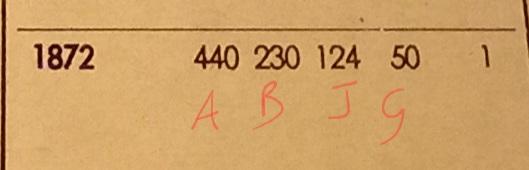

Hi Team. Delighted to see all the activity and good shopping on eBay! I have been away helping dispose of a decent 10 year old Rioja and a Chinese feast - hands are now nicely relaxed for balance staff work... So let me try and address the helpful replies. 1) the dimensions we are looking for are 422 210 126 83 and 50. 2) Yes only one pivot is broken so 422 is a decent estimate - the rest is measured 3) Buying a lathe and learning those skills at 76 years old is probably an over elaborate solution for a 10 dollar problem 4) No I have yet to figure out how to measure the balance staff length on a bare movement - No need here since the old shaft gave me a good estimate. The pivot was bent and still in the movement and the end shake was good. It broke when I tried to straighten it up ( yes it was heated etc ) The 440 option will not even let me drop the balance cock down - way too tall. 5) I think we have a WINNER and the prize goes to Bulgaria. The HELVETIA 32 gives us 422 210 125 90 53. the 83 vs 90 is the usual split collar balance spring fitting - an extra two thou there should be no problem and the extra thou on the roller shaft should also yield to a little fettling. Also to show it's Christmas, Cousins have them in stock for £5. Got to be worth a try. That's now ordered - Brilliant help as usual - Merry Christmas to all that did the research and we look forward to all those useful books being transferred to PDFs on here. No good turn goes unpunished. Also check sizes carefully before ordering on eBay...2 points

-

A few more interesting files for your perousal TM 9-1575.pdf dictionary_ebauches_sa.pdf Servicing a Platform.pdf2 points

-

I just don't understand watches with non-waterproof cases. How is the wearer supposed to wash their hands without getting water into the case?2 points

-

It all very convoluted stuff, I seem to have the idea that Dennison Birmingham also provided watch case for the early Rolex company when it was London based . They definitely had a very good reputation by all accounts. Tom2 points

-

Lots of experience is needed in repairing watches so when it comes to repairing very small movements. With experience you just go about it as just another watch repair.2 points

-

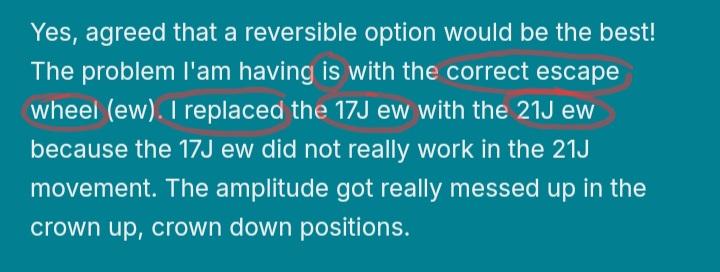

Gosh, are you Sherlock or something!? (I'm not being sarcastic!) I re-read it too and was sure he was trying to get the 17J escape wheel to work in the 21J movement, which, IMO, would have been a very bad idea. Anyway, I am glad you could conclude that all that's needed is to move the settings It goes to show how difficult communication is (or how thick "some people" are )2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

John. And others who have helped. You may be asking. Why do I ask questions at this level? I really do appreciate the time you take to try to assist me. I do read and try to take in all information. Some may think me naïve, although I am so pleased that no-one has even considered raising a concern about the level of my question. The only way I can learn is to ask a question. Perhaps someone else who is at my level but is worried about asking, will benefit. What is noticeable in the answers is the level of 'cajole'. In that, I mean all you can perceive from the answers is none criticism. What a great bunch you are. Being totally on my own and learning such and intricate hobby, for me it is intricate. My only recourse is the internet. Thank goodness for you lot. I've got tutors, friends, facilities from all over the world. Do you realise how great that is? Ta2 points

-

1 point

-

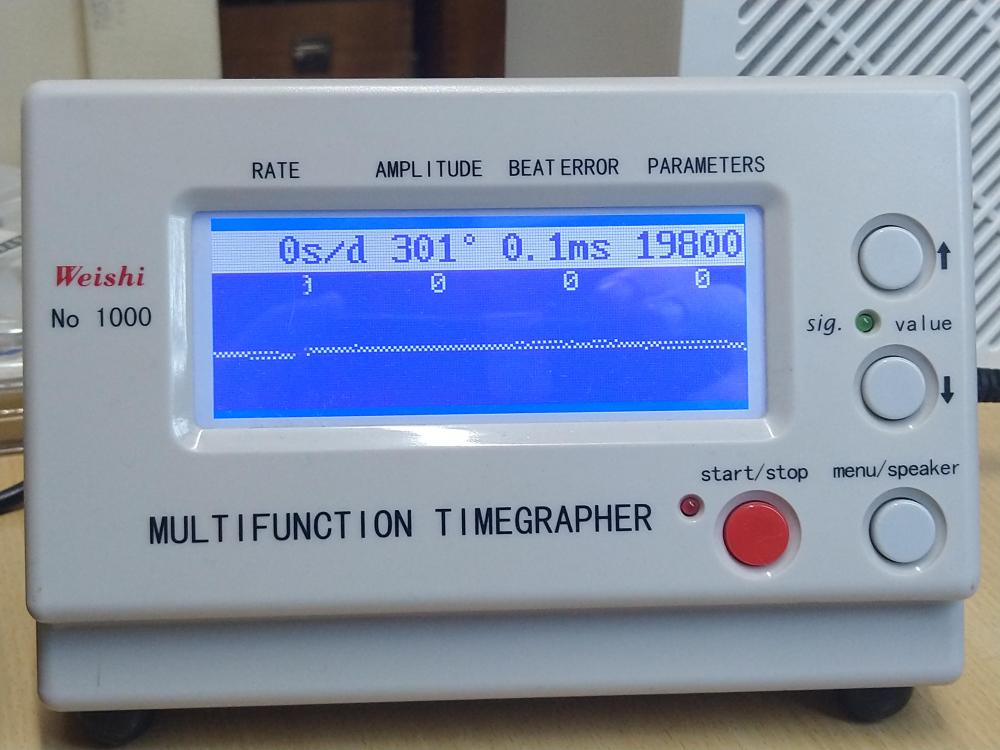

Haha, Must admit thats a good one Hector. Will be more careful composing. My initial suspect was worn pivot to a point thats too short to reach the relevent end stone. Doesn't look I was right. Your timegrapher can't identify the beat its hearing. Hairspring looks out of flat near the stud end of terminal curve, so this end section can rub on balance spokes in DU position and barely miss the spoke in DD position. The stud too looks it need an adjust to get a flat and level hairspring coil. I check , if impulse pin is loose, insufficient end play on fork pivots, dirty or worn jewels to the fork staff, heavy pallet lock on escape teeth, fork horn rubbing on roller table, guard pin out of adjust. Rgds1 point

-

So the movement is correct but must have special day and date dials for their location. I've been unable to find a similar version to see what the lens should look like so expect you'll have look at a standard domed acrylic or maybe one with a tension ring as being the easiest to fit. Edit You may get away with an I Ring and a flat crystal depending on the clearance for the hands?1 point

-

lol, I was waiting till after Christmas so I could say I'd bought them with Christmas money but figured once the cat was out of the bag I better pull the trigger. Strictly as they won't be here now till after Christmas they'll be bought with Christmas money.1 point

-

He kinda did , I told Andy about them a couple of weeks ago as I knew he was looking for them. Not a bad price either , they do come up fairly regularly. I'll keep an eye out for any more and let you know if I see em.1 point

-

It wissnae me! A big boy musta dun it an’ ran away mister. I didn’t know where they were Rich and didn’t even look as I thought Andy had first dibs. @Neverenoughwatches Tom1 point

-

1 point

-

Hi Corey. To help you with the terminology TZIllustratedGlossary.pdf1 point

-

Better look on the German site. Frank1 point

-

Thanks for this but the OP is looking for the dimensions of the 1873 staff as he already knows the Alpina 409 staff is too long.1 point

-

I had to look at the history, because Aaron Dennison (American) was a world traveler and his name ended up in or on a lot of American, some Swiss, and apparently at least one English company. Wikipedia says the Birmingham Dennison Watch Case Company was the supplier for Waltham's London office. This is especially interesting because while I would expect "Made in USA" it to be under the name, having stamped it elsewhere does seem like an indication it actually was made over here. I haven't seen another dial like that for sale.1 point

-

At the apparent going rate of nearly 500 quid I’ll just nag you to look stuff up for me Rich Tom1 point

-

Flume book shows the staff as a flume 1872. Heres the staff dimensions, numbered rather than lettered, from 1 to 4 in order of listed size sequence In sequence order of listed size even . You know you want those books Andy , you just know you do ...they're still available. Side by side comparison, I'm just too good to people, earning my browie points for the day of reckoning1 point

-

1 point

-

It could be either, but doesn't make sense to have the case made overseas and have to pay an import duty. Unless the buyer specifically requested the case to be made by Dennison in America and then assayed in the UK after importation, that just seems like a crazy idea. So almost certainly had the case made in the UK. Interesting that you mention the dial style is not synonymous with American owned pocketwatches. The dial has Made in USA under the bezel edge besides along with the Waltham name at the top. Another inducation that it was specifically aimed at the UK market that was used to that style of dial marking. Thats new to me Andy , I didn't know assaying towns had a seperate import stamp. Its been worth the thread for that information alone You have me digging out my hallmark book now forca thorough re-read1 point

-

There are no serial numbers on the case itself that tie it to the movement, which would have been nice. Only a matching caseback and bezel four digit code for those two pieces of the case. So the 5 year production difference between the movement and case could have a few explanations. If the case is original then its likely that it would have been made in the UK as standard to avoid the import duty of precious metals. Providing that this watch was made for UK export and not carried into the UK by its owner. I thought since it's assayed here then it was made here.1 point

-

I definitely noticed the hallmarks but assumed assay was just part of import requirements (or the case was English made to begin with)1 point

-

Last I heard from Ross was that he was taking an extended break due to some of the frustration he was having. I believe he intends to get back into it in the new year. I really hope he comes back, such a nice chap. Tom1 point

-

To be fair the forum search function doesn’t always live up to its name. Tom1 point

-

…my version is old and crooked, sometimes shakes and sheds all over the dial. Is there a cheap Chinese clone available?1 point

-

1 point

-

I've used all sorts from Torx Bits to pieces of metal with a point and drifted it out from inside the case. It all depends how well fitted they are as to how much persuasion they need. Is that the remnants of the tube still in the crown? You should measure the internal diameter before you start trying to remove it from the case.1 point

-

Personally, I believe the only reasonable option is to replace the escape wheel with the correct one. The wheel pivots are completely different. In one case, the shoulder is entirely flat, while in the other, it is cone-shaped. Furthermore, the design of the pivot's tip, which rests against the cap jewel, is insignificant in one case and critical in the other. Additionally, I am doubtful whether the oil will properly adhere and remain in place over time. Depending on the movement and the level of ambition, it can make a significant difference from an aesthetic perspective. My impression is that serious watchmakers always refine the pivot tip after modification, especially on more expensive movements. Personally, I don’t care, not because I’m not serious, but because I’m unsure how to go about it and don’t want to risk potentially damaging something.1 point

-

HWGIKE#32 Omega 354 Bumper Full service, new mainspring, new glass, new setting lever spring. Main spring arbor bounced and went silence, landed in my pocket unnoticed. A cleanup in my room, moving out stuff including printer, boxes, cables, stuff then hours of head scratching, magnet fishing and knee surfing for nothing, then I checked my pocket the third time and there it was. By the way the top of our grandfather clock fell on my head last weekend glass in front which was shattered into hundreds of pieces on my head then was sitting on my head like a crown, a pretty heavy piece and i survived with a very tiny almost invisible scratch. I also add a picture of my crown. No glass now.1 point

-

1 point

-

After @Mercurial posted about some of Jendritzki’s books being reprinted and available on eBay I bought a couple and thought it would be a good idea to do a review of them. This being the first. Book: THE WATCHMAKER AND HIS LATHE Author: H. Jendritzki ISBN: 2-88012-037-3 Pages: 86 A4 Reprint: 2018 Publisher: Historische Uhrenbucher, Berlin, Germany Website: https://uhrenliteraturshop.de/Foreign-Languages/Horological-Books:::47_21.html eBay: https://www.ebay.co.uk/sch/i.html?ssPageName=&_ssn=uhrenliteratur According to the publisher this 2018 edition has been re-edited updated by Hans Jendtritski and Marcel Bergeon. This book is intended to be a basic starting point for anyone wanting to get into using a lathe for watch repair, in this my opinion is it does an admirable job. At only 86 pages it may sound like it would be more of a pamphlet than useful, however it does go into the basic aspects of the Geneva style watchmaker lathe and its use in a very clear and concise manner. There are in depth chapters on turning a balance staff, making a winding stem, jewel settings and bushings, replacing pivots and making screws. Most of what is needed in the day to day of repairing vintage and antique watches. i have found this book extremely useful in understanding much more of the mechanics of using the lathe and making/using gravers including special shapes. I would recommend this book to anyone embarking on the journey of taking watchmaking to another level. Tom P.S. the books arrived to me in Scotland from Germany in 3 days1 point

-

I currently have an identical Seiko watch on the bench to the one you posted. Its escape wheel is very dirty. She lost the crystal, so its missing hands too. I dont find these any more difficult to service because of their size, but do find them harder to regulate based on some of the smaller seiko's higher beat rate. I recently had a "return" that wouldn't wind after I serviced it, which I thought was very unlikely. This is what I found when I popped off the back. She wanted to know if this was covered by warranty. Its still sitting in my job box, waiting for a reply from the client.0 points