Leaderboard

Popular Content

Showing content with the highest reputation on 12/23/24 in all areas

-

Its nice to have good quality over the whole range of tools used frequently as well as some specialist equipment. This was an accepted indication of a tradesman's standards on site, a look in his toolbox to weight up his kit. It didn’t always say all that there is to know about him, a good tradesman can make great use of lower quality tools as there are also guys with all the gear, but no idea. I hope all goes well for you seem to have things in hand and ready with your planning.4 points

-

The industry, who fund WOSTEP, pushed for many years for them to reduce or eliminate a lot of the "making" part of the curriculum. As a result, they offer two levels of watchmaker training now, one where you just work on watches, and another where you still do some lathe work (and filing and so forth), though less than in years past. I don't know the specifics of what Swatch wants equipment-wise to get approved for a parts account, but they are less concerned with what brand of screwdrivers you have, and more concerned that you have a proper cleaning machine, waterproof tester, timing machine, that kind of stuff. No, a 45 year old manual Elma isn't going to cut it for cleaning, nor is an old pump-type wet tester. Maybe they accept some of the Chinese timing machines?- but I think they want you to be able to print out results over x-number of positions. You can even get approved for Omega, but they want you to have some rather expensive Omega specific tools in particular for case work. This is going back over 20 years when Rolex still allowed parts accounts for independent watchmakers- but one of the requirements was a decent Jacot tool. Which is odd, as they definitely don't want you touching up pivots, they want you to replace parts. But at one time you had to have a good Jacot to buy parts from them. No longer an issue, nobody outside of certain dealers can get parts anymore.4 points

-

HWGIKE#33 Ronda 1217-21 Full service again. I have re-visited one of the watch I serviced earlier and where I painted the dial. The watch stopped and the paint started to disintegrate, i thought i need to clean the watch movement again as it was stopped by a paint particle, but it was not the case, the post of an intermediate wheel failed, dropped out and landed on the pallets. I remedied it and gave it a full service again. The time i serviced it the first time I did not pay attention to the mainspring arbor hole which is tightened now giving a better performance than before. I have also repainted the dial with automotive paint/spray, primer first and black mat paint on top this time (there was no primer for the first attempt). I have read as how to remove and re-apply varnish on watch dials on WatchGuy blog: https://watchguy.co.uk/cleaning-and-preserving-original-finish-on-dials/ which I also did using a water based varnish from Homebase. (interior clear gloss). First I diluted the varnish and I thought i went too thin, but I actually didn't when I went on with a thicker varnish it became a little bit patchy. Cannot see this on pics, but under microscope and in certain light conditions it is visible. It was a practice piece so I am very happy that it came out like this and very happy about the experience I gained. I am going to donate this to someone who does not only sees the big tits when he looks at a watch, but the internal values too.2 points

-

Buy two scrap pocket watches of same caliber, to eventually make a good one out of the two. You also would have your own spare parts dept, used parts ofcourse. You need help to decide what to buy. So ask questions . Shouldn't even think of repair without the right tool, so you need help on that as well. Ask questions Attack the non runner piece first. Take photos and Ask questions Keep the second piece untouched, so you have an actual guide for which part go where. As said practice tearing down and reassembling, Let us know when you feel you have gained the dexterity to safely attack the second piece. Buy then you have learned enough so we can understand what your saying. Stay with Mark's vid , so you learn and we speak same terminologies. Take Mark's courses when you think you understand what he teaches. We'll work with you to make a good runner out of the two watches you have. By then you should know, if you enjoy watch repair and decide if you want to continue or not. Next comes buying more tools. Rgds2 points

-

This watch clearly loves you. Why don't you return the favour and get a genuine replacement from Hanhart? Your dog deserves a treat too.2 points

-

I just took delivery of one of these from Ali X. I took a punt on it at the price of less than AUD $6, (£3), including shipping, and I'm pleased to say that the quality looks reasonably good. It works in the manner of a douzieme gauge, but is marked in 0.1 mm increments. The scale is marked on both sides, so it can be used in a left or right handed way. I know that these are not as accurate as a micrometer, but there are many places where a micrometer will not fit, for example, measuring the thickness of a barrel end cap. It would also be handy for repeated quick measurements, such as when turning a pivot down to a required diameter. The scale is marked in 0.1 mm increments, and I would think that it should be possible to read it to an accuracy of 50 microns with some care. It appears to be made of steel. There are a few sharp edges where it has been machine cut but not chamfered. A light touch with emery paper would take care of that. The jaws could probably do with being dressed a little, but they are flat and parallel at the point where they meet. I plan to measure a few items and compare the readings on this with micrometer measurements. I will add my results to this thread when I have done it. Here's a link to where I bought it if anyone is interested.2 points

-

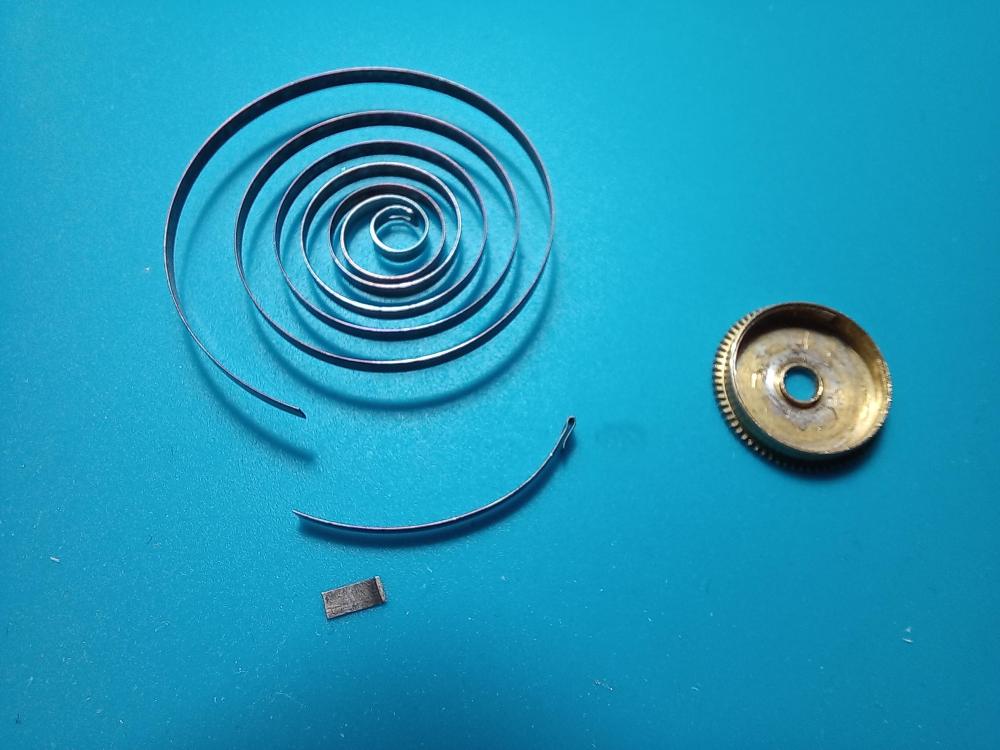

A quick update on (lack of) progress. I opened the barrel again, and discovered that the hook was still securely attached to the barrel wall. That's the good news. The bad news is that the mainspring has broken. Looks like it must have snapped when I managed to put a full wind on it for the first time. OK, I think it's time for a new mainspring. I will put in an order to Cousins after the end of year chaos is over. Merry Christmas and Happy New year everyone.2 points

-

I’ve ordered a Weishi 1000 as I’m sure I’ll need it for basic regulation in the future with 3 mechanical watches. Will see if that reads the NH35 any differently to the basic headphone and iPhone app setup I’ve been using.2 points

-

I had a few more tools and parts come in recently and this morning I was able to put them to use. Using my new titanium tweezers I set about oiling the new end stone for the chaton and putting it back on the balance. It took me about 20 goes to get the balance back in with the impulse jewel in the right way. I get the concept but just couldn’t execute it properly. Patience and taking it back out and trying again was the trick and there is something magical about it kicking in to gear on its own! Heres where I think I’m running in to a new issue. I dont have a timegrapher. Instead I bought an app for my phone and trying to use an old pair of headphone. But I’m getting really erratic results on the app. It’s showing the amplitude at 315 degrees and it’s clearly better visually on the balance. However the app is really struggling to lock on to the movement so I don’t really trust the readings yet. For example the beat error is 4-5ms and the rate is all over the place. Then I realised I forgot to demagnetise. So I popped it on my demagnetiser and retested.2 points

-

Yeah the lightning can be confusing too, but i didn't want to get the movement out, i'm happy with the rate i got , i just dont want to run in other troubles , exactly for the fact that changing a balance staff is not an easy task, in other words i just dont the watch to break on me as i want to wear it everyday for a while, and i'm not the richest man I'm not a professional this watch is for my personal use , my concern is more : can i wear the watch as it is ? I post the exact rate So we have 0 sec a day vertical position About 10sec a day dial up and down , these numbers don't bother me and i find them pretty good , but i just dont want the watch to let me down mechanically speaking2 points

-

Here's a video of the 149 in operation. https://www.youtube.com/watch?v=i5FE4KxsSfA2 points

-

As "factory" faceplates are ridiculously expensive these days, I decided to make one myself. I have the plate on the watchmakers lathe now and there's no runout, so now it's time to make some clamps. My question is this: I have seen several designs. They all have a seperate setting screw between top and bottom part to tilt the upper part. They differ however on the way the upper and lower parts are clamped. Some have a seperate screw for fixing the bottom part and another for tightening the upper part. Others have 1 single screw for tightening both the upper and lower part in one go. Are there any pro's and cons you guys are aware of?1 point

-

1 point

-

I mean the tools which aren't being sold by for example Swatch for repairing a specific Omega model. With generic tools I meant everything from Bergeon/Horotec/Horia which can be bought by the general public (on CousinsUK etc.).1 point

-

Ha, yes. In 'real life' it doesn't quite catch the light so strongly, and it's a lot less obvious from a face-on view, but I take your point!1 point

-

An update, in case anyone else has this niche issue. I taped it up, put it in the vice and carefully leant on it with my little steel staking block. I managed to angle the welded strip relative to the spring bar tube. The result is that the angle falls sooner, maybe 2mm from the end of the lugs. It's a significant improvement. The mesh is pretty robust. I caused it no other injuries.1 point

-

1 point

-

That looks to be a Seiko Diashock spring (the 3 arm type, rather than the 2 arm found in the NH3x movements). This is a great reference post naming the different shock springs you will encounter. They are without a doubt easier than other types of 3 arm springs because you only have one slot to align and they are robust & hard to break. But they are harder than Incabloc because they are not hinged and can fly away & must be placed back when reassembling. And here is Mike Bolton on MRW demonstrating how he deals with them.1 point

-

@Neverenoughwatches If you do have, or know of, any examples of this type of spring being removed that would be much appreciated. And can you tell me the name of this type of shock setting please? The only ones I seem to find videos of are the incabloc ones. Thanks. Bill1 point

-

Approaching a brand that you are interested in working for might be a good place to start. I'm in a similar position with the next step in my career. Finding out what an employer or contractor actually expects you to be capable of and wants from you shows initiative that you are keen to work for them. If its a big brand then you're going to need to be good at what you do, really good and prove that you can run a workshop and business professionally. No big brand such as Swatch is going to associate themselves with anything but very competent watchmakers with a fully kitted out workshop. So at that kind of level I would have expected you to already own a decent setup with most of the best tools money can buy and not just generic tools. And as WW quite rightly mentions good level qualifications will be required and plenty of hoops to jump through. So I'm kind of confused by this question and guessing you are a long way off from this. Doesn’t hurt to aim for something in life as long as we remain realistic about what we want to achieve.1 point

-

I think a skeleton watch would be great for observing the way the movement works but poor to work on. The bridges lack strength.1 point

-

Hi Folks, many thanks for allowing me to join your repair forum. I live in Adelaide, Australia & am a strictly amateur watch owner & 'repairer'. I have a nice Citizen 'field' watch with a unitary or monocoque case. Has a B876 movement. It was stopped when I got it & refuses to run properly, even when left outside to recharge for a couple of days. The second hand just continually does the 'skipping' thing suggesting that the battery is flat or failing. Does this skipping & apparent refusal to charge properly indicate that the cell needs to be replaced? My reading suggests that disassembly (to replace the cell) as far as releasing the front bits & freeing the movement from the case is relatively straight forward but I may then run into a movement with a back plate that needs removal to get at the battery. With the B876 movement is this likely to be the case? Such removal is probably far to fiddly for me (old eyes & fingers)! I'll post a picture of the watch in the morning... Advice much appreciated! ta, Sam.1 point

-

Hi. I think that as an independent watch repair agent wanting to get certification from a manufacturer you would need to have a decent workshop and be open to inspection from the manufacturer . not to mention training on the manufacturers product should you pass the inspection stage. A comprehensive set of tools to cover all cases not necessarily Bergeron but not rubbish either. There will probably several more hoops to jump through like membership of the BHI OR SOME OTHER BODY as proof of your competence in watch repair. All in all quite an undertaking and most likley not a cheap one. Good luck.1 point

-

oh sometimes I have to think about things? Something interesting with the original question and wrong assumptions about the answer your English is fine don't worry about it. I'm using dictation software and it does goofy things so were actually quite tolerant on our English skills on this discussion group for the most part. usually the problem we would have would be people who don't have a tech sheet and use interesting terminology to refer to parts by names that we've never heard of before. Then wobbling a balance wheels can be caused by other things like? For instance if somebody replace the balance staff and didn't do things quite right you can distort the arms and you'll get a balance wobble. so it's not just the balance pivots that could cause an issue it could be the balance itself. I was curious about something and you don't have anything to worry about. The older Rolex specifications are not the same as the newer Rolex specifications. it looks like the official specifications is anywhere from -1 to +10 seconds. then not quite that simple as specification is the average of five positions which it looks like you're doing so you're within specifications so you should just enjoy your watch.1 point

-

Well everything is back in with a concerted effort to keep the working bench clear to start getting things done. That is after I rejoin the wires from some Christmas lights that my wife cut through when she was trimming a plant. I'd like to say that she said "Oh, bother!" when she did it, but she didn't. The quartz movement that I replaced the impulse gear pivot on is working away quite happily so that's good. I know OH doesn't like quartz movements, but hey ho. The little Unimat lathe blew the RCD the other day. I reset it and turned the motor on again. RCD went again. Reset and the next time I turned the motor on I got an electrical arcing sound from the motor. So that will have to come apart now so that I can see if there is anything obvious. Actually @oldhippy, how hot did the motor on yours get? I have noticed that sometimes mine can get quite hot. I'm using the timer on my phone to work for 8 minutes and rest for 2 minutes. Sometimes I let it rest for longer due to how hot it can get. I'll start investigating a replacement motor. I have seen on YT that several people have replaced theirs as well as the drive pulleys to a toothed belt & pulleys with what looks like good results. At least I don;t have to try and work it out myself. Hard work is already done.1 point

-

A lot depends on what you want to accomplish, repair and maintenance is a lot different than an interest in Horology in general or watchmaking of high complications. assuming that you want to get into understanding basic watch operations, maintenance and repair here are some suggestions on how I would liked to have approached it but I didn’t know of this forum at the time. purchase a couple of cheap chines ST36,3600,3620 movements. These are based on Swiss movements, simple basic watches originally intended as small pocket watch movements. As @oldhippysays the size of pocket watch movements make a big difference. At the end of the education below you’ll have at least one working watch movement and there are loads of cases, dials and hands on Aliexpress to make a nice watch which will be a source of pride to wear for you. I say at least one because we have all killed a movement in our starting phase and the potential of doing it again follows us for life but drastically decreases with practice. a book reccomendation would be maintaining and repairing mechanical watches, a practical guide by Mark W. Wiles ISBN 978 1 78500 155 0. This is a modern book with the simple philosophy of teaching the basics of repair, servicing and operation of “modern “ watches. i also recommend our host @Mark watch repair channel on YouTube and his excellent, clear and concise courses at watchfix.com. Economical and gets you working practically on those movements you bought above. for tool recommendations starting out look at https://www.watchfix.com/2019/09/30/essential-day-1-tools/ here on this very site. as to lubricants I’ll leave that to you to research and come to your own conclusions, you’ll understand why quite quickly, I think. this will get you a long way in getting to grips with watches and is the leader path onto the true nature of this as a hobby, the collection of tools. Tom1 point

-

I agree completely, I tried the hollow ground ones and when they worked they were great, with no slip or screw slot deformation, but I found that they only worked on specific screw slot sizes, so I (being lazy) often used the next size down which either chipped the screwdriver blade and/or deformed the screw slot . I switched back to regular chisel type screwdrivers after a week or two of fighting with the hollow ground ones (actually I reshaped the hollow ground blades to chisel shapes). Nice to see that there is a reasonably priced tool available now for sharpening them, as the Horotec one is a crazy price.1 point

-

I am greedy I have two sets of screwdrivers. One set are traditional and one set hollow ground. I agree the traditional screwdrivers are easy to keep dressed.The hollow ground shape when shaped correctly I find do not slip because of the snug fit on the screw head. ps you can never have enough screwdrivers.1 point

-

If your aim is to understand the functionality, so that you can one day maintain and repair them, then there is no substitute for practical experience. The question of which movement(s) to begin learning on has been discussed thoroughly on this forum already. There are many good books on the subject, which have also been recommended here. Even better than books to begin with are good videos. Youtube is full of bad videos. Long-winded, bad practice, edited to make the "talent" look good instead of educating etc. etc. so you need some experience to tell bad from good. The owner of this forum, Mark Lovick, made some very good how to videos a few years ago which you can still view on Youtube. I can recommend those without reservation. He also sells a course of educational videos if you want to learn more.1 point

-

The issue I have with hollow ground screwdrivers are that they are great when you’re working on one model range with all the same slots on the screw heads. They can be a frustrating embuggerance when jumping between several manufacturers machines. I find it much easier and less frustrating to dress screwdrivers the traditional way, usually only takes a few seconds. Where the do excel is where you have something that requires regular strip down maintenance and you can dedicate a toolset for it i.e. a very expensive and unique firearm. Tom one grumpy old gits opinion1 point

-

As you are the customer the only person you have to please is yourself. If you're happy with timing results than you doing just fine. The original question was related to the balance staff and is there an issue? Somebody asked the questions should we answer the question? Then the rate to understand if there really is a problem we would need a better diagnostics. But based on the quote below everything is just fine. As I said you are the customer if you're happy then you have a happy customer outstanding. Then the second part of the quote is something different? The timing machine can only show so much not sure what your definition of letting you down would be.1 point

-

Yes, as far as I remember the automatic bridge will have to be removed before you can reach the regulator arm.1 point

-

Normally a Rolex is not what she would do when you're new to watch repair servicing. If I look at the video it does look like the balance wheel is wobbling. On a watch like Rolex everything should be absolutely perfect if you expected to time absolutely perfectly. For instance I know somebody who managed to shop that serviced Rolex watches. He had commented that they changed more balance staffs for timing issues than any other reason. So yes it does look like a little bit a wobble but Ideally if we were looking at this problem we should be looking at a side view as opposed to reflection of the light off the balance rim which makes it really hard to tell. Then the problem with Rolex timing is if you're following specifications there is an entire procedure for doing Rolex timing which unless you have the service manual you're probably not following on the other hand you're happy with the timing and your new to watch repair so probably wouldn't worry about it. As changing a balance staff when you're new to watch repair is not a desirable thing to do.1 point

-

Well the epoxy on the music box spring casing turned into a fail. Didn't adhere. I am going to look at using an old soldering iron and attempt to plastic weld the two parts to each other. I have some old plastic that I will try it on first. Other than that, I have spent the last week moving everything out of my workshop to polyurethane coat all the walls and the ceiling to keep dust down a bit. The walls were just stained cedar and dust stuck to them like nothing. Hopefully, the poly will make everything a bit easieer to keep clean. Starting to move everything back in today after cleaning the floor after all the work. One day, I'll actually fix someth8ing.1 point

-

Movement details, photos and why do you expect to have to re-attach the wires?1 point

-

Any attempt to bend this type of strap could result in broken links so I'd advise against it.1 point

-

Do no such thing. It should always be taken apart. Never clean it in an ultrasonic. Don't take this the wrong way but from what you have said I don't think you should have undertaken this in the first place. I have said many times fusee pocket watches are totally different from any other type of watch.1 point

-

Yes that's to be expected. The eccentric screw is only for fine regulation. Maybe +/- 10 seconds or so. For bigger margins, you carefully need to move the regulator arm. So first, move the fine regulation screw to the neutral position. The use the regulator arm until you you're within, let's say, +/- 5sec.. Then use the fine regulation screw again. It looks, however, as if your regulator arm is hidden under the automatic bridge...1 point

-

I read...a lot...and spend a fair amount of time visiting the forum...again reading a lot. Youtube ...not so much, in fact one of my biggest mistakes was made because of following a Youtubers cleaning process. So be careful who you watch and advice you follow...Chronoglide, nekkid watchmaker and saving time are about the only ones I watch now. Researching brand history has helped seek out particular movement calibers. All of this is pointless though unless you dive into a movement, the theory you are learning from books etc must be put into practise, lots and lots of practice. I would start by just learning to handle tweezers and screwdrivers. Even when I wasn't repairing anything I would spend half an hour a day just using the two main tools on scrap parts and movements.1 point

-

You should start with a pocket watch. They are very much like a bog standard watch movement but much bigger, take it all apart and put it all back. You don't need to bother getting it to work. By doing this you will learn how to use your eyeglass, tweezers and your watchmakers screwdrivers. Keep doing this as they say practice makes perfect. Do not touch fusee pocket watch movements as they are completely different.1 point

-

If you mean for repair, then you can't beat getting your hands dirty, follow @AndyGSi advice. If you mean in general, then reading, videos and getting your hands dirty.1 point

-

A good place to start would be to get a watch that's running, take it apart then put it back together and see if it still runs the same. A lot will come down to what tools you've got and what you're hoping to achieve?1 point

-

Those blobs are usually some sort of epoxy. You don't have to test it directly at the solder joint. You can go up the copper tracks and remove some of the varnish coating and test it there.1 point

-

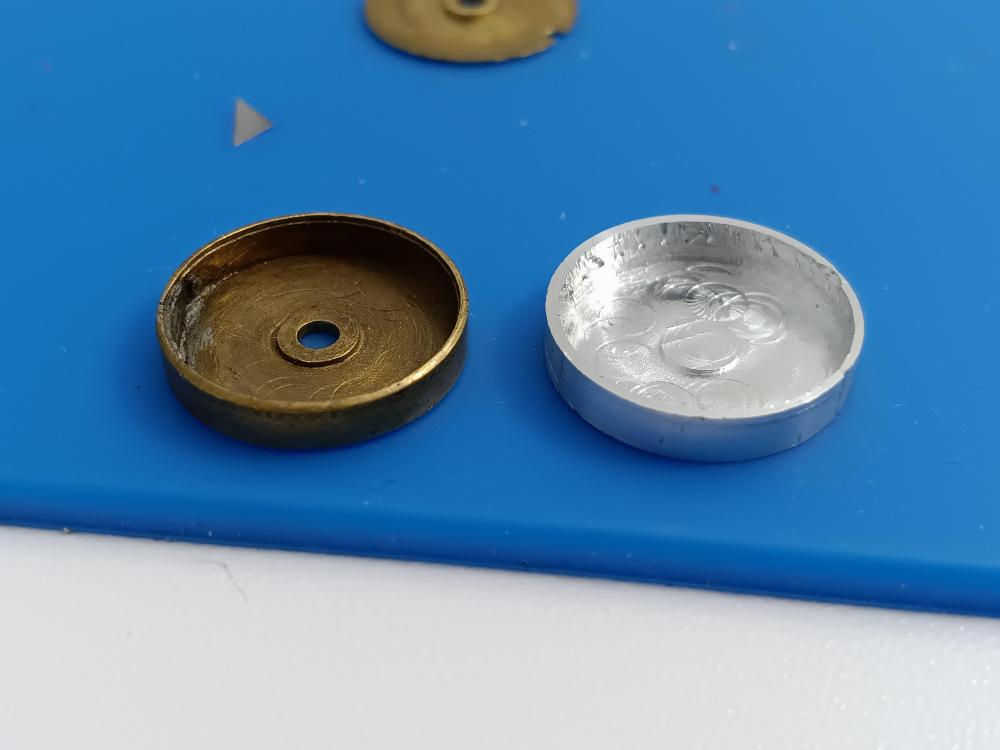

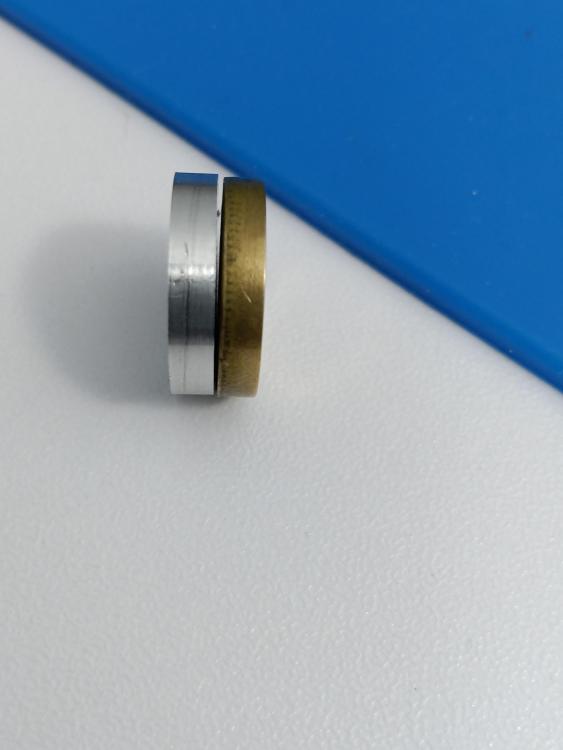

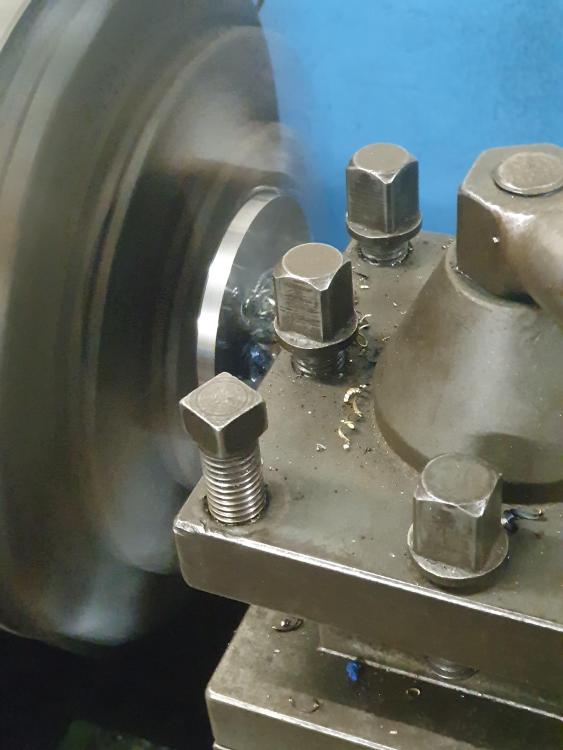

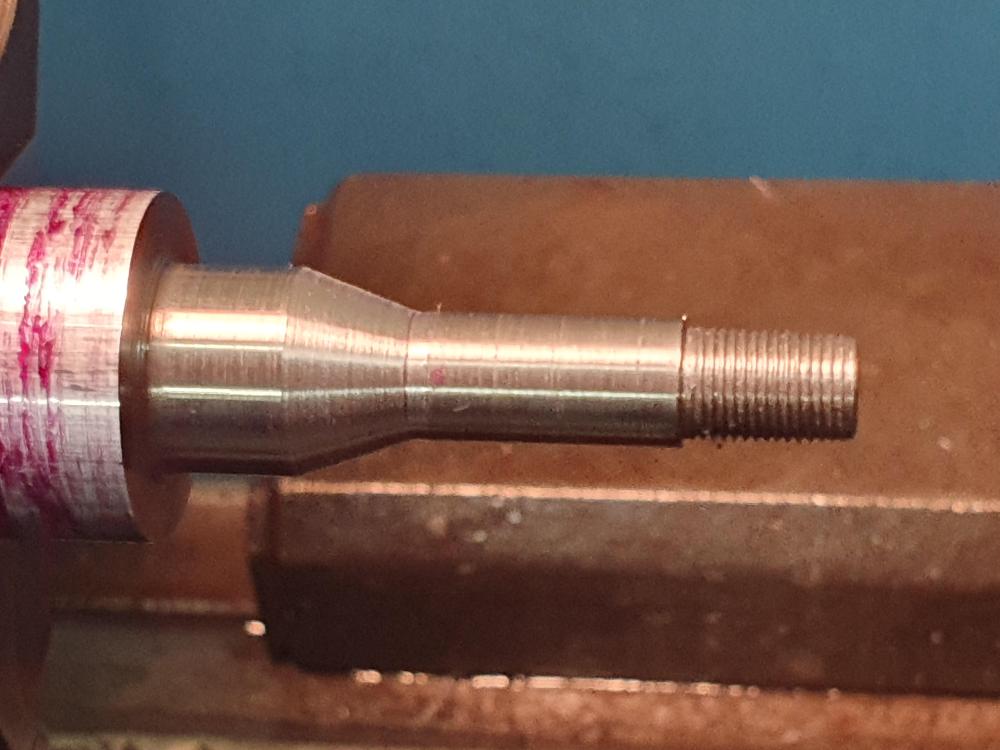

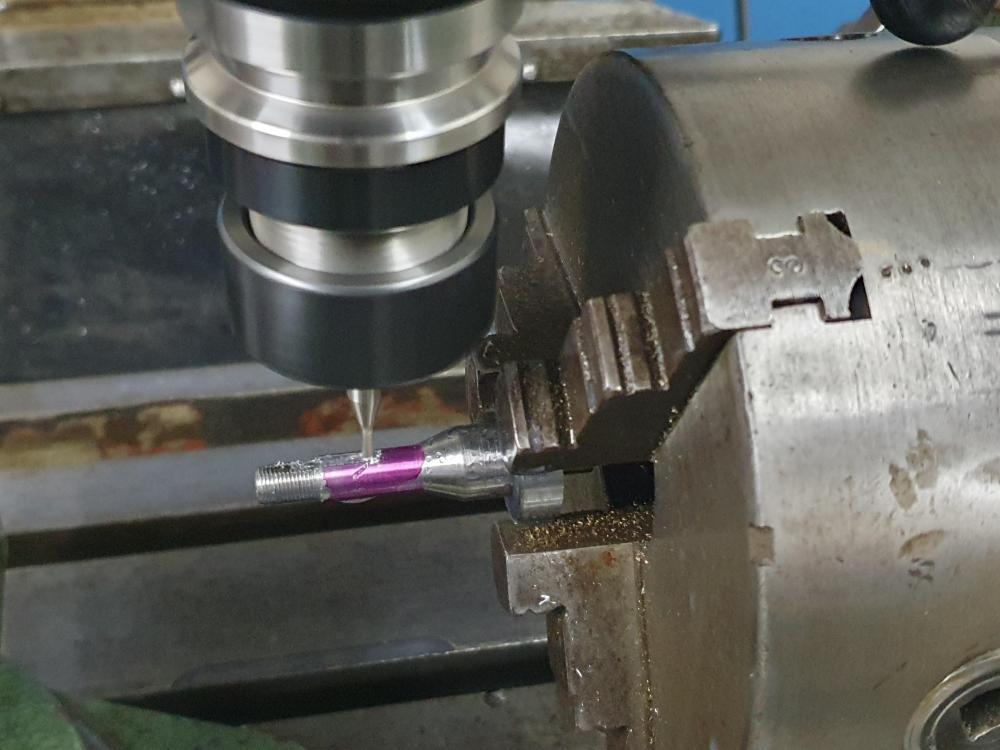

I tested out my new lathe and mill to fabricate the barrel. I'm practicing on aluminum first because lead-free brass is more expensive. Side note, I didn't think there could be a machine as messy as a mill. There are aluminum shards everywhere. I still have to dial in a few things with the lathe to get it running true, as my barrel ended up slightly taller than the stock one. The width was dead true to the original, 14.50 mm. Overall, I'd say this was a pretty good first attempt.1 point

-

1 point

-

My grandaughter that just got married has a musical rotating porcelain bear in a clown suit that had seen better days. It plays a short part of 'Send in the Clowns'. To wind it, it should have been lifted up and the plastic base that attached to the winding arbor of the music box turned to wind it up and then ireplace it on its base to rotate while it played. What had been done is people had pushed down on the bear while it was sitting on a bedside table etc to wind it. The result of that is the base centre that attached to the winding arbor had completely broken out of the base and the cover of the mainspring barrel on the music box had completely broken from the pressure of winding. All the bits were there so I took it apart as much as I could as it is riveted together so cleaning was going to be difficult. I put all the parts of the music box into the ultrasonic cleaner which has done a great job of cleaning it. I was able ro remove the mainspring which was quite set. I spent some time running the spring over a piece of round in my vice. I was able to increase the diameter of the spring and finally got some of the coils to come away from others. Allow had to fiddle around with the centre coil as it was not grabbing the arbor very well. Lubricated the mainspring and wound it back in by hand. Then worked out a way to clamp the broken part of the cover to the main part and used some 5 minute Araldite to glue the cover as well as the plastic base. Got that done before I went into hospital so the part stayed clamped for about 3 days before I took the clamp off. I should have taken more photos, but I want to get it done and sent back to Sydney before Bec & Jarryd's baby grows up. I have to make a new wooden cover that the music box is screwed to which is in turn glued to the porcelain. Hopefully get the base cut and drilled tomorrow and get it all back together. The click for the mainspring is a molded plastic setup on the arbor underneath the mainspring in its barrel. Nothing I could do with it after the damage sustained from the incorrect winding. It still works, but I will be telling Bec that if it fails again, it'll be unrepairable. I'll take some phots of it all tomorrow. Ok. It's not a clock, but principles are the same. Hey, I'm working my way up to a clock. It'll be my grandmothers Hettich first as that has been in bits for years now. A bit embarrassing really.1 point

-

Hi watch people, i trust we are all well. Thought a dedicated movement ID area might be useful. Not specifically for restoration advice but just somewhere were we could throw a movement size and pictures of the plate, top bridge anything with numbers or letters and keyless works at the forum so members could chip in and help with a quick search through their resources . Bit of practice for those with knowledge and lists and newbies could pick up the idea on how to find out what movement they are working on. Form something of a database, a lot of us have the bestfits for research but i have Flume and Swiss catalogs as well, some of us may have more, plus some movements are unlisted . This can take some real work to find out what they are. A one thread fits all movements identification.1 point

-

Spent more time in the workshop today. Organiser drawers installed, lighting up on the ceiling. Siliconed the screw, spring, part catcher bench backstop. Have worked out what I can do with my clock rig to get it out of the way. Joe Collins spring winder completed. Just have to work out some clips to hold the ratchet when I am not using it. I'll probably hit it with some black paint to tidy it up as well.1 point

-

Testing using Adsense at the moment. the forum is currently costing me IRO £250/mth to run now and the last payment from eBay ads was £77 so as you can see it’s making a significant dent in my back pocket you might ask why £250 when you can get cheap hosting accounts anywhere. Tried that last month. Disaster (you may have noticed performance issues and outages for a day or two). Moved back to a cloud system. Currently we are at 50gig of user uploaded data (images and such), this is backed up on Amazon cloud and Digital Ocean Cloud for failover and I have to pay for an 80 GB NVME SSD storage plan to get the performance we need. and as well as that the system sends almost 50,000 email notifications per month - for this I have to use a separate transactional email service. Bandwidth is not too bad as I use a lot of caching. but it all adds up unfortunately. I can’t afford to keep paying this every month. adsense has been a little encouraging. The past two days it made £4.50. So if that and eBay ads pan out then I will be able to comfortably continue with the project. I am also looking at making a theme for moderators and paying members where ads will not be served. Hopefully have this done in the next couple of days1 point

-

Hello everyone! First Mark's video i watched was "How to service a quartz movement. ETA 955.412". More than a year ago. Needless to say i found it mesmerizing, and watched as many of them as i could in one go. Been following his channel and this forum since. As i am neither watchmaker nor collector, I haven't much to contribute to the forum. Yet. (Or maybe ever.) But if anyone have any question regarding russian watches or texts in Russian, feel free to ask. Russian is my first language. Denis1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)