Leaderboard

Popular Content

Showing content with the highest reputation on 12/25/24 in Posts

-

Understood, thank you. I was wondering when I fit the cannon pinion why it was feeling super loose but I wasnt sure. This might be the issue. I’ll try tightening and report back3 points

-

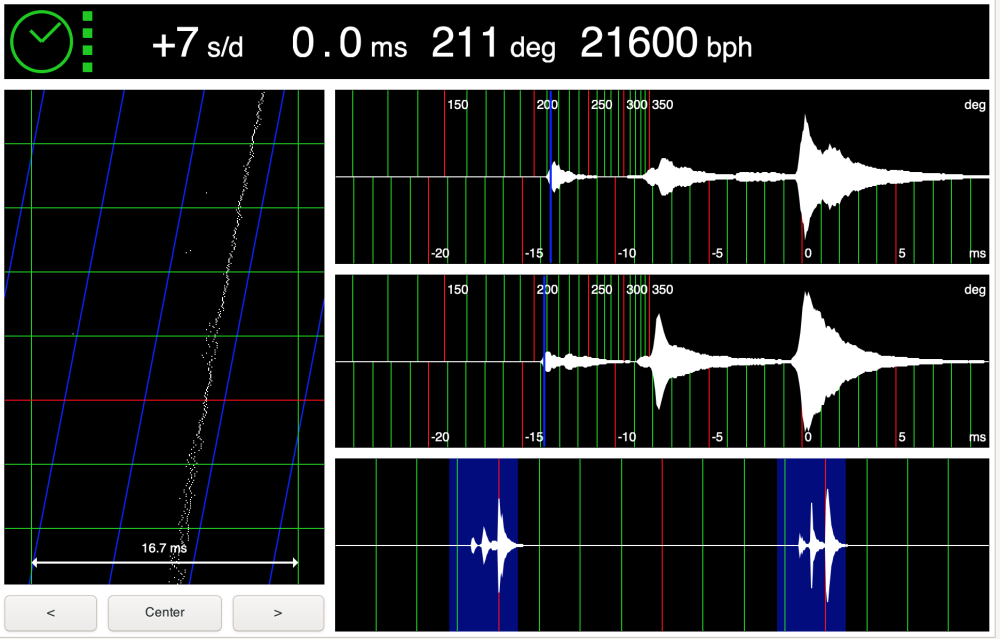

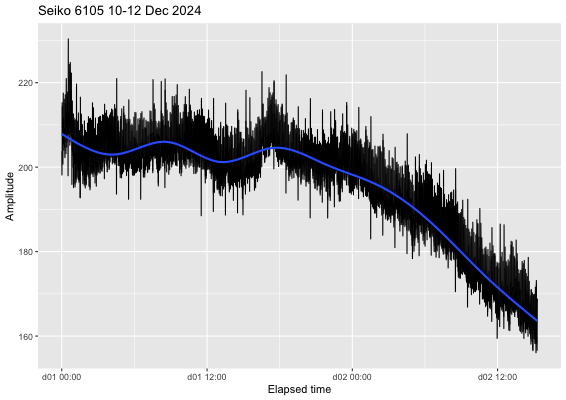

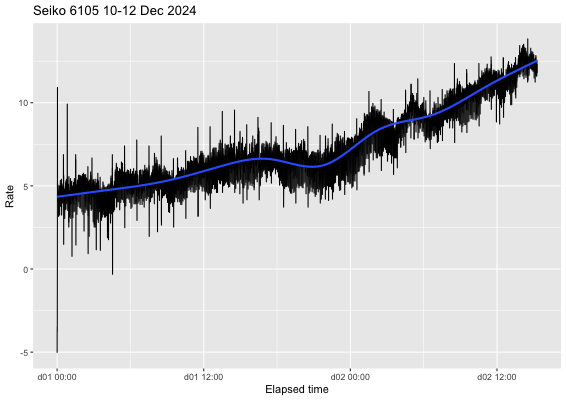

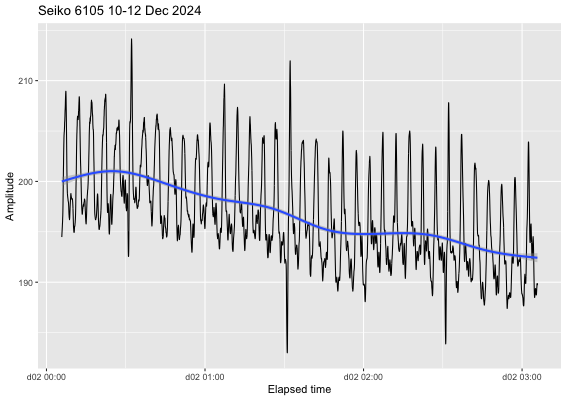

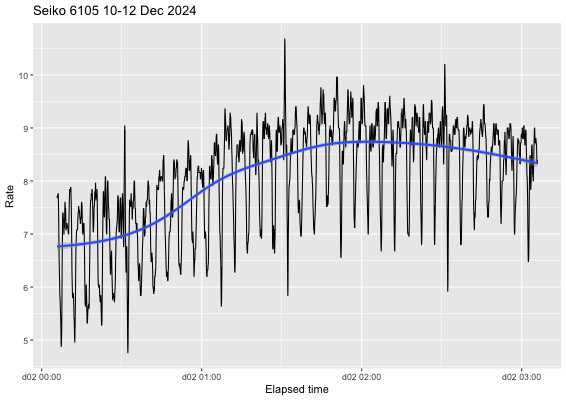

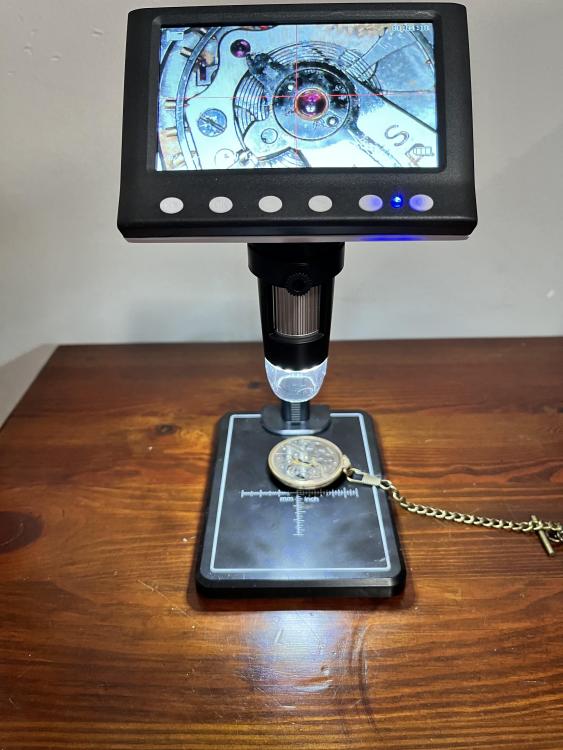

Microscope of timegrapher? Tough decision to make! We can't really regulate a watch without some kind of timegrapher, but I think getting by with a low-cost solution for that so that you can get a microscope would be the way to go. I took the advice of people on this forum who said they wished they got a microscope much sooner than they did, and I don't regret it. I bought my microscope from AliExpress. It's this one: https://www.aliexpress.com/item/1005006391635924.html?spm=a2g0o.order_list.order_list_main.29.64f51802Dlubxj I paid a total of AU$495.87 including GST and shipping for the model with no camera. I'll probably add a camera to it at some stage, but as I'm not planning to become a YouTuber I figured that could wait, and I'll keep using the electronic cheapie for when I need photos to post on this forum. I've only had it a month, but I wouldn't be without it. For a timegrapher, I use TG-Timer software (https://tg.ciovil.li/) on a Mac. Some report success with headset microphones but I threw together a Piezo microphone circuit. I sometimes think a commercial timegrapher would be simpler to use, but the software gives me things that a low-end commercial timegrapher wouldn't give such as graphs of the sounds, like below, and I can use the identical setup with Audacity to listen to the watch, too. I recently modified the TG-Timer software slightly (the beauty of open source software) to write rate, beat and amplitude to STDOUT once per second where it can be captured in a CSV file for analysis. This allows me to log the behaviour of the watch I'm testing as the mainspring unwinds over time so I can analyse it to produce graphs like these: I can also zoom in to look at cycles like these that show evidence of imperfections on the centre wheel (once per hour spike), the third wheel (once per five minutes spike) and fourth wheel (once per minute waves). I'm still learning how to make full use of this but as I become more ambitious with my repairs I can see this being a useful diagnostic tool. If anyone is interested, I can provide details of how I made the piezo microphone, the changes I made to tg-timer and the R Shiny code I use to generate the graphs above, but that's off topic here, I think. Generally using a loupe means using the eyes independently of each other, so you may be able to get by without your corrective lenses, but you probably want to consider something that clips on to your glasses since its a pain to be forever swapping glasses on and off. When I can't use my microscope, and what I used consistently before I got it was this stereo magnifier mounted on a velcro headband: It gives me something like x5 or x10 magnification, I guess, it swings up easily when I don't want it, and it fits over my glasses. I inherited this one (my dad used to use it for model ship building) and I have found it immeasurably easier to use than single loupes. There is a second plastic lens inside that flips down to double the magnification, but I mostly use it without that.3 points

-

As Case suggests, the strenth of a press unless it is something so cheap is irrelevant, strength beyond breaking a crystal is pointless and all presses are capable of breaking a crystal. The important bit for the press is accuracy of the die alignment and of course the actual dies. I posted something a few weeks ago regarding the die shapes and the comparisons between various brands. I own 5 screw presses 3 of which have dies that work on the same principle as the robur dies. So Robur is about die alignment and the quantity of dies in their sets to bend crystals, and not particularly the quality of dies, I've seen so many broken ones. The screw presses I have, have no broken dies. Haha sounds like a rag on robur, its just a press, but I do like the fact that there lots of sizes of dies that you dont get with other brands, except for one that I can think of. To answer Richard's question - why not use the Robur to fit armoured crystals ? - actually no reason at all, except not to use a domed die to bend it, the ring prevents that. But in actual fact only to a degree, I bent one enough the other day to push it out and back in again, so there is a very small amount of flex but it may compress the ring and reduce it's effectiveness. Then there is the option of making your own wooden dies, to any shape you desire. I've only just bought some felt the other day to line the domes and cups that i will make.3 points

-

2 reasons: 1) I already had the A&F before I got the robur and I like how it works/performs. 2) the robur originally came with bakelite dies I don't want to risk damaging. Only later I got some additional aluminium dies for the robur as well, so yes I could use it for armoured/glass crystals now.3 points

-

I got interested by watching some of the YouTube videos. Quickly saw the diff between content (which isn't horrible) and professionals. From there i pulled some non working pocket watches off fleabay and an st36. Disassembled , cleaned , oiled , regulated. Rinse wash repeat. Had a few misshaps but didn't dwell on them. Tools, get some good quality ones used or new. It makes a world of difference. Read up. Decarle, fried , daniels. Reread. Watch more YouTube. ( yes even the popular ones) Buy more tools. The biggest difference for me was getting a microscope. Take a million pics then take a million more. Try and form good habits every time you do something. Finger cots was the one I had to and still have to make sure I do. Don't take short cuts it will F*_! you. Buy more tools Most of all enjoy the hobby the process and the science3 points

-

Hello everyone. As promised, I am showing off my diy cleaning machine. This was built with NEMA 23 stepper motors, controllers, a power supply, and an Arduino nano. I will list the parts used below when I'm at my computer. The frame is made from 3030 extruded aluminum, which I had made by Misumo online. The cleaning basket was purchased in eBay. Some miscellaneous parts needed are an 8mm shaft, some couplers, buttons, and wire. The codes I wrote for it can be completely adjusted and changed however it is needed. I have since adjusted the speed the linear shaft moves up and down. In the future, I plan to add another stepper motor to include a turntable at the base, with 4 jars, so the entire cleaning process is one process. Right now I still need to get jars that fit, and to build a fan for a drying cycle. Please post any questions you might have, and if you're interested in the code used to build your own.2 points

-

that is a rare bird indeed, the minute hand is cool too, a lot of members are going to want to see a picture of the movement, .....Merry Christmas2 points

-

2 points

-

Of course, the second hand moves. @SiZi, time to learn what is cannon pinion for and how it works.2 points

-

Merry Cristmas!!! Nice project. I will make some photos of face plate I have, but it will be possible after holidays. The design is similar to Nickelsilver's one2 points

-

Any type of press being stronger then the other is not an issue. All are easily strong enough to crack any crystal. I can only give you my preference. I know that several people on this forum like the bergeon 5500 over the robur. Not me though. I still have the bergeon but in fact never use it. I use the robur for crystals that you need to bend a bit to get them in or out. I like the amount of control the robur provides and the fact that it allows you to have both hands free. Increase pressure a bit, check if the crystal fits, increase a little bit more if needed, etc. I can creep up to the correct fit which I especially like when using older crystals. I feel they crack easier then fresh new ones, but I may very well be wrong on that. But again, several forum members (probably way more experienced than me) prefer the bergeon. For pressing in crystals with tension rings, "glass" crystals and the occasional caseback, I use an A&F (?) screwdown press and a bunch of plastic dies. I can't imagine ever needing the amount of force the 6173 can provide for fitting or removing crystals.2 points

-

Falling down the chronograph rabbit hole. My fixer upper April 1976 arrived yesterday. Needs a crown, wheel indicator spring, crystal, new pushers, and a minute recorder wheel. Got it working and everything seems original. But waiting on the parts. The second hand constantly runs so not sure the issues. Will wait until most of the parts come in before going farther, but pretty happy all things considered. The dial has seen better days but the case, bezel and bracelet are pretty untouched by time, for the most part.1 point

-

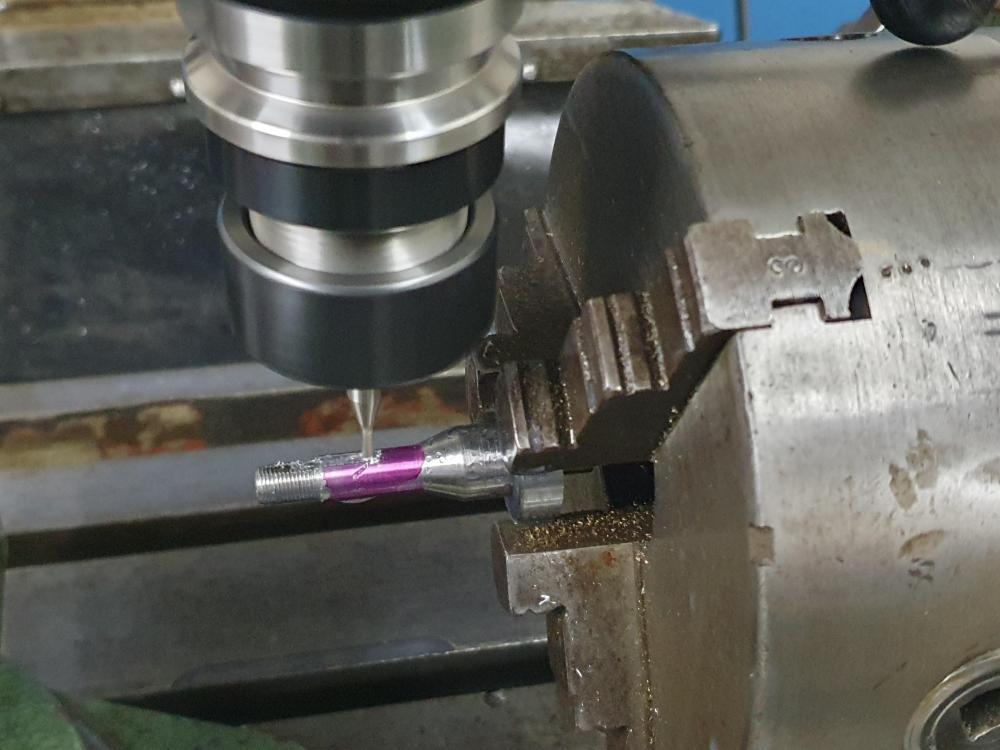

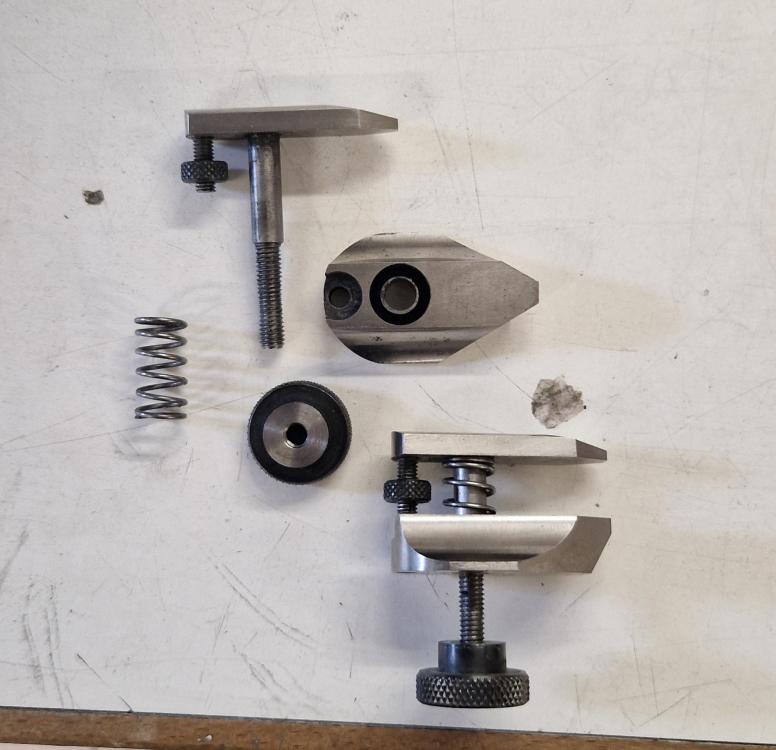

As "factory" faceplates are ridiculously expensive these days, I decided to make one myself. I have the plate on the watchmakers lathe now and there's no runout, so now it's time to make some clamps. My question is this: I have seen several designs. They all have a seperate setting screw between top and bottom part to tilt the upper part. They differ however on the way the upper and lower parts are clamped. Some have a seperate screw for fixing the bottom part and another for tightening the upper part. Others have 1 single screw for tightening both the upper and lower part in one go. Are there any pro's and cons you guys are aware of?1 point

-

1 point

-

I’ve attached a few photos of a watch I recently purchased, which I know has an ebauche made by Fountainemelon because I found their stamp. I’ve looked at photos of every Fountainemelon movement I can find, but none of them match. There is an inscription on the back indicating that it was a gift in memory of the “Guerre 1916/17" and the earliest repair mark I can find is from 1917, so I’m assuming it's from about that date. The unusual thing about this trench watch is that it has a date hand function, which seems to have been fairly rare, at least this early. I have found that a Swiss watchmaker named Alfred Hammerly patented a date hand mechanism in 1915, but so far can find nothing about him, his patent, or early examples employing his ideas. I’ve attached a couple of photos, one of the date mechanism and one of the watch face. It also seems slightly unusual in that it has 13 jewels, since the 3rd and 4th wheels only have jewels on the mechanism side, but not the dial side. I assume this is because the jewel settings would sit too high on the plate and interfere with wheel that advances the date. I’ve also read that some of the early date-hand watches had to have the date set every day, but this one advances the date. It also has a pusher at about 11:30 that stops the date hand from advancing while setting the time. It appears that Oris was one of the first makers to supply a wristwatch with a date hand, but not until the 1930’s. Since the date hand is sometimes mentioned as the first wrist watch complication I’m thinking that this watch might be somewhat rare, and I would be immensely grateful if you can shed any light on what it might be, or if you have any conjectures.1 point

-

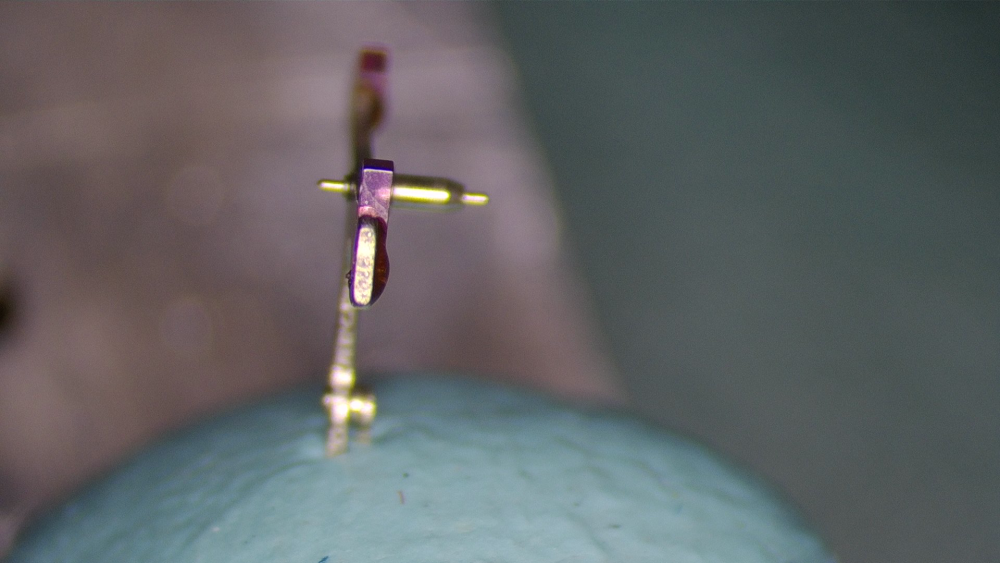

The picture is taken in moment of moving of the escape wheel, that's why it looks strange. But it is regular swiss lever.1 point

-

In your position, which if it were 20 years ago for me, I wouldn't settle for the minimum requirements a manufacturing brand would want from me. My aim if watchmaking was to be my profession would be wanting to be very good at what I did and own a workshop that enabled me to perform as much restoration as possible. A lathe and milling machine would be early important investments, which meant i could do a lot more including tool making...ohhhhh tool making....to make tools...hmmmmmmmm.....tooooooooolls.1 point

-

You should wind the movement until you get 180deg of oscillation. You then change the lift angle on your timegrapher until it matches the 180Deg Amplitude.1 point

-

I was reading a thread on cleaning fluids and thought this sounds a useful and friendly forum. Something of a rare find these days so I thought I'd better join!1 point

-

The simple answer for me...is to have the microscope . As we often say on here, you can't fix what you can't see. Watchmakers managed for centuries without a timegrapher, but what they could not do without was good magnification. If you are good with loupes and are comfortable using them then possibly the timegrapher. I know i could overcome not having a tg,( nice to have but not a necessity) a good microscope will allow me to see what the balance is doing and enable me to find most other issues. A good way to avoid becoming a slave and worshipping the tg is to not have one1 point

-

If this happens, I would also worry about other tools and watch parts getting corroded. A simple dehumidifier might help. They are cheap and easy to install. Just a matter of plugging it in.1 point

-

Michael, I assume you mean something like this: This is an inexpensive (<AU$50) digital microscope that is still my only way of taking micrographs. It's reasonable for what it is and I have found it useful, but there's no comparison between this and a stereo microscope. You can zoom in by moving the camera closer to the work (and adjusting the focus ring) but you can't zoom out enough to be able to see the whole movement. At its highest setting there is enough room, barely, to work on the movement, but I didn't really find that helpful. Since I got my stereo microscope I find myself doing almost everything under the scope. (I keep my glasses on, otherwise I'd be forever putting them on and off since I can't focus on anything nearer than about a metre without them.) The resolution with the scope is much better than the digital and the binocular vision means I get the advantage of depth perception. I'm sure it's possible to spend more money and get a much better digital microscope than this, but it's hard to imagine how it could ever compete with the immediacy of the view through microscope optics.1 point

-

1 point

-

This is the chronograph seconds so presume it's something to do with the pushers being seized.1 point

-

Ok guys I got myself a heating table and started experimenting with shellac and pallet jewels. I'm really a pallet noob. Here's an unedited video of the shellac melting. First the flakes melted into funny blobs when I had the table set to 100 degrees. I had to up the temp to 150 to get the shellac spreading more. How do you like it? Any comments appreciated. I also post some pics of the side profile.1 point

-

1 point

-

A while ago I realized it's sometimes better to ditch gadgets and learn to use your hands. I always thought using a jacot tool must be really hard and I got a rollifit clone. There was a problem and I returned it and got a refund. I forced myself to burnish the old fashioned way and it wasn't that hard after all. I did get some upper back pain from the several days of intense training though. I should work on my ergonomics.1 point

-

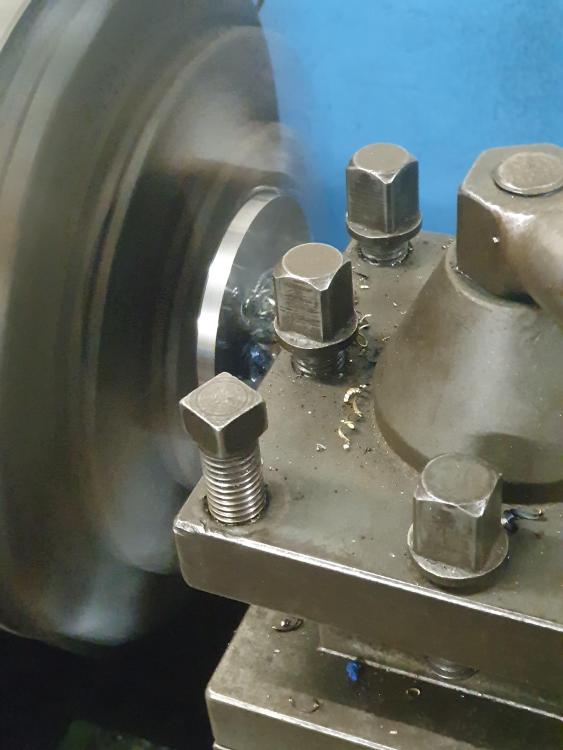

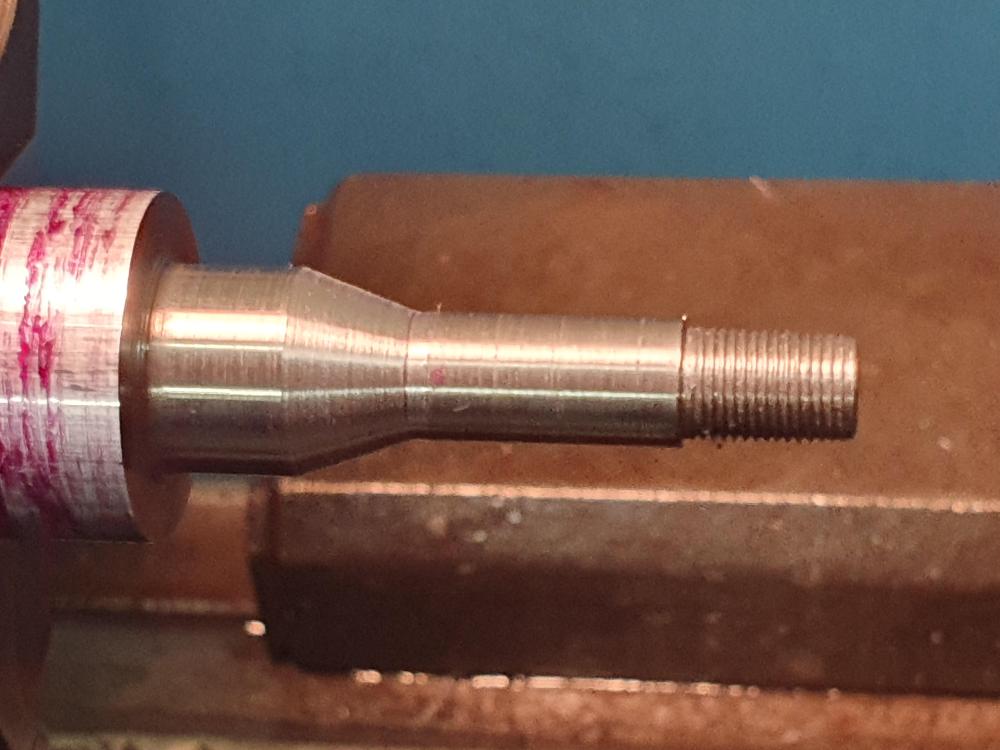

All the clamps I have used have been a variation of some sort of this one in the photo (two clamps there, one assembled one apart). The jack screw is to allow the clamp to contact the part parallel, which increases the clamping area and also reduces the chance of dinging the part. I do do quite a lot of faceplate work, and many years ago figured out that I prefer the setup in the third pic. The part is glued to a brass support (second pic), which is centered on the plate optically and held with simple clamps. I can glue and unglue newly made and delicately finished parts with no damage, and also handy for small or odd parts (I think that's a LeCoultre 409 mainplate on the support).1 point

-

I think I've discovered the purpose of the washer on the ratchet wheel. I reassembled the movement (excluding the dial side bits) without it and find that when the mainspring has some wind in it, the ratchet wheel wants to slip over the top of the click in some positions. I'm guessing that the washer was there to address this problem by holding the ratchet wheel lower. I'm still not sure it's the best solution, but if it works I may let it be. I'm letting the watch run a bit before I put the washer back in place as I dislike letting the wind down on these Seiko movements without manual winding ... one slip and it unwinds all at once, and when the click is unreliable it'll be that much harder to do it safely bit by bit.1 point

-

1 point

-

Thanks, that's really useful @Jon. The green lume I have looks pretty close to that. I have ordered some vintage tinting paste. I'll try the basic green with just a hint of the tinting paste to tone it down a touch. BTW I like the burn marks left on the card by the hands1 point

-

Wow @RichardHarris123, I didn't know you were a famous scientist! You are one of the authors, right? I watched this a few years ago. What I found interesting is the title of her presentation "how I stopped worrying about radium dials"...... BUT then she carries her watches in a lead-line bag!?!? Sounds like a contradiction to me. Personally (!!!!), I don't want to work on radium dials/hands. Which is a shame, because I love watches from the 1930s to 50s. Even when working on tritium dials, I wear a mask, wear cots (as always..), open the window, try to remove any loose lume with Rodico and then dispose of it, and wash my hands thoroughly. I assume that this level of precaution may be excessive (for Tritium), but I would think that it's the minimum when working on Radium. Especially a mask, I'd say, is essential to avoid inhaling any particles. I understand that's the main risk for Radium and its alpha radiation, which is harmless in a closed watch case with its crystal, but dangerous inside the body. I keep my watches, including one with a lot (!) of Radium on the dial and hands in a normal watch box -- I guess I should rather keep it in a well-ventilated area due to its Radon gas emissions. My approach is based on some researching on the topic + an innate fear of radioactivity (maybe based on my mother's stories of Chernobyl fallout/rain when I was a small child).1 point

-

1 point

-

That argument is used by smokers :- "I knew someone who smoked and lived to 100" People have fallen out of aircraft without a parachute and survived. If jumping out of an aircraft, I would want to be wearing a parachute.1 point

-

A bit of an anecdote but might be helpful for some real life dealings with radium. A few months ago I acquired a moderate stash of mixed parts off Facebook Marketplace. Some of what was in the stash was around 50 small tins of old watch hands with each tin containing maybe 20-30 hands. All of which were rusty and absolutely coated in flaking radium! Needless to say I wanted rid of them, I double bagged everything and stored it in the garage and managed to find a relevant government email address and fired off an email. I got a response from someone who turned out to be the IAEA representative for our country and lived in my city so he offered to come around to check them out. He ended up taking them away and disposing of them for me but while he was visiting he also offered to scan my work desk and any other areas I used which I gladly accepted. He found no trace of radium on my desk where I do all my assembly. The only suggestion he had was to move the radioactive watches I own out to the garage and open them out there as my workbench is near the kitchen and he had concerns with potentially getting radium on food. The takeaway I had from his visit was that the precautions I take when working on radium watches must be at least semi-acceptable. I put down paper towels before opening any radium coated watch and put on a mask. Once I've opened and removed the dial and hands and placed them in a zip lock bag I carefully fold the paper and throw it away. I then wipe down my desk with more damp towels and wipe down any screwdrivers/tweezers I use and also wash my hands well before starting on the actual movement.1 point

-

I've read things online about the radium dials and hands being dangerous. I've also read things that say not to worry. My take is that anything which gives you 24 hours of radiation in a few minutes is probably a bad thing to have on your arm. Something that will shed radioactive dust when taken apart is something I want even less to do with. There's a huge difference between having something radioactive near you -- or on you -- which will give your entire body a dosage of radiation, and having a small speck of radioactive material lodged in your lungs irradiating the immediate area continuously for an indefinite period of time. I wish I'd waited till I got this geiger counter to take that watch apart. I won't make that mistake again. Let's not forget that radium decays into radon. Where I'm from, most people have radon detectors, especially if they have a basement as the stuff comes up out of the ground. I don't need it coming off my arm. This is the geiger counter I bought: If anyone is interested, I can post a video of the readings I'm getting from it.1 point

-

In another life, I was a crew member of a nuclear powered submarine for 2+ years. On my first deployment one of the nuclear twidgets who worked on the reactor came into the senior petty officer berthing area with a geiger counter. After taking a couple of readings, he zeroed in on me. My watch with radium lume was setting off the compartment radiation counter. My watch was confiscated and placed in a lead container for the duration of the patrol. I was told to take it home and not bring it back aboard afterwards. I was also told that the radiation emitted wasn't in the least dangerous to me but that it posed a pain in the butt for the on-board radiation monitoring system. I'm assuming that he knew his subject matter. In any event, I sold the watch and bought another so that I could have a timepiece on my wrist while working aboard.1 point

-

Radium like asbestos needs to be treated with respect, but both seem to garner a lot of fear mongering. I dabble in antique radio restoration and a lot of radios used asbestos cloth sheets for heat control. the subject of what to do comes up a lot.just like the subject of radioactive paint from days gone by. With asbestos as with the paint, if you leave it alone there is no risk. Only if you start cutting grinding or scraping will you release particles into the air. That is the hazard. With asbestos in radios just leave it alone. or if you feel strongly about it you can spray it with water remove it to a plastic bag seal the bag and be done with it. As clockboy states finger cots a dust mask and store in a sealed container and all is good. If you are not sure if the watch you are working on is radioactive and you do not wish to assume the risk, what little there is, while taking the proper precautions, then pass such work on to some one else. For me, i will probably never work on a radium watch. But if I do, at least I have a clear understanding of what I am up against and how to handle the situation to minimize the risk to myself and others around me. That is the beauty of forums like this with learned members, being informed goes a long way to being safe. Thanks for posting and the heads up... Ron1 point

-

In this months BHI mag (November 2018) is an article “Radon Hazards of Luminous Timepieces” Understanding Risks From vintage watches. Luminous timepieces really took off during the Great War, when a wristwatch with a luminous dial quickly became regarded as a necessity. The hazards of radium paint were highlighted by the story of the “Radium Girls”, luminous dial painters of the 1920s not only shaped their brushes with their lips ,but painted their teeth, lips and eyebrows with luminous radium paint, consuming significant amounts of radium. When Radium enters the body it results in cancers and many died from this. The problem for us watch repairers is detecting if the vintage watch you are repairing/servicing has a radium dial or hands is not easy. Radio-luminescent paint ceases to glow after a few years, so lack of glow from the paint is not a reliable indication of whether it is radioactive or not. The only way to be 100% sure is to use a radiation detector. Conclusion Radiation and radon gas from radio - luminescent paint a potentially dangerous to watch collectors and repairers. Open storage in living or working areas that contain potential Radio-luminescent paint should be avoided. For those who regularly work on vintage watches should invest in a radon detector. If not sure use a mask when disassembling and store the dials and hands under cover and wear finger cots when handling.1 point

-

Don't sniff it, don't lick it. My take: if it's not disintegrating, let it be. If it's crumbling, wet it to minimize dust, and remove everything that's falling apart (pegwood is great in my experience). You can replace it with a more modern material (matching the color is fairly easy with a bit or trial and error). I wear gloves/finger cots any time I work on watches; throw them out when you're done with the clean up.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)