Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/24 in Posts

-

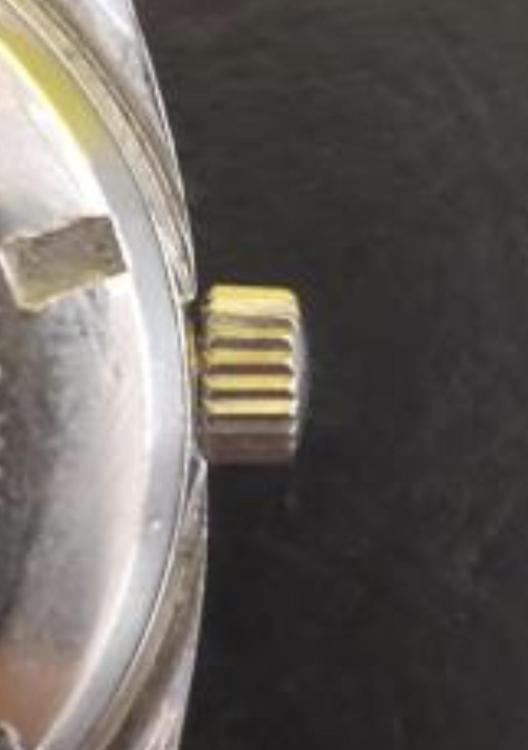

Yep winding and setting the time works. To be honest, I'm not too bothered about the wonky crown, as it still works, and I'm not going to be swimming or dunking it in water. As I said before, I've contacted my nearest BHI repair shop so I'll see what they say.3 points

-

Thats the problem with watches like this, professional repairers are not interested in any emotional connection you have. A job is a job and it could very easily run up a bill many times the monetary value of the watch. But that should not matter if it means so much to you. I was in the same position five years ago with my grandfather's watch in a bad way,that no repairer wanted to attempt a repair for me. This is where I am five years on, a room full of watch tools, two hundred watches and ££££s down . But happy and often wear that internally battle-scared watch that belonged to my grandfather.3 points

-

All sorted now. No wobble with the longer tube in place. Thanks for all the help.3 points

-

Just wanted to say thanks to everyone who has provided guidance and help on this forum as I begin my journey into the world of watch repair. Today I stripped down and rebuilt the st3620 movement. It took me about an hour to reassemble it and I reckon 20 minutes of that was getting the balance in; great feeling when it started going though Maybe that’s not much to many of you but I enjoyed it and was pleased that it still worked at the end! I didn’t clean or oil it this time but thats gonna be my next attempt. Bill3 points

-

3 points

-

The only reference I have is for snailing from Jendritzki’s lathe book if that’s of any help. Tom2 points

-

Running for a hour is good, can't be anything major wrong with the movement but just replacing the mainspring is a mistake. It almost certainly needs a service, replacing the mainspring alone will cause excessive wear on numerous pivots.2 points

-

object attachment belongs solely to its owner. It's the same when we are suffering inside ourselves for whatever reason, yet people around us are happy and completely unaware of our pain.2 points

-

If this is true, please do not even consider attempting the work yourself as a first ever watch repair project.2 points

-

What a paradox! Something that couldn’t be more special to one person means nothing to another. (Just a reflection!) So true! My assessment is that it would take at least a full day’s work to restore this watch, and significantly more depending on what might need repairing. Sure, a professional could handle it, but would the customer be willing to pay?2 points

-

Try winding the watch manually by winding crown, does it run? do the seconds hand move and for how many seconds. Shake the watch for about two minutes, does it run? After winding pull the crown out to time set position and advance the hands, does it run then? If it runs 30 seconds or more, your balance pivots are likely to be in good shape, so a new mainspring & clean might be all it needs. Not a good idea Rgds2 points

-

I believe it was Dr Sébastien Chaulmontet, Sellita's head of innovation and marketing, who said relatively recently that the market for luxury watches is flourishing like never before, while the demand for ordinary quartz and mechanical watches is more or less in free fall. Like so many other independent watchmakers, poor Bala Muhammad has probably been affected by manufacturers' restrictions on ordering spare parts.2 points

-

If I may dare to steer the conversation back to the original question, I can't speak highly enough of having a height adjustable desk. I got one when I had to work from home for a bit during COVID so I could work sitting or standing, and it's been great for watch work. The other big ergonomic improvement was getting a stereo microscope. With that you don't have to be with your eyeballs a few cm from the work.2 points

-

I've made a mistake that makes me feel very foolish. I'm sharing it here so other beginners might learn from my mistake. A couple of months ago I started working on a Seiko 6105 from 1975, the movement from a classic "Captain Willard" watch belonging to a colleague. The watch had its challenges and there were lots of things I was getting help with from more experienced people in these forums. I was at the point of reassembling the movement for the first time. The movement was running when I turned it dial up in the movement holder to fit the calendar works. All ok, check that the date advances as expected, then turn it over again to find the watch had stopped. Not only that, but the balance would now not swing at all. Not usually a pessimist, I nevertheless assumed the worst: I've caught the balance with the movement holder and broken the balance staff. I felt sick: this is no practice movement, it's a colleague's watch, and a classic, too. Mentally beating myself up, I immediately checked on eBay for NOS replacement balance complete, found one, and bought it. Later, I think it was the next day, or possibly a couple of days later I psyched myself up to go back to the watch, took the balance out and was surprised to find it apparently intact. Did I damage a bearing? Inspection follows: all looks ok. Reinstall the balance, it now swings freely! Much work followed addressing a few different issues with the watch but nothing that would explain why the balance went from swinging freely to not swinging at all. It remained a puzzle. Until a week or so ago when I was finally happy with the watch and reassembled it for the last time. I gave it a wind, dial and hands on, into the lightly restored case, set the time and date to the second, using what Seiko calls the seconds setting lever but is commonly called the hack, and strapped it to my wrist to give it a test run for a couple of days. Even then I didn't twig straight away. Yes, the Seiko 6105 is a hacking movement, the first one I've worked on. When you pull the crown out to position 3, a "seconds setting lever" in the movement moves in response to rest against the fourth wheel, acting as a brake and stopping the movement until the crown is pushed in. When I had set the calendar works I had, naturally, pulled the crown to position 3 to check that the date wheel advanced as it should ... then wondered why the movement had stopped. In the end it worked out for the best. I think I had been about to accept the watch as it was, not realising that the balance was actually touching the pallet bridge for part of its movement, and I also needed to polish out a divot in a jewel and adjust the side and end shake on the barrel arbor, none of which would have got the attention they needed if I hadn't been trying to track down what ended up being not a bug, but a feature. Now, can I interest anyone in a NOS balance for a Seiko 6105? (Just kidding: we don't do the buying and selling thing here.)1 point

-

Hello and welcome from Leeds, England. Visited Prague a couple of years ago, beautiful and we had a great time.1 point

-

This means your watch needs a clean/ mainspring/lube. As advised, should not attempt the work yourself. Rgds1 point

-

I have seen pcbs behave this way before but work perfectly fine with a battery put in. Why don't you reassemble the watch and put a battery in and observe it for awhile.1 point

-

I think the right advice has already been given. 1. Don't attempt your first watch repair/service on a sentimental watch. 2. The watch needs a full service, not just a new mainspring. 3. BHI list or someone from the forum maybe. The movement is one I've worked on and @VWatchie, too. Probably others. Nothing for a first-timer, but also rather simple for someone more experienced. Spare parts not too hard to find.. I'm more worried about the state of the crown (if you want to keep everything external 100% original). But winding and time setting works?1 point

-

Experimentation time then...1 point

-

I went on to buy some conductive tape which was said to be conductive on the adhesive side too. I cut as thin a sliver as could but when I first applied it I couldn't get connectivity. I put the pcb to one side while I researched a smaller soldering iron than the one I had thinking I'd try the technique you mention using perhaps a piece of coil wire. However, when I dug the pcb out recently I found that the break was mended - maybe the adhesive had solidified &/or I'd applied enough pressure with my Multimeter probe to complete the circuit. I half expected that the fix would fail as I re-assembled the watch but to my surprise it began ticking as soon as I inserted the battery keeping good time. The person whose watch it is was delighted when I phoned with the good news as it had some sentimental value. She sent a gratifying message in a thank you card plus a (unsolicited) contribution to my 'Tool Fund'!1 point

-

Pretty sure @Neverenoughwatches meant Mark would have to find something unusual in the watch to showcase in a new video but yes, everything is only worth the value you put on it.1 point

-

1 point

-

Mark doesn't appear to make many videos these days, it would at least have to be something special.1 point

-

that's the best feeling, seeing it take off, like starting the heart, congrats, its a rewarding feeling and hobby....1 point

-

None of us can speak for Mark but I personally I wouldn't bother him.1 point

-

It follows the trail of pus to the source of the infection. The abscess is like a pus filled balloon, once it is punctured, the blunt wire will follow it's tract to the root that is infected.1 point

-

I think your dentist did a procedure called "incision and drainage". The wire you mentioned is to tract down the abscess to the source of infection. We do this when there are more than one possible tooth causing the infection and need to determine the actual culprit. The offending tooth will need a root canal or extraction in the near future. In the meantime, rinse with a warm saline mouthrinse as often as possible and a soft diet for a few days.1 point

-

Watches like this are often better in the hands of a good amateur. The average watch servicing and repair shop can be reluctant to take things like this on. Parts if needed can sometimes be difficult to source, that is all time that a business might not want to lay down. Richard's suggestion is likely going to be the best or a recommendation from someone that has found a reliable repairer. Shame we can't see inside it to evaluate the situation better, I'm doubting that you will want to tackle removing that screwdown caseback.1 point

-

Aha! I have seen tweezers fitting this description for sale, both with a "factory look" and others with a modified/homemade look. They are often labeled as something like roller jewel or pallet fork tweezers, neither of which ever made sense based on their geometry.1 point

-

So at 95W maximum which is less that 0.5A a 6A diode would be fine. In my opinion the 1000V would also be suitable for what it's doing.1 point

-

1 point

-

I think a lot depends on how the stud pushes out and how it pushes back in. I tend to consider that a staking tool is required to do both, I consider...will the friction fit still be the same or has it been made less and what will I need to do to make it back as it was. I also consider that the re-fit of the stud's position needs to be correct in both height and rotation in the hole and will those adjustments by stake to get the stud right be problematic in some way and loosen the friction fit further ? That all needs to be achieved while the hairspring is attached to the stud. The centering of the hairspring over the balance jewel is done with the stud in the cock, that means the stud will be removed and refitted more than once. There are pros and cons to both ways, just my preference to remove the pin .1 point

-

That is how I do it, having worked on many cheap movements that have fixed studs and making hairspring repairs , you just get used to removing and refitting the brass pin. I use stiff tweezers to push the pin out, one leg is shorter with a slot in the end that straddles the pin. The pins aren't so bad to make either, I use copper rather than brass, from copper wire.1 point

-

1 point

-

I always call them. They are very old school—Their site really doesn’t list much of anything except some tools and supplies and their search function isn’t very effective.1 point

-

OK. I hope it goes back in as easy as it came out!1 point

-

Thank you, yes the spring is pinned to the stud. I'm optimistic I won't have to unpin/repin it. The stud is friction fit to the cock and I have been able to push it out using my staking set.1 point

-

What is the case number? It should be stamped on the back1 point

-

The spring is fixed by a tapered pin in the hole in the stud, isn't it? That's what I'm seeing at 8 o'clock in your very first photo. If so, you need to remove that pin, then either replace it or use a fresh one to re-pin the spring after. Firm tweezers with unequal length tips are often used to push these pins back in.1 point

-

Thanks for sharing @RichardHarris123@RichardHarris123. Sad story. Boy, would I love to visit his workshop and see his tools and methods!1 point

-

The B does just indicate that it's blue. The bridge if bought new from a supplier should come with jewels.1 point

-

1 point

-

The ticket I have worked out as follows apart from M C T Date November 2016. O/h = overhaul M/S =mainspring. ‘scap’ = Escapement Ref No is the ticket number which the owner would get. Smith is the owner’s name. Service due November 20211 point

-

Well it isn’t pretty that’s for sure, Iam sure somebody else has had a go, the label maybe his but I wouldn’t blame him for that crap job. If he is accredited to the BHI no way would he produce work of that natureents.1 point

-

This is strange. After Richards post I thought I know of that person so I went to his web site and thought something fishy here. I have watched his videos and interviews and seen his work and I must say no way would he have done this sort of thing. He is highly respected in clock making.1 point

-

1 point

-

The picture is taken in moment of moving of the escape wheel, that's why it looks strange. But it is regular swiss lever.1 point

-

I got interested by watching some of the YouTube videos. Quickly saw the diff between content (which isn't horrible) and professionals. From there i pulled some non working pocket watches off fleabay and an st36. Disassembled , cleaned , oiled , regulated. Rinse wash repeat. Had a few misshaps but didn't dwell on them. Tools, get some good quality ones used or new. It makes a world of difference. Read up. Decarle, fried , daniels. Reread. Watch more YouTube. ( yes even the popular ones) Buy more tools. The biggest difference for me was getting a microscope. Take a million pics then take a million more. Try and form good habits every time you do something. Finger cots was the one I had to and still have to make sure I do. Don't take short cuts it will F*_! you. Buy more tools Most of all enjoy the hobby the process and the science1 point

-

You should start with a pocket watch. They are very much like a bog standard watch movement but much bigger, take it all apart and put it all back. You don't need to bother getting it to work. By doing this you will learn how to use your eyeglass, tweezers and your watchmakers screwdrivers. Keep doing this as they say practice makes perfect. Do not touch fusee pocket watch movements as they are completely different.1 point

-

Hi a repair like that is best done with a wire soldered at both ends once continuity has been established and the cut tested run a little super glue along the wire for protection. Too big a break for the paint method I am afraid.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)