Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/24 in all areas

-

Look Rich, we don’t all have a wallet dedicated to dodgy cards like you! Tom3 points

-

Sorry but yes I'd missed the details between the photos. Edit Now I realise what's going on and that you've pulled the hand from the tube. I'd use a plastic disc in place of the dial and try levers.3 points

-

Tightened the canon pinion and now the hands work as they should Thank you everyone!3 points

-

All fixed now for the grand sum of $5. Could have been $2.50, but I bought two diodes in case I botched the first one. Tight, but it all fits and it works more to the point. In the first photo you can see the diode sitting just under the switch with the capacitor out of the way Then with everything tucked away. Bench tested and have two different motor speeds. Just the plastic cover to put back on and then bolt it back to the lathe. Really appreciate all the help guys. Thanks to everyone for their input.3 points

-

first link has terminology and hinting at how it's done. The second two links is a book you might find it interesting. then if you look at YouTube there are lots of videos on finishing. for instance in this video ad about exactly 1 minute and 10 seconds it looks like a wheel. actually the kind a wheel you're talking about here. Often times for wheel type refinishing you'll find that in books on watchmakers lathe as I'm sure I've seen it before in a book somewhere in the universe just can't quite remember which one. But in a case in the video look at the interesting patterns are doing on that wheel? https://monochrome-watches.com/a-technical-perspective-all-you-want-to-know-about-finishing-in-haute-horlogerie/ https://watchprint.com/en/technical-insights/360-high-end-horological-finishing-and-decoration.html https://www.booksimonin.ch/en/5640-horological-finishing-and-decoration,-hi.php3 points

-

Wouldn't that further compress the tube against the pivot, making it even harder to remove? Sorry @Neverenoughwatches, I disagree. Nobody should own a gym card. But, IF you do, please drill a hole in it an use it for this watchmaking task. That'll be the most useful it'll ever be.2 points

-

2 points

-

2 points

-

Hi Cees, Actually just pressing with something round from inside against something, may be soft wood, is needed here. The 3 screws where the worst bent place is, need to be removed. Where the screw holes are, this are weak places, so risk exists for the rim to break, but I have straightened even worse bents. This is matter of luck, and if needed, the balance rim together with the hairspring are to be replaced. It is good for one to have orphan balances collection from which to choose one with proper size. This balance is bimetallic (steel/brass), but is not cut. I would not heat it, would just hope it will not break2 points

-

Where are you buying? Where are you located? Can't order from CousinsUK? They have it. https://www.cousinsuk.com/product/sellita-sw2001-parts-list?code=SELSW2001134# The brass colour one will fit as well, but it'll look quite ugly.2 points

-

I'm still unsure as to which term is which, the best I could find was that sunburst relates to dials and sunray is an engraving technique used on steel wheels Anyways nice to meet you Michael , tbh I much prefer using our real names or a form off, some I use first Initials after I discover their name in case they prefer to remain anonymous. Over time here many of us become what i would consider friends, colleagues in clockwork collaborations . I think I can put quite a few of us in that category. Which is nice to have that an extended framework of neutral friends. Rich. It was just a matter of time Michael before you gave in Harry ?2 points

-

Hi All, Always struggled with removing the barrel arbour without pinging it across the room or pulling the mainspring out with it. I now screw the ratchet wheel screw into the arbour and easy peasy out it comes, gives you something for your tweezers to grip on. Haven't tried to use the method for re-installation yet as the screw head is rather large and obscures the view, maybe find a screw with similar thread but with a small head on it. Regards & Happy New Year to all CJ1 point

-

1 point

-

I've managed to straighten an extended third wheel pivot a couple of times. They're buggers for bending when the indirect center seconds drive wheel is removed. Think I rolled the pivots between two flat steel bars If you don't get those straight, the wheel intermittently disengages with the seconds pinion. I remember doing something with the 5 spoke wheel's hub as well. Anyways rolling is a good way to straighten out stufft that is round and malleable.1 point

-

Its ok to own one, just dont use it to go to the gym, let it run out of date. It kinda makes you feel like you're making an effort to stay healthy1 point

-

Brilliant idea!! I'd then expect the ring to deform when gripped and pulled.1 point

-

I and a couple of friends once toyed with the idea of opening a bar called “The Gym” @Knebo I don’t think so as there is a ring on the tube, gripping that should work Tom1 point

-

Haha, I always said that "Gym" is the worst swear word.1 point

-

The Pultra is like that as well but only one clamps tailstock to bed , presumed the other was just a guide. Dell1 point

-

@Jessye, what You say confirms my suggestions. The real rate is much off than timegrapher can accept and calculate. Now, we need to know if this is the original hairspring for the balance. It is quite possible that someone has replaced the hairspring with one from another balance... What You need to do is use timer to count the free oscillations for exactly 1 minute. The balance must hang on the hairspring (You hold the cock with tweezers) while the downside tip is resting on glass. In this condition the hairspring for sure will be free and not touching anywhere, so errors from hairspring imperfection are avoided. Then You must make the balance oscillate and watch the timer and count. You balance must make 150 oscillations/minute. 149 means the watch will loose about 10 min / 24H. The way to show video here is to upload it in Youtube and paste the link in the message.1 point

-

If you don't hit the chip, then your credit card will still work.1 point

-

Haha i just reeled a few off while I was in there looking for some spare cash1 point

-

The items that you circled in blue are a clamping accessory and I think the collet holder that is also needed for the reamers. In older versions of the Seitz tool, the holder is in a slot in the wood base sections.1 point

-

Thanks for your ideas! Have you got an old credit card that you can drill a hole into or push a pin through and drop the card over the cannon pin. Any card , library card supermarket clubcard etc. Gym card, building merchants card, costa coffee loyalty card, old man's drinking club card, casino member card night clubcard, pole dancing stripclub card, gentlemen's club card , Blue Oyster club card, Club Privė club card etc etc .1 point

-

1 point

-

I'm assuming the hands are The hand would be specifically for ML the caliber probably has no relevance to it. I've looked at a few but cant see enough to understand how it's fitted.1 point

-

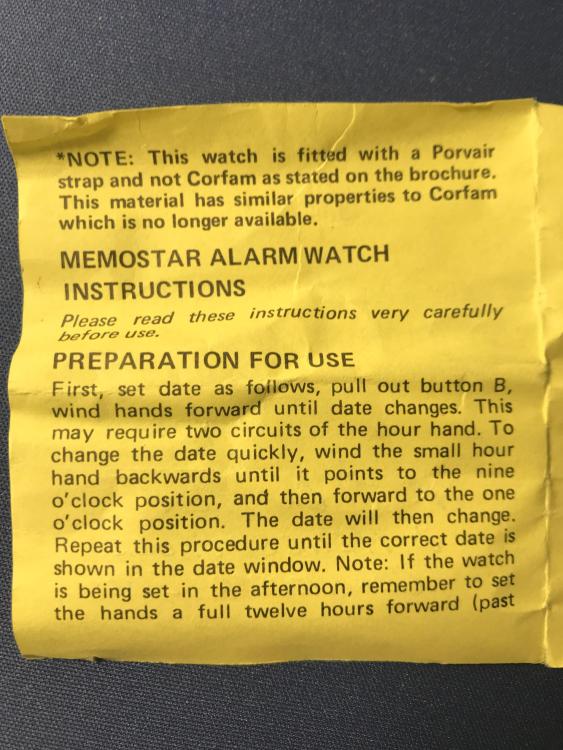

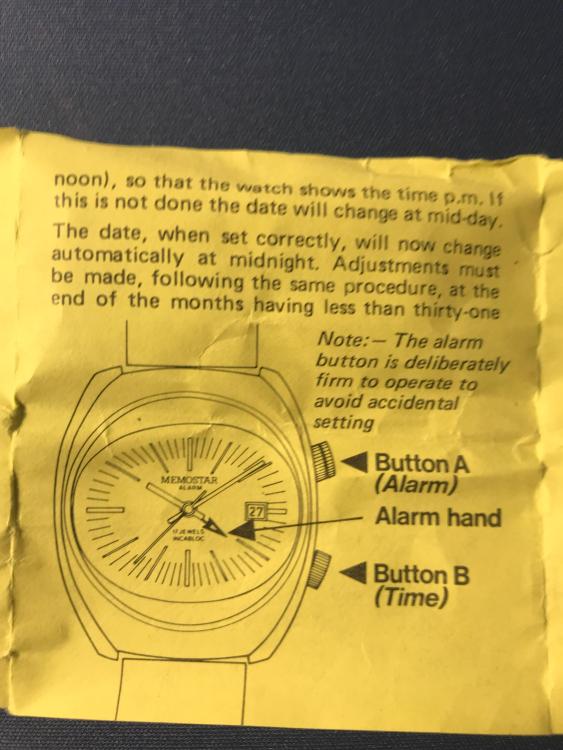

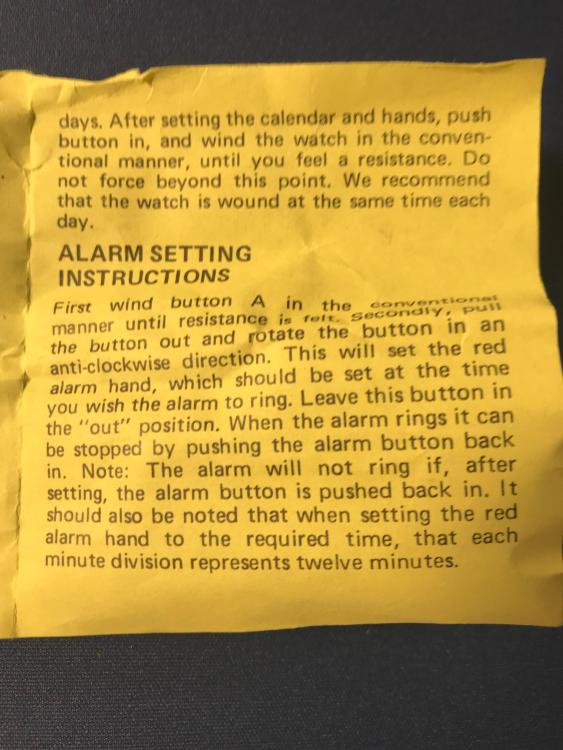

Andy, actually you can do all those things with the face attached. Roll the time setting forward until the date just clicks over. Very slowly turn the alarm until it goes off. Everything is now at 12 o'clock so just put the alarm and hands back on. Seems to be working ok on mine and I've attached a photo. I'm going to let it run for a month to double-check that the date wheel clicks forward every day. Mike, thanks for your help and those instructions. Actually I was lucky in that I obtained the watch with its original box and instructions which I've attached here for interest. It's a really lovely piece. The service video was fascinating. I see that his one also has the one-piece plastic date wheel. Coincidentally when you first see his watch it is showing 12 as the date. This is what mine showed because 12 is in the window when the tooth next to 1 is being moved by the Date Star spike (or in my case, not being moved!).1 point

-

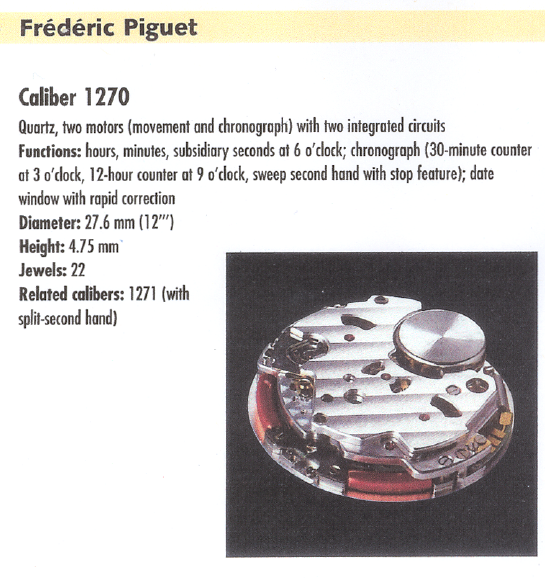

Omega and piguet appear to be using the same movement or similar movement as I do not know how exactly they are the same with a different movement number. I'm attaching the parts list from one of the companies in the service bulletin from the other. See you can see how they compare. 3027_Omega 1270.pdf 337_fp 1270.pdf1 point

-

Not in the way it would be with an electrolytic. I expect it's just the resin case due to heat.1 point

-

It's a pair of XY suppression caps so not the same as a failing electrolytic that bulges.1 point

-

If the cap is starting to bulge then its probably on its way out, is it domed on the top as well ?1 point

-

Yes the brass will work but as per @Knebo comment I too think it would look wrong and potentially destroy any value in the watch.1 point

-

always helpful when asking questions about a watch is to give us a picture of the watch movement so we can see what you're talking about. his is because often times the movement was used in other watches and may conceivably have a different number that were used to seeing. the problem with any mechanical watch is eventually it needs to be serviced including quartz watches. So you of a vintage quartz watch it probably needs to be serviced. In other words entirely disassembled cleaned and relubricated etc.1 point

-

Such a lot of countersinking to all the jewels, very strange. I'm thinking a lot of these jewel settings are pressed in and some are rubbed-in jewel settings. As regards to the 1000 cousins jewels, I bought the same vial of jewel off Ebay. About half of it was rubble and bits of metal, discarded,defective and damaged jewels. I sorted all the ok stuff, measured it up and added it to stock. If you use just one jewel from it, you will just about break even. I think its basically just floor sweepings.1 point

-

1 point

-

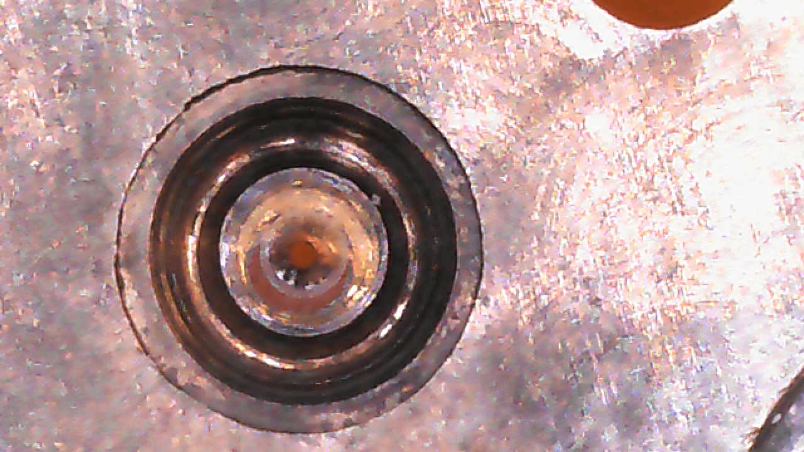

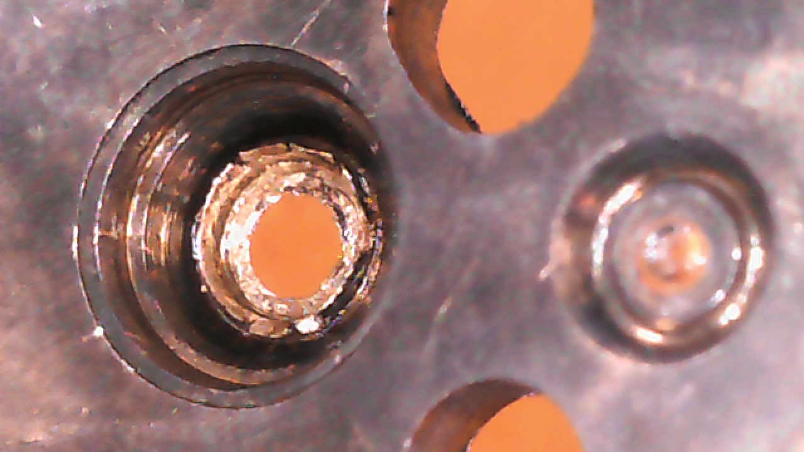

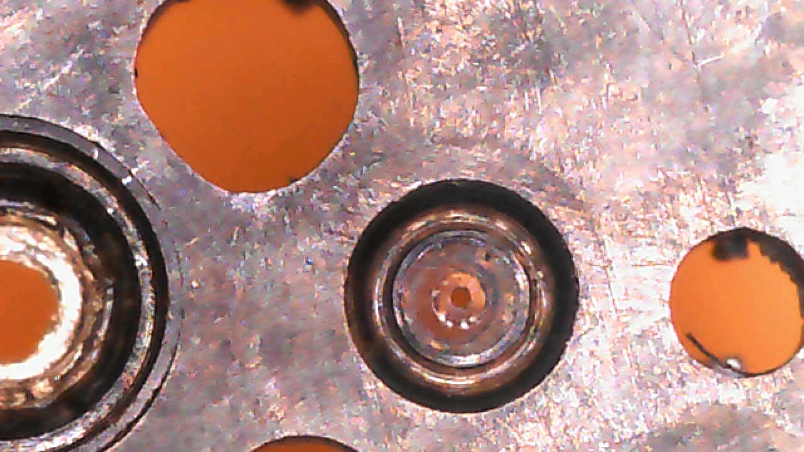

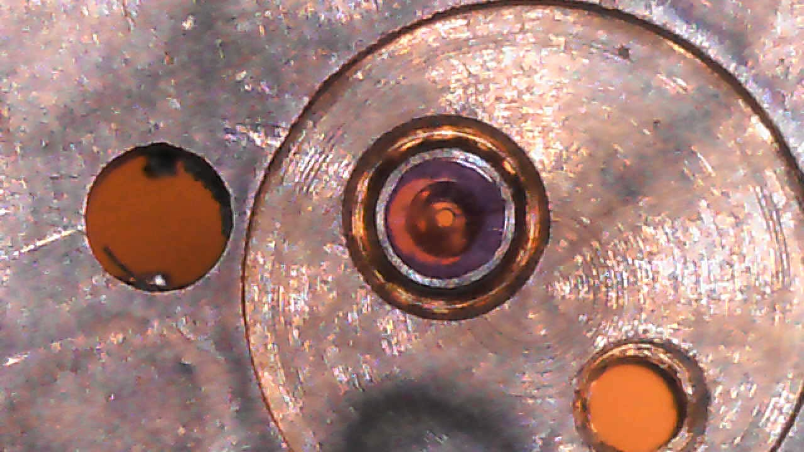

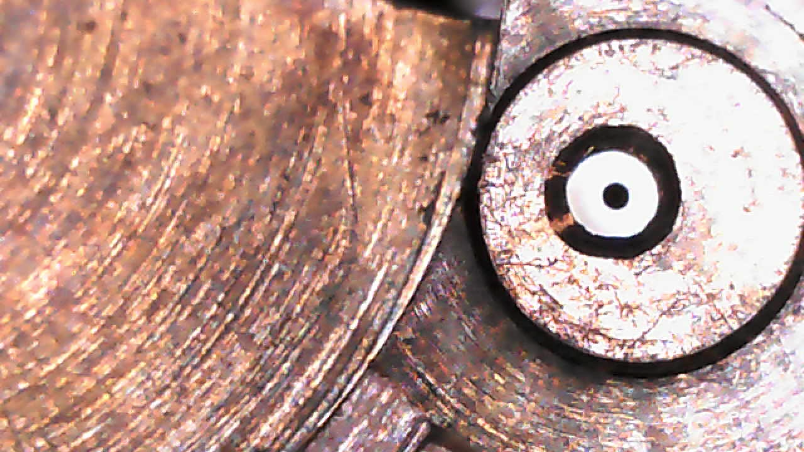

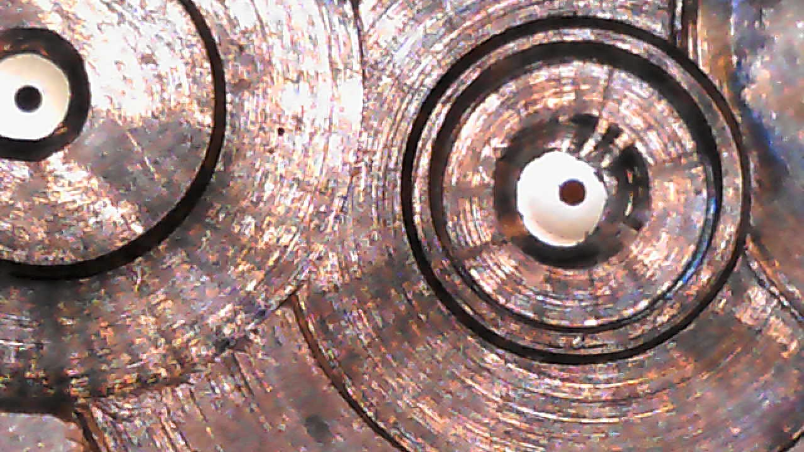

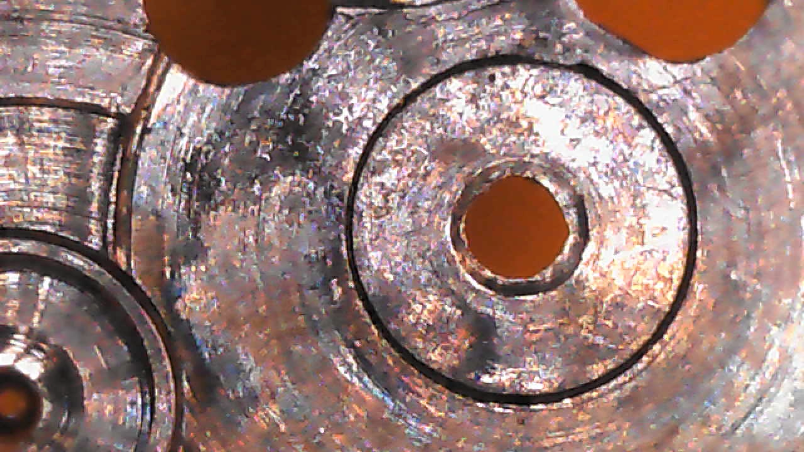

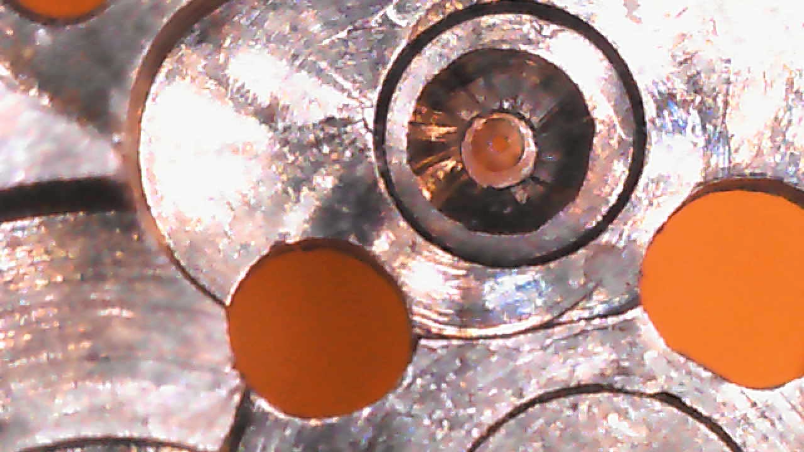

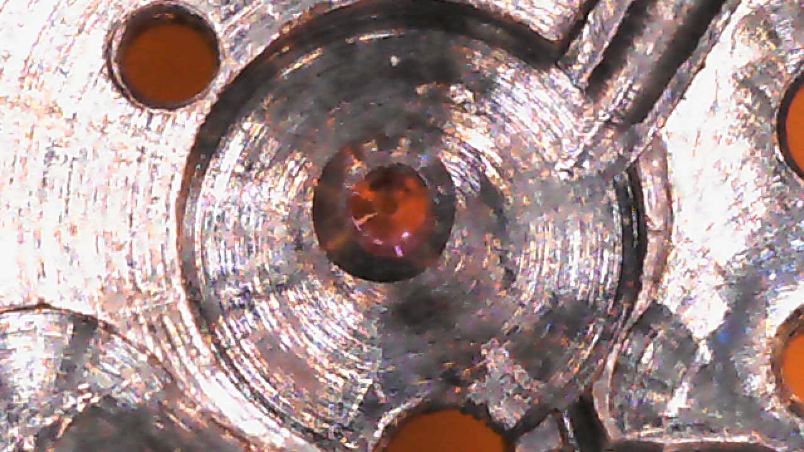

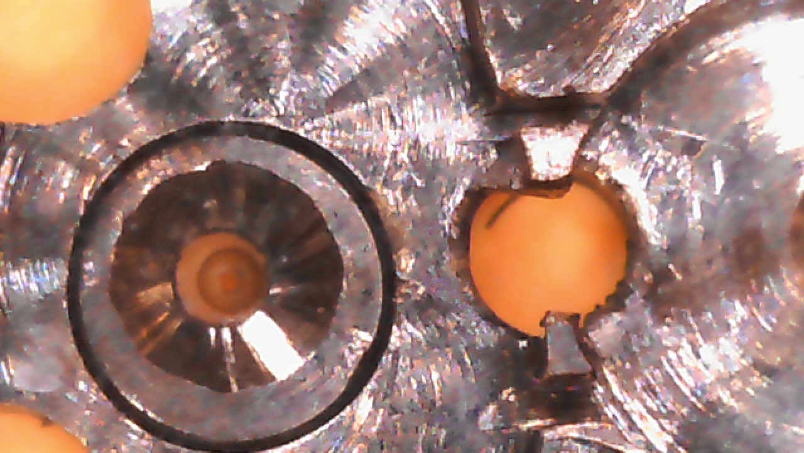

It won't surprise me if the hole is already ruined, and it may not be all my doing. All the jewel settings on the plate have been crudely countersunk. Balance jewel: Pallet jewel is the most obvious: Escape wheel where the jewel is missing still shows signs of having been countersunk which is why it's so thin and out of round at the edge: Fourth wheel: Third wheel: There's also some butchery presumably to create adjustable banking pins: Clearly someone has put quite a lot of work into this plate. I wish I could be confident they knew what they were doing. The dial side of the plate looks untouched: The balance jewel is red so likely not original. Is it still rubbed in or has a friction fit jewel been used? I can't tell. The pallet jewel: What remains of the escape wheel hole. The feathered edge is somewhat chewed up. It looked ok before it went into the ultrasonic but when I came to try to open it up it already had cracks. Fourth wheel: Third wheel: @nevenbekriev, I loved the video: very helpful. However all the donor movement parts I have use friction fit jewels so I don't have anything I can harvest a suitable jewel from. Side note: I don't have ANY spare jewels. Cousins do a jewel assortment of 1000 hole and cap jewels for £9.95. What are opinions on that? Is that likely to be useful, or will I just have 1000 jewels all the wrong size whenever I need one?1 point

-

If it's a genuine one then it could be worth some money and depending where in the world you are there should be an independent repairer. What test equipment have you got and can you post photos of the movement.1 point

-

1 point

-

Hi David. Kalle Slaap's (Chronoglide) workshop is located close to Amsterdam. Worth a visit. He also regularly gives courses to beginners and advanced students.1 point

-

1 point

-

Welcome @boogeez. You'll see, this place gets better and better with more active participation. Enjoy, learn, share!1 point

-

Absolutely! I'm planning to post a full walk-through when I service it in January (hopefully). I already know/assume that it has a loose cannon pinion (shout out to @SiZi) and running at pretty low amplitude (220°, dial up, fully wound). PS: If anyone has any service manuals or oiling chart, please share1 point

-

1 point

-

Hi Nev. Just out of curiousity: how would you go about straightening the balance wheel? Would you use pliers? My game plan would be to remove the screws, machine a cone shape with a slot (where the balance wheel arms would fit in), fit the dent balance on it and then gently tap it down until it is snug all around. But, being an engineer, I might be over- engineering it a bit.. Would heat be needed?1 point

-

I would consider this watch as 'easy fix' This is because usually I work on movements in much worse condition. The only part needed is the minute wheel, it can be found (if one have big collection of minute wheels) or made. The movement is FHF, but parts are not interchangeable, so no point to search for donor. Balance can be straightened, the stone(s) can be replaced, the pallet and balance staffs are routine task.1 point

-

Just wanted to say thanks to everyone who has provided guidance and help on this forum as I begin my journey into the world of watch repair. Today I stripped down and rebuilt the st3620 movement. It took me about an hour to reassemble it and I reckon 20 minutes of that was getting the balance in; great feeling when it started going though Maybe that’s not much to many of you but I enjoyed it and was pleased that it still worked at the end! I didn’t clean or oil it this time but thats gonna be my next attempt. Bill1 point

-

1 point

-

https://archive.org/details/watchmakerslathe00good and The Modern Watchmakers Lathe And How To Use It Hardcover – January 1, 2003 by Archie B. Perkins (Author)1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)