Leaderboard

Popular Content

Showing content with the highest reputation on 01/01/25 in Posts

-

Thank you! Will do! I used to worry about things I knew I would have to deal with sooner or later, but nowadays, I have learned to apply a principle that a highly valued colleague of mine often reminds me of. It has proven to work fantastically well and beyond expectations in all sorts of situations: "Attack exactly one problem at a time!"3 points

-

I'm sure a small lathe would fit on top of (or inside?) a tumble drier when not in use.3 points

-

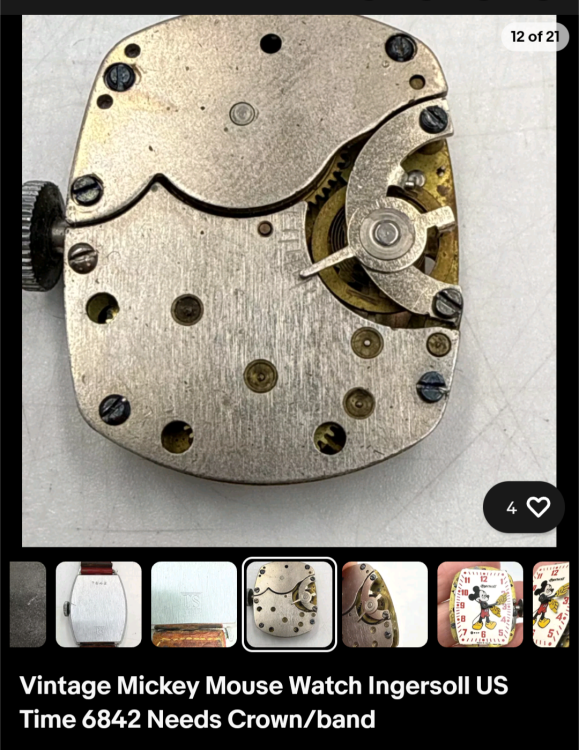

These watches are a bit more complex than an ordinary watch. Definitely worth repairing, definitely 10000% not a watch to work on as your first repair. Don't mean to sound condescending but if you can't open the case (99.9% sure it's a snap back and probably bezel), don't mess with the guts. If you want to learn to repair watches, scrounge through the million threads here. If that seems boring, watch repair isn't for you- take it to a pro.3 points

-

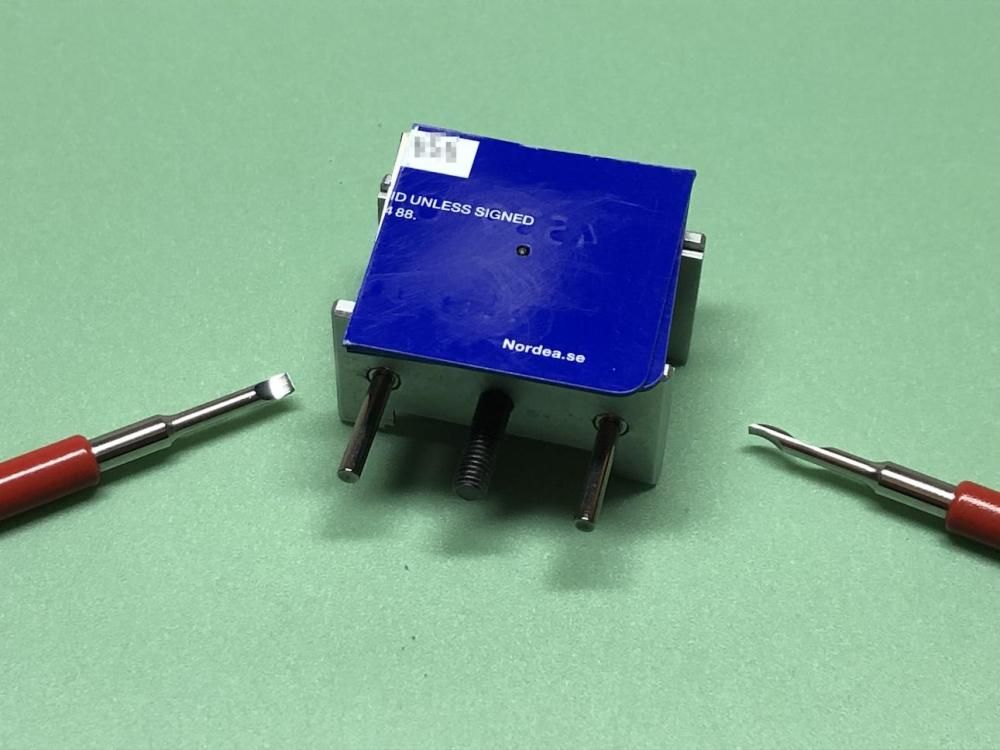

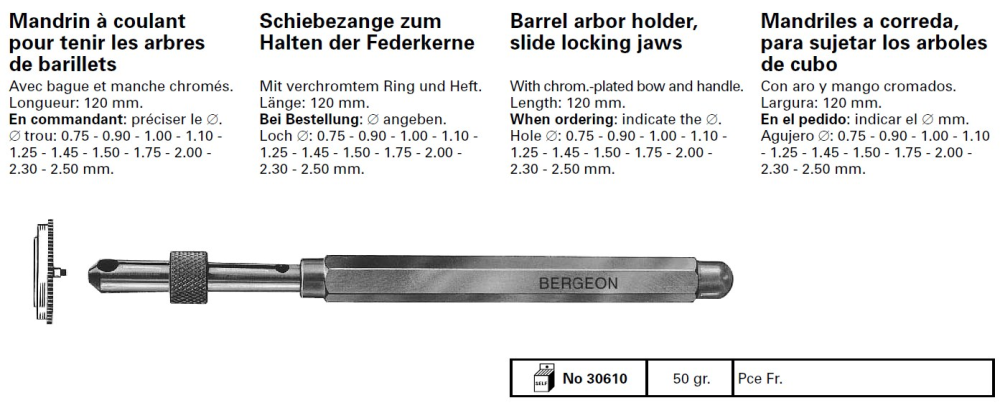

Trying out my idea for sandwiching a barrel within another barrel to stop the mainspring from popping out . These little vices are great for holding round parts , pegwood inserts for gripping. Just wondering that i have enough barrels , as long as dont make to many mistakes enlarging the hole on the lid I think I'll be ok. A thought occured to me while i was making the barrel hole larger. I've thought about this a lot when working with metal. What precautions do folk here take with their eyes, besides the obvious of glasses visors etc. I've noticed metal filings can become engrained into the skin of fingers when not wearing gloves. Anyone had any mishaps, I've pulled bits of steel from my eyes with magnets many years ago at work. Magnets only draw on ferromagnetic metal though, what about brass or other ? Works a treat, the arbor backed out of mainspring and lifted out...no hassle and no crawling around on the floor looking for flung pieces. The paper traps the small barrel inside the big barrel so it doesn't move around when turning the arbor out. Could make the hole a little bigger if need be, but if you have nightmares about losing your barrel arbor then this could be your answer.2 points

-

Hi. In your case all the advise is sterling. Do NOT mess with it. “ overwound “ is a misnomer. What has happened most likley is the oil has dried up either in the movement or the spring so when it was wound up it stuck, hence the wrong term. Overwound. It needs a good service by a professional.2 points

-

A little 8mm Geneva style lathe would be the goto Mike. Now I have things in place, apart from a couple of shelves, I plan to do just what you suggest. A bit of 18mm ply as a base should do the trick methinks. I am determined that this be the “year of the lathe “ for me, learning lots in preparation for this goal. Tom2 points

-

I've searched plenty Rich. Maybe a little one like your pic, fixed to a solid square of wood, I could then put it away when not in use, hmmm2 points

-

The biggest danger here for a beginner is that overwound spring. Technically not overwound, as a spring cant be overwound, only wound up so tight that something might break. It is fully wound but unable to release its energy due to dried lubrication or malfunction. Try pushing the start button and then giving it a little shake to see if it will tick.2 points

-

I have the whole set of barrel arbor holders. This happens when you live in Watch Land and frequent flea markets (I got a lot of other cool sh!t too). I use then rarely, but appreciate them when I do. Well worn stout nickel tweezers are my go-to. And I do occasionally search the floor, and not just for barrel arbors. The purpose made tools work well, but good pinvices well employed can work as well.2 points

-

Things can get much more interesting as the size of the mainspring and barrel increase in size.2 points

-

2 points

-

I know I may be a bit OTT but I don’t like the idea of not being able to burnish the anchor pivots of the torsion clocks I restore, I know nothing moves very quickly and the anchor only rocks back and forth but if I burnish the pivots ( I don’t polish just burnish) it removes another variable because torsion clocks need to be as friction free as possible, anyway after a bit of thought I have found a way to mount them in the lathe. Dell1 point

-

Hi All, Always struggled with removing the barrel arbour without pinging it across the room or pulling the mainspring out with it. I now screw the ratchet wheel screw into the arbour and easy peasy out it comes, gives you something for your tweezers to grip on. Haven't tried to use the method for re-installation yet as the screw head is rather large and obscures the view, maybe find a screw with similar thread but with a small head on it. Regards & Happy New Year to all CJ1 point

-

I think I've seen that before, quite simple really.... when the inner coil has already been opened up. Maybe we should all do it like this in future lol. So you can't beat a good experiment when a point needs to be made lol. I tried this on a dozen or so barrel assemblies and to be fair 50% of the arbors did come out surprisingly well. That being said they were not particularly tight fitting to begin with. The remainder either did not want to come out without some force or bent the inner coil when I exercised it. One barrel did decide to explode the mainspring out when i lifted the barrel off of the staking block . Now who wants to help me put this lot back together ....come on hands up people. The moral of this story is....dont believe everything you see on YouTube1 point

-

Here's a little YT video that makes it look too easy. Why would this not work?1 point

-

Yeah, you're right about the last two coils. I have lauched a few springs doing that so I'm extra careful. I know that taking the arbor out first looks very easy when I see Mark do it1 point

-

Yes the difference between a pocket watch mainspring and a wristwatch mainspring as far as size goes is quite spectacular. Then if you want a bigger Hamilton go to the Hamilton deck watch mainspring. It's about 3 feet long and has the force of. Normally when I play with a mainspring like that I would have it under a towel so if anything goes flying the towel will contain everything but on one occasion the barrel escaped fluid a 45° angle from where is sitting bounced off the door and went down the hallway fortunately it didn't enter in a rooms it just went down the hallway quite a distance. Then things get even more interesting if you go to clock mainsprings. Typically they will wear or should have face protection and very heavy gloves. As if a clock mainspring gets away from you things can get very interesting if not life-threatening dependent upon the size of the mainspring.1 point

-

Hi. I have done this before on watches, the stud arm comes off and the regulator arm lifts off. Screwdriver in the slot opposite the stud and open carefully as it’s hard, it should lever off leaving the regulator arm. From the underside there looks to be two screws ?.1 point

-

When it is working correctly moving the tail auto moves the part that has broken, but you can also move it manually. It is just friction that works it.1 point

-

Mike, the biggest issue with 6mm lathes is there are far fewer collets available for them. 8mm collets are still made and with an additional drawbar(may not be required) you can add to the set more easily if you need to. The BHI recommends 8mm because of this, you can read their recommendations in the free to view lesson 1 of the DLC. Tom1 point

-

6mm is the collet size, the smallest and the most common size. Could probably do just about everything that an 8mm lathe can do. The main thing with a small lathe is getting one that has been looked after. That the head and tailstock are in good alignment, recently discovered my big one is a touch out somewhere between the headstock and 4 jaw chuck or the bed tailstock end and the jacobs chuck. Will end up shimming the tailstock on the bed somewhere to get it closer. But anyways there are things that you can ask to confirm how good the alignment is. Next important thing is getting a good range of accessories with the lathe, that saves an awful lot of hunting around for them after the initial buy.1 point

-

1 point

-

This is one of those tools that I appreciate the most. I now have two sizes of this tool (1.0 and 1.5 millimetres), which cover most of my needs. There is at least one interesting and entertaining thread about these tools: "Barrel Arbor Holder vs. Pin Vice"1 point

-

1 point

-

1 point

-

Happy new year everyone!! Some may already be in 2025, others will follow soon. It has really been a great pleasure to get to know you in 2024. I thank you all for your help. I think this forum is really one of the best and kindest places on the Internet. Love and peace to you all!1 point

-

1 point

-

That defeats the objective of using the arbor vice. Once the mainspring is removed from the barrel, the arbor is easily taken out. Its the leap of the mainspring from the barrel as the last two or so coils are about to be removed. If the arbor is still attached then , thats when you're going to be on your knees searching for it and probably the barrel as well. Best to get the arbor out safe and sound before taking out the mainspring . Unless the idea is to put the barrel assembly minus the lid upside-down over a big hole on a staking block and then push out the arbor. That idea seems to have problems attached to it, lining up the arbor and stake hole and not being able to see to work the hook free. If an idea at all then cover the barrel with the mainspring facing up or put the barrel into a larger barrel with an enlarged hole in its lid.1 point

-

Excellent! @VWatchie, please let us know how you get on riveting the second hand back on to the tube.1 point

-

1 point

-

Here's that dial and tonneau case from a 1948 Life magazine ad. Too bad they don't picture the movement. https://clockhistory.com/0/ingersoll/document-1470-1.html?page=2 The Ingersoll wristwatch movements from the 1930s were not terribly different than the later Timex movements in the 50s except decentral seconds. And all of them were basically scaled down versions of the Ingersoll dollar pocket watch movements from the 1920s Here's the movement from the late 1940s model, resembling the dollar watch construction.1 point

-

1 point

-

1 point

-

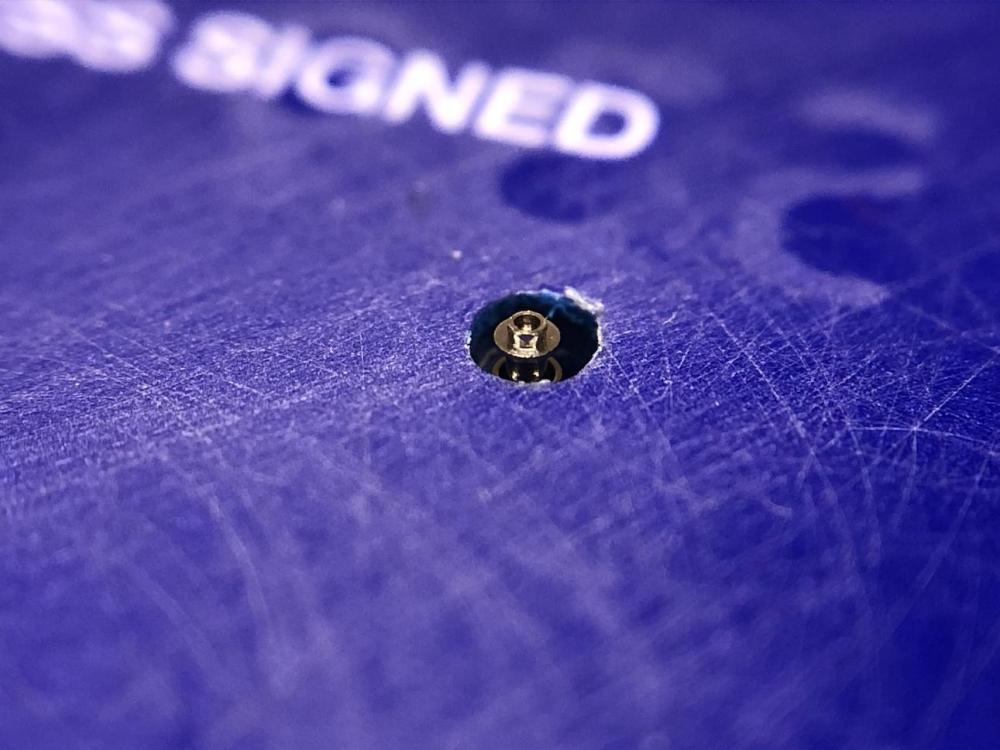

Yey well done " our kid " Happy New Year "H" x I remember years ago before contactless and card machines when we had to sign a receipt for our goods and then the cashier would check our signed receipt signature against the one on our card that was used to produce the receipt so that they matched. I never used to sign my cards and once a cashier asked me to sign my card in front of her so she could check it against the receipt I had signed 5 seconds earlier. " yes they both match thank you sir " Just googled the machine that did that, chunka chunk manual machines that the cashier swiped the credit card details over onto carbon copy paper that we signed. Wow ! Blast from the past....late 80s1 point

-

Excellent! And beautifully documented. Happy new year!1 point

-

Glad it worked out, happy new year to you too. What makes me laugh is the "Invalid until signed " almost impossible to write on.1 point

-

Mission accomplished! I really can't thank you all enough for your help. WRT is all about this, and what a fantastic way to finish the year! Before getting in there. Two layers of my wife's card were required. Ready for the operation. Hand levers are ready to go. Not too much force applied and it snapped off with a slight click. Oh, that thing is tiny. Zero damage to the pivot. Wishing you all a truly Happy End of the Year and New Year!1 point

-

Right - I have been chuckling about this. It's like Gandalf telling all us hobbits down here in the Shire how easy it is to defeat a Balrog.1 point

-

Sometimes the barrel is launched spinning with such velocity that I can hear it skidding and rolling against a wall for several seconds.1 point

-

Nice work. I find that an acid works best for cleaning battery juice damage. The battery juice is potassium hydroxide and is very alkaline. Sodium bicarbonate is also alkaline, so there is no reaction. I used to use vinegar for neutralizing battery juice but I found that phosphoric acid works even better. The phosphoric acid comes in the form of a rust remover bought from a hardware store. I dilute it 1:1 and brush it on with a size 00 artists brush. The acid works immediately and bubbles can be seen. It also brightens up brass and removes rust, the green corrosion crystals and stains from the plates, without any hard scrubbing. Do not leave the acid on for too long, as the brass will start turning reddish from "dezincfication". It usually takes less than a minute. I then wash the parts immediately in distilled water. I have managed to revive many shorted circuit boards this way.1 point

-

1 point

-

1 point

-

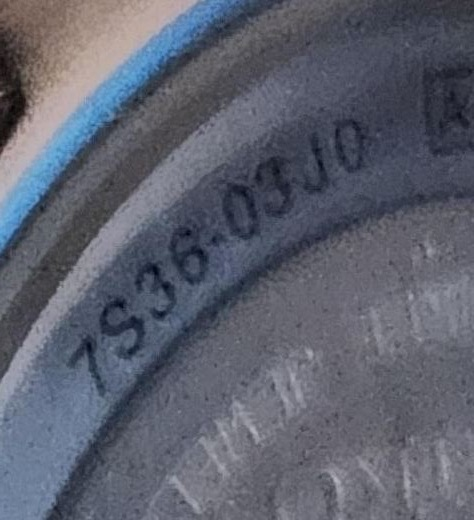

ideally you should resist from DIY alternatives to gaskets for watches. Fortunately gaskets are used in lots of watches so if you go to a variety of watch material houses they will actually have gaskets. Then if you're doing lots of watches really even have a gasket assortments. Then if you have a watch like perhaps Seiko for instance there is typically a caseback number on the back of the case. This is where typically have a four digit number which is the movement number and then it separator fall by the actual caseback number. Then for a variety of sources you might be lucky and looked up the part numbers so for instance at the link below you can enter in a case number and if you can't get your case number to come up usually if you have some of the numbers removes like the last three for instance you are likely end up with a grouping of cases that are similar if you're lucky. Because the other unfortunate problem with caseback numbers is it also depends upon where the watch was supposed to be sold and depending upon like in the US if it's an out of country watch we might not have a listing at all but we might have a listing that's a similar watch that was sold in this country if were lucky. http://cgi.julesborel.com/ so we do get a listing we just don't get a complete listing unfortunately http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_CS^7S36-03J0 the other thing of interest to do is to take the caseback number 7S36-03J0 and just search on eBay for which you get a lot of watches and miscellaneous casing parts. then if you not finding what you desire which I'm not need to go to the Internet and find this now we know your caseback number and a heck of a lot of other numbers to. https://www.theseikoguy.com/watches/7S36-03J0/ so basically to avoid complications and problems always best to say with the original gasket.1 point

-

Plenty of 'rule of thumb " no definite answers.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)