Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/25 in Posts

-

3 points

-

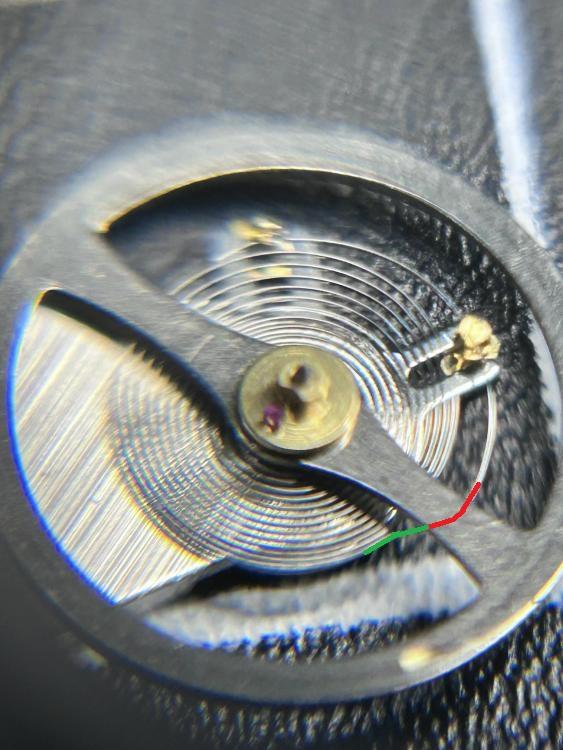

You might call (old balance and new hairspring matching) a miracle. Every balance wheel will oscilate isochronically only with a certain length of hairspring.3 points

-

No problem, I've had many Rolex, Tag and even Seiko as fakes and expect most of the time the seller is unaware of what they're selling. Theres been a few occasions though when I've been bidding on lots where the seller has placed an obvious fake Rolex dead centre in the pile of watches and they've sold for a lot more than they should have.3 points

-

For some reason, I've never appreciated patina. I like my things clean and sparkling. Maybe it a dental thing.2 points

-

2 points

-

I dread to think what you've been watching over the xmas holidays Tom To compliment with Tom's reply, the general guide is...IF IT SLIDES USE GREASE , IF IT REVOLVES USE OIL. And there lays the opportunity to begin open verbal warfare on the complexities of which oil or which grease on which watch part. Or....a light hearted pleasant discussion about adult movies.2 points

-

Hi @thricci@thricci, You 100% have a loose cannon pinion. It's a relatively easy repair. And if it goes wrong or you don't have the tools, it should be an easy part to buy on eBay. There's nothing you can inspect visually, but it's an absolutely clear case.2 points

-

I mentioned that in another post, I too like them to look pretty much new. Each to their own as far as aesthetics go.1 point

-

The designs sound very interesting, it would be good to see them. Tom1 point

-

As it's friction fit then I expect you'd be able to rotate it. Not hard to find but not cheap. https://mehima-singh.com/product/seiko-part-943805/ https://www.ebay.co.uk/itm/305819985168?_skw=seiko+943805&itmmeta=01JGM935KYG131BK63NTWSXCTR&hash=item47344aa510:g:5FIAAOSwZVtm~teU&itmprp=enc%3AAQAJAAAA8HoV3kP08IDx%2BKZ9MfhVJKnCDhgr6GKpnwRNSR8DxupPhTlWLcI2tUIMQ2qfp8vHUqBnUI442IzPhqAoIGUO1V%2BW1ZsFddeR94aOLYjSFRBEd3do4FObKOKmNiyp8KK5Q6G5Zh44YcYObu9lxQs6R9xcZEoNZyUozO1NduwKrzsF44UK%2BpvaT242V4UdpA%2BjujDvSYKxUE9sHtkFg33%2B1k%2FppJgZgYXNZvmbDrr9JH8AVx4undDmois3iFRS2JQSROvo3Nf535epVfclKUPe8fE7Wy51swRpK2NShCFKtrni8gz9Y%2FU%2F9DdUvWPzq2u6UA%3D%3D|tkp%3ABk9SR4LajImFZQ1 point

-

Have you thought about trying to rotating the pin 90 degrees? Or even just getting a new lever?1 point

-

I think I might strip the movement down. I have an old 50’s watch on the bench too that was my father in laws that was a non runner (FHF Standard 96-4). Ive been able to strip it, clean it, peg all the jewels and reassemble. It has some drag in the train of wheels but even with that I’ve managed to get it to 270 amplitude and bang on beat error and +2s a day. 18 hours later it’s still got the same beat error and rate with 221 amplitude. My guess is I have broken or damaged something. So I’ll strip it down and try and understand what I’ve done. I don’t think I’ve damaged the train of wheels but my guess is the pallet fork or the balance wheel.1 point

-

It's alive! The watch is +12-20 without regulation. Overall, I'm happy with the Zaria movement. It's well-designed and thought out for a small movement. The long center wheel seems problematic, but sacrifices are made for size. The watch suffers in the "looks" department, which keeps the price down. The yoke spring went flying but I found it on the floor after a short search with the magnet.1 point

-

First you should check if the setting on mainplate is movable. Then shim the cock such that you can stop the balance by tightening cock screw by less that 90 degrees on one hand and free the balance to run full swing ( on the other hand) by loosening cock screw back by same 90 degrees That is loosen and tightening the screw , stops and sets free the balance to oscilate. Then you should check if all looks good at the this height , where the balance oscilate full swing, check; Fork horn not rub on roller table. Balance rim stand at least .5mm above fork cock. Hairspring at least 1mm away from balance spokes and underside of the cock. You don't want any part rub. Next put the watch on timegrapher, if all looks good in at least three positions ! Undo all. Go to the setting on mainplate to move it for adjusting without the shim. Shim and gouging is ugly and folks tend to frowned upon them. Rgds1 point

-

Was it an Incabloc version of the 139 as the non version balance staff is slightly longer.1 point

-

Just where a grease is required, on metal to metal sliding parts like keyless works. D5 according to Moebius is for metal to metal rotating parts, like brass bushed arbor. this is my opinion not a request to start a lube war Tom1 point

-

One of those handy "racing calendars" with a one tenth sec 24 hour indicator.1 point

-

Thanks. I already ordered the part from cousinsuk. I'm just waiting also for the complete chinese automatic bridge to practice on.1 point

-

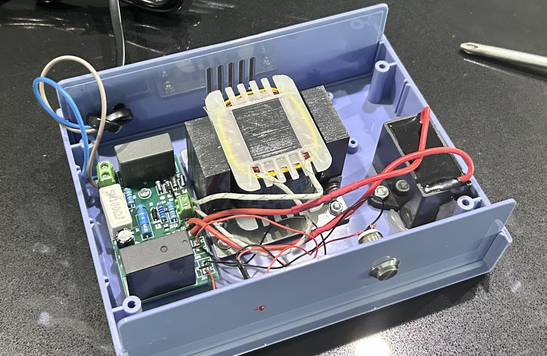

Well, the demag tool looks legit. Wow, they are selling these things cheap! Well, the demag tool looks legit. Wow, they are selling these things cheap!1 point

-

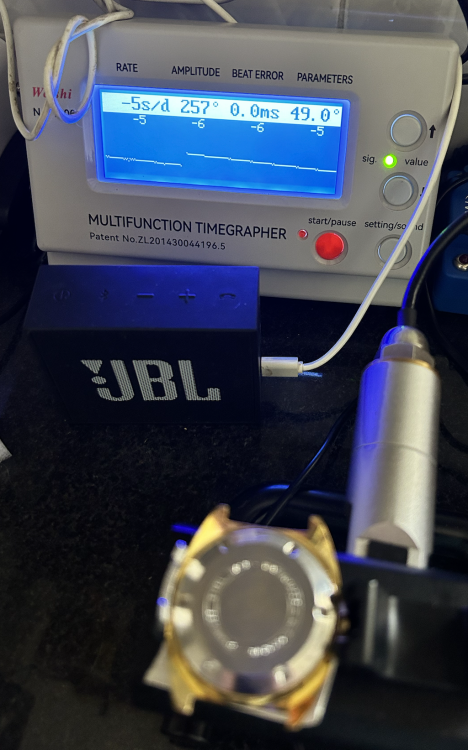

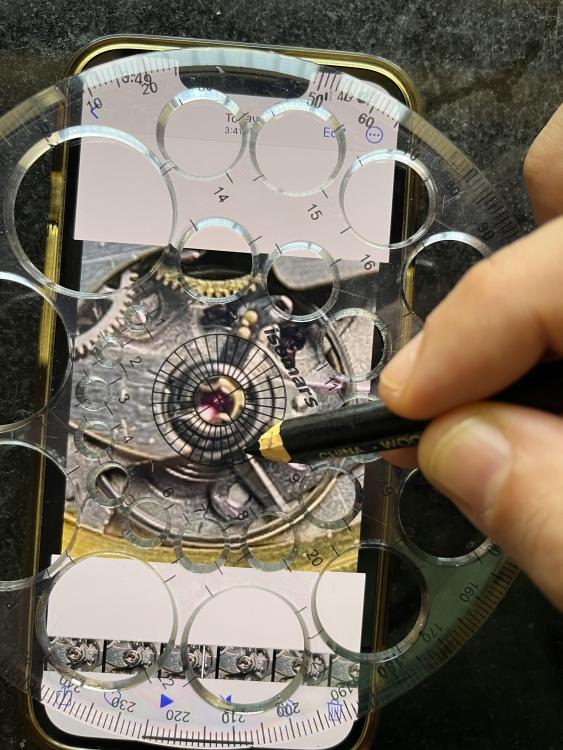

I just wanted to close the loop on this thread for the benefit of future queries... I have carefully studied the amplitude and concluded that the lift angle for the PUW 1461 is 49 degrees. You can see the video below. I played the video on my phone and placed a 360-degree protractor on the phone screen and marked out the movement of the balance wheel spokes to try and get as accurate an estimate as possible. I determined a 260-degree dial-down amplitude. I then adjusted the lift angle on the timegrapher till I achieved this amplitude, and it seems like 49 degrees is accurate. Timegrapher reading: Video in super slow-mo: This is how I did the measurement:1 point

-

Hi Rob and welcome to the forum. Attached a little reading for you dictionary_ebauches_sa.pdf TM 9-1575.pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

Haha, interesting idea. An potentially one with which you could make a lot of money! Some Rolex models will literally be +100% in value if it has a tropical (black that has become red-ish) patina. Please post a picture of your Everest!! I'm a fan of that watch, too. How old is it?1 point

-

I'm not sure you really want A answer to this question. Ideally in a perfect world you would diagnose the problem in a watch. You would repair the problem and verified that the problem is indeed fixed. Then the watch can be disassembled cleaned lubricated etc. Then you have a completely serviced watch it is now running. But if you determine that whatever repair you did it didn't work and you have to disassemble which unfortunately happens occasionally. Then yes you have to basically start over as you're going to screw the lubrication up. I suppose it depends upon what you had to take off and what exactly you're doing. So for instance if you change the mainspring and you decided that's not the problem you wouldn't have to take the mainspring out again and replace it with another new one or even just taken out clean it all up and put it back together if you did it properly the first time you shouldn't have to take it apart again. But if you disassemble the watch especially the balance wheel you will screw up the lubrication. On the other hand if you're new to watch repair you need to practice. Watch repair is all about practicing to get better. In other words you need to practice observing what a running watch looks like. Looking at what the hairspring looks like when the balance wheel oscillating. Plus you just need the practice of disassembling and reassembling the watch and having a functional watch afterwords. What you do not need to do is practice disassembling a watch reassembling hoping that the outcome will somehow change because it will Not. In other words you if you have a watch that's not running you haven't actually done anything to repair anything other than disassembling reassembling the outcome is not going to change typically. So yes sometimes you may have to service a watch twice. The first servicing just to fix the problems verify the problems have been fixed. If you had to taken apart multiple of times to get those problems fixed then ill have to service at the second time. You don't want to ask that question? Notice this is a discussion of four pages? But, As you've asked I believe it starts on page 2 I snipped out an image this is what's being used. From electrical engineer's point of view you might find those pages interesting to look at.1 point

-

There's a chance that your watch is simply not fully wound. As no hand-winding is possible with this calibre, you'd ideally wear it for a full (and active) day. Then measure again. Haha, yes, I had seen this starter kit as well and it baffles me that they'd but the 5ml of HP1300 instead of 2ml, and that they'd put 9501 AND 9504. Makes no sense to me. They could have added a breaking grease for automatics or Fixodrop instead.1 point

-

Yes the difference between a pocket watch mainspring and a wristwatch mainspring as far as size goes is quite spectacular. Then if you want a bigger Hamilton go to the Hamilton deck watch mainspring. It's about 3 feet long and has the force of. Normally when I play with a mainspring like that I would have it under a towel so if anything goes flying the towel will contain everything but on one occasion the barrel escaped fluid a 45° angle from where is sitting bounced off the door and went down the hallway fortunately it didn't enter in a rooms it just went down the hallway quite a distance. Then things get even more interesting if you go to clock mainsprings. Typically they will wear or should have face protection and very heavy gloves. As if a clock mainspring gets away from you things can get very interesting if not life-threatening dependent upon the size of the mainspring.1 point

-

I don't suppose we can get pictures of the timing machine with its results? Then out of curiosity did you try to wind the watch up in any of fashion? I would I combined the quotes here. So what can you learn for the future? Let's see we started a conversation with lubrication and did any of our lubrication answers help with your problem? Then you're going to do something with your sons watch what exactly did you do? That would help to give an answer for the future. How can you tell that this watch has a young age?1 point

-

So either the first figures weren't correct or you've changed something with the balance when making the adjustment. Without seeing the timegraoher and how the balance looks and oscillates it's difficult to say.1 point

-

Trying out my idea for sandwiching a barrel within another barrel to stop the mainspring from popping out . These little vices are great for holding round parts , pegwood inserts for gripping. Just wondering that i have enough barrels , as long as dont make to many mistakes enlarging the hole on the lid I think I'll be ok. A thought occured to me while i was making the barrel hole larger. I've thought about this a lot when working with metal. What precautions do folk here take with their eyes, besides the obvious of glasses visors etc. I've noticed metal filings can become engrained into the skin of fingers when not wearing gloves. Anyone had any mishaps, I've pulled bits of steel from my eyes with magnets many years ago at work. Magnets only draw on ferromagnetic metal though, what about brass or other ? Works a treat, the arbor backed out of mainspring and lifted out...no hassle and no crawling around on the floor looking for flung pieces. The paper traps the small barrel inside the big barrel so it doesn't move around when turning the arbor out. Could make the hole a little bigger if need be, but if you have nightmares about losing your barrel arbor then this could be your answer.1 point

-

That’s the only thing I had thought of but as the burnishing requires speed not pressure I think it will be ok but only time will tell. Dell1 point

-

You should always have the regulator lined up dead centre to start the timing proses1 point

-

1 point

-

Happy new year everyone!! Some may already be in 2025, others will follow soon. It has really been a great pleasure to get to know you in 2024. I thank you all for your help. I think this forum is really one of the best and kindest places on the Internet. Love and peace to you all!1 point

-

Welcome to the forum @BangDroid. Nice introduction! Always good to hear a bit more. For cleaning, you'll need also something like naphta/benzine/lighter fluid. IPA is for rinsing afterwards.1 point

-

1 point

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)