Leaderboard

Popular Content

Showing content with the highest reputation on 01/07/25 in Posts

-

3 points

-

3 points

-

I sometimes modify the end of balance pivots, but only in certain situations. On a number of very small calibers (LeCoultre- your ears are burning), you end up with a large difference between horizontal and vertical amplitudes. Like 70 degrees. To get the vertical amplitude up to a reasonable number you end up rebanking horizontal. The classic fix is to flatten the pivot ends. But, I learned from an esteemed watchmaker here a seemingly counterintuitive technique, and I was instructed by him to do it on the watches he produces: you put a slight angled flat on the pivot end with a fine Degussit stone. I thought it was a terrible idea- but it works, and I have used it with great success on a number of pieces. You do have to check that you don't throw up a burr, and if you do take it off. I have the special Bergeon tool to flatten pivots, as well as a lathe and Jacot tool, and the Degussit and angled flat really gives the best results.3 points

-

Those are nice looking timegrapher plots. The fact you got a reduction of 15° makes me think that the Omega Instruction is referring to balance jewels. I will definitely try it next time. The operating range of HP1300 is the same as 9010. If a watch reaches -15°C whilst on a wrist, then I would think that person would not be worrying about the correct time3 points

-

2 points

-

Exactly. Seems crazy but it works. A funny thing with truly flat pivots- if there is any contamination of the oil in the balance jewels, with particles, one will inevitably make its way to the pivot, get under it, and act like a ball-bearing, increasing the amplitude. Obviously we imagine that our jewels and oil are always spotless, but this weird technique also precludes any issue there. A more elegant solution is what is referred to as "Daniels" cap jewels (around here at least). The cap jewel has a slight concave area, a little offset from center. This forces the pivot against the hole jewel in the horizontal, dropping the amplitude a bit. I worked on a series of watches years ago where this was an option to get the amplitudes closer. In a more extreme example, Vulcain at one time had cap jewels that were conical, again pushing the pivot against the hole jewel. Don't lose one of those! Found an ad for the Vulcain "Exactomatic"2 points

-

2 points

-

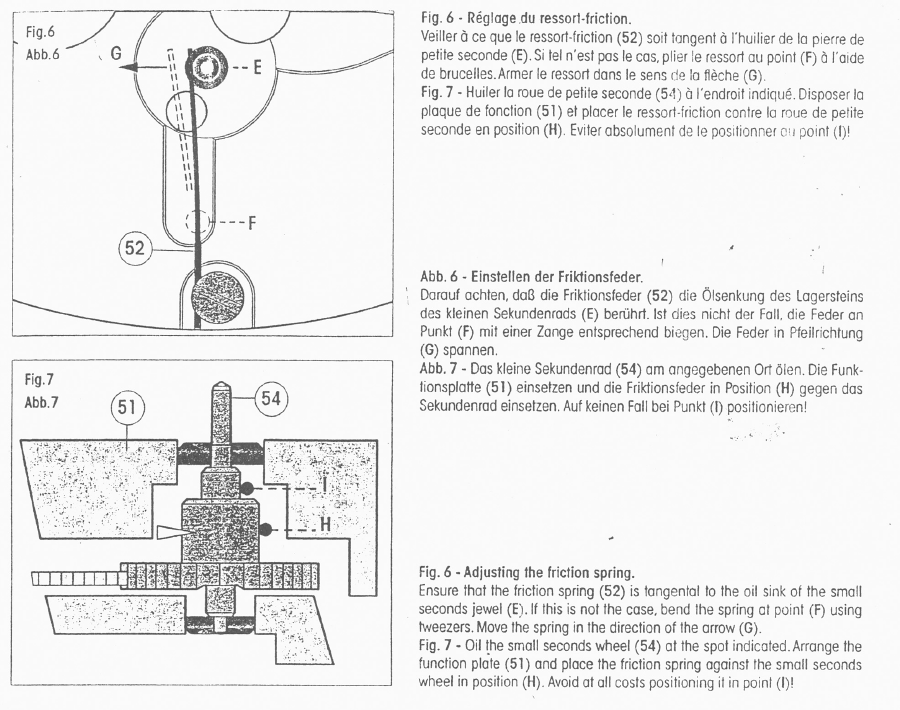

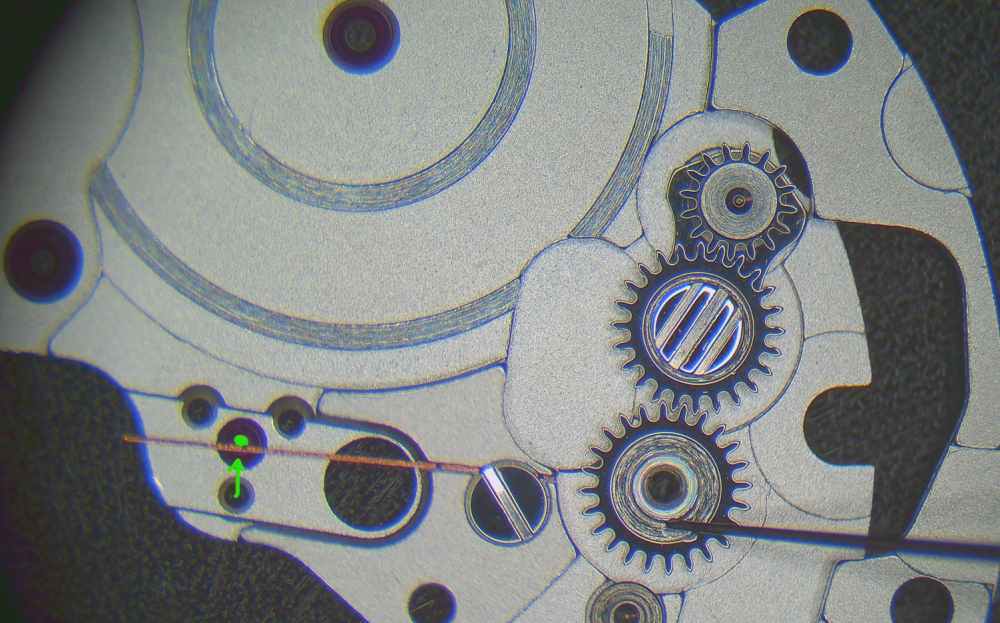

I think a thicker oil is a better solution than dulling pivot ends. As you say yourself, dulling pivots is a permanent "solution". I'd rather call it "damage". A thick oil washes away and may actually reduce wear a little bit as opposed to a thinner oil. I though the same @mikepilk, but didn't think of expressing it in such a funny way. Yes, it makes more sense in the context of the whole sentence in the Omega document. Indeed! And considering that it's only one side of the balance, not both! But yes, the viscosity difference is huge. 150 cSt for 9010 and 1250 cSt for HP1300 (both at 20°C). At 0°C (@nevenbekriev) it's 625 cSt vs 5900 cSt, respectively. No worries! Yes and no. - Yes, it's a spring that presses against the centre seconds pinion to prevent jerking/jumping of the seconds hand. - But no, in this movement it's not from the top (like Omega 55x or older Rolex), but from the side. Here's a picture of the underside of the barrel bride. The green dot would indicate the place where the centre seconds pinion will be located and the green arrow the direction that the spring pushes against it. I find this solution more elegant and less tricky to adjust than the "from the top" ones. On the other hand, one has to be a bit careful when installing the bridge (see technical guide comment on Fig 7).2 points

-

Yes, it’s easier and faster, but as I see it, it’s a temporary solution. I would primarily adjust the banking/pallet jewels, as it’s a solution that lasts over time and spares the next repairer the trouble of figuring out what needs to be done to fix the problem. It also doesn’t involve any modification of the movement. The fastening mechanism is designed so that the pallet jewels can be moved back and forth, and it’s no more unusual than adjusting the length of the hairspring with the regulator arm.2 points

-

2 points

-

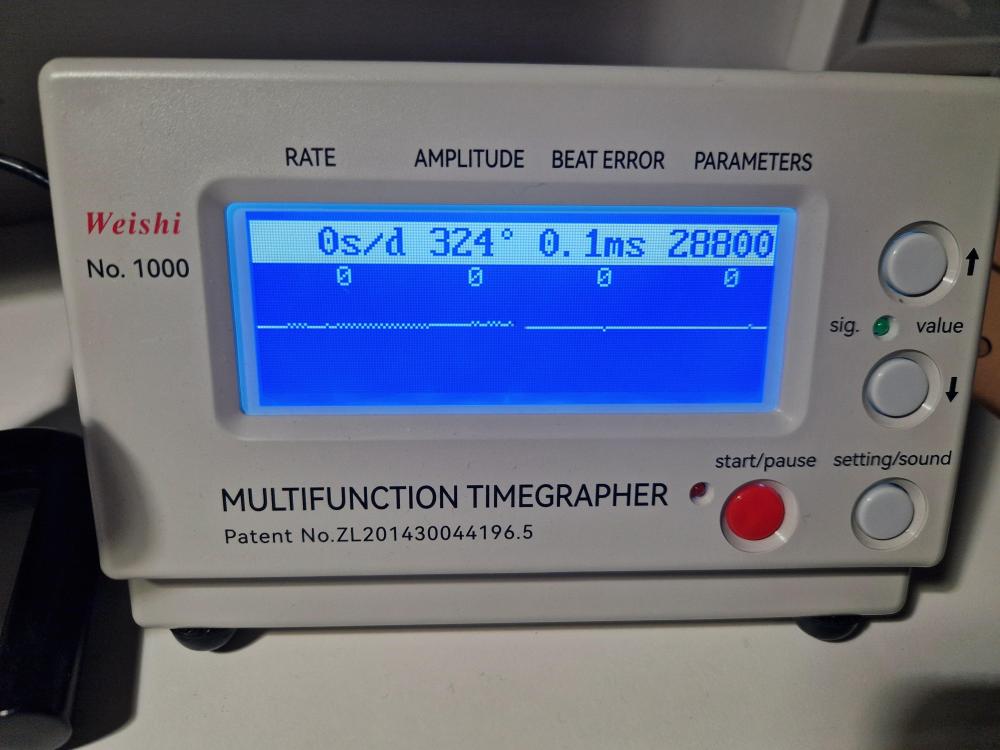

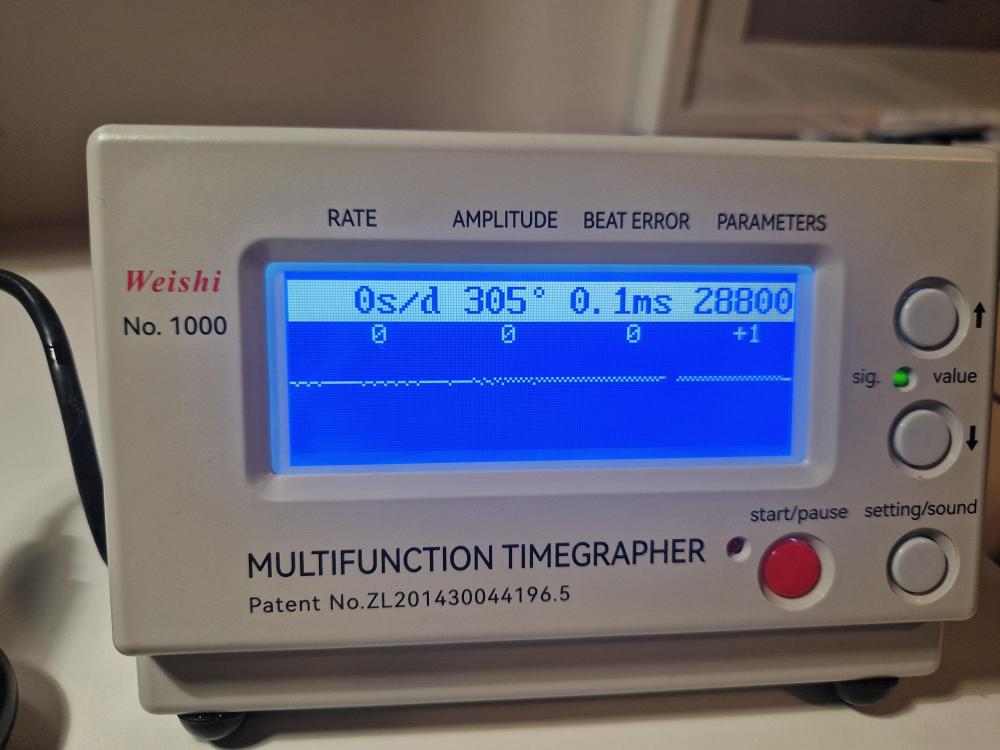

Ok everyone!! I managed to reduce the amplitude by about 20°. - increasing tension on centre-seconds spring: minus 5° (more would probably be possible, but I didn't want to push it too much) - replacing 9010 with HP1300 on the upper balance jewel setting: minus 15°. Now, the highest amplitude I can get is 325°. No more knocking even if I try hard: full manual wind, then vigorously rotating the watch to maximize automatic winding, and then straight on the timegrapher, dial up. The fact that there's now an imbalance of lubrication between train side balance jewels (HP1300) and dial side balance jewels (9010) has --fortunately-- a very limited impact. The amplitude difference is only around 5° and the rate difference around 3 seconds (I didn't record the rate difference before the change of lubrication, so it may have already been the same). I will admit that the better solution would have been a weaker mainspring. However, it's extremely hard to find a suitable one. After that, adjusting the pallet depth seemed like a more serious intervention (despite @VWatchie's kind encouragement -- I'll try it on a less valuable watch soon!!). Finally, HP1300 certainly won't do any harm on the balance jewels. And it just "washes off" at the next service!. So no lasting changes to the movement. I'm satisfied and will leave it at that. Hopefully the above impacts on amplitude will be helpful for someone down the line. Highest I can provoke purposefully now (dial up): After an hour of settling down (dial up):2 points

-

2 points

-

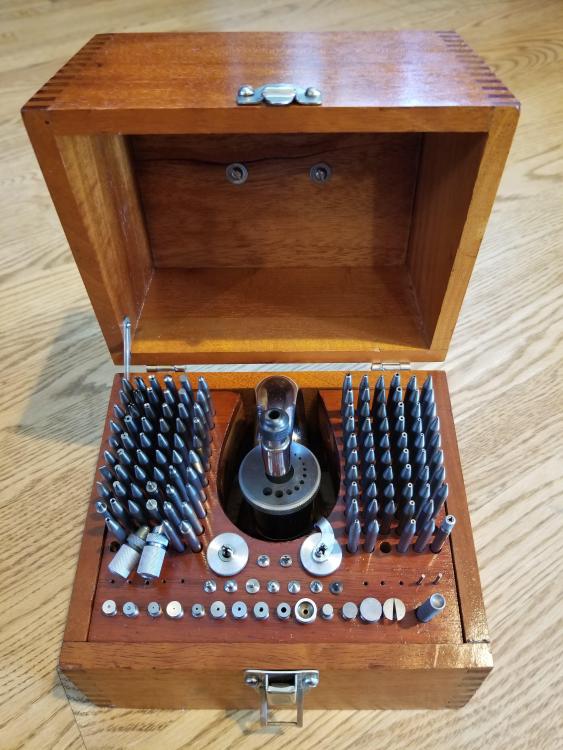

Several months back I came across this K&D 600 Series staking set from an old jewelry store that no longer services watches. I finally got around to restoring it. The case top had a crack running through it, by the handle. I cut that part off and replaced it with a new piece of mahogany. Sanded and stained the wood. Cleaned up the hardware. De-rusted all of the stakes, stumps, etc. and cleaned and lightly oiled them. Disassembled the frame to clean, lubricated and re-blued some of the parts. It turned out better than I expected.1 point

-

I know I may be a bit OTT but I don’t like the idea of not being able to burnish the anchor pivots of the torsion clocks I restore, I know nothing moves very quickly and the anchor only rocks back and forth but if I burnish the pivots ( I don’t polish just burnish) it removes another variable because torsion clocks need to be as friction free as possible, anyway after a bit of thought I have found a way to mount them in the lathe. Dell1 point

-

Personally I think Microscope, I know Michael that you are younger than a lot of us here so your eyesight is probably better than most of us. I didn't really get into the loupe idea, initially I managed sort of....i didn't know a Microscope was even a watch tool at the time, I wasn't in any forums and had only watched Mark's videos and he doesn't use one. I just thought what can i use to make this easier as my depth perception was crap, so googled microscopes. Picked one up for a hundred from a guy that used it to repair electronics, phones and the like. As they say ...it was a game changer for me. Then a lathe then a jacot, the Microscope has had 100s more time than either of the other too. Without it I may have even given up by now or at best moved onto clocks.1 point

-

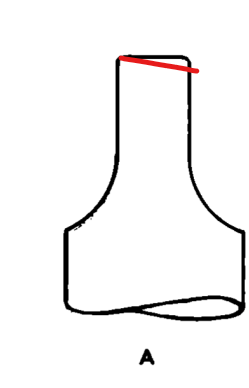

I can not confirm by observing this personally, but OP says the rivet is not high enough and not popping at all above the surface of the balance arm. In this case using flat punch will be wrong as it will deform the balance arm. So only domed or conical punch may be used to rivet the staff that will be able to act on the rivet but will not hit the arm.1 point

-

all parts on a movement are delicate. Imagine the rivet is only a thin piece of metal. What you need to be sure of is that the stake is pushing the rivet out and down. The dome of the stake must be narrow enough to get inside the rivet to push it outwards. We had a really good discussion about this around a year ago with some good pictures that visualised the proceed .1 point

-

Remove all hardware, sand everything down to bare wood, stain, and then apply a few coats of polyurethane. Let poly cure a few days before putting it back together.1 point

-

Very kind of you but we still don't know what's inside. If it is a quartz and the battery has leaked it may be beyond repair. A new movement may be available. We could do with more information from the OP.1 point

-

Send it to me if you like. I'd consider myself to be an improving, semi-competent amateur. I don't usually break thinks any more, and if it's a service it needs I can usually cope. Probably not worth the postage for you though if you are in Arizona. But I'm happy to give it a go - absolutely no guarantee offered but no charge for my time.1 point

-

Microscope, definitely. Even to inspect your work from the Jacot lathe, I feel that a microscope is necessary or at least extremely helpful.1 point

-

I think I'm going to unwind it to clean and get a proper coat of 8200 tonight. I just can't imagine whatever factory oil was used in 1960, without vacuum seal, is going to be right for a fine watch I've put so much toward getting everything perfect.1 point

-

The rivet will still expand with a convex punch, might as well try and see how it holds. Yes, they generally should stick up a few hundredths of a mm.1 point

-

Once I had problems with some old oil: I had good amplitude when the room temperature was normal, but in the morning (winter time, my 'shop' is in a cabin) the amplitude was bad and slowly recovered by heating the room.1 point

-

Body heat would certainly be a factor Mike...thats why I said IF the balance gets near 0°C . Just depends what your doing......maybe Nev think Knebo has ice-sculpture for a hobby That's just way to wierd to be true, the balance staffs on my bench are shaking in their regulator boots.1 point

-

I meant its only a permanent solution in the fact that it will stay as is, where as oil may change over time. It can of course be rectified without changing the endshake again. Its a fairy well recognised idea, I've read it a few times and mentioned here and other forums. I did try it once on a scrap movement in a rather rough way, the effects were quite devastating to the amplitude If you want to learn something....if you want to find things out...then you have to do something that gives you an answer....you have to experiment So you don't store your watches in your fridge Mike ? For safekeeping against theft or fire risk. How very odd, it was the first place I thought of when planning my home security And is probably why I'm always late for everything I do I think @nevenbekrievmade his point then, the UK has had quite a few 0°C this year, quite tolerable really....for me anyway. At 0°C HP1300 has 3x the consistency of honey and half that of treacle at normal room temperature. If the balance gets anywhere near 0°C then it ain't moving. My next experiment is to oil bal cap jewels with honey .1 point

-

Not for Orient that I'm aware of. If you've not got anything left then it will be down to measuring with calipers and even then probably having to buy several options to cover yourself. My first thoughts were that it would be a Tension Ring but from your description it could be something more special. https://www.cousinsuk.com/category/acrylic-tension-ring-armoured Edit This is the other type I thought it could be from your description. https://www.cousinsuk.com/product/special-form-underlayed-sternkreuz-u1 point

-

Welcome to the forum. Photos would help and you're always best starting a new post when needing help. The hands should be push fit and removed with what's called hand levers. Different shapes and sizes are available depending on the application. https://www.cousinsuk.com/search?searchTerm=hand levers1 point

-

1 point

-

I would change the oil as a first option. Easy to do, and saves making changes to the movement. As you say, adjusting the jewels isn't difficult, and you don't need any special tools. I sit the pallet on an old pocket watch plate which I heat. It can also be useful if you are lacking amplitude. I had a movement where I couldn't get good amplitude when everything looked perfect - apart from a bit too much lock. Pushing a pallet jewel in gave an extra 30° amplitude.1 point

-

Congratulations, and I'm surprised it had such an impact. It goes to show how critical the oiling is. Excuse my laziness, I know the information is in one of your previous posts, but is this a spring that presses against the top of the pivot (opposite the second hand) to prevent the second hand from jerking/jumping? I would have guessed significantly less than that. Very interesting! The only possible downside to this solution is that the next watchmaker will face the same problem. In the long run, I would still encourage you to consider @nickelsilver's suggestion to adjust the pallet jewels slightly outward. It's fiddly, yes, but it's a skill worth having in your toolbox.1 point

-

1 point

-

1 point

-

Because the contacts are covered by the circuit board. And I wouldn't want to risk breaking the wires by jamming a probe into that little gap.1 point

-

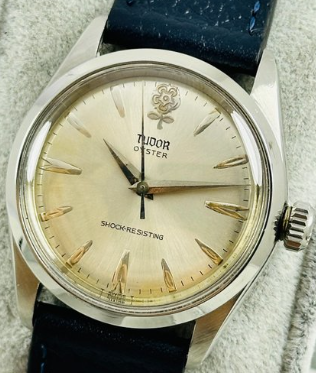

Comparing it with something like this then I agree that it doesn't look quite right. https://www.blackbough.co.uk/product/tudor-oyster-big-rose-ref-7934-steel-vintage-wristwatch-dated-1959-wxtrbr/1 point

-

The movement looks like a legitimate Tudor 1156; those are a bought-in ETA movement rather than a Rolex manufactured one, so not particularly valuable. https://www.emmywatch.com/db/movement/tudor--1156/ https://welwynwatchparts.co.uk/products/tudor-cal-1156-movement-spares-repairs I can find several variations of the dial layout & have no idea which are originals or year variations - or imitations; sorry.1 point

-

I guess you have to consider not only how old the spring is but how old the oil on it is. Ok the oil has never done any work as far as sliding lubrication goes but it has protected the spring from corrosion. The oil has been subjected to the atmosphere in whatever environment that was, humid ? dry ? vacuum sealed packaging ? If the oil was mineral or worse still organic it has still undergone an aging process. Even new sealed oil supply has an expiry date if we choose to take notice of it. I can't answer your question for you, but those factors I would be considering Michael.1 point

-

Its surprising how easy broaching out a hand hole is, a 10 micron increase in diameter shows up quite visibly as a distance travelled up a thin tapered broach. I just pick what I need from a large selection of preowned hands and make them fit.1 point

-

For what it's worth, D5 on the pallet fork pivots robbed around 30 degrees of amplitude on an ETA 2472 I worked on a while ago. I also played with D5 on the balance pivots which had less of an effect. I'm wearing that particular watch right now and it's at ~340 degrees in the horizontal positions today compared to ~300 degrees 2 years ago, so this migth not be a viable long-term solution. Your mileage may vary.1 point

-

I personally wouldn't go around telling women thst they had developed a patina . But there are plenty of things that are fully appreciated for the their age related colour changes. A piece of antique furniture can be completely ruined if it's not sympathetically restored, this goes for antiques made from most materials. Its something that an antique dealer actually looks for, there is even a process that mimics an aged look....distressing an item.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)