Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/25 in all areas

-

Hi, that's very kind of you. Thanks fellerts . I live in Hamar. I just had the staff riveted. It sits completely solid. Must admit that I am very happy . The trick was to grind the punch into a more conical shape so that the punch sat in the shoulder groove. I then polished the punch step by step up to 7000 grid. The whole process with the punch in the drill and under a microscope. When it was finished grinding, I heated the punch to an orange color and then cooled it quickly in oil. After use, there are no marks in the punch, i.e. hardening was good. The next time I use a Chinese punch, it will be sanded to the purpose and then hardened. In the near future, I will probably buy a new Bergeon of medium size and supplement as needed. But when I found a method to "save" my Chinese punches, I will calm down for a while. The next problem with my punches it is over and out. But it would be interesting to hear more about your Boley and Bergeon. I'll get in touch.5 points

-

I wanted to share with all my vintage C E Marshall watch cleaning machine from the forties(?). I won a low bid on the Bay which quite surprised me until it arrived in drastic condition. I do like restoring old machinery though so I rolled up my sleeves and went to work. The cosmetics were pretty straight forward, cleaning, sanding, painting and so forth. But the challenge was the electricals. I do have some background in electronics so I was able to figure out the systems in place..switches for on/off, reversing motion and heater element; mechanical train for reversing function; replacement for heating element that couldn’t be sourced. It all came together and it works well. The machine employs a rotation table that holds the jars and the motor can be easily raised and lowered with a unique spring assisted system that locks solidly in any position.4 points

-

You should be able to reharden the punch. Reshape it, as you don't have a lathe, chuck it in a drill and use stones to get a nice shape. Heat just the end (a centimeter or so) to orange, quench in oil nice and vertically. When you come out of the quench stick the oily tip back in the flame to ignite the oil, let it burn a few seconds (it may just burn out)- that will suffice for the tempering.4 points

-

Try Vetus brand tweezers which are available from many sources. I use brass tweezers from Cousins for 80% of the time but brass is too soft for work that requires some force, like pushing home setting lever springs. Brass is also too soft to be ground to very fine tips. So for very fine work like picking up tiny screws from the calendar works, I still have to use stainless steel tweezers. But all tweezers, regardless of brand or material, require regular maintenance. The tips need to be straightened and dressed. I like my tweezers to have very a light touch, so I always thin the metal near the joint at the back down to make it more flexible.3 points

-

3 points

-

If I recall correctly, the USB connection will not provide the max resolution of the camera. For that, you would need to record to the micro SD card. If you are running Windows, you can use the built-in Camera app and view/record/take photos from that. I have a slim HDMI cable, which is easier to deal with to connect to my monitor. Overall, I have been disappointed with the typical microscope camera setup. If I can see the whole movement in the eyepieces I want to be able to see the whole movement through the camera. The problem boils down to needing a larger image sensor for the camera. Instead of buying a much more expensive camera, I am working on getting the pieces to connect my DSLR to the microscope. I should have those by Thursday. Hopefully, that will better match with the FOV through the eyepieces, even if there is vignetting.3 points

-

I use these from Cousins. https://www.cousinsuk.com/product/titanium-tweezers-cousins-swiss-style https://www.cousinsuk.com/product/brass-tweezers-cousins-swiss-style2 points

-

Thanks to collegues' inputs I've now got one of the 2 problem movements going - the one that had suffered corrosion. Having added some solder to the pads the drive wheel worked but only when the 'plate' was pressed down in a certain way. And the movement stopped when I replaced the back. I employed a YT tip (adding flux to my copper braid) in wicking away most of the solder leaving only a thin coating. However, the problem remained. Checking the drive & 2nd wheels showed that the initial closure - when the solder was raising the 'plate' too much - had bent their plastic upper pivots. Trying to straighten them wasn't successful so I used one of my Temu micro drill bits to widen their upper 'seats' a fraction & this did the trick. Maybe too much info but I am pleased to have got my friends clock going again and am grateful for you folks' help. Your interest was also a source of motivation.2 points

-

As the seller has 99.6% positive feedback, it sounds like it was a genuine error. So order another !2 points

-

There is a few things I need to say here ....thats a shocker . So first off I'm assuming we are talking about the thickness of the tip that should WEDGE itself into the screw slot. Bottoming out of the tip in the slot is the common scenario of a blade about to slip out and indiscriminately scratch anything in its path. Particularly if the screwdriver is not held perpendicular to the screw head. Now I'm a joiner of 40 years and before that picked up my first driver at around 3 years old, apparently forcing it into the speaker of my dad's radio 55 years ago . So i should know how to handle a driver...yes ? actually no i did not...not in the case of watchrepair. Mainly because the tips of watchmaker's screwdrivers are thin and have little surface contact. It took me a day on and off of scratching up old movements to figure out what I was doing wrong. The tip needs to fit the slot thickness snuggly as a wedge and not bottom out...that's it. Unless you are very good at holding your driver straight up and down. Reminds me of when my apprentices would hold a hand driver or battery driver at all manner of angles and wonder why they chewed up screw heads. " Hold the jeffing thing straight " I would whisper gently in their ear . Rambled on long enough me thinks... secondly learn to dress your drivers....nooo... not cute little outfits.....shape them. Nice accurate equal angled sides that fit as a wedge and a straight end. The wedge fitting sometimes lifts out the screw as well. I've seen folk polish driver tips ??? I dont get that, not completely , it might look nice and shiny and ward off some corrosion, but it has no grip. I generally go no higher than 400 grit, the flat bottom can be a bit rougher if you like. I like a bit of grip same applies to my soft tweezers, more so in fact. I dont repair Patek watches so I'm not fussed about zero damage to screw heads. If I did then i would change my ideas. And lastly the driver should more or less suit the size of your hands if they are one way or the other. I have stupidly large joiner's hands for a guy of only 5'9" , took me a while to get accustomed to using diddy tools. Oh and holding the driver head, more steady control is achieved by having it on the middle pad of your index finger and not on the last pad near you fingertip. Think thats it, I may be back later today....if you're lucky....or maybe unlucky as the case maybe2 points

-

My experience is you are constantly dressing screwdrivers to fit. The bigger the variety of movements the more you need to do it. If a watchmaker specialises in say, 2 or three movements they conceivably have a set of drivers dedicated to each. Tom2 points

-

@LittleWatchShop That's good to hear - I was assuming my vintage Dumonts were probably not a good long term solution, but I have been really happy with how they feel and how effortlessly they dress. I've picked up 3, 3C, P and maybe something else. I might try to get a couple of 3 for reserve stock. Generally I've been paying $12-$15 for tweezers that don't have rust visible in photos.1 point

-

For general assemble/disassembly work, my most used tweezers are No. 3 Brass from Cousins. Not sure where they're made, but they're certainly inexpensive. https://www.cousinsuk.com/product/brass-tweezers-cousins-swiss-style?code=T62250 I really wanted to try brass tweezers but didn't want to spend tangible money on something I didn't know if I would like. The Cousins option made it easy for me to experiment, and I'm glad I did. My various Dumont stainless steel tweezers still get occasional use.1 point

-

RicharHarris123, LOL, it's NOT a stupid question. No Sir, it does NOT work with a battery..... I should've made that clear.1 point

-

OK, it was simple. The cap jewel for the balance was missing! That's the way it came. I thought it was odd when I took out the chatone, but I'm learning. Now the watch is running great up or down. Thanks! The loose movement is more of an issue. I suspect the original movement ring was not provided and this is a substitute. I tried the ring from the other watch, which has a small tab, but I can't get it to go in and I don't want to use any more force for what is clearly a misfit, so that tells me it's not a match even though they're the same watch. The tab (see pic ring on the right) looks like it is needed in the watch I'm working on. My movement ring doesn't have one and the ring is thinner. Not sure how to proceed. Just for fun. On a different watch, the Westclox, I needed a new balance so I ordered one. NOS no less; it's at least 40 years old. Well, the Seiko folks packed it in junk foam, which rotted out and glommed onto the hairspring and it was toast! The seller told me that Seiko fixed their packaging flaw, after inspecting his stock. Watches are fun...1 point

-

Looks clean enough so doesn't appear the battery has leaked. Can you fit a new battery and see if you get any sort of twitch from the seconds hand as it could just need freeing up. Failing this there are still replacement movements out their. https://www.ebay.co.uk/itm/205152415028 Edit The movement is actually and ISA 1198.103 or 1198/32 https://swisswh.com/product/isa-swiss-movement-1198-32-1198-103-disk-at-3/1 point

-

That should have been the link. Maybe this will work better with all the Fitbits. https://www.ifixit.com/Device/Fitbit_Smartwatch1 point

-

Yes they are. Not sure if this is the one you're looking for but this site is the best for anything like this.1 point

-

1 point

-

1 point

-

There's more that one way to skin a cat. Tung oil will work, but it won't provide quite as much moisture resistance as polyurethane would. Poly also creates a hard surface, protecting the wood from scratches. Tung oil will need to be periodically reapplied.1 point

-

I'd like to share a blog post that I feel is very relevant to this discussion. Replace "Reddit" with "watchrepairtalk" and I think it applies perfectly here. https://brooker.co.za/blog/2023/04/20/hobbies.html Being conscious of which quadrant you fall into is key, I think, to enjoying any hobby. There are members on this forum that can MacGyver their way around most any problem with a toothpick, some scrap brass and rodico, and others who will spend days and/or fortunes on obtaining the _perfect_ tool for the job. Learn to spot the difference and think about what type of hobbyist you are (or want to be).1 point

-

Many of us have gone the exact same route. If you are serious about watch fettling, I'd say a binocular microscope was essential. I can't imagine working with a loupe now.1 point

-

@Neverenoughwatches - thank you so much for taking the time to reply. I’m coming to realise that I may eventually need more screwdrivers but that’s a way down the road for now. I’ll definitely have a go at fitting the drivers to the movement I am working on though, and be a bit braver in creating the wedge to prevent bottoming out in the screw slot as that’s definitely what happens at the moment. Interesting about holding the screwdrivers as well. I too thought everyone can use a screwdriver, but it turns out not so much when working on such a small scale. I’ll try using the different part of the index finger I have been using a 600 grit diamond plate (which I use for my hobbyist hand tool woodworking) to dress the screwdrivers but I may try something a bit coarser.1 point

-

The professional watchmakers I know all have several sets of screwdrivers, each set honed for a particular movement or brand. I'm also often told not to use the same screwdrivers for quartz and mechanical, I guess because of magnetism, but I just de-mag mine often.1 point

-

1 point

-

Keep looking one will turn up eventually . In the meantime I dont think we have seen the damaged hairspring. Do you think it's beyond repair?1 point

-

I drilled and tapped the centre of the brass so I could add an arbor then drilled a series of holes 3mm in from the edge all the way round starting at .5mm but each hole a bit larger than the previous one , I did it on my little mill with the brass blunted on my smaller rotary table but could be also done by scribbling a circle around the brass and drilling to that line then put in the lathe and turned the brass down to reveal 1/2 the hole. I see someone on YouTube has made one so Have a look at this video it should help. Dell1 point

-

In fairness the seller refunded it right away. No apology though (goes a long way in my book!) and since the seller seems to be the only supplier of these parts Im not sure of my next move, for what was essentially a donor buy.1 point

-

I started with eye loupes, then to a cheap digital microscope, then a more expensive digital microscope, then finally to a trinocular microscope. I wish I would have just bitten the bullet early on and just had gotten the trinocular microscope. It would have been the cheaper option than going the route I did. I love my Eakins microscope. Cheaper than the Amscope equivalent, with only minor hardware differences (when I compared it to @spectre6000's Amscope microscope).1 point

-

A big difference between DU and DD suggests an issue with the balance cock jewels or pivot, or excessive balance end shake allowing the balance to touch the centre wheel or something else when turned dial up. Or possibly the opposite: perhaps it's running fast when dial down because of jewel or end shake issues and slows down to normal when dial up. The relative amplitudes DU vs DD should give you a clue as to which end to focus your attention on. Regarding being loose, doesn't this movement have case clamps that secure it? As always, photos would help.1 point

-

We probably got around 15 years on you then . Lol eyesight does go downhill very quickly. So I expect a microscope is going to make a big difference to you. Its just nice to have a comfortable seating position.1 point

-

Yes, seen them called a shoulder or step but not underlay. One of the problems with terminology. Correction, step and underlay seem to be different things.1 point

-

1 point

-

Check your punch(es). Often the part that actually makes contact gets flattened over time, and they need a little touching up to be nicely convex again.1 point

-

The rivet will still expand with a convex punch, might as well try and see how it holds. Yes, they generally should stick up a few hundredths of a mm.1 point

-

Body heat would certainly be a factor Mike...thats why I said IF the balance gets near 0°C . Just depends what your doing......maybe Nev think Knebo has ice-sculpture for a hobby That's just way to wierd to be true, the balance staffs on my bench are shaking in their regulator boots.1 point

-

I sometimes modify the end of balance pivots, but only in certain situations. On a number of very small calibers (LeCoultre- your ears are burning), you end up with a large difference between horizontal and vertical amplitudes. Like 70 degrees. To get the vertical amplitude up to a reasonable number you end up rebanking horizontal. The classic fix is to flatten the pivot ends. But, I learned from an esteemed watchmaker here a seemingly counterintuitive technique, and I was instructed by him to do it on the watches he produces: you put a slight angled flat on the pivot end with a fine Degussit stone. I thought it was a terrible idea- but it works, and I have used it with great success on a number of pieces. You do have to check that you don't throw up a burr, and if you do take it off. I have the special Bergeon tool to flatten pivots, as well as a lathe and Jacot tool, and the Degussit and angled flat really gives the best results.1 point

-

Yes. And you see the 2 thinner than hair wires protected by blobs of epoxy. I wouldn't go probing anywhere near them.1 point

-

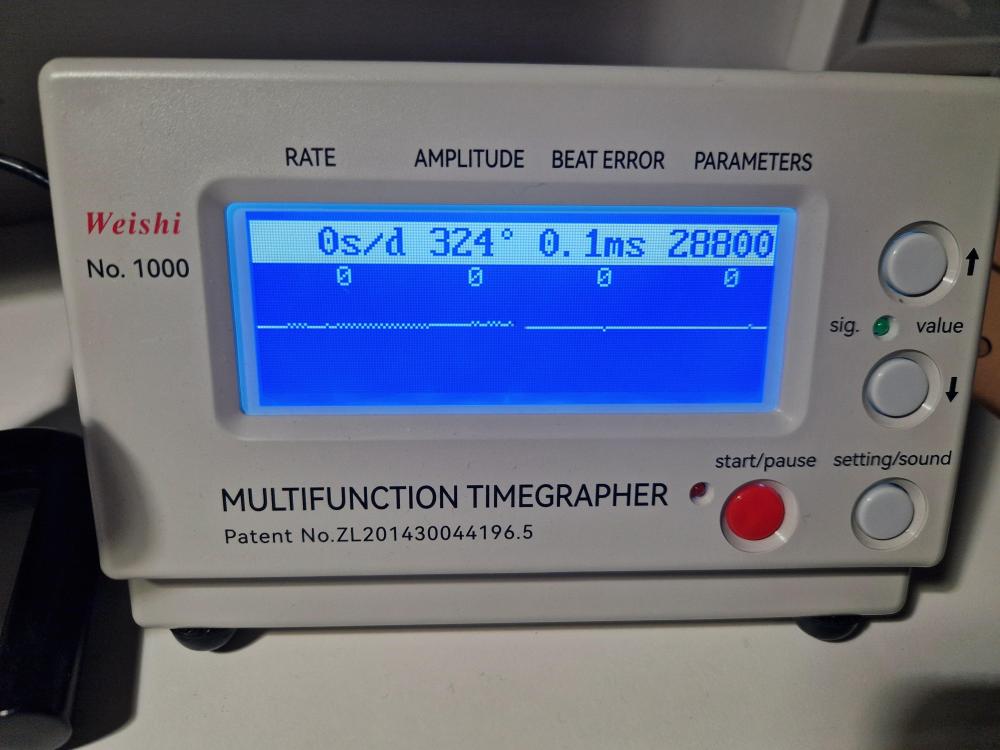

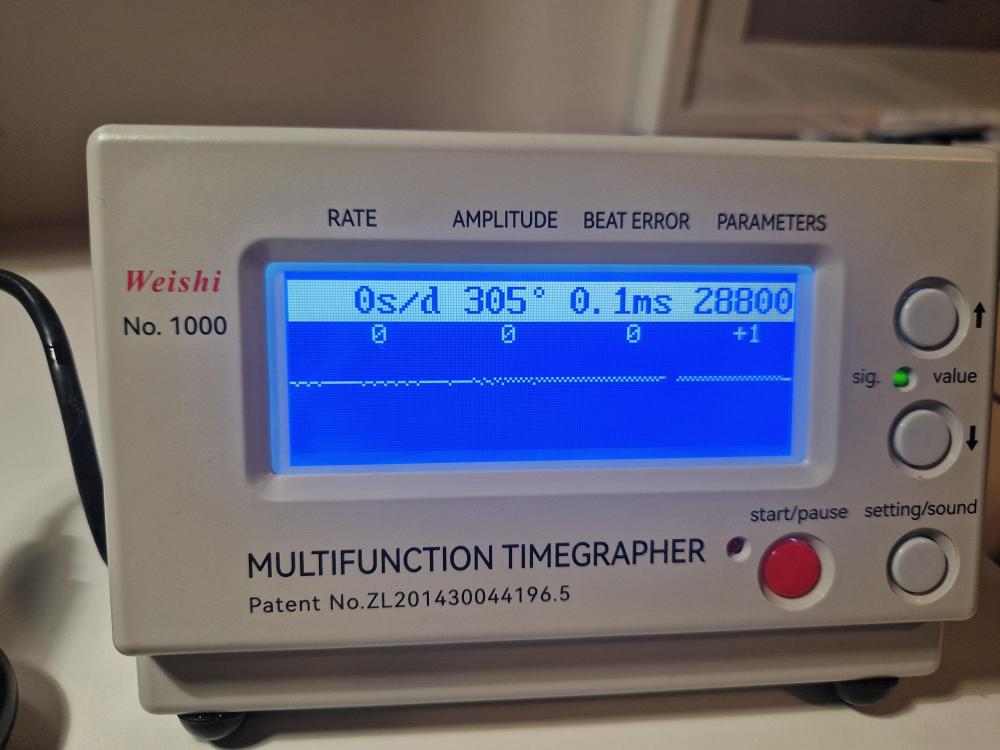

Ok everyone!! I managed to reduce the amplitude by about 20°. - increasing tension on centre-seconds spring: minus 5° (more would probably be possible, but I didn't want to push it too much) - replacing 9010 with HP1300 on the upper balance jewel setting: minus 15°. Now, the highest amplitude I can get is 325°. No more knocking even if I try hard: full manual wind, then vigorously rotating the watch to maximize automatic winding, and then straight on the timegrapher, dial up. The fact that there's now an imbalance of lubrication between train side balance jewels (HP1300) and dial side balance jewels (9010) has --fortunately-- a very limited impact. The amplitude difference is only around 5° and the rate difference around 3 seconds (I didn't record the rate difference before the change of lubrication, so it may have already been the same). I will admit that the better solution would have been a weaker mainspring. However, it's extremely hard to find a suitable one. After that, adjusting the pallet depth seemed like a more serious intervention (despite @VWatchie's kind encouragement -- I'll try it on a less valuable watch soon!!). Finally, HP1300 certainly won't do any harm on the balance jewels. And it just "washes off" at the next service!. So no lasting changes to the movement. I'm satisfied and will leave it at that. Hopefully the above impacts on amplitude will be helpful for someone down the line. Highest I can provoke purposefully now (dial up): After an hour of settling down (dial up):1 point

-

I've had a couple do this to me in the past. I now make a full uninterrupted video of every parcel I open.1 point

-

A common microscope setup is the Amscope, with 10X eyepieces and 0.5X Barlow lens. Giving up to 22.5X magnification and 170mm working depth. You need at least about 150mm working depth.1 point

-

Try adding a small trace of light oil to the spring contact surfaces. That can often cure intermittent connections. (eg. A small amount on a cloth or cotton bud & scrub the contact surface with it; not enough to creep and affect other parts of the device). The oil film prevents air getting in to the critical metal-to-metal contact area & causing tarnish or corrosion). 3-in-1 oil is commonly use in electrical repair for this type of problem, also noisy volume control etc.1 point

-

Tightened the canon pinion and now the hands work as they should Thank you everyone!1 point

-

I have to say that I nearly didn't post this: I felt embarrassed to have made such a blunder. But this forum is so supportive it felt safe to share, and it might save someone else from making the same dumb mistake. And if others have a chuckle at my expense ... I'll survive.1 point

-

If you mean for repair, then you can't beat getting your hands dirty, follow @AndyGSi advice. If you mean in general, then reading, videos and getting your hands dirty.1 point

-

A good place to start would be to get a watch that's running, take it apart then put it back together and see if it still runs the same. A lot will come down to what tools you've got and what you're hoping to achieve?1 point

-

It's good practice to peg the hole jewels. As I suggested, most don't bother with the balance hole jewels, unless there looks to be hardened crud on them, or there's a problem with amplitude. The smaller holes are a real hassle to peg. It's hard to get the pegwood sharp enough, then it breaks off in the hole. I use an old sharpened oiler to push the bits out. The holes that are really essential to peg (thanks to info from nickelsilver) are the pallet arbor jewels. As they aren't lubricated, and tiny bits of dirt can kill the amplitude. Even if I don't peg any other jewels, I always try and do these. Happy pegging1 point

-

I bought some from Horotec a few weeks ago and it's great, and I'm pretty critical of pegwood. Just their standard stuff.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)