Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/25 in Posts

-

4 points

-

I know for my 8mm wolf the tailstock runners and sliders that fit inside them are exactly to a mm size. Runners 7mm and sliders are 4mm. I did similar to Caseback for using the 1/8" shank carbide drills. But instead of the ER collet holder I drilled out a 4mm brass tube to the drill shank diameter and depth to use as a sliding drill feed.4 points

-

Thats exactly what i did this morning , a little alteration on what I already had. I dismantled a tv stand for one of my customers before xmas and I kept the rods that held it together . Checked last night and they were 7mm. Ah-ha I have just the job for you guys. Some junior hacksaw cutting and one 1/8" hole later.....tadahhh...1 very accurate pivot drill runner . Tried that completely free hand after watching this video of Nev's and some encouragement from him. 0.3mm carbide drill into a barrel arbor, I couldn't believe how actually easy it was...since the carbide drills are renowned for easy breakage.3 points

-

3 points

-

If they don't both move freely then yes. Essentially trapped between the bottom plate and their respective bridges. To fully identify this as a no endshake issue, fit those two components into their bearings in isolation and then check for free motion.2 points

-

My Pultra uses a leaver tailstock and although the headstock takes 10mm the tailstock takes 8mm and as can be seen by the video is very accurate. But you could also do it like the Pultra 10 , a runner and different size brass collets like this, it fits in a runner or collet. i have also made a mount to fit my tool rest. just shows there are lots of ways to re pivot or other drill work including all the ways posted above.2 points

-

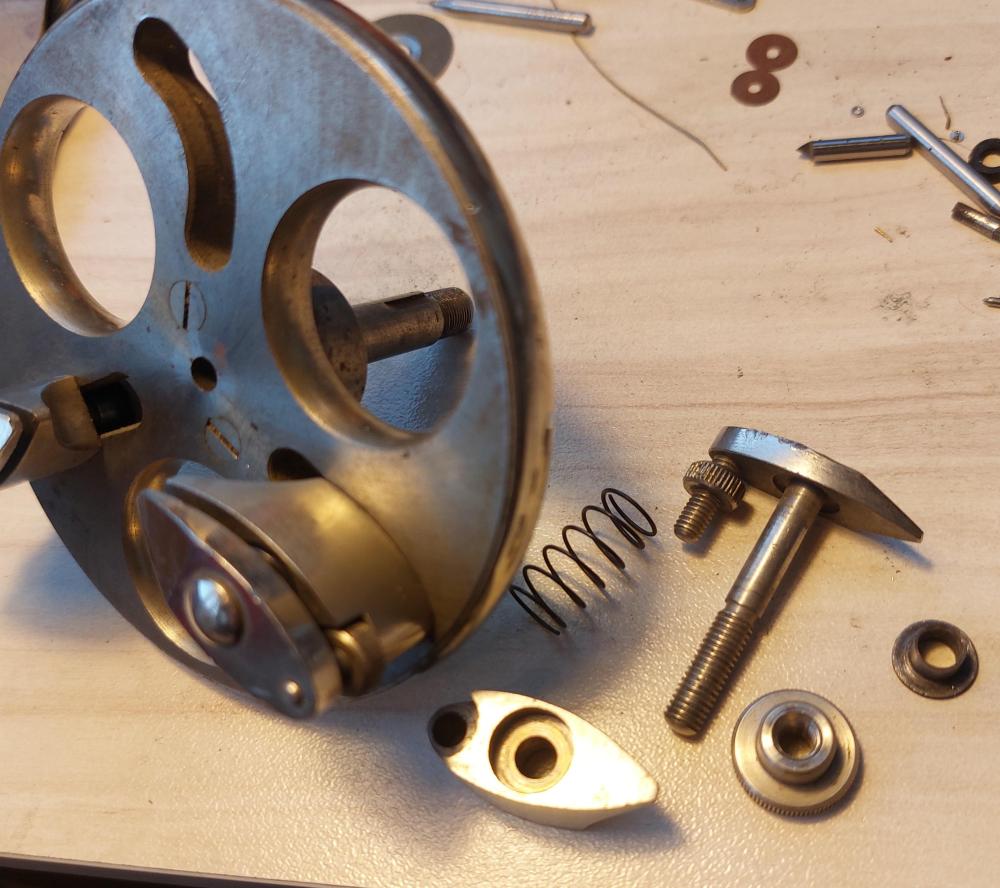

No thats all solid Andy, all the workings are at the front. Just had another look at the spring, it has to be held at both ends for it to operate. So i found a groove at the bottom of the holding post that the other end of the spring sits into. I think the spring is wound into the post, if so then it may wind back out without being damaged. Re-sizing is probably doable but some tricky work involved but if the rivet on the post gets busted up....its formed over just like the tube on a seconds hand.2 points

-

Normally when somebody comes the group there are base questions I like to ask like what is the watch doing before you attempted the service it? But here we find you have how many watches? Then run for a few seconds and stop was that before or after servicing? As you're new to watch repair there is no main issue because you're having probably lots of issues. But we can go with the pallet fork issue for now we need a side view of the pallet fork out of the watch so we can see the pivots. Then we need lots of pictures the pallet fork in the watch from a variety of directions. Remember your the eyes on the watch and were attempting to diagnose based on your descriptions and as a newbie you're going to miss things lots of things which is why we need the pictures. It's quite amazing what a small group of people will see when looking at a picture. Yes we've all had different experiences which means when all of us look at the pictures conceivably will see something slightly different which is why group help is quite helpful for problems. Strangely enough this suggestion comes up quite a bit on this discussion group. Typically it's the newbie in other words my watch is not running I will clean it again. But unless cleaning is the problem cleaning again isn't going to fix the problem. But it does seem to be the favorite repair tactic of newbies cleaning the watch again which in reality you need the practice of disassembling and reassembling anyway. Maybe that's because it's not the problem? This is where you need to stop doing what you're doing take a step back and evaluate the situation where is the problem? It might even help to just take a day off and approach the problem with a new set of fresh eyes rather than repeating the same steps over and over and over again which you seem to be doing quite consistently with the exact same outcome. Then you can help us out with pick one watch it be really nice it was a watch you never touched before so we can start fresh but I'm guessing that's out. I don't suppose you know the condition of the watch before you attempted to service it? We need the exact model number of the movement. Generic questions of I have a dozen Omega watches all doing the same thing is not helpful as each watch tends to be unique with unique problems. Then if you could remember what exactly you've swapped on this watch in other words which parts did not originally come with the specific watch that would be helpful. Then as were reviewing everything you're doing what lubrication's are you using on the watch? This is where newbies shouldn't be starting on automatic watches as it adds to the complications of. Plus these are not your normal automatic watches anyway their vintage automatics which are going the present some interesting challenges all by themselves. Plus the automatic shouldn't even be added in until the watches running anyway. A2 points

-

Something more - we here are not able to help much as we only know that the pallet fork doesn't act as it should, but we can not see why and how exactly it happens. Thus we can only give principle advice, like check everything about pallet fork, but it seems You know this already, so not of big help. Please, try to make video when You try to actuate the pallet fork. The balance out, use non-magnetic tool to move the fork. You can fix somehow you phone as to have both hands free. Locking the 'autofocus' of phone camera helps alot. Swapping parts is not correct test here, so no point to make any conclusions based on it.2 points

-

Thanks to collegues' inputs I've now got one of the 2 problem movements going - the one that had suffered corrosion. Having added some solder to the pads the drive wheel worked but only when the 'plate' was pressed down in a certain way. And the movement stopped when I replaced the back. I employed a YT tip (adding flux to my copper braid) in wicking away most of the solder leaving only a thin coating. However, the problem remained. Checking the drive & 2nd wheels showed that the initial closure - when the solder was raising the 'plate' too much - had bent their plastic upper pivots. Trying to straighten them wasn't successful so I used one of my Temu micro drill bits to widen their upper 'seats' a fraction & this did the trick. Maybe too much info but I am pleased to have got my friends clock going again and am grateful for you folks' help. Your interest was also a source of motivation.2 points

-

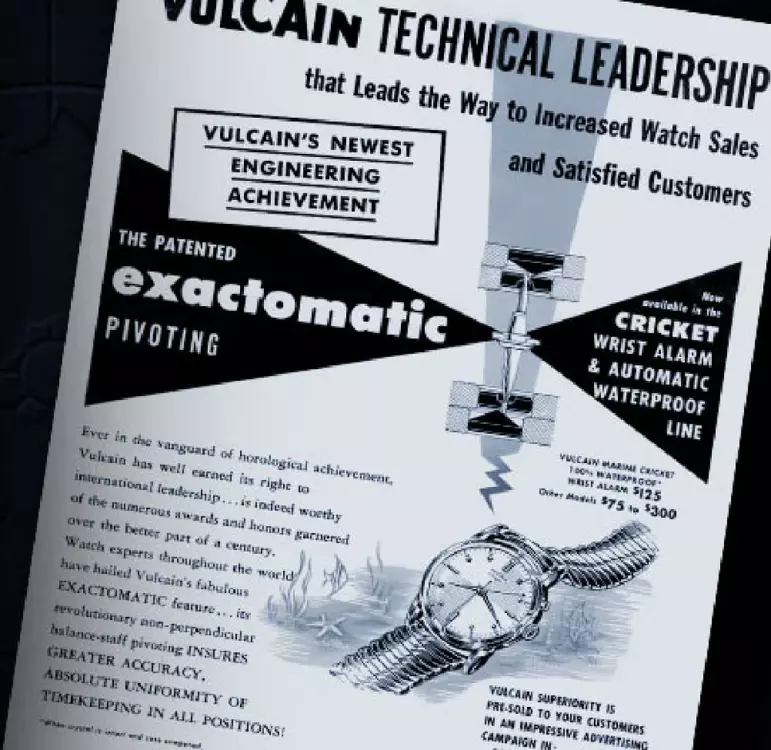

Exactly. Seems crazy but it works. A funny thing with truly flat pivots- if there is any contamination of the oil in the balance jewels, with particles, one will inevitably make its way to the pivot, get under it, and act like a ball-bearing, increasing the amplitude. Obviously we imagine that our jewels and oil are always spotless, but this weird technique also precludes any issue there. A more elegant solution is what is referred to as "Daniels" cap jewels (around here at least). The cap jewel has a slight concave area, a little offset from center. This forces the pivot against the hole jewel in the horizontal, dropping the amplitude a bit. I worked on a series of watches years ago where this was an option to get the amplitudes closer. In a more extreme example, Vulcain at one time had cap jewels that were conical, again pushing the pivot against the hole jewel. Don't lose one of those! Found an ad for the Vulcain "Exactomatic"2 points

-

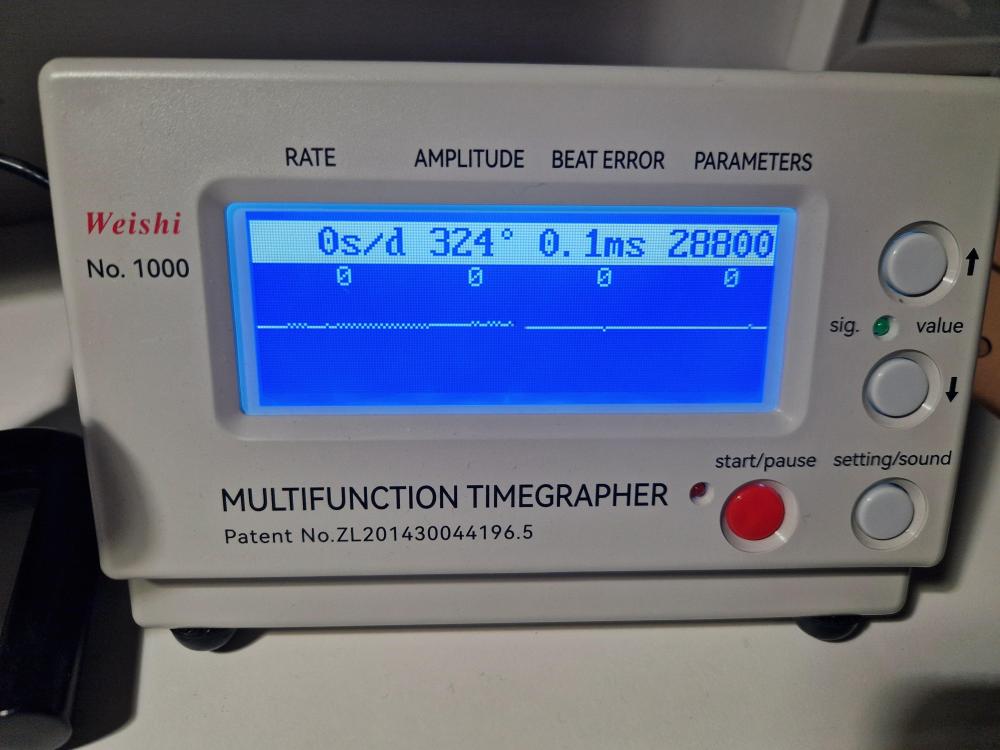

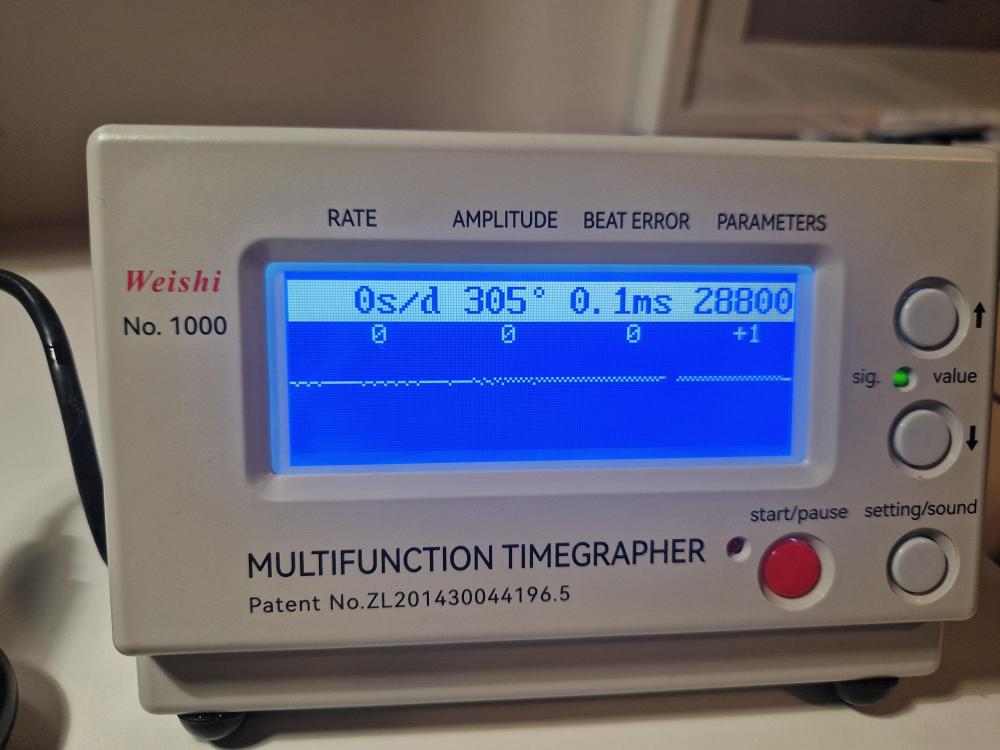

Ok everyone!! I managed to reduce the amplitude by about 20°. - increasing tension on centre-seconds spring: minus 5° (more would probably be possible, but I didn't want to push it too much) - replacing 9010 with HP1300 on the upper balance jewel setting: minus 15°. Now, the highest amplitude I can get is 325°. No more knocking even if I try hard: full manual wind, then vigorously rotating the watch to maximize automatic winding, and then straight on the timegrapher, dial up. The fact that there's now an imbalance of lubrication between train side balance jewels (HP1300) and dial side balance jewels (9010) has --fortunately-- a very limited impact. The amplitude difference is only around 5° and the rate difference around 3 seconds (I didn't record the rate difference before the change of lubrication, so it may have already been the same). I will admit that the better solution would have been a weaker mainspring. However, it's extremely hard to find a suitable one. After that, adjusting the pallet depth seemed like a more serious intervention (despite @VWatchie's kind encouragement -- I'll try it on a less valuable watch soon!!). Finally, HP1300 certainly won't do any harm on the balance jewels. And it just "washes off" at the next service!. So no lasting changes to the movement. I'm satisfied and will leave it at that. Hopefully the above impacts on amplitude will be helpful for someone down the line. Highest I can provoke purposefully now (dial up): After an hour of settling down (dial up):2 points

-

Hi all New hobbyist here... after 100+hours of self flagellation I am turning to this forum for help....trying to get my first vintage beater running. Any insights Background: >I have accumulated a cache of old omega bumper movements (28.10 RA, 30.10 RA, Cal 351)....mostly out of a combination of availability and the fact I like the watch, have lots of educational material on assembly and find the movement beautiful and solid to work on (less flimsy parts flying around). >Most of these donor watches will "run for a few seconds or minutes then stop"..... main issue is with pallet fork, it will simply not snap back quickly when movement is wound up for "flick test"!! Driving me crazy...very sluggish and feel I have tried everything recommended online. >I have tried everything to get just one movement running using various combinations of inter-changable parts but cannot get it running beyond a few minutes (at very good rate) before coming to a halt >The movement is clean as a whistle (many rounds of us machine with naptha or IPA, reclean certain parts by hand). >I believe the barrel/spring and wheel train is correctly installed, ml (have disassembled and re-assembled multiple times)...train runs smooth as glass and a puff of air on escape wheel (with pallet fork removed) provides an energetic turning of wheels and backlash with balance removed. >All pivots and jewels appear to be in good shape, pegged and cleaned. Parts are old but do not appear overly worn, I have replaced any parts I view as suspect from donor movement or with new oldstock part. >Testing fork on its own with balance in place results in steady tick/tock of fork and a clean balance swing with a puff of air, testing balance on its own also shows a functional balance >Pallet fork seems to be locking up against escape wheel...have tried 3 different forks (all vintage parts) and cannot get it working..... >Feel like i have exhausted all online resources and love the hobby so much but after hours and hours of observation cannot seem to get any of these running and am losing confidence. >Any advice on other trouble shooting or tests? I feel like the advice is going to be clean the train again (which i have done ad infinitum) so I feel like it's something to do with the pallet fork but unsure why swapping it out is not helping. Alternatively I wonder if the escape wheel is messed, i cannot see any issues under my microscope, no obvious broken teeth. >My amscope does not have a camera but can try take photos if requested via iphone and would even order a camera if it helped me share and diagnose this problem. >It's an insanely addictive but frustrating hobby, the only upside is i have become a pro at taking apart and assembling the omega wheel train but it sucks to bump against the same issue day after day after day Kind Regards and if any of my questions are stupid so be it, have to learn somehow TB1 point

-

Thanks @Neverenoughwatches. I was out the whole day and didn't have time to reply. Perhaps @VWatchie could start a new thread and do walkthrough with lots of photos for the benefit of others who find that their tweezers are too stiff.1 point

-

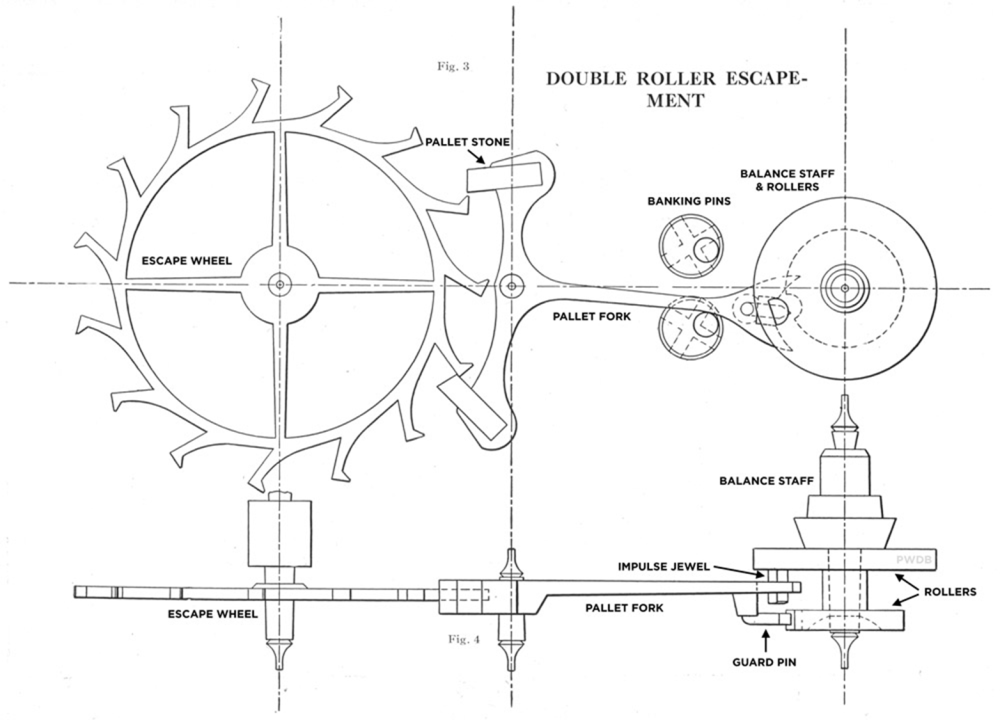

Ideally, from the side your escapement should look like this. As others have said, the end-shake of the pallet fork and escape wheel have to be the same, otherwise the escape wheel tooth will hit a different part of the impulse face of the pallet jewel in dial up and down positions. The escape wheel tooth should be hitting half to 3/4 the way up the pallet impulse face, as the diagram shows. If you have a jewelling tool this would take no time at all to adjust both the escape wheel and pallet fork end-shake to be the same. You might have to move the pallet fork up or down on the arbor to suit. Remember the guard pin should be in direct line with the safety roller in both dial up and down and the fork doesn't scuff the underside of the roller in dial up position. This WOSTEP handout will help WOSTEP handout.pdf1 point

-

1 point

-

If I understand correctly what happens, You must help the pallet fork to move to the other side sometimes, it not always wants to do it by itself? If so, then there might be no axial free play of the staff. Can You check it? Check the axial free play of the escape wheel - grasp the pinion with tweezers and move it up/down and will see that it moves a little. About the same movement must be in the pallet fork staff. Does it?1 point

-

Thank you Tom! makes sense and sorry for missing that1 point

-

@tb1982 the site doesn’t allow for the upload of video files. The accepted way is to host them somewhere like YouTube and then link to them here. Tom1 point

-

1 point

-

Very disappointed with you all! You can service a chronograph but can't resize a simple bracelet, what I do is, oh wait, throw them in the bin and buy a regular bracelet or leather strap. Hung by my own petard again. Hehe.1 point

-

Exactly WW , I only had one to deal with and it pinged off three times while trying to wind it back it. I just did it for the experience, I bagged it back up in more pieces than I took it out1 point

-

Hi. Once had a go at one years ago took for ever and you could see the join, never again buy another bracelet. And save your sanity, the bloody springs go every where.1 point

-

I have started printing things for my cleaning machine, and started with these basket inserts. They fit quite well, although I haven't tested the resistance to chemicals. These were printed in the standard filament that comes with the printer, as the filament I ordered is still on its way. I ended up printing many more of these so I can have a few disassembled movements ready in baskets while it's in use.1 point

-

1 point

-

Pocket watches were probably a great source once upon a time, but they're really not as plentiful as they once were, are much more expensive than they once were, and parts are much more challenging to acquire. The large size is likely a good stepping stone, but it's not like we're talking tiny women's movements. A typical men's wristwatch size movement is large enough, and it's what you're most likely to be working on anyway. The ultra cheap chinese stuff is good cost-wise. Parts are a problem again, but you can pick up whole watches somewhat reliably (subject to batch size), and that's not nothing. Quality is obviously poor, and it may not work out of the box for reasons other than dirt. Might even be able to find something you'd want to wear? Maybe...? Any thread on the subject of finding movements to learn on wouldn't be complete if I didn't chime in with 404s (watches purchased under £4.04 plus shipping). Get a mid-grade fully jeweled Swiss movement in a mens watch case size that you stand a chance of finding parts for. You're looking for them to tick a little (compare second hand location between photos if it's not explicitly stated), but not really run all the way, which usually means they just need a clean. Depending on your location, you can get in very inexpensively. Low cost of entry, parts availability, similarity to what you're likely actually wanting to work on, and a level of quality that ensures you stand a chance of success. Plus, when you're done, you might even want to wear your first success! They're a bit harder to find, but I've snagged several 404 vintage mens watches in reasonably modern sizes with full stainless steel cases, mid-grade quality, fully jeweled Swiss movements that I wouldn't hesitate to wear on a daily basis.1 point

-

Just around the join H , where the pair starts, here are 4 that I did when I started. The vetus I think were the first, so a bit rough looking. The second pair down are very heavy strong machinist's tweezers, I had to thin both the flat and the edge ( you can see were they curve in then back out ) because the tension was unreal on them . Third are titanium and the bottom ones are brass. I dont actually use any of these now except maybe the machinist one in place of pliers. I used a miniture drum sander to take out the bulk of the material then finished them better by hand.1 point

-

1 point

-

There's something before the .257 that I can't quite make out.1 point

-

Given the train of wheels runs freely and reverses briefly when tested without the pallet fork, and the fact that the pallet fork action is sluggish when tested, points towards a problem with the interaction between the escape wheel and the pallet fork. Until the pallet fork snaps back and forth between the banking as it should, the watch cannot be expected to run well. If the fork movement is sluggish, the balance will receive little to no impulse to keep it oscillating, and the watch will struggle to run. A close inspection of the escape wheel, pallet fork and pallet fork pivot jewels is in order. Check vertical division, alignment and endshake - do the escape wheel teeth align with the vertical centre of the pallet stones? Are the pallet fork stones clean and free of damage to the working surfaces? If they pass inspection, you need to examine the interaction of the escape wheel teeth with the pallet fork, the lock, slide, lift and drop. Once you have corrected the pallet fork action, such that it snaps quickly back and forth, hopefully the watch will run. If you still have issues at this point, you need to remove the pallet fork and do a free oscillations test of the balance wheel, but for now based upon your description there is clearly a problem with the interaction between the pallet fork and the escape wheel, so concentrate on that known issue first. I hope that helps, Mark1 point

-

Photographs! If I interpret you correctly, the winding pinion is not turning when you turn the crown. Is it possible you have installed it in reverse? The sawtooth face of the winding pinion needs to mate with the corresponding edge of the sliding clutch. If the winding pinion is turning, then look to where the winding pinion meshes with the crown wheel to determine whether the crown wheel turns when you turn the crown. (The winding pinion is the bit that looks something like one of these: . I think it's what you meant by the "winding gear", but you might have meant the crown wheel or even the ratchet wheel.)1 point

-

1 point

-

I'd look at just removing the top right screw first on the battery cap and see if it will slide out. Have you removed the stem and will the movement come out of the case? Edit What is the actual number of the movement?1 point

-

You just need to lift the tongs rounded with circles a little up. They are meant to act as springs. The back cover must press them and the whole ring and thus to press the movement towards the case bottom. Of course, You can use the other ring after grinding the tab - it's presence is not important at all.1 point

-

So, it seems like maybe brass is too soft for a first pair of nice tweezers that I would do most of my work with? I'll probably go with stainless steel for the time being instead and maybe add brass later to supplement. I found an eBay store that has new old stock Dumont Dumoxel #3 and #3C listed at $25 or best offer with free shipping, among other tools and watch parts. Here's the link if you're interested.1 point

-

Well I’ve been struggling with this movement for some time. It was still locking up today after firing it up for the first time in a couple of weeks. Decided to check the end shake of the pallet fork and it did seem a tad to much, which seemed to me a reasonable possibility. So I adjusted a smidgen (actually two smidgens at first, but that was too tight, so backed off a smidgen), and am testing now. Will re-case tomorrow and wear for couple of days to see if i have finally licked this devil. If not, thinking might be time for me to sell as salvage.1 point

-

These aren't designed to be shortened and they have no set removeable links as a normal metal strap would. I'll try and post a few photos tomorrow showing what's involved. It's not easy and could easily be ruined so my advice would be to just get another strap.1 point

-

Neat to see how someone from a filmmakers perspective looks at a watch movement1 point

-

Start saving up to replace your tweezers one pair at a time with good Swiss made tools, or at least with something better than what you're using that will hold their tips better without need to dress so often. I also spent like 2 years with Esslinger econo tweezers and what a difference it made the first time I picked up something better. I've been collecting used Dumont and Peer tweezers from ebay for about 1/3 price of new, dressing them as necessary and very much happier than with my Esslinger stuff. I might try these but I honestly wonder if they are different from the ones sold by Esslinger in the USA. I have #3 brass and use them often, but never for anything important due to how soft they are and how quickly they bend up. They feel like tin rather than brass and I need something sturdier.1 point

-

Try Vetus brand tweezers which are available from many sources. I use brass tweezers from Cousins for 80% of the time but brass is too soft for work that requires some force, like pushing home setting lever springs. Brass is also too soft to be ground to very fine tips. So for very fine work like picking up tiny screws from the calendar works, I still have to use stainless steel tweezers. But all tweezers, regardless of brand or material, require regular maintenance. The tips need to be straightened and dressed. I like my tweezers to have very a light touch, so I always thin the metal near the joint at the back down to make it more flexible.1 point

-

I use these from Cousins. https://www.cousinsuk.com/product/titanium-tweezers-cousins-swiss-style https://www.cousinsuk.com/product/brass-tweezers-cousins-swiss-style1 point

-

If you want to use larger drills, maybe this would be an option? Drilling attachment tip? https://www.watchrepairtalk.com/topic/31193-drilling-attachment-tip/1 point

-

Hi, that's very kind of you. Thanks fellerts . I live in Hamar. I just had the staff riveted. It sits completely solid. Must admit that I am very happy . The trick was to grind the punch into a more conical shape so that the punch sat in the shoulder groove. I then polished the punch step by step up to 7000 grid. The whole process with the punch in the drill and under a microscope. When it was finished grinding, I heated the punch to an orange color and then cooled it quickly in oil. After use, there are no marks in the punch, i.e. hardening was good. The next time I use a Chinese punch, it will be sanded to the purpose and then hardened. In the near future, I will probably buy a new Bergeon of medium size and supplement as needed. But when I found a method to "save" my Chinese punches, I will calm down for a while. The next problem with my punches it is over and out. But it would be interesting to hear more about your Boley and Bergeon. I'll get in touch.1 point

-

OK, not big problem happened. There is simple way of 'un-tightening' cannon pinions and it can be used here easily. You need to source hard pin (HSS drill bit tail or something of the sort) that enters in the hole almost tight. I mean the original state of the hole, now the pin will enter to the point where the indent is. You will press the cannon to go to the end with some force then. Next is to use dull nail clipper and squeeze the thin part of the cannon from several different angles around the indent, this will form the tube round and calm inside again.1 point

-

1 point

-

I dont see a way to push the indents back out so it looks like they will need to be removed. Cutting broaches are normally used to cut brass, may not be too effective on a cannon pinion. Would want to test an old cannon pinion's hardness on a cheap file. Other than that a hss drill bit or a small round cutting burr might take out the indent then finish off with a smoothing broach. Will a 1mm pin polisher fit inside to smooth out ? You could reduce one in diameter to fit.1 point

-

I would run a drill in it (if you don't have a lathe then fine by hand, holding drill in a pinvice) to open it back up. It won't necessarily be a perfect hole, but there is no force here, it will work fine. Measure the post and I'll see if I have something the right size and stick it in the Post. Edit- just remembered I have a 2-66 here that's been disassembled for years. Post measures 0.35, hole gauges at 0.36.1 point

-

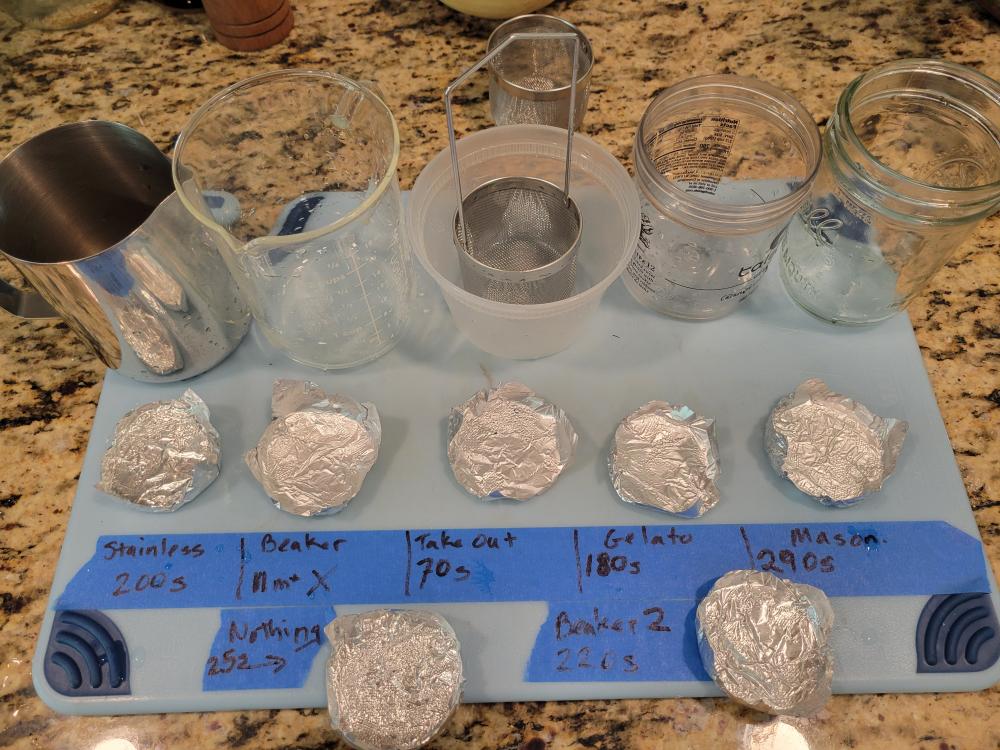

An excellent proposition. So my methods were: Square of foil pressed into the bottom of a cleaning basket Steel nut on top just to keep the foil from floating Basket goes into test vessel (or directly into the ultrasonic for the control) Test vessel is filled with enough water that it sits on the bottom of the ultrasonic's basket. Run ultrasonic until first evidence of holes in the foil Each test vessel was run by itself to try to keep things consistent. Results were interesting: Directly in the ultrasonic: 25 seconds Thin-walled stainless milk pitcher: 200 seconds Thin-walled glass beaker: over 11 minutes and zero pitting Thin-walled plastic takeout container: 70 seconds Thicker-walled plastic gelato container: 180 seconds (have not tested other flavors) Thicker-walled glass Mason jar: 290 seconds The beaker was the surprising outlier, so I tested it again, and this time came up with 220 seconds. Maybe a weird piece of foil, no idea. I should do more runs and get more data, but I already stared at my ultrasonic cleaner for an hour. The test is, of course, a VERY coarse one, and there are definitely questions about its overall usefulness. That said, I think it's interesting to see. I haven't been super happy with the effectiveness of the 5 minutes in Mason jars I've been doing, so this tells me maybe I should switch to the plastic containers or just clean for longer.1 point

-

So a lathe motor question was all it took to get to see @nickelsilver work space? Wish I had asked a year ago. I have a large roll of 3mm TPU filament for 3D printing. Makes a great belt.1 point

-

Hi everyone, I got myself into fitting a new balance staff on an Omega 30T2. It's working properly now and it seems to be fairly accurate so far, however it's been running just for a couple of hours. I have one question though, since I'm just an enthusiast. When getting the hairspring stud back in it's position, the regulator pins were so close together that the spring wouldn't get between them. One of them seemed straight, and the other one a bit bent inwards. So really carefully I straightened it up, and the spring went in perfectly. My doubt is should I close them back together or not. The watch is ticking nicely, and the spring bounces a bit between them. I've read different opinions, some saying it should bounce, some saying it shouldn't. It's a Breguet spring. I'm letting it run now, to check it's accuracy. Assuming it goes well, may I leave it as it is? Should the pins grab the coil, shoud it be really tight without grabbing, or should it bounce? I'm uploading a picture and a short video I managed to take. IMG_4784_mpeg4.mp4 Thanks!1 point

.thumb.jpg.97d4683b1fdeb4caecd4dc355e462351.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)