Leaderboard

Popular Content

Showing content with the highest reputation on 01/10/25 in all areas

-

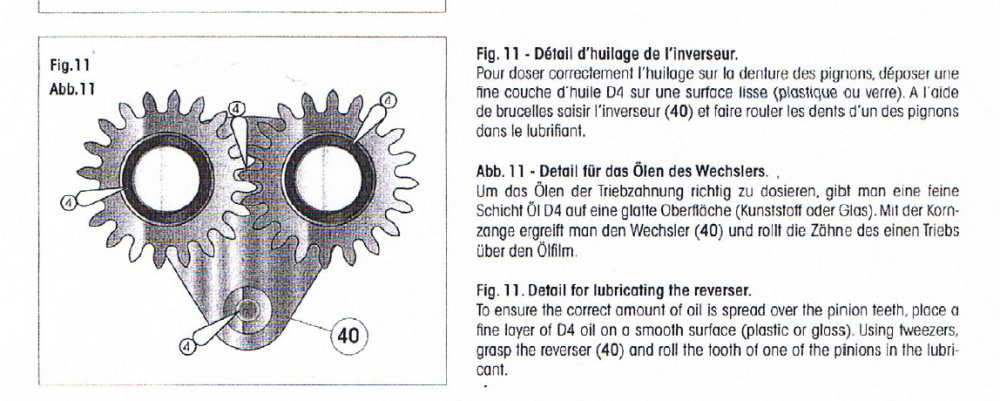

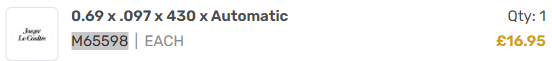

OK, finally my write up on the full assembly! The order of assembly is a bit unorthodox (train, auto-works and keyless before barrel bridge), but it works. 1. TRAIN: see previous posts. Extra info: oiling: escape wheel 9010, fourth wheel 9020 (instead of 9010), third wheel HP1300. 2. KEYLESS WORKS: see previous posts 3. AUTOMATIC WORKS (without rotor): this wheel needs no lubrication the wig wag reverser is oiled as follows: I use 9504 instead of D4 for the teeth. I srpead the grease as thinly as possible and then run the wheels over it. In all the other places, I use HP1300 instead of D4. The wig wag is secured with this small plate (screw not pictured here). No lubrication here at all. 4. BARREL and BARREL BRIDGE: breaking grease 8217 in the barrel, thinly distributed this is a supposedly original JLC mainspring for the calibre but please refer to this thread on my issues with rebanking which essentially concludes that the mainspring may be too strong. note that it turns counter-clockwise HP1300 I put a very small amount of HP1300 on the jewel for the click (despite no lubrication indicated in service manual) 9415 (!) on the click spring click in place other wheels in place... Now the centre seconds pinion: first, oiling the rim of the tube. I used 9020 instead of 9010. then in goes the pinion and now I apply a bit of 9415 specifically on the opposite side of where the friction spring will be (so that the friction spring will then spread the lubricant around the pinion, instead of accidentally just pushing it down to the wrong place when installing it) Barrel and ratchet wheel Now this last one, which needs to be lubricated in itself. I use 9504 instead of HP1300. This wheel slips when the watch is manually wound and thus disengages the automatic works (so that the rotor doesn't turn when wound manually). after applying a few drops of grease, I spread it around by moving the arms of the wheel. I squeeze a small amount of HP1300 under the steel disk with a scalpel. A bit fiddly: preparing the underside of the barrel bridge. Always HP1300. tiny drops of HP1300 here Finally, installing the barrel bridge. BE VERY CAREFUL that the centre seconds tension spring is positioned on the pinion ON THE SIDE OF THE BALANCE. The little window in the bridge allows gentle manipulation to nudge it in the right direction. There are lots of wheels etc to align, so take your time until it all falls into place. Now the pallet fork. ...and the balance. Balance jewels lubricated as usual with 9010. I let it run for a few minutes to scrape of a "channel" of epilame from the pallet stones (I know, this may be overkill, but I buy it). I then remove the balance again and oil the exit stone with 9415 in 5 small applications and advancing the pallet for in-between applications. and put the balance back afterwards. One of the 9415 drops. Not so easy to photograph. BASE MOVEMENT DONE. It runs well. Next post will be the complication module "calibre 929".5 points

-

As it is -3°C this morning, and I'm currently wearing my latest project for timing (Memostar AS 1931), I decided to measure the case temperature after a walk, to see if the oil turns to treacle as you and Nev suggest. Using a thermocouple, the case temperature measured 25°C. Not surprising, as body temperature is about 36°C, metal is an excellent heat conductor in close contact with skin, and the watch is under clothing. So no need to worry about oil turning to treacle3 points

-

https://www.horia.ch/en/Products/Pivotinglathe/Accessories/Lantern-N-1-N-4.html If it's a Steiner you might be able to change the lantern. Not cheap though. I ordered one and it was a perfect fit for my old Steiner.3 points

-

2 points

-

Hello dear watchbangers! First of all, happy delayed new year! Here I am with another post to a watch that I tried to service well! ( To the best of my abilities!).Of course before you read the whole report, you can also watch it live as a video: This time I received another German watch whose owner told me that he had sent it in to service at a pretty prestigious watchmaker a few years ago. Unfortunately, he said that the watch was acting up soon after the service but just kind of forgot about it and just asked me If I could have a go at it! So I said yes and got to work! Now the watch did work, but was very inaccurate. Now the outer appearance seemed pretty neat! The watch has a gold ( or something gold looking) plated case with what I presume being a stainless steel caseback. Next to the qualities the watch provided such as being “ water proof, shock proof, stainless steel and shock proof” the case back also had an engraving of a company: Zeppelin Caterpillar Metallwerke GmbH. I assume that this watch was to commemorate an employment or an important event/ milestone of the company or employee. So I opened up the case back to check out what was inside! The movement powering the watch was a PUW 1361 movement which in my opinion had quite the nice design, especially the pretty large train wheel bridge which covered around half of the movement. It would be interesting to know if they did this out of a clear technical stand point or if they also tried to construct close to the very typical ¾ plate found in older German watches. Also interesting to mention is the engraving on the inside of the case back which included some previous watchmaker marks as well as the company name and the hint to remove the movement through the front ( Stupid me tried to do it from behind before checking the engraving before realizing that there were no holding screws or rings. ) So I popped off the bezel and lifted off the hands. Then I turned the watch to let the movement with the dial pop out, unscrewed the dial and put the sensible parts away. The dial itself looks fantastic in my opinion! It has a great sunburst silver finish with a date window at 3, set indices at 6, 9 and 12 and the rest are milled. As it was in great condition, I was not going to touch it, maybe just clean it with a Q-tip or blow dust off it. Now turning my attention to the movement, I started by taking of the clunky rotor of the movement by unscrewing and removing the small locking slide under the rotor. This held the rotor against the post. For protection I already removed the balance wheel and the pallet fork and its bridge here already Next I removed the two reduction wheels, the direction wheel, some sort of friction spring and the transmission wheel down to the barrel. Embedded in the underside of the automatic bridge, there is a small spring which I also fiddled out, I assume this stopped the reduction wheels from turning free somehow. With all the moving parts removed from the automatic works, I noticed the nasty amount of oil which was on the main bridge. I literally cannot fathom how, why and what kind of oil would even end up there haha. Now, next up I removed the post of the rotor, You can also see the blurry milling marks on the metal components on the movement parts, which I personally also dig. It gives it a pretty technical vibe. Next I took off my favorite little jewel caps again! Yay! This time the jewel caps acted as a bearing for the escapement and third wheel pivots. With that done I unscrewed all the screws for the main bridge and took them, and the bridge off to reveal the inner-workings of the watch movement. This revealed the further nasty contamination of the mysterious oil was had already been spotted on the main bridge. Underneath the main bridge there was the inbuilt ratchet- click system for the mainspring barrel. The click and its spring where fixed but I did remove the pictured wheel and screw. Here is the movement without the barrel, the third wheel, the second wheel, the escapement wheel and the transmission wheel and spring for the barrel. Lastly I removed the minute bridge which is still depicted. The minute wheel however was still stuck in place as the canon pinion was pressed onto it from the front side. I flipped the movement over to deal with the front side! Here I first removed the hours wheel the little friction spring. Then I took out the date lever, its spring and the cover plate as well as the date ring. Next I removed the setting wheel bridge, the setting wheel, transmission wheel, the cannon pinion, the setting lever bridge, the yoke, yoke spring, both clutches, and the jewel cap from the plate side. Here the minute wheel also falls free being released from the clutches of the canon pinion above xD Lastly I removed the date wheel and the spring hidden beneath it! Of course before the cleaning, I took out the shock jewels from the KiF Settings. I also opened the mainspring barrel, that thing was so nasty… it definitely needed a cleaning! Interesting to see the combined barrel lid and some sort of ratchet wheel. A cool picture of the visible milled main plate with the manufacturers movement stamped into the metal. PUW Caliber 1361. A picture of cleaning the watch parts outside on the balcony. The fumes where filling up the flat each time so I decided to clean them outside this time! I did a 1:2 Elma Wf Pro and Suprol cleaning cycle. Now after everything was sparky again I reassembled the watch back to completion and lubricated along the way. I just reversed the disassembly steps! Should I also maybe add assembly and lubrication pictures in the future for reference? Lubrication list: Moebius 9010: Cap Jewels for escapement and third wheel , seconds hand wheel, rotor post for rotor. Moebius 8213: Mainspring barrel inner walls as breaking grease ( maybe using something stronger like Kluber would also yield better results) Moebius HP1300: slower turning wheels like minute wheel, third wheel and the rotating posts for setting/transmission wheel and date lever/ date ring surface for example. Molykote DX : High friction points like the gearless system, the transmission wheel from automatic works to mainspring barrel, cannon pinion/ minute wheel friction . Moebius 9415: Pallet fork jewels ( maybe using 9010 would have yielded better amplitude results as 9415 is actually made for 28.8k beat watches. ) A comment regarding the reassembly: When I first finished the basic train wheel and gave the barrel a spring to see if the train wheel turns freely, I was shocked to see that the third and escapement wheel where moving in a sort of “jittery” behavior! I desperately searched for the cause, disassembling and reassembling the basic movement a few times to see if I managed to build it incorrectly or to see if I had snapped off a pinion or two. Only after an hour or so did I realize that I had not screwed the cap jewels back on, eliminating the excess end shake! There is a pretty cool clip in my video where I have both “versions” next to each other, comparing the smooth vs. jittery flow of the train wheel assembly! After reassembly and lubrication I slapped the movement onto the timegrapher and got it regulated pretty nicely on the dial up side! There are some slight noises on the reading and the amplitude could be higher but I am satisfied! Once I am a bit more experienced and safe with my regulation, I will try and regulate to 6 positions as best as I can and also explain/document my thoughts and procedures! So after the regulation I made sure that the case was all cleaned up by chucking it into the ultrasonic bath after some manual cleaning and after polishing the old crystal up with some polywatch! Then I attached the dial to the movement, re-cased it and pressed the acrylic crystal back on. It snapped into place perfectly! This is a final picture after I attached a Nato strap to it to test it actively on my wrist! In conclusion, this was a nice watch to work on! I loved the milling marks and the cool little details such as the cap jewels and the screwed on rotor post ( maybe there is also a hand wound variation?). I was especially disgusted at the amount and placement of strange oil in the watch from a previous watchmaker/ technician which I find pretty shocking in my opinion because according to the owner, it is quite the high level watchmaker he sent it to. Now if you have any comments, criticism or thoughts do just put them down in the comment and don’t hesitate to reach out! See you next time people and I hope you have a great start into our new year!2 points

-

I wanted to share with all my vintage C E Marshall watch cleaning machine from the forties(?). I won a low bid on the Bay which quite surprised me until it arrived in drastic condition. I do like restoring old machinery though so I rolled up my sleeves and went to work. The cosmetics were pretty straight forward, cleaning, sanding, painting and so forth. But the challenge was the electricals. I do have some background in electronics so I was able to figure out the systems in place..switches for on/off, reversing motion and heater element; mechanical train for reversing function; replacement for heating element that couldn’t be sourced. It all came together and it works well. The machine employs a rotation table that holds the jars and the motor can be easily raised and lowered with a unique spring assisted system that locks solidly in any position.2 points

-

I like to use very hot tweezers to redress the pivot, so having it stick out of a lantern provides plenty of support, and I can still get at it with my thick nickel/brass boys, or the classic #8. I have done it your way too, if the bend isn't too great.2 points

-

Never had a problem with the tension ,only on non watchmaking generic tweezers these I use on clocks or for soldering where the tips don’t matter other than to hold the material. I also own some crossover tweezers that when you release them they shut they are of th generic type but useful at times. Yes @Neverenoughwatches on the whole friendly , informative and inventive a good mix of brain power and very helpful what more do you need on a forum, I have looked at a few forums and not many have this mix.2 points

-

2 points

-

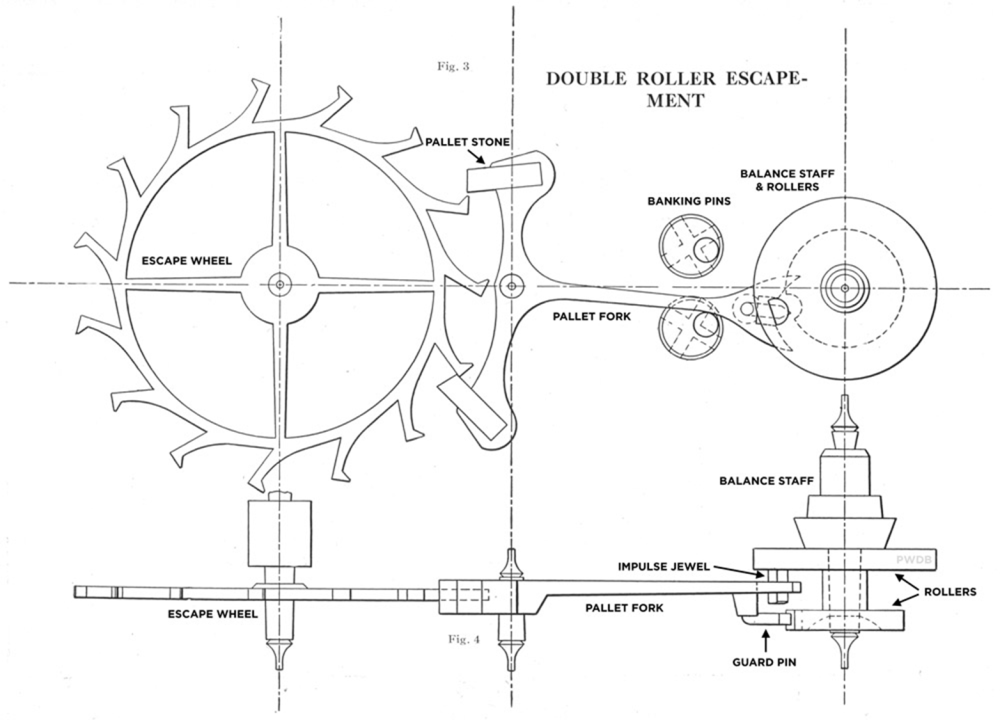

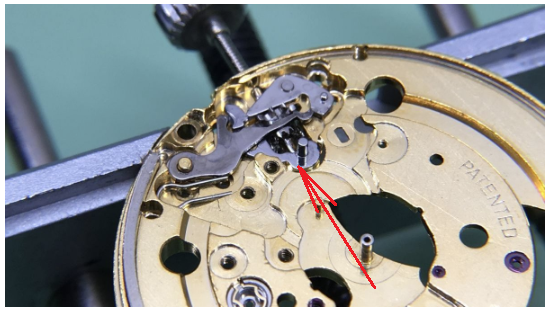

Ideally, from the side your escapement should look like this. As others have said, the end-shake of the pallet fork and escape wheel have to be the same, otherwise the escape wheel tooth will hit a different part of the impulse face of the pallet jewel in dial up and down positions. The escape wheel tooth should be hitting half to 3/4 the way up the pallet impulse face, as the diagram shows. If you have a jewelling tool this would take no time at all to adjust both the escape wheel and pallet fork end-shake to be the same. You might have to move the pallet fork up or down on the arbor to suit. Remember the guard pin should be in direct line with the safety roller in both dial up and down and the fork doesn't scuff the underside of the roller in dial up position. This WOSTEP handout will help WOSTEP handout.pdf2 points

-

My adult son sent me that link the other day. He is not that interested in watches but he follows the slo-mo filming account and knew I'd like to see it. He said he was a bit intrigued by the mechanics of the watch movement, but I don't think it will go past that (which is a shame because he could eventually inherit some good stuff!) At that magnification and speed, it is impressive to see the chronograph engage, and it gives new appreciation to the need for sharp teeth on one wheel to ensure rapid engagement without damage.1 point

-

This is one of the reasons why people assume cleaning will fix all problems as for quite a few watches cleaning will fix the problems. Especially if certain conditions are met. In other words hopefully the watch hasn't been worked on by anyone else in the past and left in a non-running condition. Had been lubricated with organic oils that went bad so watch just came to a stop. That's actually a good thing for organic lubricants the watch stopped in did not wear out. But now that we of modern synthetic oils they typically just spread across the plates never seen again and on early automatic watches are definitely a problem for the automatic components that did not have jeweled bearings and if the watches continuously run cleaning will not fix the problems and it will disintegrate. Now we end up with a interesting problem for pre-cleaning is it good or bad? I know of people work and Rolex shops and all watches are pre-cleaned. So that were all on the same page here the watch is disassembled in other words hands and dial come off possibly the calendar ring but not always as one of the calendar rings apparently can be pre-cleaned. But typically anything that's painted comes off entire watch is run through typically a separate machine than the normal cleaning machine. Now in the watch is look that it's nice and clean as Rolex is obsessed with and shakes they can properly check that they can do a nice evaluation and continue on with their servicing but his pre-cleaning universally accepted by everybody? Your timing is quite interesting because yesterday we had a discussion about this at work. Where I work we have another watchmaker who typically is somewhere else but every couple of months he comes to join us for a couple weeks and we did have a discussion about pre-cleaning so Josh's thoughts on pre-cleaning are like arriving at the scene of a crime and it's been cleaned. In other words the body is gone and we did make a joke it's been cremated. The entire scene's been cleaned everything is been patched everything is been fixed and how exactly do we evaluate the condition if we can't? As Josh is typically doing a lot a wristwatches including vintage he looks for things like filings which disappear with pre-cleaning. So we do end up with interesting problem here. One of the problems we run into is parts listings and even service bulletins were written at an exact point of time. For instance I was doing a project with somebody working on a 12 size Illinois watch He was very happy because the watch had been made for 30 years and all the parts according the parts book interchange. But the reality was over the 30 years they change things lots of things they just never revise the parts book at all. Even things like our wheels initially in the project because they're all the same we removed all the our wheels and discover later on that they're all sized slightly differently. In the early days of especially pocket watches that are typically made in batches and parts may not interchange between the various batches. The earlier watches even possibly something from the beginning of the batch to the end of the batch might not interchange as there is a lot of hand fitting and machineries would go out of tolerance plus revisions do we ever see the revisions? I know Omega has revisions not only do they have revisions but they have documentation comment to specific calibers at least newer calibers where they talk about specific problems for those specific watches plus revisions of parts. Whereas the revised part numbers do not have any designation that they been revised which I find quite annoying. So often times you will see the original parts were these the upgraded parts were these there may be a color difference or they'll tell you how many wheels in the teeth or something but if you don't have the revision document that's going to be a problem then anything from or specifically vintage related to the escapement is going to be a problem if you swap only one of the components and do not understand exactly what you're doing as they typically will not work not without some form of adjustment. This is why students in schools such as wostep spends so much time adjusting escapement's as if you work on anything a vintage you're going to have to understand how to do that.1 point

-

1 point

-

Could be location dependent, dunno. But I have scored big time on FB. In every case, the owner was disinterested in the item(s) and just needed some cash or wanted it out of their way. You must be diligent though. I am looking daily...several times per day. Ebay commands premium prices though I picked up a BB Crystal press for $10 the other day. Nobody bid. Not sure how that happened.1 point

-

Ok, let me say what I see. Looked again both videos. I am pretty sure that what happens is not due incorrect depth of the escapement. Can say nothing about the height position of pallets/escape wheel, but again, the problem for sure is not there The movement behaves as like the pallet fork is not completely free, but near the end of the second video, it seems that the escape wheel acts lazy, even didn't advance for a moment when it was released and should advance. this suggests that something in the train is not free. More - looks like the obstruction appears periodically. OP, now about axial free play. It must exist. In practice, if it is bigger than 0, then friction will be normal. When it is close to 0, then friction rises as shoulders of the staffs or pinions are pressed between jewels. Big free play is something not good, but if pivots still can't get out of the holes, the friction will be OK. You say there is almost no free play. May be it is OK, but better prove that the pallet fork is really free. For this You need to have it alone in the movement (at least no escape wheel and balance). If it is free, you will be able to shift it by gentle jerking the movement or with very slight blow of air, or even alternating the position of the movement, as the fork is not poised. Then, check the freedom of escape wheel, alone again. It should rotate by slight blow and rotation would not stop immediately. Check again separately the rotation of 4th wheel. 4th wheel - You said it is replaced? The long pinion for the second hand was broken? You don't put the dial when testing movement, don't you? As the long pivot may touch the hole of the dial. Or the hand bush when ihand is on may touch the hole, and this usually happens periodically. Not only missing axial free play may lead to lack of freedom. The other frequent reason is bent pivot. But other reasons exist - it is possible that pinion diameter is larger than it should be and the hole is 'narrow' for the pinion. Such thing may happen if a wheel is replaced...1 point

-

Welcome to the forum. Clutch wheel looks wrong or maybe just the wrong way round compared to this. As far as I'm aware the only difference between the 2788 & 2789 is the Date & Day/Date Edit Should have watched more of the video as you went into it but around 2:00 it's too far off the screen to see what's happening.1 point

-

One thing is certain: I am doing a LOT wrong .... lol! Update: I got one movement running last night (Cal 351 bumper - by trying to find the combination of pallet fork/base plate and escape wheel that has the most frisk movement). It ran all night and continues to run on the timeographer (though fast with notable beat error). However - every single movement arrived from ebay in the same condition. "Runs for a few seconds or minutes then stops". It's curious to me that all movements appeared to display a fault in the same way. Some of the movements are more beat up (worked on, scratched than others). On "stopping" it always seems to be linked to escapement (not barrel/spring). I understand that scavenging parts from 4+ movements is slightly insane but it's what I have and certain parts are scarce and I've read a lot on the interchangeability of the parts, I seem to be able to consistency install a clean, free running barrel and wheel train, i seem to be struggling with precision (end shake, cleanliness, alignment) of the escapement (balance, pallet, escape wheel). That seems to be a pattern. Now that I have one movement working I'm going to focus on this movement. I was able to get the fork whipping back and forth in a frisky manner on the power test. I even used the same fork that was installed on the movement I filmed and described in an earlier video (the 30.10 RA). However in this movement (Cal 351) the fork was very frisky and worked well. So I can only assume the prior movement either had a bad (too tight) escapement or too bridges etc. I will now let the movement settle, de-magnetize it and continue to observe it. If i get one working watch out this bag of parts I would consider it an acceptable outcome. It's certainly been very educational.1 point

-

Let's start again. Unless the movement was a new concept and not proved, then the same issue couldn't happen to all of them, but no, it's a tried and tested movement. So, the problem isn't with the movement, your doing something wrong, let's find out what it is. @JohnR725 wasn't criticising you, nor am I, we just want to discover the problem and help you.1 point

-

For pallet stones I use option 1 because it is fast and works well with my antique pallet warmer. And I can judge better by the dry shellac flake size how much I will be melting in. But when inserting a roller jewel I find the cold liquid application far easier.1 point

-

I've tried all 3 methods, but with number 2 (probably because I use a larger hotplate) the thin strand bends away when I approach the workpiece. 1 and 3 both work, but 1 is faster.1 point

-

Even their shipping was pretty expensive. I don't remember how much but for an order the size of a matchbox (I got the fork thingy too) they only had one shipping option, a costly one. Better still than having no spares available.1 point

-

It's possible but unlikely that several different pallets all have an identical problem. The fact that swapping pallets did nothing to resolve the problem is evidence that the problem is not in the pallet itself. End shake is determined by the distance between mainplate jewel and bridge/cock jewel. If that is the problem, there may* be nothing wrong with the pallet so swapping in a different pallet should not be expected to resolve it. * There may, of course, but other issues with the pallet that will become more apparent once the end shake is addressed. You can't assume that they all have the same problem. Even if they exhibit the same symptoms they're unlikely to all have the same issue. It's not hard to think of four or five different scenarios that would result in the watch running for a little while then stopping.1 point

-

It sounds like all your donors suffer from the same problem... How is it possible for so many movements to have reduced endshake in the escapement? Someone correct me if I'm wrong, but endshake typically doesn't change unless someone goes in there with excessive force or a jeweling tool, or perhaps changes out components with no regard for them being matched at the factory as John suggested. I'm not sure what I'm getting at, I just find your situation very curious. Are we missing something here?1 point

-

Underground building might be tornado proof, in Texas, Oklahoma and panhandle. Seen walnut trees uprooted there. See photo of Dallas cowboys cheerleaders custume, lack of unnecessary safety features. https://pin.it/6UKGn4eYE Rgds1 point

-

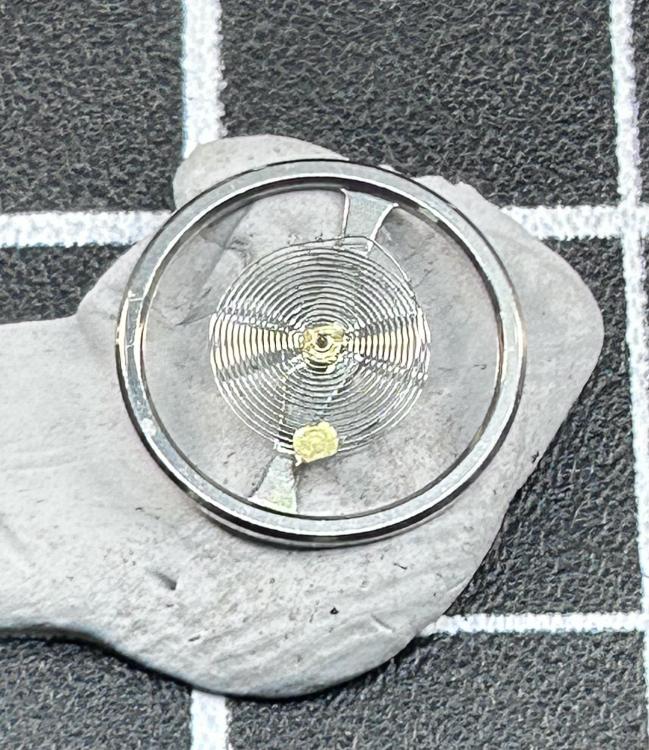

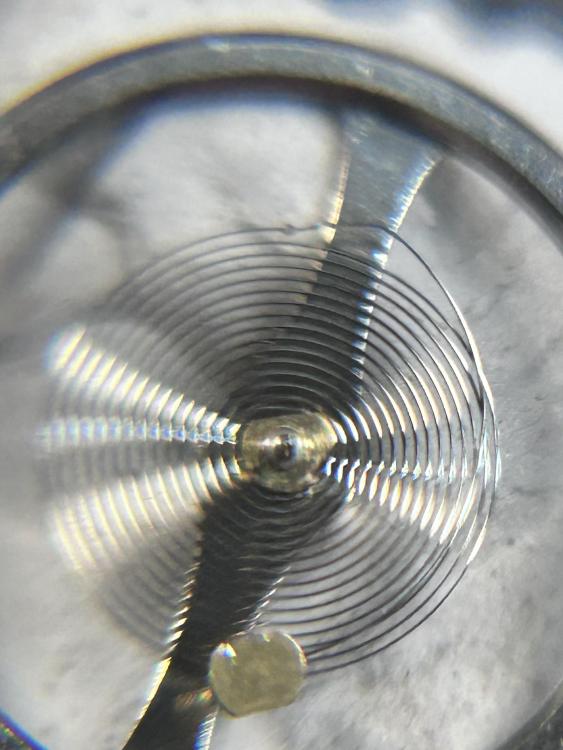

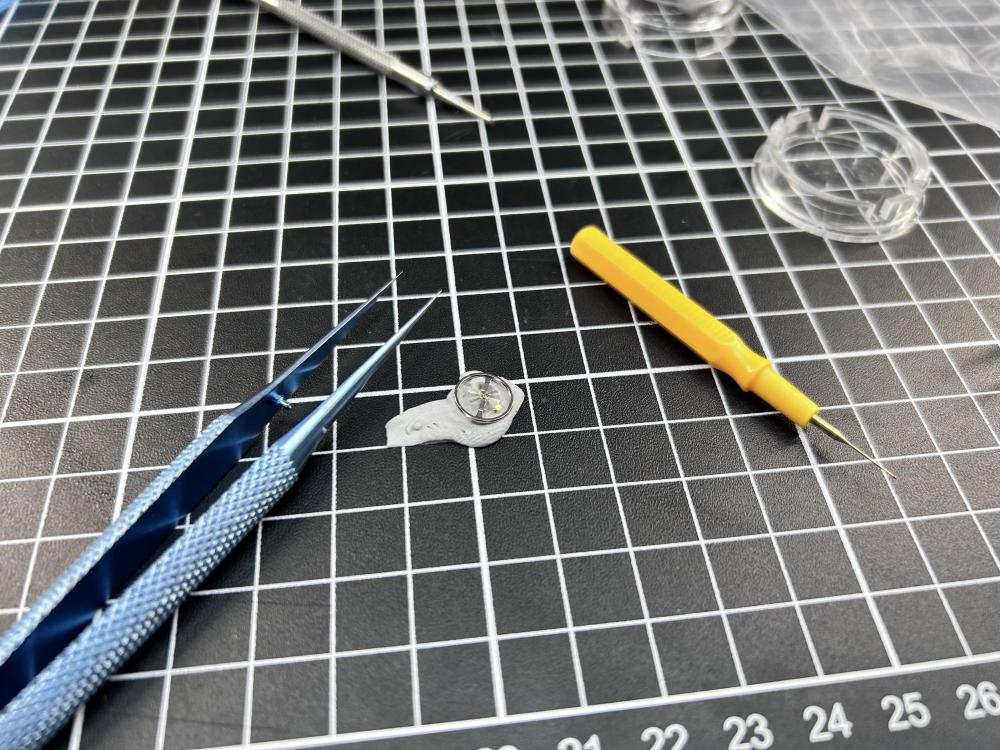

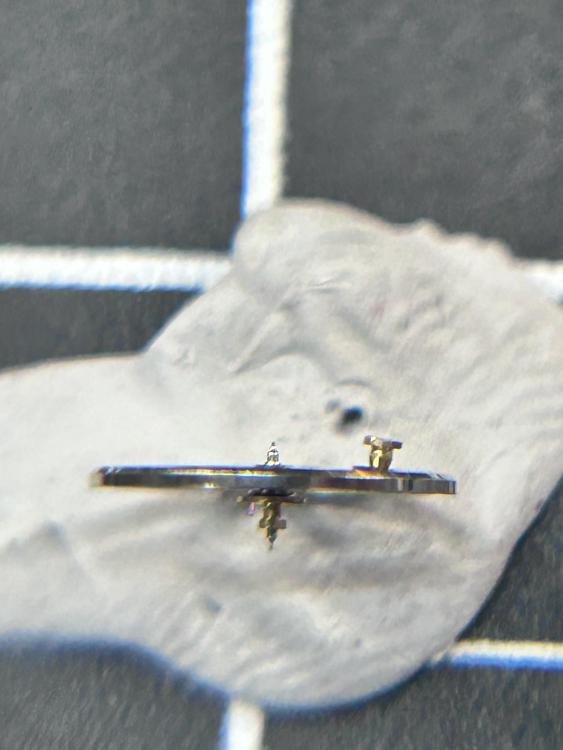

This morning I made myself a coffee and set about looking at the hairspring. Wow are these things tiny!!! Originally my plan was to see if I could address the issue on the balance cock itself, but I’m finding magnification is a real problem. I bought some cheap loupes and they really are a struggle to use effectively. I was using the 25x and found it really fuzzy making seeing what I was doing almost impossible. Plus the working distance was so small I couldn’t get my tweezers in there to do any work. So I’ve bitten the bullet and bought a replacement balance wheel. I then proceeded to take the balance wheel off the cock so I could see it a lot better and have a bit more of a play with it. I put the wheel in some rodico and used my loupe to snap a photo: My completely novice guessing thought that maybe the last bend was wrong, causing the terminal curve to wrap too far inside? So I grabbed my tweezers, a yellow oiler and gently set about seeing if I could adjust the last bend: Whilst it’s not as easy to see, I found using the 15x loupe much easier to use. Partly because it’s a much cleaner image. Holding the bit just before the bend with the tweezers I was able to gently tease the bend with the oiler to something that looked better to my eye. However I have no idea if this is correct. At this point I’m using it more as a practice exercise. I’m definitely on the look out for a scope though. Not having cheap loupes around my head I’m sure will make a big difference. As a consequence of adjusting the bend I have put a twist in to the spring. But before I fix that I’ll wait for the experts to advise if I need to do anything else beforehand.1 point

-

Thanks Jon, I believe this is the issue, misaligned fork and escape wheel (in the vertical axis) and non-identical end shake.....might have hit my limit on this one as I'm not ready to take on these adjustments and start adjusting jewel depths. I really wanted to thank everyone for their amazing help going to test for movement in their own bearings (with no train) and try a few other plate/bridge combos to seen any have better movement1 point

-

Fixed it. The sliding pinion was in reverse. It took the 10x mag to see the difference in splines and it was not as obvious as others I have worked with. Anyway winds fine now.1 point

-

Thanks @Neverenoughwatches. I was out the whole day and didn't have time to reply. Perhaps @VWatchie could start a new thread and do walkthrough with lots of photos for the benefit of others who find that their tweezers are too stiff.1 point

-

I really should read the entire discussion before answering questions yes that's definitely a problem. Oh and when you're checking for play make sure there's no power on the watch as that will prevent you from checking for play but yes there has to be a small amount of play in the wheels. I don't suppose you have a tool for adjusting jewels?1 point

-

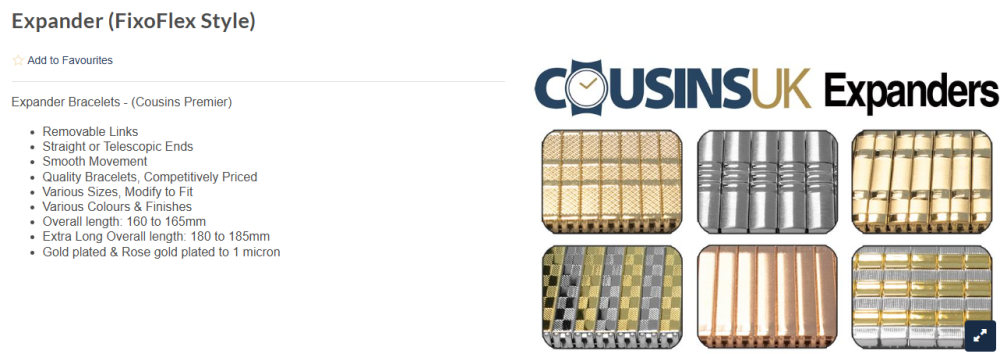

Very disappointed with you all! You can service a chronograph but can't resize a simple bracelet, what I do is, oh wait, throw them in the bin and buy a regular bracelet or leather strap. Hung by my own petard again. Hehe.1 point

-

1 point

-

Exactly WW , I only had one to deal with and it pinged off three times while trying to wind it back it. I just did it for the experience, I bagged it back up in more pieces than I took it out1 point

-

Pocket watches were probably a great source once upon a time, but they're really not as plentiful as they once were, are much more expensive than they once were, and parts are much more challenging to acquire. The large size is likely a good stepping stone, but it's not like we're talking tiny women's movements. A typical men's wristwatch size movement is large enough, and it's what you're most likely to be working on anyway. The ultra cheap chinese stuff is good cost-wise. Parts are a problem again, but you can pick up whole watches somewhat reliably (subject to batch size), and that's not nothing. Quality is obviously poor, and it may not work out of the box for reasons other than dirt. Might even be able to find something you'd want to wear? Maybe...? Any thread on the subject of finding movements to learn on wouldn't be complete if I didn't chime in with 404s (watches purchased under £4.04 plus shipping). Get a mid-grade fully jeweled Swiss movement in a mens watch case size that you stand a chance of finding parts for. You're looking for them to tick a little (compare second hand location between photos if it's not explicitly stated), but not really run all the way, which usually means they just need a clean. Depending on your location, you can get in very inexpensively. Low cost of entry, parts availability, similarity to what you're likely actually wanting to work on, and a level of quality that ensures you stand a chance of success. Plus, when you're done, you might even want to wear your first success! They're a bit harder to find, but I've snagged several 404 vintage mens watches in reasonably modern sizes with full stainless steel cases, mid-grade quality, fully jeweled Swiss movements that I wouldn't hesitate to wear on a daily basis.1 point

-

Yes, it can happen. I was aware of the risk before assembly, having read that part of the manual. It's easy to avoid misplacing it if you nudge the spring in the right direction through the "window" in the bridge. I think the window is designed for that purpose.1 point

-

It's alive! The watch is +12-20 without regulation. Overall, I'm happy with the Zaria movement. It's well-designed and thought out for a small movement. The long center wheel seems problematic, but sacrifices are made for size. The watch suffers in the "looks" department, which keeps the price down. The yoke spring went flying but I found it on the floor after a short search with the magnet.1 point

-

The problem we (Amateurs/hobbyists) have is our volume of repairs/ servicing is low compared to a full time pro. As a result replacing a jewel is not a common repair. So IMO spending a large sum of money on a tool that might be used maybe once a year is a waste. When I have had to change a jewel I have used my very old Seitz jeweling tool. It works just fine using care.1 point

-

Interesting discussion, reading between the lines there seems to be a general assumption that Chinese = poor quality, but seeing that a significant percentage of the "quality" equipment we consume is manufactured in China, this must call into question this assumption - how can people reconcile the fact that they may well be reading this very rant on their flagship quality phones... made is China? Conversely, there seems to be an assumption that Swiss made = quality, again is this really the case as there is a reasonable chance that some manufacturing probably takes place in China or other similar locations. What we know for sure is that the Swiss made equipment (and we all know who we are talking about) is very expensive compared to its Chinese of Indian counterpart, and I just cannot allow myself to be exploited in such a way. The Swiss manufacturers are trading on the Swiss brand and associated/assumed quality, but as stated above and in other posts on this thread, the actual value that this quality differential presents is questionable in real terms. Yes it is high quality, but is the bump in quality actually worth the huge premium???? My strategy is to first look at Chinese clones of the equipment I am looking for, simple equipment eg spring bar tool is a bit of a no-brainer, but for more complex equipment one should dig a bit deeper. A quick look at pictures is often enough to weed out the poor clones, and reading reviews by actual users can increase confidence further. I did this when I purchased my Chinese Horia tool, and like the users above have had a great experience made all the better by the feeling I wasn't paying a 10x mark up for a "Swiss Made" sticker. Only if there is absolutely no option would I buy the Swiss versions, and the experience is usually marred by the feeling that I am supporting this exploitation of watchmakers (especially the nonprofessional hobbyists) and someone in an office somewhere is laughing at us for paying well over the odds for equipment they are buying/assembling/manufacturing at a tiny fraction of what I have just played for it, talk about spinning straw into gold. My philosophy is that I give the cloned version a try, and if it's no good then, and there are no other realistic options, I take the plunge and get the Swiss version. Worst case is that I pay for both tools, in the example above I end up paying $1960 instead of $1800, but the best case is that I can save $1640..... I'd be crazy not to take that gamble and in addition get that warm and fuzzy feeling that I hadn't allowed myself to be screwed over in the process. Sorry for the long rant!1 point

-

Mine is a used Swiss version and it seems to function perfectly. So basically it's a very very nicely made tool that seems to last almost forever. The one at work which is also used came from a school and it's only problem is sometimes the pushers don't like to stay in place but otherwise the tools seem to last forever. Interesting about the price mine was used as I said, the person selling it didn't really know what it was and I think I paid about the same price as you Chinese version. But yes you're right unfortunately Swiss tools are astronomically expensive. Then the unfortunate thing about Swiss tool prices are they keep going up and up with the quality going down. At least for some of the stuff if you look at newer versions versus older versions they don't seem to quite as nice. With considerable price difference. You need to actually expand that a little bit why would people purchase new tools when they could purchase used tools. For instance a lot of the tools that I have are used tools purchased over the years and I am extremely happy with them. Basically a lot of the tools maybe weren't made to last forever but they're basically going to last forever. Then we do have an interesting problem? Why would people insist upon purchasing brand-new extremely expenses Swiss tools when there is better alternatives either used or Chinese or possibly something else. Lovely acquaintances I have ordered one of the staking sets from cousins it still isn't in stock. Apparently the ones that did come in that instantly disappeared were missing the punches. So I guess they're waiting for the rest of them to show up from somewhere on the planet. So even though I tried to explain that the vintage is perfectly fine his obsession was only to purchase the brand-new in the box. There is some sort of psychological thing that brand-new in the box from the Swiss is what you must do or else and is to be quite honest beyond our comprehension and endeavor going to reach those people in total waste of time let them by their silly expensive tools and waste all their money. Like the staking set the local college requires the students to purchase toolset a rather expensive set. The staking set is now so expensive that the school offsets part of the cost and requires the student to sign a note if they leave before the completion of the school the staking set goes back to the school. But from the students I've heard that have the staking set they have to refinish the punches because the finish sucks. This means I know a couple of students who would like to acquire a vintage set and I believe one of did finally get a vintage set something it has decent that actually works out-of-the-box even if it's a vintage. Oh minor clarification here somewhere else in the group were discussing where those six dollar jewels are going away. One of the material houses in the US are selling about a closeout price because they are being closed out. Cousins has a lot of them listed as discontinued so breaking a jewel with a inferior tool might not be in your best interest. But even out of the box I don't think the tool is that inferior but just a warning jewels appear to be disappearing. I'm not sure if these 60% rule applies to tools as I think it's a watch thing. If you look at the companies that sell tools in Switzerland such as bergeon Do they actually make all the tools they sell themselves? When I was going to school in Switzerland quite a while ago basically when we visited they purchased everything they were doing no manufacturing themselves. Which is why the stuff that they sell could have been sold by other people. But if you look on their website now they appear to acquired brands of stuff so doubted the sole supplier of those things. Then if you look at the link below they indicate that their manufacturing more and more and more their stuff which to certain drift find interesting it probably suggests that the number of people making tools to sell is shrinking because obviously the demand of people needing tools has decreased which unfortunately has the rippling effect of driving the price of stuff up considerably https://www.bergeon.swiss/company/index I do find it interesting problem with purchasing Chinese stuff in that depending upon what it is or whose cloning at in other words the Chinese clone their own stuff that their cloning from other people you can end up with a vast quality difference of seemingly identical stuff sometimes. But still you get some really excellent inexpensive products out of China1 point

-

I forgot to mention it in my post, but when looking for tools I have learned that it can be profitable to note the names of tools in both English, French and German. Neither eBay nor chatGTP usually manages to translate tool names correctly and therefore it is easy to miss many listings which can be costly. My Jacot tool purchase is a good example of that. I intend to compile a list of tool names in English, French, and German as I go, but it would probably be beneficial to include multiple languages such as Italian, Dutch, and Spanish too, but right now it just consists of the following: English Jacot Tool French Tour à Pivoter German Zapfenrollierstuhl1 point

-

Depending on the sideshake and diameter of the arbor at the pivot, you can have a situation where the shoulders at both ends are making contact with both hole jewels at the same time if the endshake is very small. It can be exacerbated by very short arbors too, particularly the pallet fork*. 0.01mm is hard to visualize, I made a sketch of an arbor with jewels and exactly that much endshake to illustrate. *Troubleshooting a new-build tourbillon a few years back I had a situation where the fork was ultra free, with "feelable" endshake, but the watch was having amplitude issues- ended up adding 0.01mm endshake fixed it.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)