Leaderboard

Popular Content

Showing content with the highest reputation on 01/11/25 in all areas

-

3 points

-

For those that have never had the privilege of working on these wonderful clocks. Here is quite a good one its no the best but worth a look. https://www.ebay.co.uk/itm/135493455842?_skw=antique+clocks&itmmeta=01JHAZHXKVNW53S4J5X56WZW8A&hash=item1f8c0a0fe2:g:yksAAOSwECllMT0e&itmprp=enc%3AAQAJAAAA0HoV3kP08IDx%2BKZ9MfhVJKmlncLG90toRv%2FFe7L8ub1oyrW1qRhmXTUpwud0TZNcaB5BpQwYwKIIYP3wGuVeKZXijKw2WTpPlkLUlexU6BXsfVLsZLFr354NVxu31NaTv6bFl4QHJ4wnZI1QQ1UUTTfEnlCD2tEnpz3K2Q8U4xdf2Mx%2FcpAot%2Bh8nh07bma2ScidnksCy%2BJydqbAhxihmX8Gb2g7AoWlJitIKkJbC1H9%2Bd90HTyZJ6QJMEMwdIrETMQrwuW91LcLFyy2FW%2BAR8A%3D|tkp%3ABk9SR5Lax9-KZQ2 points

-

Hello, So, I have started entertaining myself by researching all the different models of the ISA 1198 watch movement. Fascinating. I then returned to my project and purchased a helmet magnifier. I really appreciate the support from you guys for having opened up a whole new world that I didn't know existed. A big thanks to Bonefixer for the offer, but I think I got bit by the horology bug.... lol. Time will tell. I'll let you guys know how it turns out!2 points

-

It would appear then since TBRP have taken over they've lowered their standards as yours is a completely different casting to the one shown in the photo.2 points

-

Experience. If this was a top of the range part of the train there pivot holes would be jeweled and the pallets would have pallet stones instead of all steel.2 points

-

2 points

-

Wow, that's a lot of lateral play. My vintage Robur has very little. I'd also send it back.1 point

-

1 point

-

I would love a long case but my Bungalow is not big enough most of my clocks are year going1 point

-

The movement on the shaft makes it look like a cheap Chinese tooltbh I wouldn't be impressed at all for the price. And like Richard said thats regardless of how well it works. As a comparison this preowned KWM cost me 28 quid , German made, the shaft has almost zero side movement fully extended. Another sold the following week with less dies for 18 quid.1 point

-

Hello Luke welcome to the forum. I have added a couple of files for 6our interest. Cheers TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

Looking at the video. That’s too much slap in the shaft, for that price I would send it back it’s way too sloppy.1 point

-

I wouldn't be satisfied, whether or not it effects function. At the price I would expect better tolerances.1 point

-

That is a bit more than mine has. You could argue (and I would agree) that you might expect some better workmanship for that price tag, but it won't affect how it works. Like Neverenoughwatches already wrote, you use it to press a crystal. Nothing critical. You're not doing any drilling or reaming operations with it.1 point

-

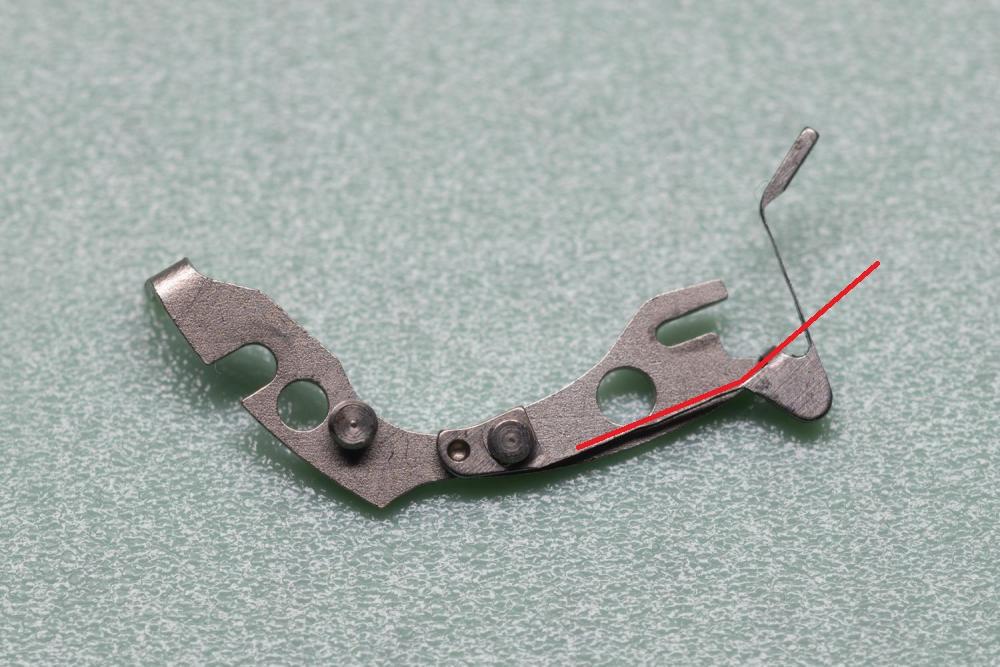

Why don't You try to rectify the spring? What You need to do is to straighten the angle I have shown to a straight line. Don't look at the drawings of the springs, the real ones are just like yours but without that bent. I see the spring is bent a little up, but at first try without rectifying this. If really needed, the rivet may be removed and the spring then can be bent down and then new rivet placed.1 point

-

1 point

-

Pre-cleaning at least in service centers typically would include the balance wheel and pallet fork. In our previous location when we had a Specific machine for pre-cleaning I would pre-cleaned the pocket watches and they did include the balance wheel and pallet fork. Although the pre-cleaned machine really wasn't happy with something as large as an intact pocket watch intended to vibrate quite a bit. With the baskets on top of the machine usually falling to the floor. Then one is talking the Josh today that used to work in the Swatch group service center asked what their policy was and no pre-cleaning. On the other hand Swatch group service center doesn't do vintage and typically cleaning would fix the problem. That is if the watch even really had a problem other then it was time for an overhaul. Then of course they would probably change the mainspring barrel and the escapement components. So basically disassembled cleaned reassemble lubricated only if there's some sort of problem with a deal with it but apparently they didn't have a lot of problems. As basically these are brand-new watches at least by the standards of this group are probably less than 10 years old. But as I mentioned I know Rolex service centers they always pre-cleaned and typically have a separate machine for that. One of the ways the hobbyist could do pre-cleaning would be basically to ultrasonic in a fluid such as lighter fluid or any type rinsing solution. Versus actually running it through a multistep cleaning machine which isn't always really necessary. Then yes having a reasonably clean watch that the gears spin And the balance wheel turns and you can verify that yes the watch runs. Then if you're concerned about a reasonably dry watch put a little oil on it. After all you're in the evaluation phase are going at some point in time disassemble and properly clean it. Is amazing what a little fresh oil will do on a clean escapement for instance. But yes it's definitely nice before the complete servicing to discover if there is problems. Because ideally this is the time to fix the problems as opposed to surprise my watch doesn't run and it's now back in the case which occasionally happens on this group.1 point

-

This is one of the reasons why people assume cleaning will fix all problems as for quite a few watches cleaning will fix the problems. Especially if certain conditions are met. In other words hopefully the watch hasn't been worked on by anyone else in the past and left in a non-running condition. Had been lubricated with organic oils that went bad so watch just came to a stop. That's actually a good thing for organic lubricants the watch stopped in did not wear out. But now that we of modern synthetic oils they typically just spread across the plates never seen again and on early automatic watches are definitely a problem for the automatic components that did not have jeweled bearings and if the watches continuously run cleaning will not fix the problems and it will disintegrate. Now we end up with a interesting problem for pre-cleaning is it good or bad? I know of people work and Rolex shops and all watches are pre-cleaned. So that were all on the same page here the watch is disassembled in other words hands and dial come off possibly the calendar ring but not always as one of the calendar rings apparently can be pre-cleaned. But typically anything that's painted comes off entire watch is run through typically a separate machine than the normal cleaning machine. Now in the watch is look that it's nice and clean as Rolex is obsessed with and shakes they can properly check that they can do a nice evaluation and continue on with their servicing but his pre-cleaning universally accepted by everybody? Your timing is quite interesting because yesterday we had a discussion about this at work. Where I work we have another watchmaker who typically is somewhere else but every couple of months he comes to join us for a couple weeks and we did have a discussion about pre-cleaning so Josh's thoughts on pre-cleaning are like arriving at the scene of a crime and it's been cleaned. In other words the body is gone and we did make a joke it's been cremated. The entire scene's been cleaned everything is been patched everything is been fixed and how exactly do we evaluate the condition if we can't? As Josh is typically doing a lot a wristwatches including vintage he looks for things like filings which disappear with pre-cleaning. So we do end up with interesting problem here. One of the problems we run into is parts listings and even service bulletins were written at an exact point of time. For instance I was doing a project with somebody working on a 12 size Illinois watch He was very happy because the watch had been made for 30 years and all the parts according the parts book interchange. But the reality was over the 30 years they change things lots of things they just never revise the parts book at all. Even things like our wheels initially in the project because they're all the same we removed all the our wheels and discover later on that they're all sized slightly differently. In the early days of especially pocket watches that are typically made in batches and parts may not interchange between the various batches. The earlier watches even possibly something from the beginning of the batch to the end of the batch might not interchange as there is a lot of hand fitting and machineries would go out of tolerance plus revisions do we ever see the revisions? I know Omega has revisions not only do they have revisions but they have documentation comment to specific calibers at least newer calibers where they talk about specific problems for those specific watches plus revisions of parts. Whereas the revised part numbers do not have any designation that they been revised which I find quite annoying. So often times you will see the original parts were these the upgraded parts were these there may be a color difference or they'll tell you how many wheels in the teeth or something but if you don't have the revision document that's going to be a problem then anything from or specifically vintage related to the escapement is going to be a problem if you swap only one of the components and do not understand exactly what you're doing as they typically will not work not without some form of adjustment. This is why students in schools such as wostep spends so much time adjusting escapement's as if you work on anything a vintage you're going to have to understand how to do that.1 point

-

I've had several. They all had a small amount of play on the spindle. Don't worry. It doesn't effect it's performance.1 point

-

Welcome to the forum. Clutch wheel looks wrong or maybe just the wrong way round compared to this. As far as I'm aware the only difference between the 2788 & 2789 is the Date & Day/Date Edit Should have watched more of the video as you went into it but around 2:00 it's too far off the screen to see what's happening.1 point

-

1 point

-

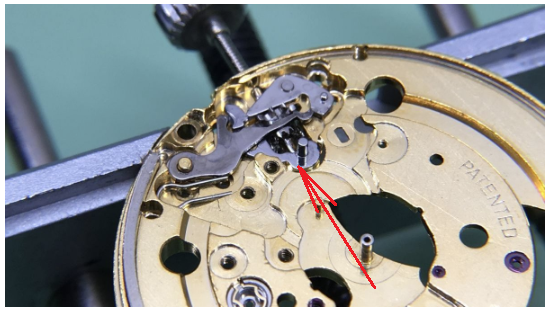

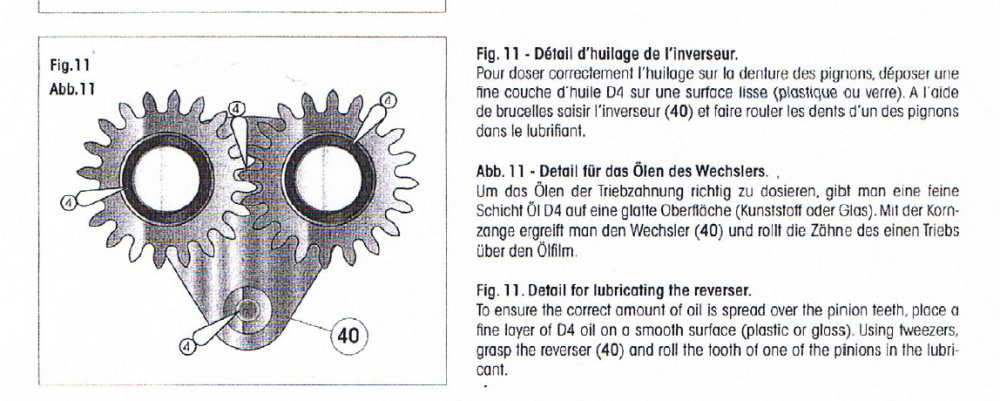

OK, finally my write up on the full assembly! The order of assembly is a bit unorthodox (train, auto-works and keyless before barrel bridge), but it works. 1. TRAIN: see previous posts. Extra info: oiling: escape wheel 9010, fourth wheel 9020 (instead of 9010), third wheel HP1300. 2. KEYLESS WORKS: see previous posts 3. AUTOMATIC WORKS (without rotor): this wheel needs no lubrication the wig wag reverser is oiled as follows: I use 9504 instead of D4 for the teeth. I srpead the grease as thinly as possible and then run the wheels over it. In all the other places, I use HP1300 instead of D4. The wig wag is secured with this small plate (screw not pictured here). No lubrication here at all. 4. BARREL and BARREL BRIDGE: breaking grease 8217 in the barrel, thinly distributed this is a supposedly original JLC mainspring for the calibre but please refer to this thread on my issues with rebanking which essentially concludes that the mainspring may be too strong. note that it turns counter-clockwise HP1300 I put a very small amount of HP1300 on the jewel for the click (despite no lubrication indicated in service manual) 9415 (!) on the click spring click in place other wheels in place... Now the centre seconds pinion: first, oiling the rim of the tube. I used 9020 instead of 9010. then in goes the pinion and now I apply a bit of 9415 specifically on the opposite side of where the friction spring will be (so that the friction spring will then spread the lubricant around the pinion, instead of accidentally just pushing it down to the wrong place when installing it) Barrel and ratchet wheel Now this last one, which needs to be lubricated in itself. I use 9504 instead of HP1300. This wheel slips when the watch is manually wound and thus disengages the automatic works (so that the rotor doesn't turn when wound manually). after applying a few drops of grease, I spread it around by moving the arms of the wheel. I squeeze a small amount of HP1300 under the steel disk with a scalpel. A bit fiddly: preparing the underside of the barrel bridge. Always HP1300. tiny drops of HP1300 here Finally, installing the barrel bridge. BE VERY CAREFUL that the centre seconds tension spring is positioned on the pinion ON THE SIDE OF THE BALANCE. The little window in the bridge allows gentle manipulation to nudge it in the right direction. There are lots of wheels etc to align, so take your time until it all falls into place. Now the pallet fork. ...and the balance. Balance jewels lubricated as usual with 9010. I let it run for a few minutes to scrape of a "channel" of epilame from the pallet stones (I know, this may be overkill, but I buy it). I then remove the balance again and oil the exit stone with 9415 in 5 small applications and advancing the pallet for in-between applications. and put the balance back afterwards. One of the 9415 drops. Not so easy to photograph. BASE MOVEMENT DONE. It runs well. Next post will be the complication module "calibre 929".1 point

-

Fixed it. The sliding pinion was in reverse. It took the 10x mag to see the difference in splines and it was not as obvious as others I have worked with. Anyway winds fine now.1 point

-

Yes. And you see the 2 thinner than hair wires protected by blobs of epoxy. I wouldn't go probing anywhere near them.1 point

-

You shouldn't expect too much more cost to replace the crystal - it's very routine, and case cleaning should be included in service. Case polishing might not be included, though your case has a lot of gold fill wear so anything beyond a light buff might make it worse. But if you are game for it, replacing the crystal is something you could do yourself. You pop off the bezel with a knife. It is possible to buy actual mineral glass crystals usually measured to 0.1mm increments, or acrylic/plastic (not sure which you have now) that are sold in various increments. The glass ones can be glued in using hypo-cement or UV-curing glue, and the plastic ones are inserted by flexing them downward to smaller diameter and setting into the bezel to expand back with an inexpensive press tool. Crystals are about $10-$15 and a workable press could be under $25.1 point

-

Yes the opening will be up at the top or just off center from the top (typically toward the right of the crown from the back side). A very fine razor blade pushed into the gap where it meets the mid-case should pop it right open. Those are not usually tightly sealed and only take a slight bit of effort in the right place to snap open.1 point

-

@CYCLOPS Thanks for the encouragement. I got the screw out but I really had to use a fair bit of force - I had indeed opened the screw out with my somewhat new to all this screwdriver technique!1 point

-

1 point

-

I always call them. They are very old school—Their site really doesn’t list much of anything except some tools and supplies and their search function isn’t very effective.1 point

-

Thanks for the offer! I actually found a NOS one today at McCaw Supply (Toledo OH). Was their last one, so feel lucky. I was thinking this was an opportunity to explore the world of 3D printing but looks like it will have to wait for another project. Happy Holidays and thanks again for the offer.1 point

-

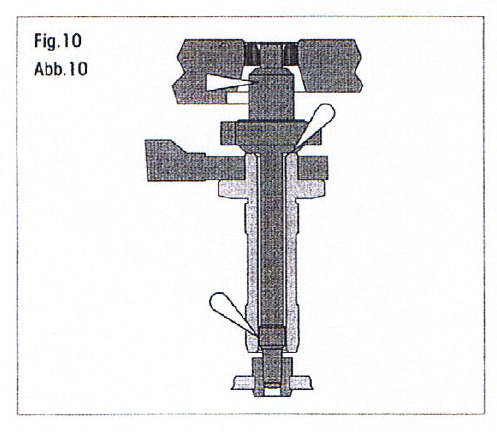

Maybe the stud on the underside of the setting lever (the bit that holds the stem) is worn or sheared off -> Not the most typical failure, but may be good to rule it in/out before you go too far down the road of adjusting/replacing the stem. The image above isn't the same as yours, but you get the idea.1 point

-

The two angles are different and if you google impulse angle of pallet stone you will get an answer1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)