Leaderboard

Popular Content

Showing content with the highest reputation on 01/14/25 in Posts

-

Filing is really frowned upon on escapement components. Although I've seen pallet fork horns where one of them is thinner than the other one because somebody is modified it and then they catch becomes the escapement will never be perfectly symmetrical like it's supposed to be. We end up with a interesting problem here don't we? So in a very clear rules on using the banking pins solely for horn clearance but of course not adjusted correctly will affect other things. The general rule is adjusting the safety first that's the horn clearance. Then checking the guard pin which usually isn't played with not as much as movable banking pins. Then once all of that is correct then you can look at the pallet stones and make sure they look correct. But we also have these hard and fast rules of told Locke must be this doesn't always apply if it would conflict with the safety. In addition to conceivably over time the design of the lever escapement has changed slightly. So basically everything just has to work Yes it's really quite amazing what proper lubrication will do to the balance pivots and the escapement. A lot of times I will do what I call pre-timing where I will attempt to get the watch to Run in any fashion so I can verify that the watches in beat the timing is reasonably close as I won't have to be fooling with the balance wheel after it's all nice and clean. I remember one watch that really a performance totally sucked and I was lubricating with the method that I really do not like to do but I was being lazy which is Not removing the balance from the bridge just lifting it up and dropping a little oil on the pivot. It really is better if you remove the balance wheel so it's out of the way and eventually I did do that and oil on the pivots amplitude improved considerably and everything else just basically disappeared it's one of the problems of as the amplitude drops everything gets magnified. So if you are amplitude is practically nonexistent then you shouldn't worry about really anything else until that gets up because that will affect everything. One of the reasons I want to look at the graphical display but we can't see it in fine detail it is? Another thing to have a spectacular improvement on amplitude is proper escapement lubrication. Whereas if you had not properly lubricated your escapement in other words some of the escape wheel or the other pallet stone is not lubricated you'll actually see this in the graphical display of a line that looks rough. Often times on a freshly lubricated watch all notice that one line looks rough the other looks fine and just a little bit of lubrication on the other pallet stone the problem will go away. Plus it's also interesting what letting the watch run overnight will do sometimes.4 points

-

Good morning! My next walk-through. This time of an Universal Geneve 2-66 calibre in a "White Shadow" watch. With less than 2.5mm thickness, the movement was one of the thinnest automatic movements at its introduction in 1966 and for decades to come. Some say it was the thinnest of all, but I found the Piaget 12P was 2.3mm and introduced in 1960. That would make the Universal 66 the second-thinnest automatic movement unitl 1985 when the Frederic Piquet 71 came in with 2.4mm. ANYWAY, it's very thin! Another cool story is that no other than Patek Philippe poaches the movement engineer of Universal and let him basically copy the UG 66. They then introduced the Patek calibre 240 in 1977. They looks strikingly alike. Apparently, Universal sued Patek, but settled out of court and then went bankrupt during the quartz crisis. (see my post here for a picture comparison of the UG and the Patek: https://www.watchrepairtalk.com/topic/3470-which-watch-have-you-got-coming-in-the-mail-show-us/?do=findComment&comment=270754 ) As usual, I'll share the walk-through in several posts. Today: disassembly. Hands and dial off reveals the keyless works (two dial screws) Note: the dial washer doesn't fit too well. I'll look for another one for assembly. NOTE on letting the power down! The power is held by TWO clicks. One directly at the ratchet wheel (dial side) and one in the automatic works. I first completely removed the click at the ratchet wheel and then held back the click of the automatic works. It worked ok, BUT is not ideal. It lets the rotor spin to release the power in that direction (instead of the crown). I therefore suggest to first remove the automatic works completely (rotor, wheels and click). THEN proceed as usual by holding back the ratchet click and releasing power gently by holding/slipping the crown. To show the (supposed) better practice, I'll post my pictures in a different order from my actual disassembly. This is how I think it SHOULD be done (in retrospect), 0. Remove the balance 1. Automatic works: remove the rotor The automatic bridge (please ignore that the barrel bridge is already off and don't remove it before releasing the power!) VERY gently with this spring on the click! It's insanely thin. The end of the spring rests in a small hole in the mainplate. I'll show that in my pictures for assembly. Note that the wig-wag winding wheels for the rotor can stay in place. They are riveted to the movement. A total of three ball bearings here! Two are visible, and the backside of it (that wigs and wags) also has a ball bearing. The rotor also has one. So four ball bearings in the movement!! 2. Turn movement over and release the power with the usual method (hold back click and gently let the crown slip through your fingers) The click is here: Then disassembly the click I also took the hour wheel of (no picture, but obvious). NOW, IMPORTANT. The apparent cannon pinion here, is not a real cannon pinion!! It should be completely free. The movement doesn't have a central centre wheel and therefore the "true cannon pinion" also isn't in the centre of the movement. This "false cannon pinion" is just a reduction wheel for the minute hand. DO NOT have the stupid idea of tightening this "false cannon pinion".... like I did ... But ok, onwards. 3. After letting the power down, I go back to the train side. Note on pallet fork: the lock is very heavy. If amplitude turns out to be very low after service, I may have to push the pallets in a bit. Note that there a two different screws for the train bridge!! The one on the edge is a bit shorter. Barrel bridge. Again, note that there are two different screws! The one at the crown is longer. Now, the larger wheel next to the barrel is the decentralized centre wheel with cannon pinion. I will show how to disassemble it in a later post. The ratchet wheel is under the barrel 4. Dial side cover plate Watch out, under this wheel is basically the crown wheel. There's an outer crown and also a seat around the post. the downwards bent side goes down on the setting lever careful, very strong spring here this lever engages and disengages the integrated wheel directly with the ratchet wheel for manual winding Now again very careful with the spring under the lever! It is very thin and very springy. I actually lost it and couldn't find it even after 1.5h on the floor... and since I managed to buy one, there are now only very few left in the world! finally the stem with the pinions removing lower balance jewel for cleaning barrel open. NOTE that the square bit of the barrel arbor points up from this perspective (not pictured). This is important to remember for assembly. This concludes today's post of disassembly. Next post will show the disassembly of the integrated decentralized centre wheel and true cannon pinion -- and tightening it (because it was slipping).3 points

-

Learning how to lubricate a watch takes considerable practice. Once a watch has been lubricated, you must clean it to remove all traces of the oils and greases if you wish to lubricate it again. Similarly, if you want to try servicing used watch movements, you need a way to remove the old lubricants and any other dirt from the parts. For this reason, I suggest that acquiring the means to clean watch parts would be a good choice. Some people choose to clean parts by hand, but ultrasonic cleaners are quite affordable and work very well and will save you a lot of time. I suggest you look into buying an ultrasonic tank, jars for cleaning solution and rinses, parts baskets, pegwood, pithwood, a cleaning solution and a rinse. If you can afford a gallon of professional watch cleaning fluid and a gallon of rinse, they tend to work better than most home brew cleaning supplies. When you’re learning, it helps to remove unnecessary variables where you can, and using commercial watch cleaning products takes out some guesswork if you need to troubleshoot your cleaning process. Depending upon the cleaning fluids you choose, and the humidity where you live, you may need some form of heater to dry your parts whilst preventing condensation forming and causing rust. A hair dryer on low heat will suffice. For more information about watch cleaning products and using ultrasonic cleaners, this video is an excellent resource : I hope that helps, Mark3 points

-

I'll be needing to call you then for advice next time "She" finds and I haven't hidden well enough my next watch acquisition2 points

-

How very dare you! Take that back right now! defo not a lawyer, though if I had my time again divorce lawyer seems like a lucrative career Tom2 points

-

The 6619 is slightly larger and deeper than the 6119 and I think that's where your problems will lie along with lining up the stem. Edit Just realised that I think your 6119 is a typo as the case you've shown is a 6619. Here's another. https://www.ebay.co.uk/itm/3868924654372 points

-

Can't say I've heard anyone mention that they were a solicitor or a lawyer. But then why would they ? bit like telling folk that you're a politician or a car salesman. I mean if you want members to help you....then you keep that sort of thing quiet.2 points

-

I have some experience with Russian movements (Vostok, Raketa, Poljot), although not specifically the Zim 2602, and my impression is that Russian movements are generally not manufactured with the same precision as Swiss and Japanese movements. A few years ago, I spent an enormous amount of time trying to make these Russian movements as precise as Swiss ones, but the reality is that it's not possible. Despite significant variations in rate, they can, of course, still be regulated to run very accurately and are therefore practically just as functional as Swiss movements. Personally, I believe you’ve done a good job and don’t have much to gain from performing another service/inspection. The results you’re getting are probably quite close to what can be considered optimal under the circumstances. A few years ago, I wrote a more detailed post about this, which I think you might find interesting.2 points

-

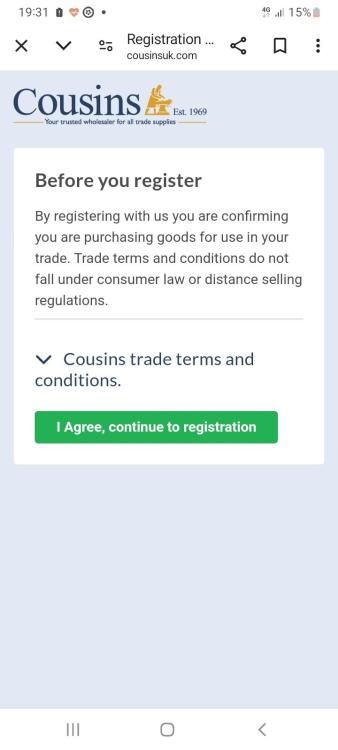

My impression is that this is their way of working and their policy. That is, they do not refund any money until they have received an assessment from the product manufacturer, as they lack the expertise to determine whether the product is defective or not. The explanation is that Cousins is purely a distributor with no practical experience in the watchmaking industry. For this reason, many watchmakers choose to trade with distributors such as HS Walsh and Gleave and Co instead.2 points

-

Hello everyone. As promised, I am showing off my diy cleaning machine. This was built with NEMA 23 stepper motors, controllers, a power supply, and an Arduino nano. I will list the parts used below when I'm at my computer. The frame is made from 3030 extruded aluminum, which I had made by Misumo online. The cleaning basket was purchased in eBay. Some miscellaneous parts needed are an 8mm shaft, some couplers, buttons, and wire. The codes I wrote for it can be completely adjusted and changed however it is needed. I have since adjusted the speed the linear shaft moves up and down. In the future, I plan to add another stepper motor to include a turntable at the base, with 4 jars, so the entire cleaning process is one process. Right now I still need to get jars that fit, and to build a fan for a drying cycle. Please post any questions you might have, and if you're interested in the code used to build your own.1 point

-

High chance the old chapter ring won't fit the new case. Try messaging the seller to get the ID and see how it compares to your dial.1 point

-

So from what you've said it would appear you haven't got a pierce 103 so photos of the movement may help confirm this. You need to be using at least a pair of digital calipers to get some sort of accuracy.1 point

-

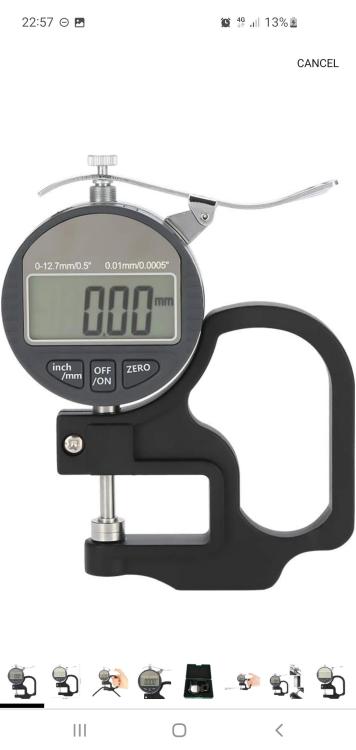

0.1mm per division is far too inaccurate for watchmaking. You'd at least need a 0,01 accuracy. A feintaster would be nice, but they are often very expensive. A thickness gauge (analogue or digital) with a 0,01 accuracy is a low cost alternative. You could use a screw type micrometer as well, but care should be taken not to damage your part.1 point

-

1 point

-

I can't remember exactly what the form stated, I know I made up a bull company name that sounded cool . For some reason I'm thinking there was a mentioning of non business/ no warranty..I may not have the right though. Lets sign up again and see what happens. Here we go, that was easy to find out Thats a get out clause right there, good work Cousins Tick the box and wave bye-bye to your standard consumer warranty They only deal b2b Rich. Which is what Tom said a day ago , "Tom the lawyer"1 point

-

Welcome to the forum. What's the serial number of the movement? Are yo aware of this site for pocket watch information. https://pocketwatchdatabase.com/guide/company/waltham/models Edit Should have added that good quality photos always help and what parts are you looking for.1 point

-

Hi. Looked after carefully they will last you years, I have some screwdrivers ( no replaceable blades) with solid blades, back then. No fancy sets you just bought the sizes you wanted. One or two suppliers I think put sets together maybe five, seven drivers of recommended drivers. The suppliers I used then are long gone . A .G Thomas Bradford still exist though.1 point

-

1 point

-

I meant completing the form as a business to business account, I don't think there is an alternative. So then as Tom rightly stated public consumer rights dont apply. Anything ive bought on line including ebay from a business has had a good returns policy. A company I deal with sometimes....Chronos Engineering, I once had a fault proxxon tool from them...another was shipped and delivered before I even sent the first one back...thats an excellent customer service and support.1 point

-

I dont understand this, I thought irrespective of what the reason is, so even the right to change your mind a refund process can be started if its within a 14 day period of the sale...or would that be the receipt of goods ? Nearly all retail sellers are distributers. Do electrical sale retailers understand the workings of computers and how to fix them. Cousins terms seem very unfair, I'm surprised they get away with this. Probably why they suggests they only deal with other businesses, devious to my mind. If they can't honour the consumer rights act then they should not accept orders from the general public.1 point

-

You are certainly right about that! I was just talking to the lady from Cousins, and she said the same thing. She said when there is and issue with a tool they can’t start the return process until the manufacturer approves it. I told them I was going to wait one more week to see if they heard anything from Robur, otherwise I will just try to do something myself to fix the tool.1 point

-

Not that post you've added here H, you questioned something very similar regarding very short rate fluctuations about a year or so ago. The final opinion was mainspring power fluctuations, I'm sure John had a lot to say about it. I'll try find it. I tbought the same Nev until Andy corrected me. Might that be a 6 or 8 leaf pinion possibly resulting in a six minute revolution ? Its quite easy to see the 5 minute repeating fluctuations. Found it ! https://www.watchrepairtalk.com/topic/28929-serviced-eta-2763-having-erratic-rate-and-amplitude/?do=findComment&comment=244717 This thread made interesting reading again. A fairly deep discussion of gearing power fluctuations. I take that to be the gradual meshing of teeth and pinion leaf interaction. The increase and decrease of friction as the modulus of teeth/leaf come together and then seperate. Better designed and manufactured teeth would have less friction so less fluctuations .1 point

-

Hard to see: The scale of these graphs is day/hour/minute1 point

-

Looking at amplitude graph, we can see that it can change from 290 to 250 and again to 290 in 3 sec. Do You guess what I will say here? Well, this is not true. For sure it is not real. Do You really have to use this software??? OK, I se I am wrong here, as it is one hour long record, not one minute1 point

-

Based on the photo it's out by 2.4 degrees. I'm no expert but I'd be surprised if that made a measurable difference to your measurements. In any case, you can check easily enough: measure the same watch dial up with the mic in the position photographed, then turn the mic over, and the watch over, and measure dial up again. Or adjust it with a spirit level and do before and after measurements. I'm sure others here would be interested in the results of the experiment, and if it really does make no measurable difference then you save yourself the hassle of returning and replacing it.1 point

-

1 point

-

NOS stem came in with a little drama and I cut to correct length thinking i had plenty of excess stem. Cut it close, so to speak but everything worked out and the quick set jump day and date feature works perfectly. Now to find out what is going on with the minute recorder as the hand slightly jumps but doesn't actually move forward on the dial.1 point

-

Agree. I've told Cousins I want to return the press and die set for a refund. Without the rebur press the die set is useless to me.1 point

-

It's a pocket watch movement recently serviced and cased. I know that many would crucify me for this, but in certain cases like the watch has no historical meaning, sentimental value, or the case itself is just not too nice/precious/ uniq then the watch just might receive a second chance to live. ( I also understand that the movement was designed for the pocket.)1 point

-

Yea, with that level/lack of quality, you're better off buying the Chinese tool that @VWatchie recommends in the other thread about the other dodgy Robur.1 point

-

I would send it back, seems like Robur has been bought out and the quality has gone down the swanee. It's a long time since I've used that idiom.1 point

-

1 point

-

Great to meet both of you. I've already got a question posted to the shock settings category regarding a current project of mine, restoring an old LL Bean Hamilton "pocketwatch" from the 80's - turns out its just a watch movement inside with a hefty movement ring. I've also got a really cool vintage 60s Seiko on the way I'm excited to crack into this week.1 point

-

A basic check one does when checking a hairspring is how well centered and flat it is at the collet. Out of flat is visually quite clear in the watch, out of center is harder to describe, mainly the inner 1/2 of the coils look "jumpy" as the balance oscillates. Adjustment is done with the balance out, hairspring on, in ideally a set of hairspring truing calipers. These permit a better view of the spring, and better access, than regular calipers, though those work as well. Adjustment is done on the first 180 degrees or so of the spring from the collet. The caliper is adjusted so the balance can spin with no play. Just slowly turning the balance, follow the first coil/s of the spring from its exit from the collet, and it should make a nice progressive spiral. If it is out of center, it will seem to spiral out, then cease, then out, or even go back-and-forth sort of. As with everything it takes a bit of practice to figure out where and how much to adjust, but the basic rules of hairspring adjusting still apply. Adjustment in the flat is done 180 degrees from maximum error, in the round, 90 degrees. When checking the flat in the caliper, you have to focus on the first 4-5 coils, as the rest are influenced by the weight of the stud and will naturally look low. When all good, those first few coils will look distinctly flat viewed from the side, and the whole spring will look like one of the optical illusion spirals as the balance slowly spins (viewed from above). The effect on timing from a spring out of true at the collet can vary from almost unnoticeable to rather extreme. I was just working on a new-build, first time on the timing machine. I saw there was a little truing needed at the collet, but ran a cycle anyway. In my case, the verticals were slow compared to the horizontal, with an apparent poise error equaling 60s. I trued it at the collet, and the difference in both h/v and the "poise error" were cut in half. Another reason not to chase dynamic poise if everything isn't as perfect as possible. The effect of centering at the collet is used by good regleurs sometimes by introducing an error. Sometimes you find the verticals just want to run slow, with regulator pins adjusted perfectly etc. Like, perfect poise, but 15s slower than horizontal. Sometimes throwing the centering out at the collet by say half a spring thickness can resolve this. It is pretty much unnoticeable visually. Also, you have to guess which way to "throw it out", haha. A Levin hairspring truing caliper and a Swiss simple caliper that works well too1 point

-

Wouldn't that depend on how the pallet is weighted? I used to do this until I ran into a movement where this test just didn't do it for me. @nickelsilver then suggested a very small puff from the blower and that's the method I've been using ever since when the pallet wouldn't fall by itself. Anyway, thank you for the tip, I will absolutely look into it.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)