Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/25 in all areas

-

I decided to give it a shot with positive results. Marked the banking screws so I could undo it, I move the outside banking pin inward a tiny bit to adjust for the visual alignment difference of the fork shaft toward the balance jewel and lessen the lock on the exit stone. That little change put the watch back in beat (yay I don't have to mess with the collet again) and amplitude jumped from 220 to 255. Exactly what I needed. Adjustment to the mean time screws brings the rates down most of the way and I still want to finish a dynamic poising to bring PU closer to the horizontals.4 points

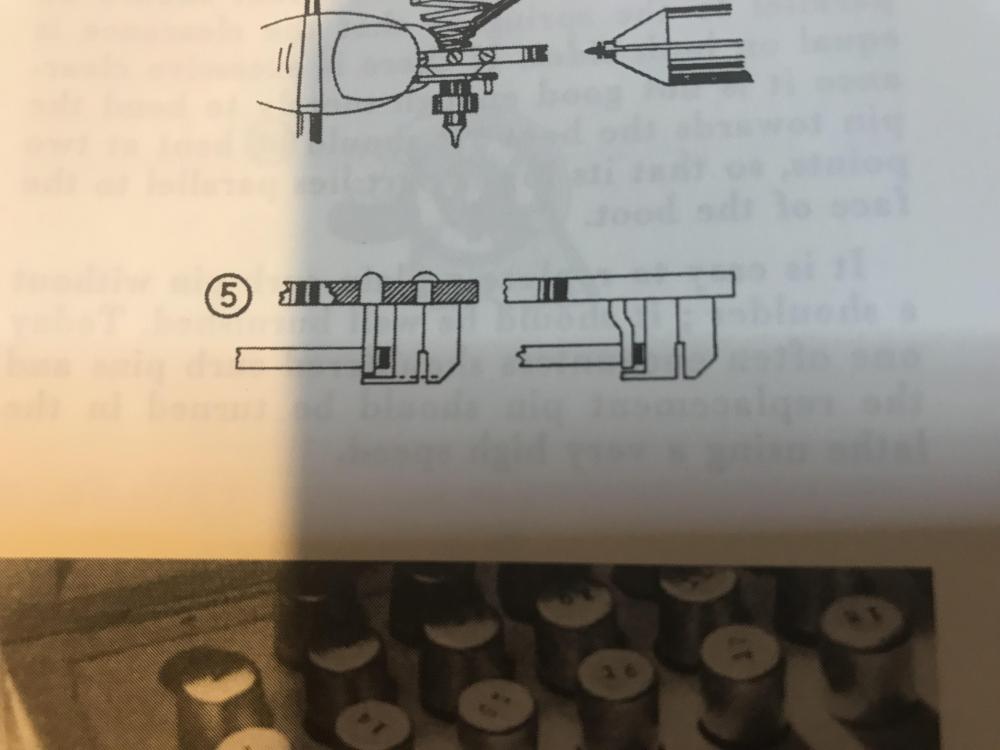

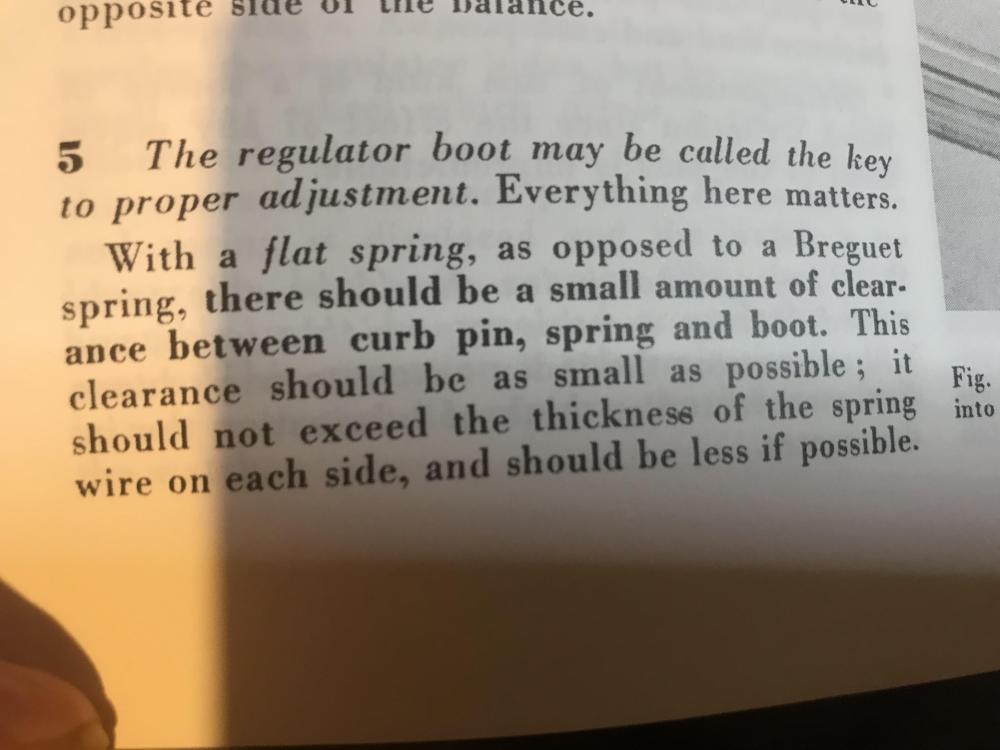

-

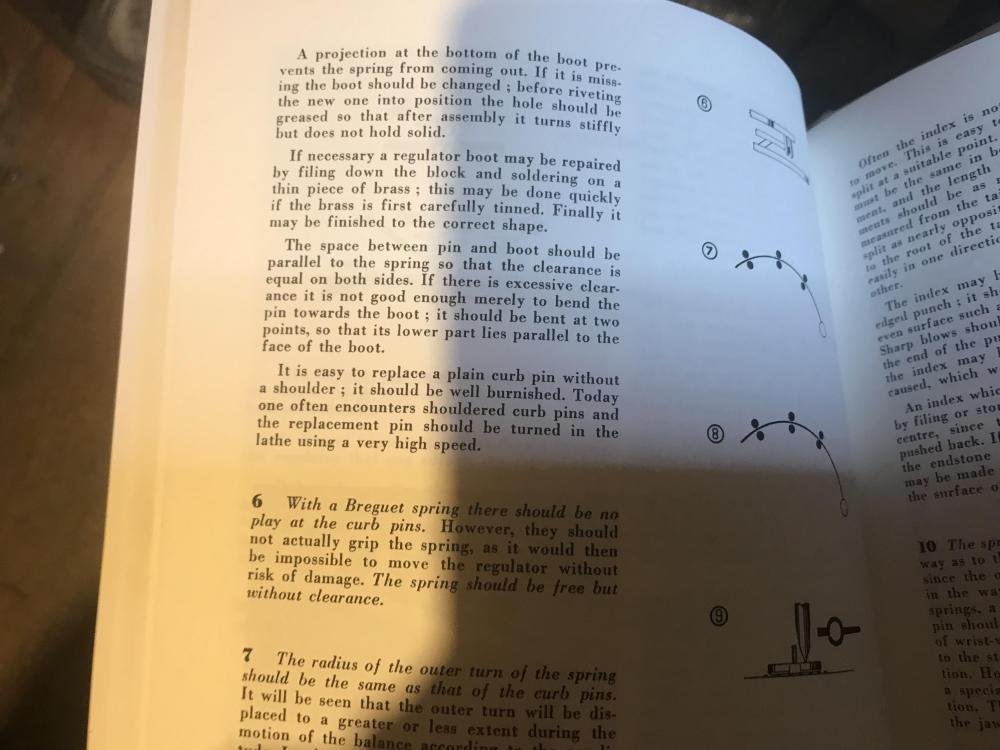

Punching out the staff always has that chance of deforming the hole, widening the hole. Using a Platax is just a safer way of punching out the staff, from what I understand of the tool it's more to do with not bending the balance arms, the hole is still at the same risk. Punching a tight fitting riveted piece of steel through a non steel hole....surely has consequences...maybe not first time but subsequent multiple times.3 points

-

As @nevenbekriev says, the arbor endshake only affects how tight the winding feels. In fact, the barrel arbor doesn't even move when the movement is running.3 points

-

Oh no, theory tsunami happening here... Here's what I know and have measured: The lift angle of 48° is not a Hamilton factory suggestion, but rather an anecdotal number from this thread - so 48 might have been the angle measured one time on one watch (whose banking pins may have been moved, remember these American watches mount banking pins on eccentric screws for too-easy adjustment) So I have been measuring at 48° all along, and previous checks of the balance at 180 were close enough that I didn't try to dial it in further. Until just now. I took all the wind out of it and brought it up until the 2 arm balance was landing in the same spot on both swings and adjusted lift angle until I had 180. That angle is 45°. I didn't do this precise a measurement before moving the banking pins, so either the LA went down 3° after moving them, or the original 48 number was a guideline that may not have been exactly right on this particular watch to begin with. With slow -motion video and laying a protractor over my phone to measure the angle beyond 180 per swing, I am seeing about 240° - so less than 255 as I suspected, and pretty consistent with the difference between measuring with LA at 48 vs lower at 45. And the tg calls this 235. If someone else wants to do the science and move their banking pins around to test amplitudes, you are welcome to. I am not messing with this one any further.2 points

-

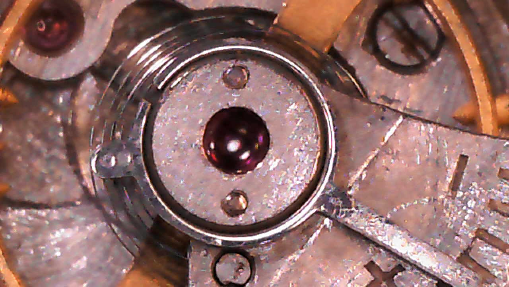

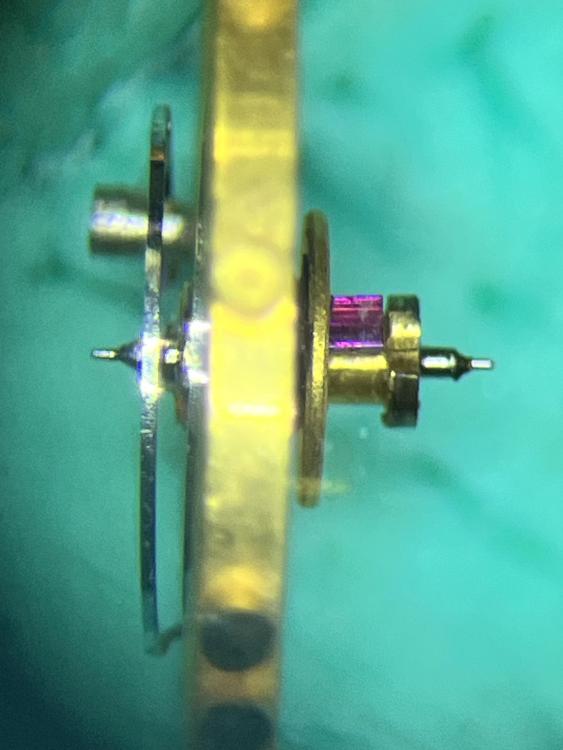

My 2ct: pictures are too blurred to judge the condition of the pivots. But both don‘t look good at all (worn). The upper, right, looks tapered in 2nd pic (very bad). The lower pivot looks slightly bent, if true will put the balance out of poise. With such issues I would change the staff. The hairspring seems not belonging to this watch: its collet was forced open unduely. Consequently all weight screws had to be filed down excessively. I agree, it is not much fun working on such a botchered watch. Frank2 points

-

Maybe 0.3 is already a bit too much. I would drill 0.2 or what the diameter of the old pin is. Put in a tapered pin for hairsprings, tap till tight and cut to length, polish the head. Frank2 points

-

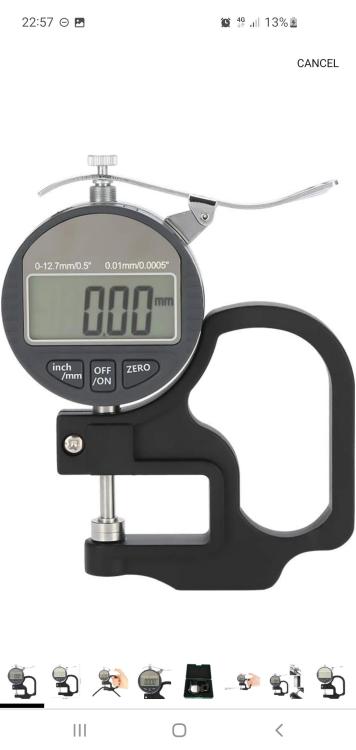

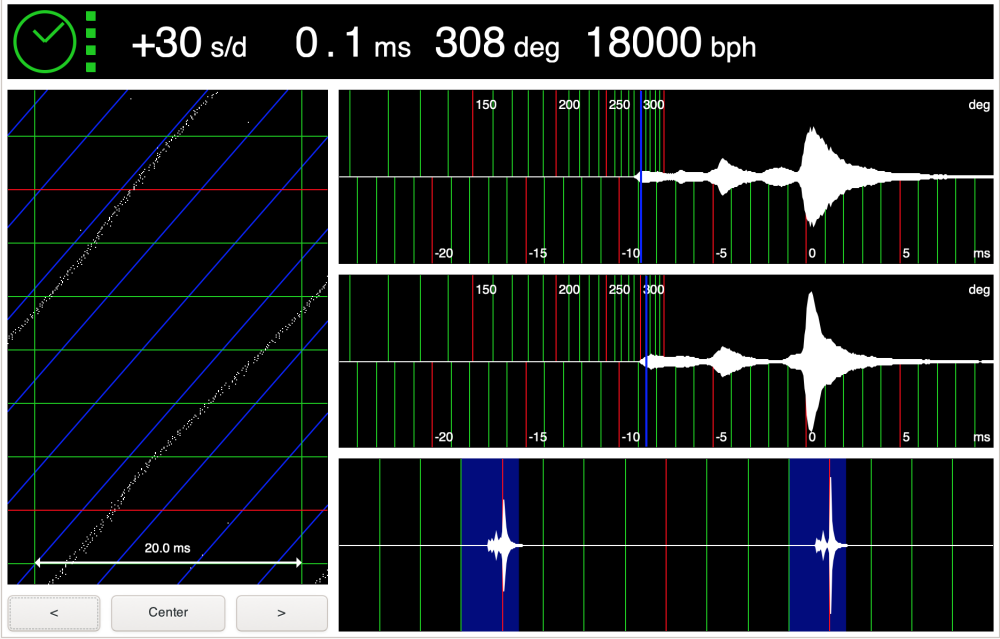

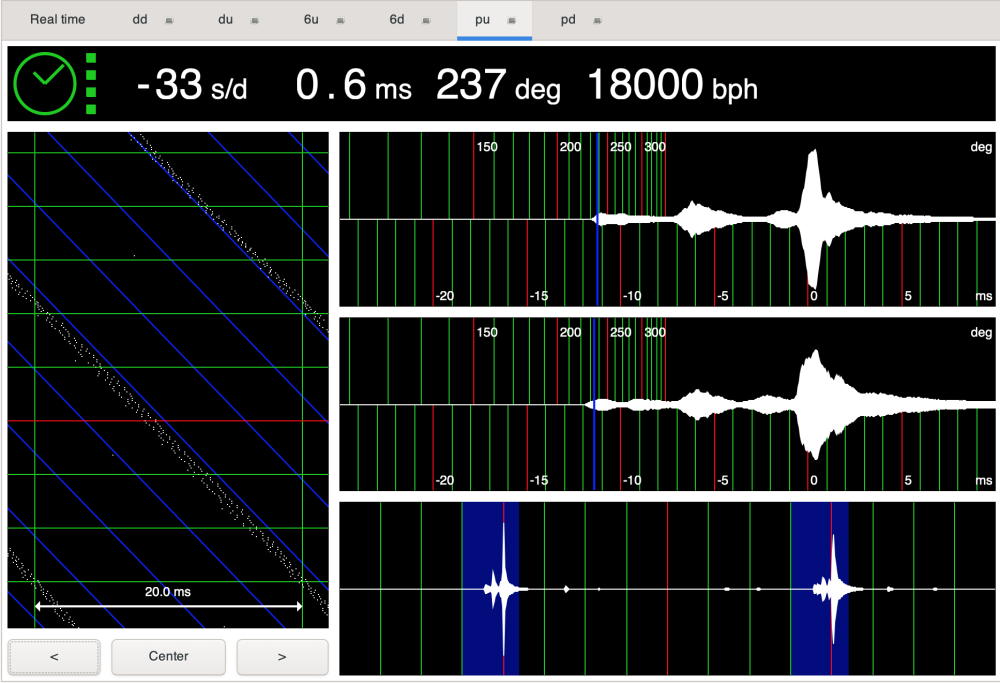

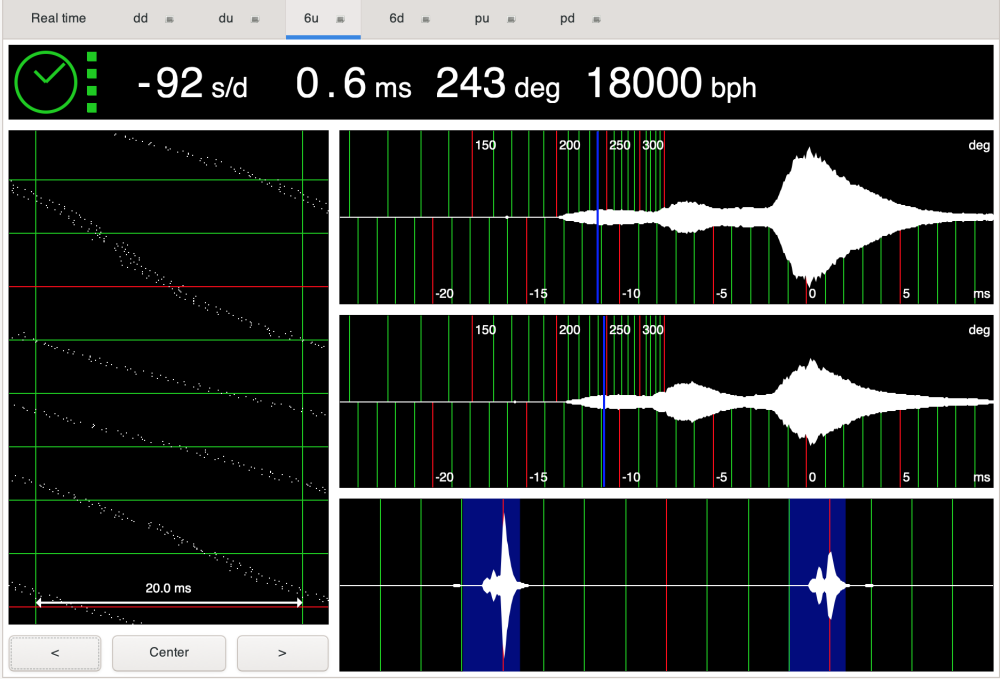

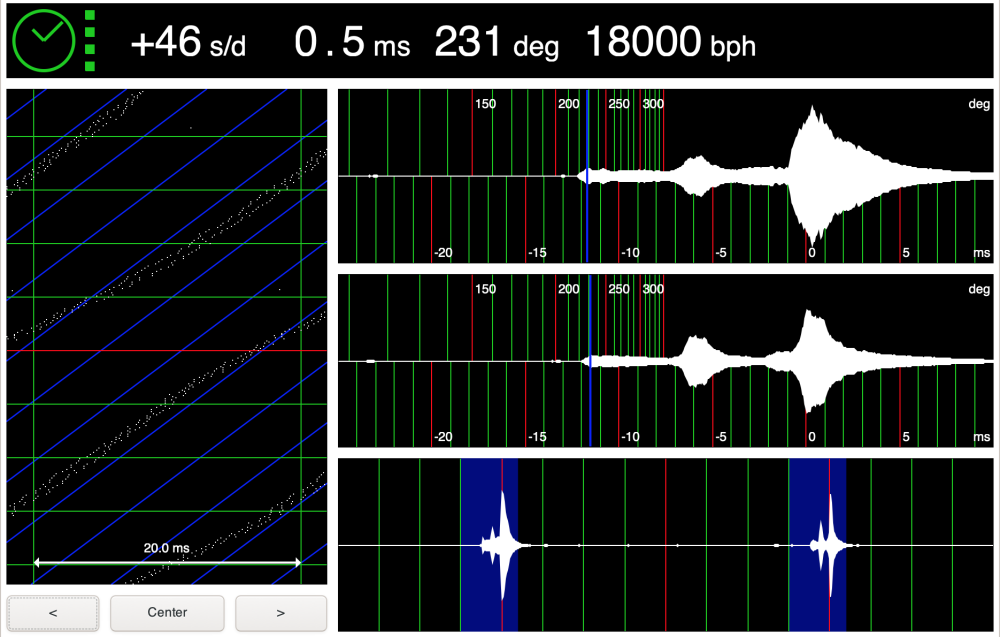

The "urgh" is a comment about the graph. A straight line shows a watch that is running at a constant rate. In the roughly two minutes shown on the graph the rate varies between about -80 and -10 seconds per day. That too is to be expected even for a perfectly working Rolex movement. Yes, but not like this, I think. I've got more than two minutes a day difference from different vertical positions. Some explanation of the images below: Top line: stats. Should be self-explanatory. I have lift angle set to 42 degrees for these. Left panel: graph of watch rate. Red horizontal lines are a minute apart; green horizontal lines are 10s apart. A healthy watch running at a constant rate produces a straight line here. A non-zero beat error produces a pair of parallel lines. The blue oblique lines have an angle that matches the rate shown in the top line (which is averaged over several seconds). These disappear if we're more than about 70 seconds fast or slow. The trace tracks down the screen in much the same way as if it was printing on paper tape so the most recent measurement is always at the top. Right panel: traces of the sounds picked up from the microphone: tic, toc and both. The last sound, when the lever strikes the banking pin, is set to zero on the upper two graphs so that the amplitude can be read off the scale to the left from the start of the first sound (when the impulse jewel contacts the fork). The third graph shows the full period, tic and toc, with the regions shown in the graphs above shaded in blue. This is particularly useful when running with less than about 100 degrees amplitude when the software will treat the second sound (unlocking?) as the first and give inflated amplitude values that must be ignored. As well as the numbers in the top line I'm mostly looking here at the graph on the left to see how steady the rate is. I showed the pendant down results above; here are the other five positions. These were recorded about 8 hours after a full wind. DU - not straight but not awful: DD - a bit faster but still pretty straight: Pendant Up - more than a minute slower than dial down, but still nice straight traces: 6 Up (or whatever we call this) - this is troubling, not just because it's around two minutes a day slower than the horizontal positions, but it's also irregular, fluctuating between about -110 and -60: 6 Down: Yes, I'll do that. I was holding off because the dial has a foot missing and I'm waiting for some low temperature solder I've ordered to arrive before I attempt a repair, but I have another (uglier) dial it can use, so I've put that and the hands on, found an 18mm band and will wear it for a bit and see what happens. I've got nothing to lose! Perhaps. It does appear smaller in the photo, but it's hard to be sure because the focus is poor and the lighting is different on the two sides. But if the pivot were really smaller than it should be I would expect that to be evident in excessive balance side shake. When I checked balance side and end shake, side shake was negligible (as in I couldn't see/feel any) and end shake was just enough that I wasn't concerned.2 points

-

2 points

-

Tbph Andy I'm not entirely sure, I've never really given it any thought as they don't cause me issues. The ones I use now are still mostly the cheap ones I bought about 5 years ago. The tips don't seem to magnetism, I dont ever remember having to demagnetise them. I do have almost a full set of bergeon aquired in tool joblots here and there and also 3 sets of old swiss/french drivers but I rarely use anything but the cheap ones. The tweezers I am more picky about.2 points

-

Steel screwdrivers have been the goto and norm for so long without major issues as long as they are regularly maintained including demagnetise. I think there are some beryllium bronze versions kicking about now for a suitably extortionate fee which could be worth a try but I would expect them to need extra dressing and maybe wear out quicker. I am sure I have seen recommendations from some of the professionals here that you can repurpose old twist drill shanks as screwdriver bits too. Tom2 points

-

D'oh. Silly me. Yes of course it does. I was tired and I'd had some nice wine2 points

-

What equipment You think You need? You are able to register the rate and it's differences in vertical, then You have all needed. We need to see if the pivots are not bent and also picture of the hairspring from above first, also You can check this balance in another 2602 movement to be sure, but be brave and go ahead2 points

-

Good morning! My next walk-through. This time of an Universal Geneve 2-66 calibre in a "White Shadow" watch. With less than 2.5mm thickness, the movement was one of the thinnest automatic movements at its introduction in 1966 and for decades to come. Some say it was the thinnest of all, but I found the Piaget 12P was 2.3mm and introduced in 1960. That would make the Universal 66 the second-thinnest automatic movement unitl 1985 when the Frederic Piquet 71 came in with 2.4mm. ANYWAY, it's very thin! Another cool story is that no other than Patek Philippe poaches the movement engineer of Universal and let him basically copy the UG 66. They then introduced the Patek calibre 240 in 1977. They looks strikingly alike. Apparently, Universal sued Patek, but settled out of court and then went bankrupt during the quartz crisis. (see my post here for a picture comparison of the UG and the Patek: https://www.watchrepairtalk.com/topic/3470-which-watch-have-you-got-coming-in-the-mail-show-us/?do=findComment&comment=270754 ) As usual, I'll share the walk-through in several posts. Today: disassembly. Hands and dial off reveals the keyless works (two dial screws) Note: the dial washer doesn't fit too well. I'll look for another one for assembly. NOTE on letting the power down! The power is held by TWO clicks. One directly at the ratchet wheel (dial side) and one in the automatic works. I first completely removed the click at the ratchet wheel and then held back the click of the automatic works. It worked ok, BUT is not ideal. It lets the rotor spin to release the power in that direction (instead of the crown). I therefore suggest to first remove the automatic works completely (rotor, wheels and click). THEN proceed as usual by holding back the ratchet click and releasing power gently by holding/slipping the crown. To show the (supposed) better practice, I'll post my pictures in a different order from my actual disassembly. This is how I think it SHOULD be done (in retrospect), 0. Remove the balance 1. Automatic works: remove the rotor The automatic bridge (please ignore that the barrel bridge is already off and don't remove it before releasing the power!) VERY gently with this spring on the click! It's insanely thin. The end of the spring rests in a small hole in the mainplate. I'll show that in my pictures for assembly. Note that the wig-wag winding wheels for the rotor can stay in place. They are riveted to the movement. A total of three ball bearings here! Two are visible, and the backside of it (that wigs and wags) also has a ball bearing. The rotor also has one. So four ball bearings in the movement!! 2. Turn movement over and release the power with the usual method (hold back click and gently let the crown slip through your fingers) The click is here: Then disassembly the click I also took the hour wheel of (no picture, but obvious). NOW, IMPORTANT. The apparent cannon pinion here, is not a real cannon pinion!! It should be completely free. The movement doesn't have a central centre wheel and therefore the "true cannon pinion" also isn't in the centre of the movement. This "false cannon pinion" is just a reduction wheel for the minute hand. DO NOT have the stupid idea of tightening this "false cannon pinion".... like I did ... But ok, onwards. 3. After letting the power down, I go back to the train side. Note on pallet fork: the lock is very heavy. If amplitude turns out to be very low after service, I may have to push the pallets in a bit. Note that there a two different screws for the train bridge!! The one on the edge is a bit shorter. Barrel bridge. Again, note that there are two different screws! The one at the crown is longer. Now, the larger wheel next to the barrel is the decentralized centre wheel with cannon pinion. I will show how to disassemble it in a later post. The ratchet wheel is under the barrel 4. Dial side cover plate Watch out, under this wheel is basically the crown wheel. There's an outer crown and also a seat around the post. the downwards bent side goes down on the setting lever careful, very strong spring here this lever engages and disengages the integrated wheel directly with the ratchet wheel for manual winding Now again very careful with the spring under the lever! It is very thin and very springy. I actually lost it and couldn't find it even after 1.5h on the floor... and since I managed to buy one, there are now only very few left in the world! finally the stem with the pinions removing lower balance jewel for cleaning barrel open. NOTE that the square bit of the barrel arbor points up from this perspective (not pictured). This is important to remember for assembly. This concludes today's post of disassembly. Next post will show the disassembly of the integrated decentralized centre wheel and true cannon pinion -- and tightening it (because it was slipping).1 point

-

Much better library than mine, now where do I pick up my library card? Tom1 point

-

A heavier mainspring just showed up in the mail, so I guess I'm not done...1 point

-

1 point

-

@mbwatch personally I think you have done rather well on this watch. but you do know us unruly lot by now, if there’s a rabbit hole to go down, we’ll find it. Tom p.s. Especially me and Rich1 point

-

For Jendritski I have “the watch repairers manual “ and “the watchmaker and his lathe” also have Fried “the watch repairer’s manual “ and “bench practices for watch repairers “ probably much the same as you Rich. Tom1 point

-

There seems to be a bit of different thinking about some of Frieds stuff. I certainly don’t know enough to call any of his work into question. I think the dog leg part of it is somewhat like regulator pins, if you do bend them then the working edge still needs to be parallel, which would make sense. I would love if the German company who reprinted some of Jendritski’s stuff would do his adjustments book, it seems fascinating to me. I think I am a bit like @VWatchie , I will try to get the absolute maximum possible performance out of something and tear my beard out trying! Tom1 point

-

My bit so far is Jendritski says they can be moved but pretty much as a last resort and that they should be upright and straight. For the ultimate I suppose you need to find a copy of Jendritski’s adjustment book or trawl through either Daniel’s watchmaking or the textbook the theory of Horology. Tom1 point

-

Makes you wonder how close listed lift angles actually are compared to movements that have had adjustments made to the escapements before they left a factory ? More than me Tom ? Thats going to make for some interesting discussions, oh whats that !.... John saying he is going on holiday for two weeks starting tomorrow and not taking his phone or having any access to the Internet while he's away1 point

-

I’m around that bit in Jendritskis book right now so I might be able to add more confusion tomorrow Tom1 point

-

Thank you very much, Tom. That is very helpful. Thank you, Frank. I couldn't reliably measure the old pin diameter but as I implied this is really an exercise in learning the theory & also practicing working on such miniscule parts. A propos the latter, I'll try tapering the pin into a smaller inner hole but my understanding is that the top of the pin is often folded over to lie something like the spring's thickness above the near part of the boot. In what cases can the pin just be "cut to length" if, by that, you mean the height of the boot?1 point

-

So are you suggesting that by moving the banking pin you change the lift angle which then changes the amplitude and the reality is nothing is actually changed at all other than the lift angle? Which then resulted in a apparent amplitude change that doesn't really exist?1 point

-

Any small gauge copper wire. Like you might see used in a car or motorcycle. It doesn't have to be thick. I think I just took a strand from a random wire I had. I will try to find a photo if I still have one.1 point

-

I did check it last night visually at 180 and it was still consistent at 48° but now you mention it, I was not feeling confident it was running as high as 255 because it looked more like around 240. And a change to the banking could be responsible. I didn't verify where 180 landed exactly but I will do that. Realize I have to think through which way it would go; I narrowed the banking so would the LA might get smaller. But even if the measurement is inaccurate, the balance is oscillating much more vigorously than before the banking adjustment.1 point

-

I would look at the beat error, it’s way too high. If the beat is way out it can cause a watch to not start or just stop. Tom1 point

-

As far as I remember my set cost me around £15 back in the 70's on an apprenticeship that was nearly 2 weeks wages. I can remember a basic watch clean £2. 10 shillings. No wonder I'm poor, so if you would all like to donate to my benevolent found I would be more then happy.1 point

-

Sorry to barge into your thread with my ignorance, but does altering the banking pins change the lift angle significantly? In my mind it should, but if we're talking hundredths of a mm then maybe it doesn't matter in most cases. Edit: I ask because I wonder if the timegrapher needs to be adjusted to account for changes in the lift angle.1 point

-

1 point

-

Hi. I believe that cousins at one time supplied pinsreads for insertion. Have a look through their catalogue. The distance is critical as in the fact that the spring beats between the boot and the pin so the larger the gap the longer the travel. This would have an effect on on the rate.1 point

-

Hi. I have both and use them equally, first sign of screws sticking they get demagnetise treatment. The older ones mainly on clocks.1 point

-

@GPrideaux it might just be the photo (or me) is the upper balance pivot worn? It looks smaller in diameter to me and not polished and smooth. Most I have poked around the pivots have been the same diameter both ends and, at least to me, these look different. Tom1 point

-

1 point

-

Looking at the numbers (I don't understand the graphs) I don't get what is "Urgh"!? So the fastest rate dial-up is about +20 seconds and the slowest rate in the pendant down position is about -20 seconds, right? So that makes a delta of about 40 seconds. I'd say that's not too excessive, perhaps even what should be expected, or there about? That too is to be expected even for a perfectly working Rolex movement. Despite the Breguet hairspring, when the power reserve is almost completely depleted, all bets are off. However, with a good number of hours remaining in the mainspring, then yes, that seems excessive! As hard as it may be, that is sometimes the best thing you can do. Let your subconscious mind process the problem and before you know it your conscious mind will serve up a solution or something new to try out. Watch repairing should be enjoyable. Never let it bog you down. And, since you have another 2602, it might let you discover some differences that could help you with your current 2602. Can I be so bold as to suggest that you wear the watch for a week or two (while working on the other 2602) to see how it actually fares? That is, wind it fully every morning, wear it during the day and then, if you prefer, let it rest on its back during the night. That would be very interesting! Perhaps it would prove to be a reliable timekeeper!?1 point

-

Hello thank you for taking the time to read my introduction. I have been working on watches for the past couple of years. I’ve always been interested in watches but never thought I would venture into watch repair. I got started in the hobby out of frustration with work that was done on my Longines 12.68N watch. A watch that was given to me by my father. Paid a lot for a service that never happened. Long story short, I put the watch away, spent a year studying and reading anything to do with watch making. I also began to invest in proper watch repair tools. I Purchased a lot of cheap movements and began the journey of watch repair. A year ago I serviced my longines and it is happily back in my collection. I’m really enjoying this hobby and look forward to being a part of this group.1 point

-

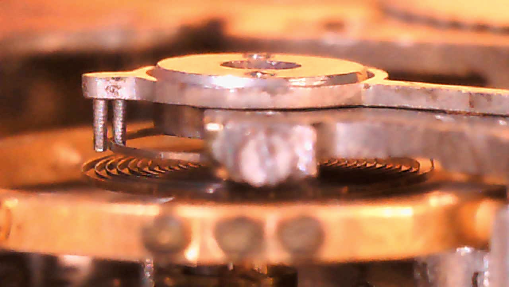

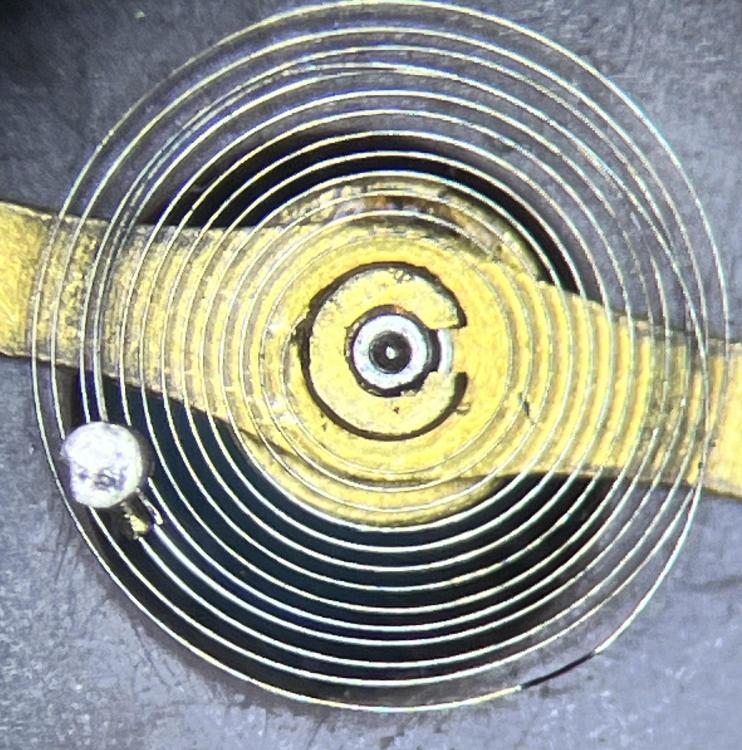

I appreciate the feedback and encouragement. I think what I most lack is knowledge and experience. I've seen a video or two at some point of someone using a Poising Tool, which I don't possess, but principally I think I need to read more about dealing with positional error. I'm not giving up on it, though, and while you're willing to keep offering help and encouragement (nudging) I'll keep going. I'm just not going to let it keep taking all my attention as it has the past few days. I'll post some images of the balance and spring shortly. Here's the balance spring from above, in motion in the running watch (with not much wind in the mainspring, hence the low amplitude). Here's a static image with no power in the train: A view from the side: The imagery above is using my digital microscope. The ones below are iphone through the eyepiece of my stereo microscope. With the balance removed, a top view: Not perfectly concentric in places, but I wouldn't have thought that would be bad enough to explain what I'm seeing. Pivots: (The black ends on timing screws are where most of them have had their tops filed off at some stage.) The pivots look ok to be, but ... am I imagining it? The impulse jewel doesn't look quite straight. It's not loose, though ... I touch it gently with tweezers and it doesn't move. And I think that's a crack in the safety roller. The focus isn't great (I need to learn to take better pics with the microscope) but that's definitely a crack.1 point

-

As WW says, without abusing them they will last you a long time, the smaller sizes would wear out sooner but these tend not to be used so much anyway. And the big ones will be passed down a generation or two unless you get heavily into clock repair. You won't need to think about this again for 10 years.1 point

-

Thats just the drive wheel for the sweep pinion The caliber is also listed as a moon phase triple calendar1 point

-

As Hector said, the arbor end shake in the plate/bridge will not affect the running of the movement. It is important that the arbor will stay upright so the barrel will be not tilted and stay on correct distance as to ensure right mesh of the barrel with the pinion of the 2nd wheel, so wear of the holes in the plate and bridge is something bad, but not because of the friction. The arbor rotates only when winding.1 point

-

So from what you've said it would appear you haven't got a pierce 103 so photos of the movement may help confirm this. You need to be using at least a pair of digital calipers to get some sort of accuracy.1 point

-

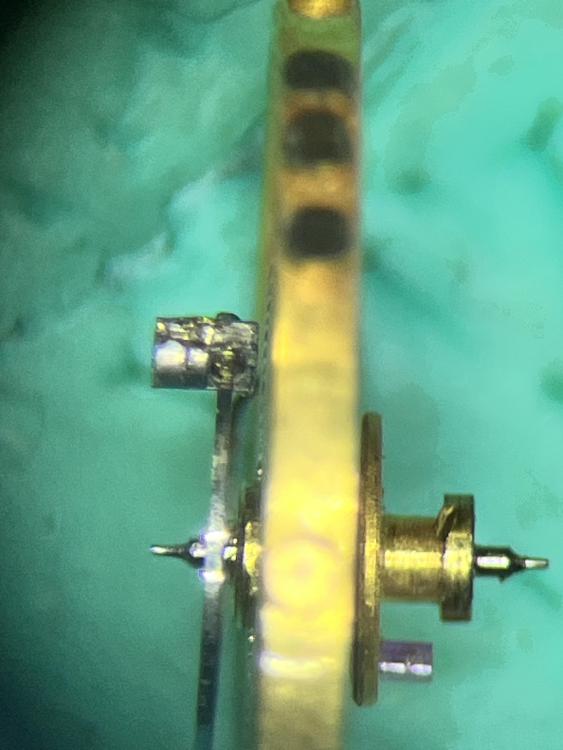

0.1mm per division is far too inaccurate for watchmaking. You'd at least need a 0,01 accuracy. A feintaster would be nice, but they are often very expensive. A thickness gauge (analogue or digital) with a 0,01 accuracy is a low cost alternative. You could use a screw type micrometer as well, but care should be taken not to damage your part.1 point

-

Hi. Looked after carefully they will last you years, I have some screwdrivers ( no replaceable blades) with solid blades, back then. No fancy sets you just bought the sizes you wanted. One or two suppliers I think put sets together maybe five, seven drivers of recommended drivers. The suppliers I used then are long gone . A .G Thomas Bradford still exist though.1 point

-

Not that post you've added here H, you questioned something very similar regarding very short rate fluctuations about a year or so ago. The final opinion was mainspring power fluctuations, I'm sure John had a lot to say about it. I'll try find it. I tbought the same Nev until Andy corrected me. Might that be a 6 or 8 leaf pinion possibly resulting in a six minute revolution ? Its quite easy to see the 5 minute repeating fluctuations. Found it ! https://www.watchrepairtalk.com/topic/28929-serviced-eta-2763-having-erratic-rate-and-amplitude/?do=findComment&comment=244717 This thread made interesting reading again. A fairly deep discussion of gearing power fluctuations. I take that to be the gradual meshing of teeth and pinion leaf interaction. The increase and decrease of friction as the modulus of teeth/leaf come together and then seperate. Better designed and manufactured teeth would have less friction so less fluctuations .1 point

-

Cheers Jon, There was a lot of swearing on the initial reassembly video - lol. But from 2 hours to 30mins to 15 mins, I'm hoping it's learning and not luck I haven't regulated it. It's a bit off on the timegrapher. I might need to strip, wash, reassemble and lube again. Then I'll look to collet work. although the eyeball view looks like it's positioned between the pins, just a case of how deviant. I've got a few of them so I need the practise... Such an interesting movement as you say, and most of these are powering on, albeit a little roughly. This was actually the second as I replaced the balance from a partial movement into the blue Omnta and that's working well. It will need servicing though. Thanks for your support - before and after!1 point

-

Test your coil with a multimeter it should read 3K ohms plus or minus 0.3 K ohms approx. If the tiny copper wire to the right hand pad as you look at the watch with the crown on the right is damaged then this might work. If it damaged on the left pad this won't work. Also try this if both wires to pad look good.....but only solder to right hand pad. Take a piece of wire and solder both ends. Now solder the wire to the main body of the coil wires and then hold other end on the right pad to achieve 3k ohms plus or minus 200 ohms with a multimeter. Some coils vary in resistance. Solder to the right hand pad but not to close to the end or the circuit board won't screw on properly. Hopefully you now have a working coil. If if doesn't work don't blame me at least you tried, maybe even try to resolder again and again until.....it works1 point

-

I have started printing things for my cleaning machine, and started with these basket inserts. They fit quite well, although I haven't tested the resistance to chemicals. These were printed in the standard filament that comes with the printer, as the filament I ordered is still on its way. I ended up printing many more of these so I can have a few disassembled movements ready in baskets while it's in use.1 point

-

Hi a little reading for you TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

1 point

-

One downside: Check where they are coming from if buying on eBay. Many are coming out of Ukraine. I'm still waiting for a Pobeda that I ordered using BUY IT NOW on 5/5 and which the seller delivered to ship on 5/7. The seller has a great history and did nothing wrong. I wasn't paying any attention to wear he was - I just liked the look of the watch and the price was irresistible.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)