Leaderboard

Popular Content

Showing content with the highest reputation on 01/16/25 in all areas

-

I put a piece of broken mainspring between the friction spring and pinion, then support the whole lot on a small stump and press the hand on with the staking tool. If you just support the spring, the pinion can make an indent in it. An extra arm and hand would be nice, but I hold the movement in the left hand, come down over the staking tool with it's back to the left, and situate the movement on the stump. I do put a little Scotch tape on the stump to avoid scratches.4 points

-

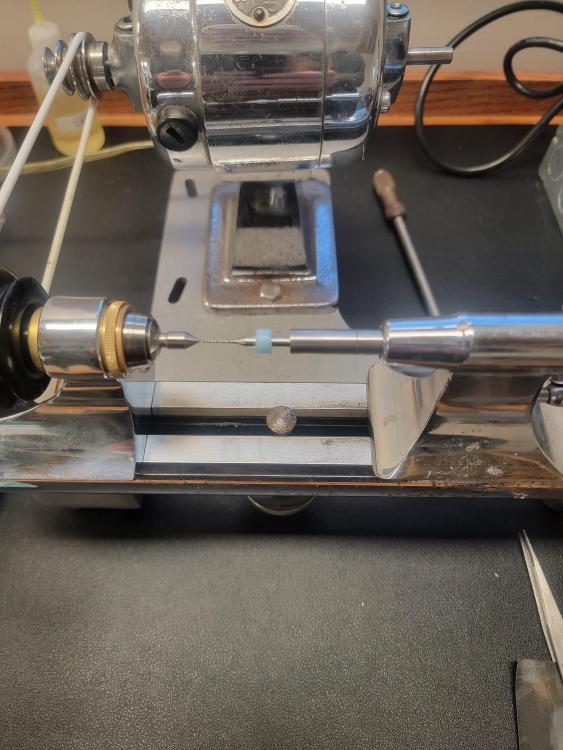

I got a new Sherline--not to replace my WW lathes--but to complement them. I wanted something that could handle bigger stock as well as have access to many inexpensive accessories. Had to make a mental leap from hand turning to cross slide turning. So far, I am having fun. My first project is a WW tailstock runner that supports a 1/8" carbide bit. The first attempt was a fail. I got too aggressive and removed too much material. My second attempt appears to be a success. I only needed to remove about 300 um from this 1144 steel rod. Then drill a near perfect 1/8" hole. I turned the rod between a 3-jaw chuck and a live center. I may follow up with a set screw to hold the bit. Stay tuned for other cool projects. Here is my Sherline setup3 points

-

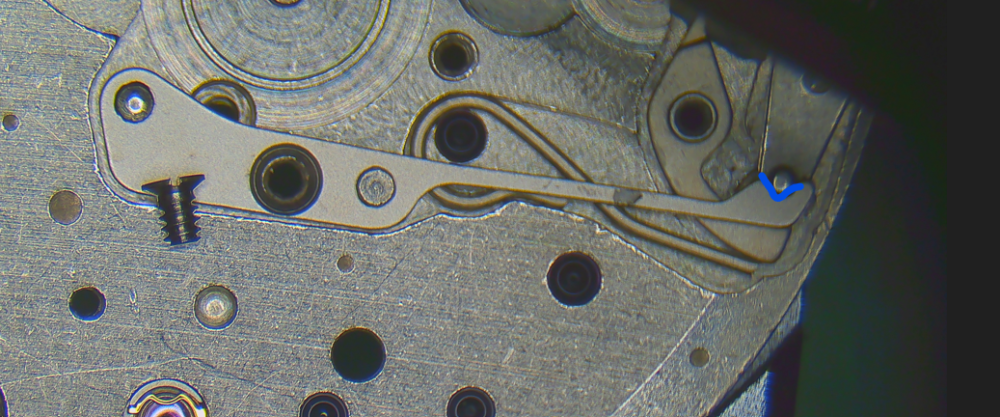

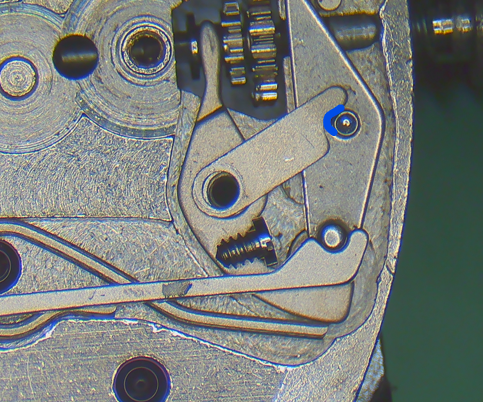

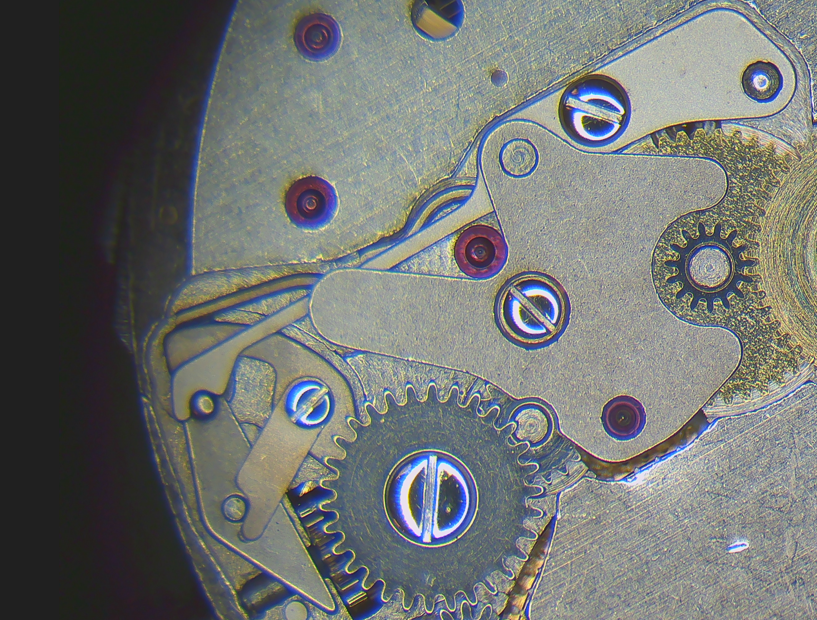

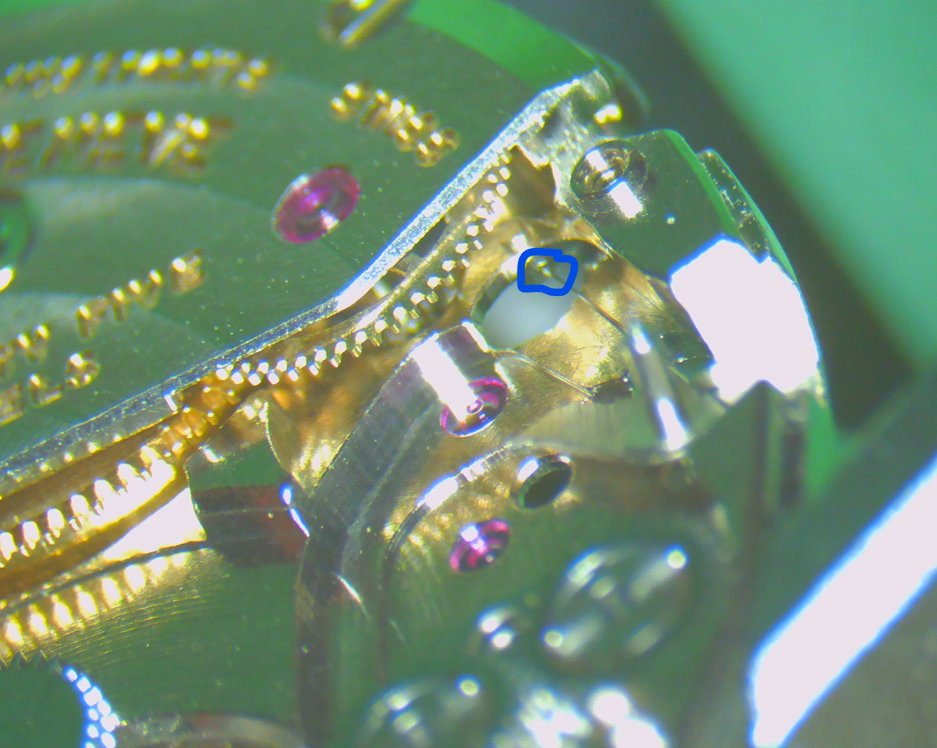

Well that was fiddly. Held some old mainspring in place with Rodico. Hand held the movement in the staking set over a small flat stump, and hoped for the best I need to do some tweaking with the spring as the seconds hand is juddery. I put a drop of 9010 on top of the pinion. I guess it would be better without? I hate these springs - It's one of the things I dislike about some Omega movements.3 points

-

Such a deep question. Is there any stopping, once started? These and other existential questions are only for you to know. I think you know what you are going to do, as you have put so much time and effort into breathing life into these watch movements I think it's about the achievement rather than the money, as long as that isn't silly money3 points

-

If you’re a hobbyist don’t focus on sunk costs. If you’re not a hobbyist…don’t focus on sunk costs … …sorry, a bit of economist humor if there is such a thing but really it all depends how much you’d like to see the watch in good order.3 points

-

I'd say that matches with what i was trying to explain Michael. Who knew you'd cause so much discussion and a compendium of rabbit warren holes to dive down. My resistance to comment with that had one of my right handed fingers poised over my phone keypad for almost ten minutes Tom. Buckets of sweat were pouring from my forehead, eventually my left hand intervened, took charge and just managed to reach the power off button of my phone. It was touch and go at one point and my WRT forum membership was in dire jeopardy, luckily I pulled through it ok and things are nearly back to normal with me......I say normal........poorrrnnnnnnnnn. Yes there Is something not quite right with me, the medication helps to a degree. Apparently if my doctor prescribes a high dosage there could be a real danger to me, a danger that I could end up acting like a mature responsible adult, that's just a risk I'm not prepared to take. Maybe when I'm older, just not right now ....you have my sincere apologies people . And if you if think I'm a crazy person...you should meet my daughter !!!3 points

-

@JohnR725 having spent most of my working life in IT I can understand what you mean about garbage in - garbage out (gigo). I can figure out what you’re trying to get across to us on here John, I just find it hilarious when the technology does things like in one of your posts above replacing “horn” with “porn”, not once but twice. i you think you have it bad with voice recognition, I’m Scottish! Thank you for all you do here Tom3 points

-

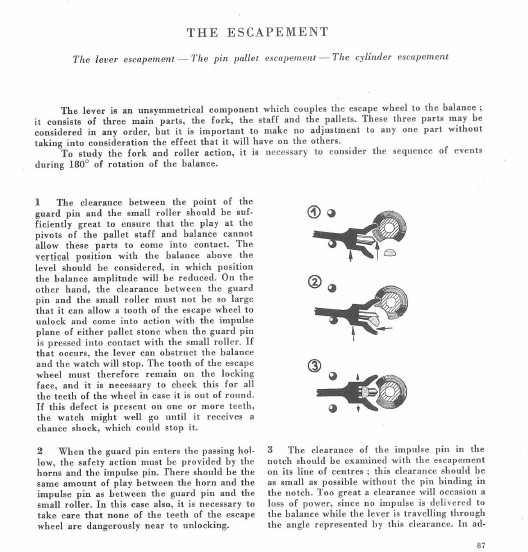

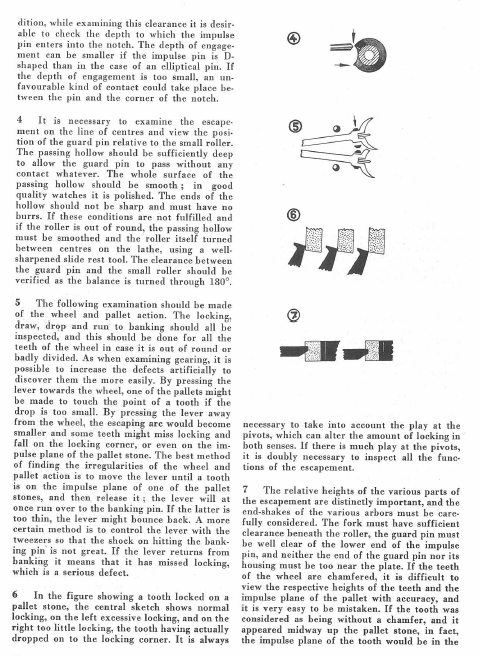

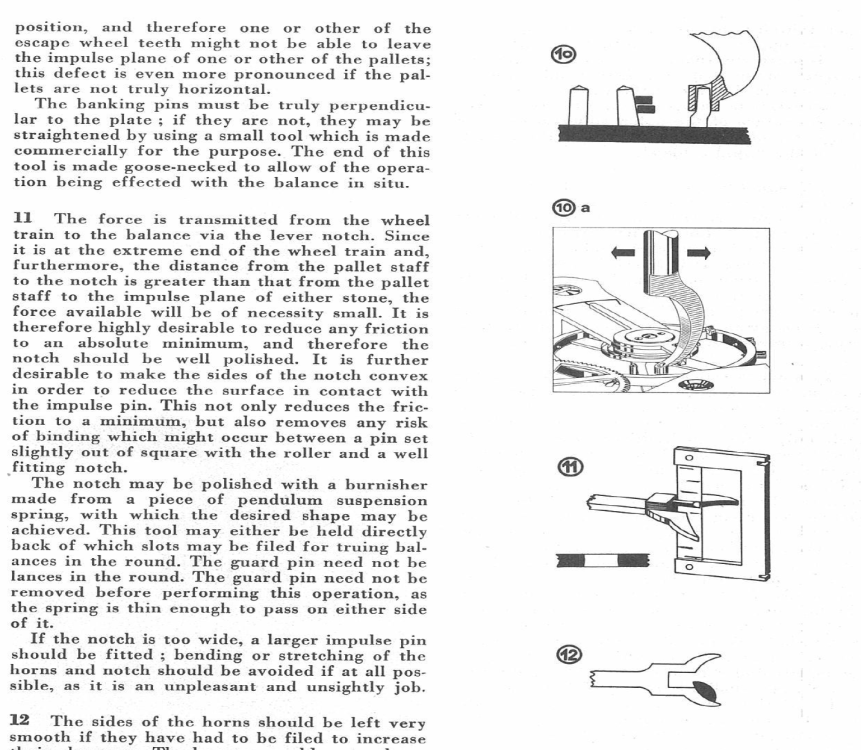

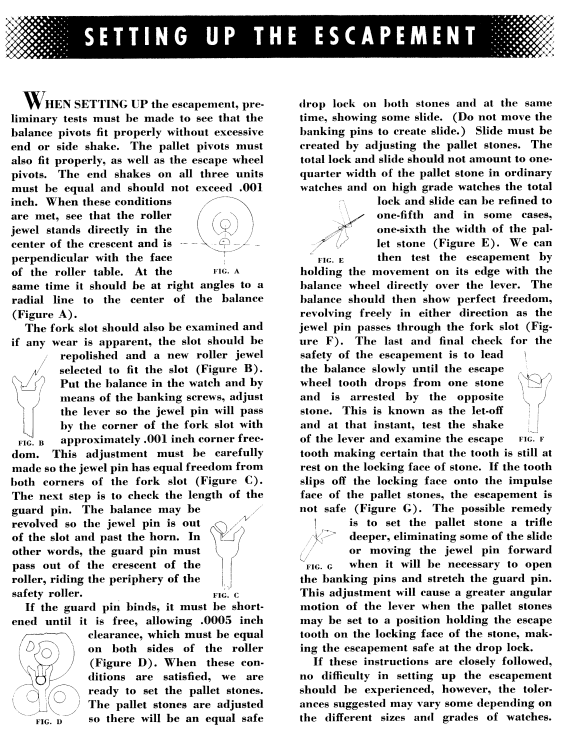

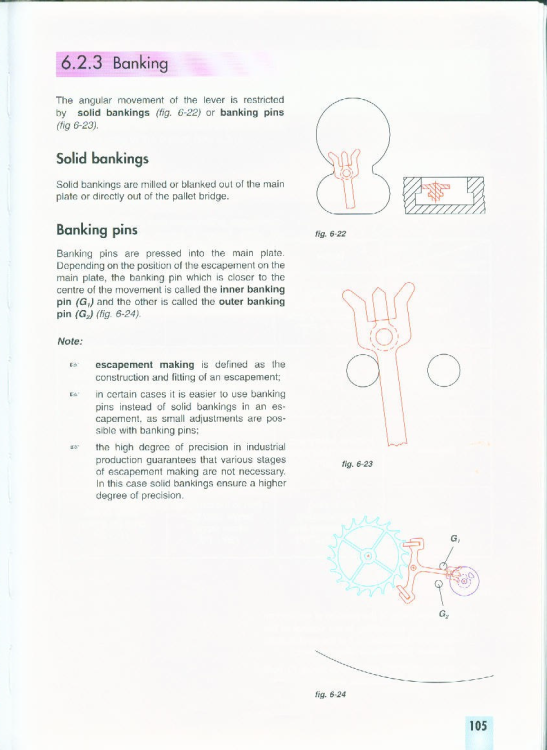

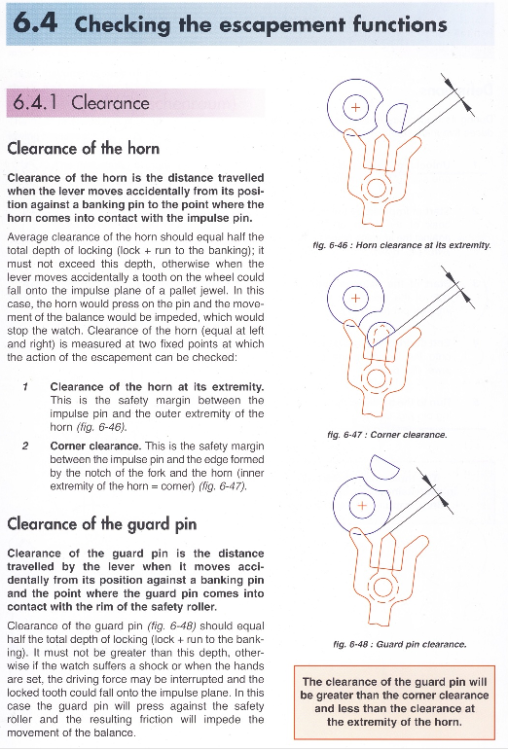

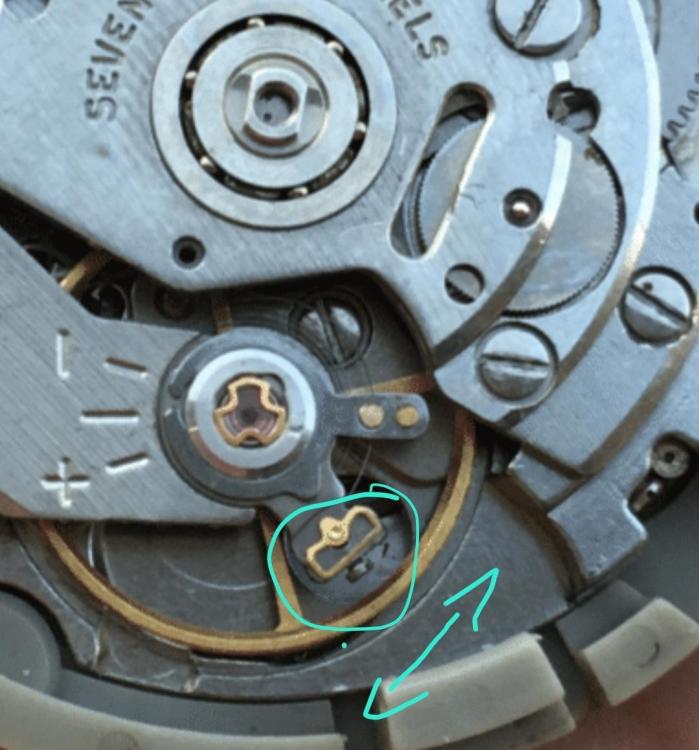

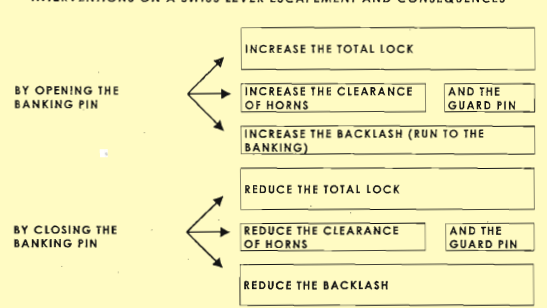

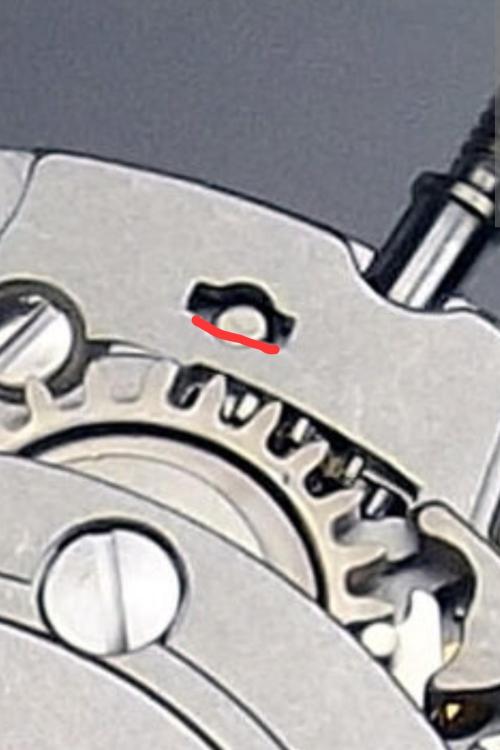

yes you thought it wouldn't hurt but I should be watching YouTube right now instead I'm looking at a book or two or three. fortunately one of the books is falling apart so I will scanned that farther down the meantime let's look at other things. I'm not sure you really want to know what I was thinking because? My asking a question about something I'd quoted gets the same thing that the person who asked the question gets ultimately we get a discussion and I may end up with a mild headache. which book? by the way he really sucks with indexes in his books let's start with the Swiss watch repair manual. isn't that nice his banking pins are not movable but don't worry the famous company that puts their tools in yellow boxes will sell you a tool for bending those so yes they can be bent to make adjustments. so in the image below and I'd have to go and look at another reference is basically it's saying that both the horn clearance the guard pin clearance is identical but another reference I have I think suggests one should be?okay and the other reference I look dad the guard pin clearance has to be equal to or less than the horn clearance. Then just a minor warning of every single reference you look at is going to have slightly different terminologies so he is going to have to deal with whatever terminology I use. It is the consequence of looking at different references over time. Then one of the references indicates the clearance on the gents watch should be no more than 0.04 mm and are going to measure that how exactly? So in other words the roller jewel has to pass really close to the Crescent to the safety roller but it must not touched. Then both sides are supposed to be equal this is where with the balance wheel removed you can look at the fork when it's pressing on either banking PN and look straight down at the balance jewel citing off the end of the four can just make sure both sides are equally spaced and if do not equally spaced definitely somebody's played with the banking pins. Usually if they play with the banking pins they do not get the escapement symmetrical they might build to do it but usually they don't and usually they don't play with the guard pin which is really nice. So yes on American pocket watches you should always check your horn clearance and get out your feeler gauge of zero point something millimeters let me know how you managed to get that in there so basically just get it as close as possible without touching and the watch of course has to run. continuing on to section 10 I really should airbrush out some offending text. Yes occasionally on vintage watches I've seen where people have modified the fork horns apparently it might be a sin the move the banking pins I guess? Plus other types of things it really shouldn't be done even if it is in the book although it doesn't actually say to grind the horns to oblivion either notice the reference to the pins can be straightened it doesn't say why they got bench in the first place? searching for something in the computer like the word escape but comes up with a lot of entries here's something from Elgin and the math I came up with 0.03 mm which is slightly better than whatever was listed up above from somewhere else. so basically the roller jewel has to pass as close as it can without touching. if you look at things like early watches pick on American pocket watches movable banking pins as they had to make adjustments. Then we end up with banking pins shoved the end with very little adjustments other than nifty tools for bending them. Finally ending up with machined slots no banking pins at all and you're not supposed to change that. to a certain degree there is amusement when looking at the various reference material. This is basically out of a more modern Swiss book that happens to be pink in color at least I assume that's for this came from because the artistic work looks like the same thing. It's amazing the things you accumulate with time in any case there is some minor specifications of what clearances should be based on other things. So the peculiar wording here is they're not used to dealing with movable banking pins that have been moved to need to go back to where there supposed to be. So basically adjust the banking pins from foreign clearance if you're lucky nobody touched the guard pin you don't have to play with that and then conceivably it might have to move the pallet stones although rumor has it that this particular watch that isn't going to happen because the pallet stones are friction in so material to read now I need to go look in the timing book see if it makes any references the banking pins at all because a baking pan isn't exactly part of the escapement sort of and that book is filled with all sorts of amusing theoretical things.3 points

-

The slots have been distorted by over tightening. You need a screwdriver with a head the same width as the slot. But as the slot is wide, you need to blunt the tip, so that it doesn't sit on the bottom of the slot. If it does it's likely to slip.3 points

-

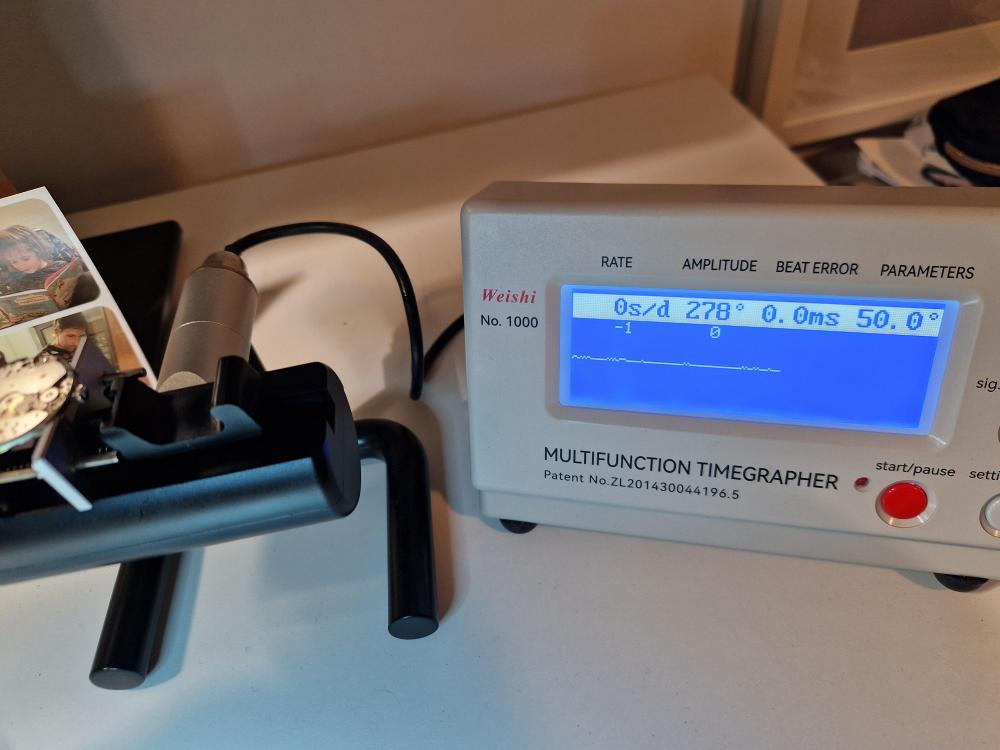

The high beat error can be responsible for the balance not starting up by itself. You should be able to adjust the beat error with the stud carrier here: When you get the beat error below 1.0,or better to below 0.3, it should start up by itself. If not, you have a different problem. This may indicate another problem. But first correct the beat error, wind fully (!), and check power reserve again. Best of luck, C2 points

-

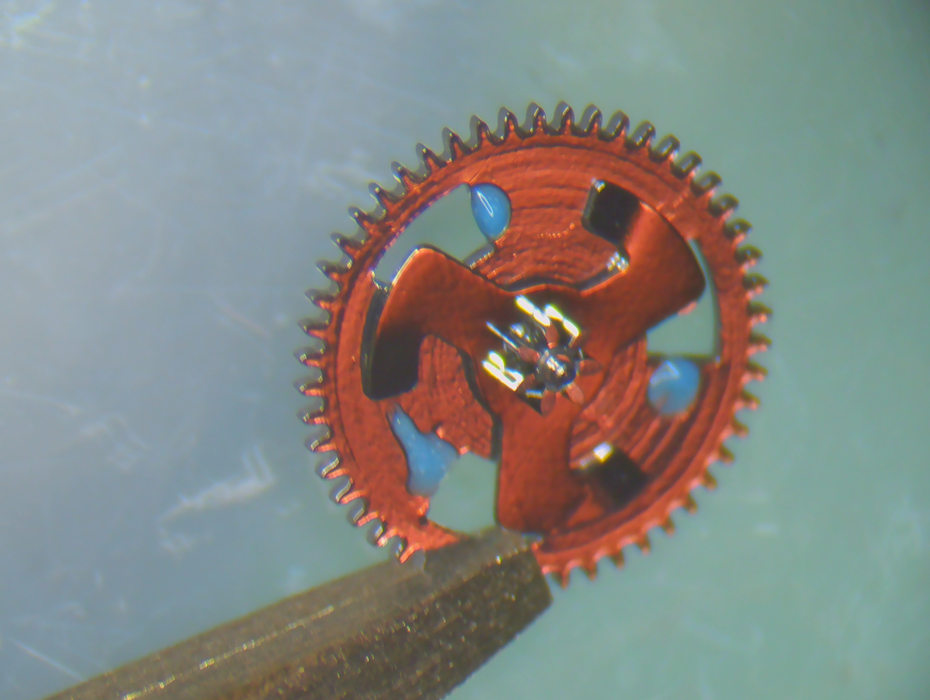

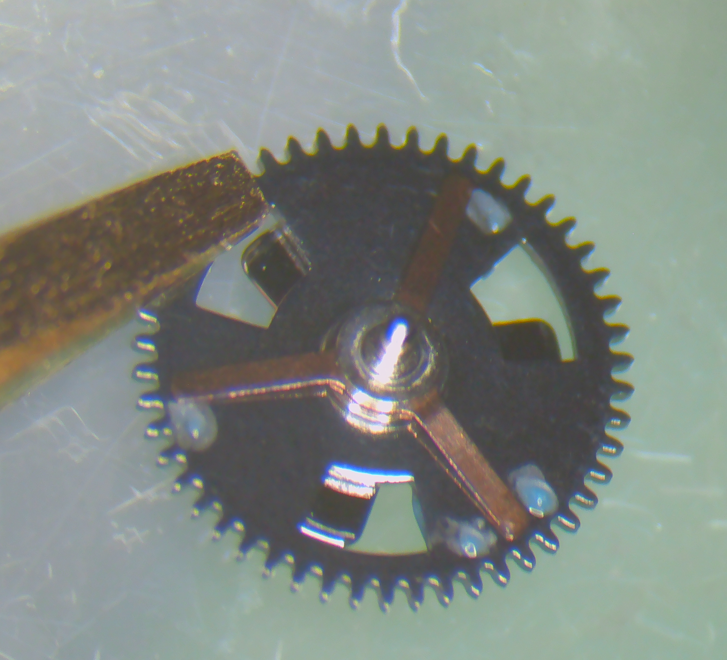

Ohh, I agree so much. Sorry, a bit off topic, but one day recently I felt like starting a thread with a rant against the Omega 55x (and some other series) which are sometimes hailed as the "greatest movements ever". I don't get it... Stupid tension spring, hardly serviceable reverser wheels, brass rotor bearings that are badly worn on pretty much every one I've seen so far (and to replace them properly, you need a specific reamer to get the bearing hole to fit the axle... otherwise they're too tight).2 points

-

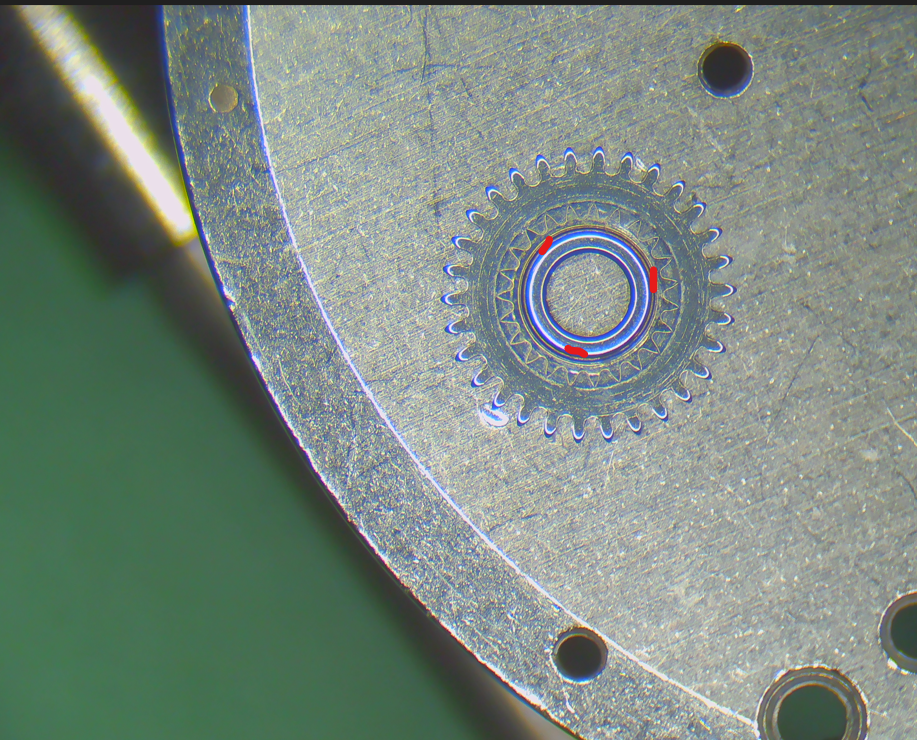

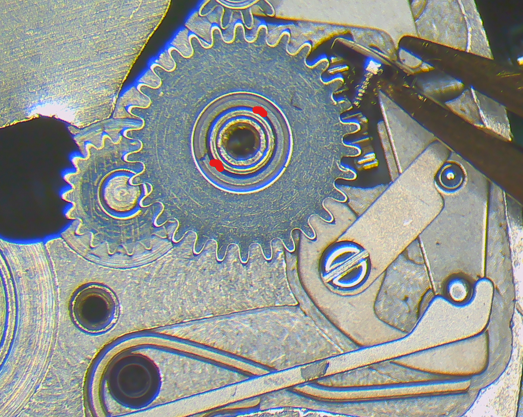

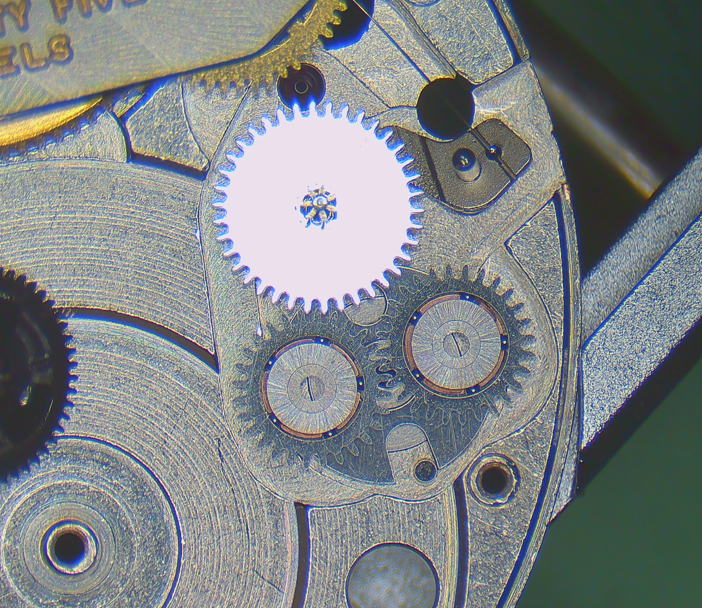

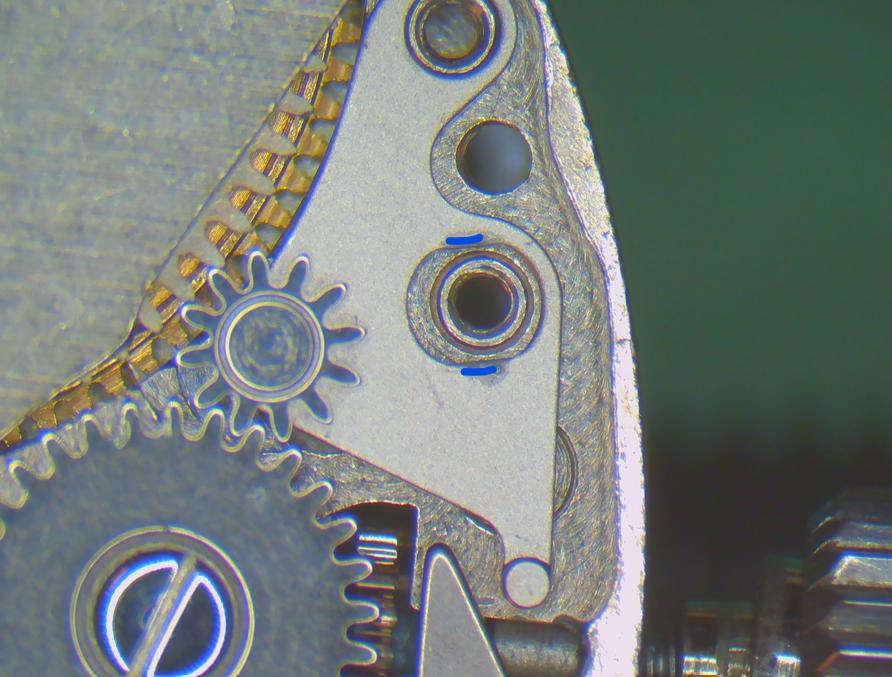

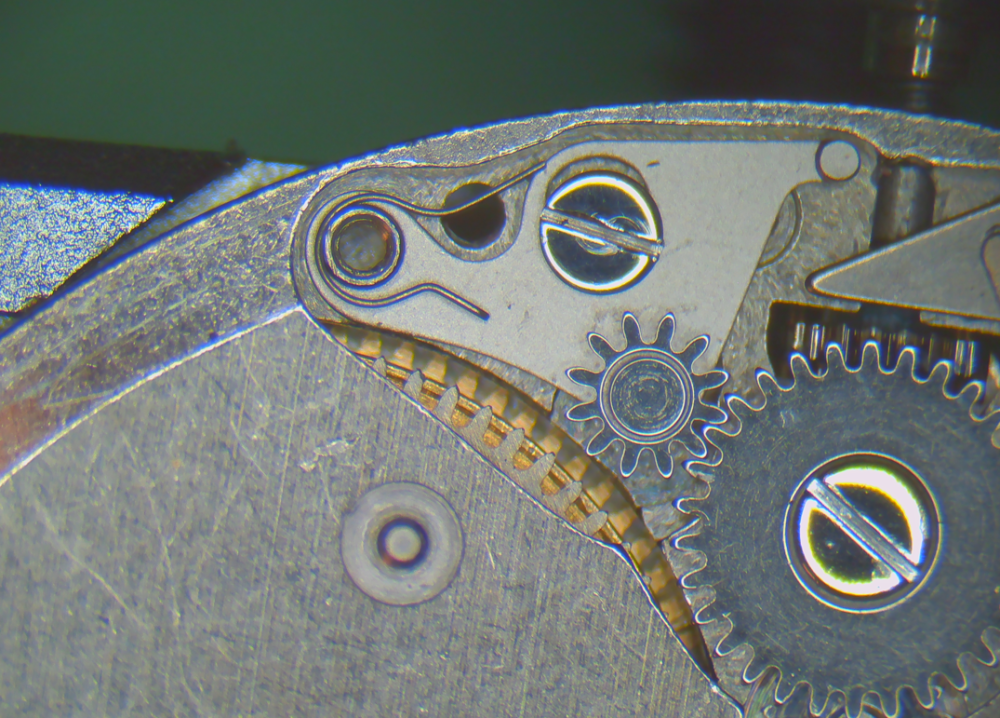

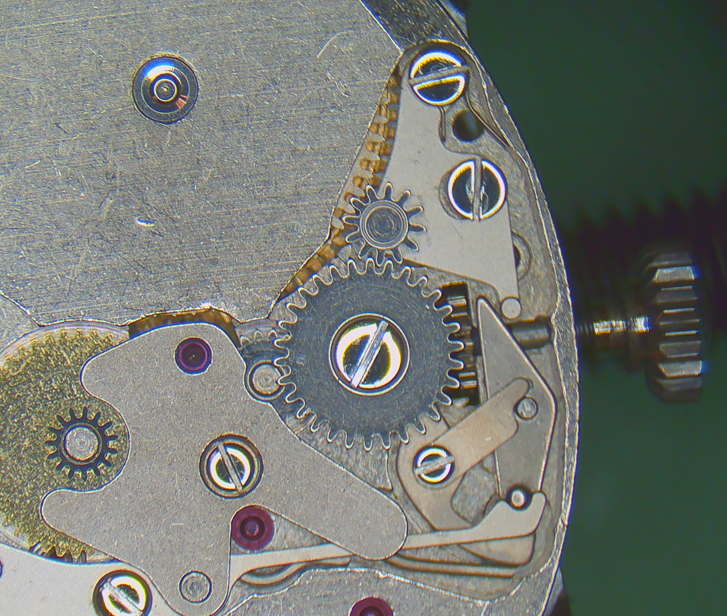

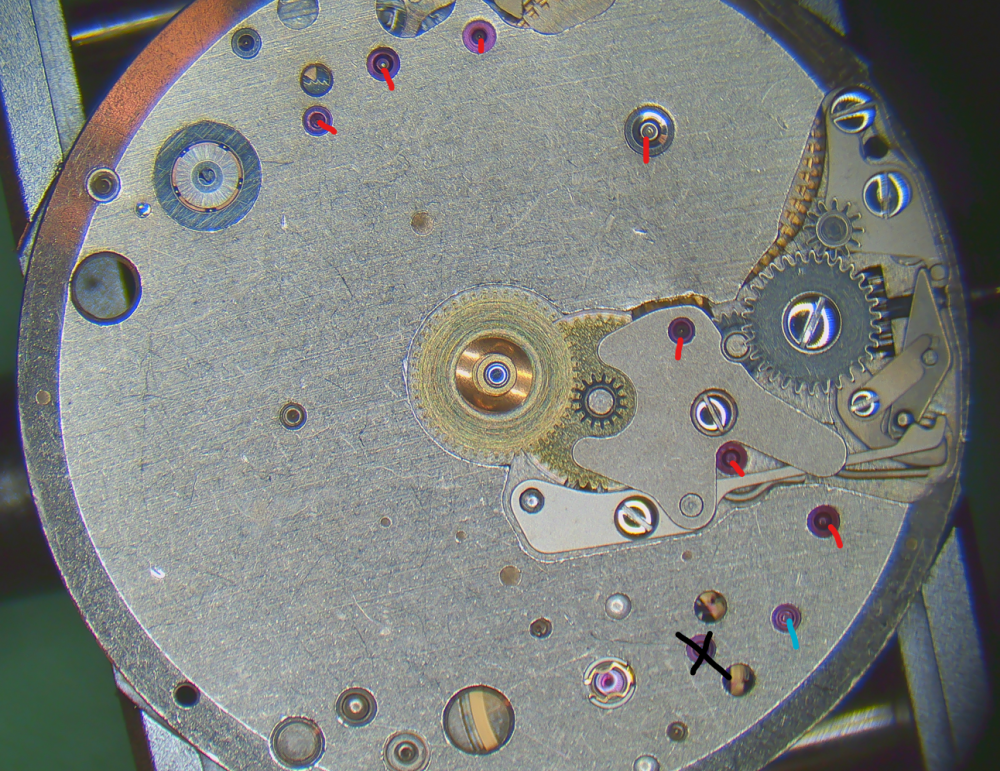

With all indirectly driven second hand movements such as this one, I always test that the movement runs well without the wheel over third staked on or the sweep second pinion and brake spring in place either with or without its own cock, as some do and some don't. Only the basic wheel train should be seen working. Great to see the 3rd wheel arbor spin flawlessly within its jewel without the pallet fork in place, then you can cross that off the list knowing it isn't bent. Test the wheel over third for flatness by placing on a staking block, then cross that off the list. Then stake on the wheel over third (properly) and check if anything has changed on the timegrapher (I like to spin the wheel train at this point and check that the wheel over 3rd is staked on perfectly because you can see it spin quickly if the pallet fork isn't in place), then place the sweep in place and see if that mucks up your timegrapher readings without any brake spring first, then with it. Then add more parts and check. So, at every point you add a component or adjust something, take readings. If you are methodical in this way, you will find the problem and what caused it. Inspection of parts is key. One bent wheel or bridge and fouling will occur as you are having.2 points

-

If your screwdrivers are new they are probably not sharp enough. A too-blunt driver will sit on the slot rather than in it and be unable to turn the screw. But don't think you should make it as sharp as possible as if it is too sharp it will bottom out and be loose in the slot. In that case it is likely to slip out of the slot as you try to turn it, bruising the screw and potentially scratching the movement. You should be able to see the driver sitting in the slot, and you should not be able to turn it at all without the screw moving. I've been doing this for about a year, on and off, and am only now coming to properly appreciate the importance of correctly dressed screwdrivers, and the need to be willing to adjust them for different movements so that the stone is starting to get used quite frequently. (More experienced watchmakers will likely have several different sets, each adjusted differently; I have just the one set.) I have a sharpening tool similar to the one linked above, but I don't find it particularly helpful compared to holding the tool on the stone by hand, and using magnification and feel to make sure it is sitting straight.2 points

-

In the first video where the watch is failing to run, the centre seconds drive wheel isn’t moving, even when the balance is oscillating. In the second video where the watch is running, the centre seconds drive wheel is turning as it should. This suggests that this wheel is getting fouled against the bridge that partially covers it in the first video. This could be because that wheel has been bent when removing it, such that it is no longer flat, or perhaps it is not staked back on far enough and is sitting too high on the extended pivot that drives it. I hope that helps, Mark2 points

-

It shouldn't make any difference when removing the auto bridge, and on disassembling. But on these ETA movements, when assembling, pull the crown out before removing the stem, or the yoke can slip out of the slot on the clutch. We've all been there: dial and hands on, remove the stem to case the movement, and then can't get the stem back in. I wrote a note on my service sheets to remind me! ETA_2836-2.Asembly and Lube.pdf2 points

-

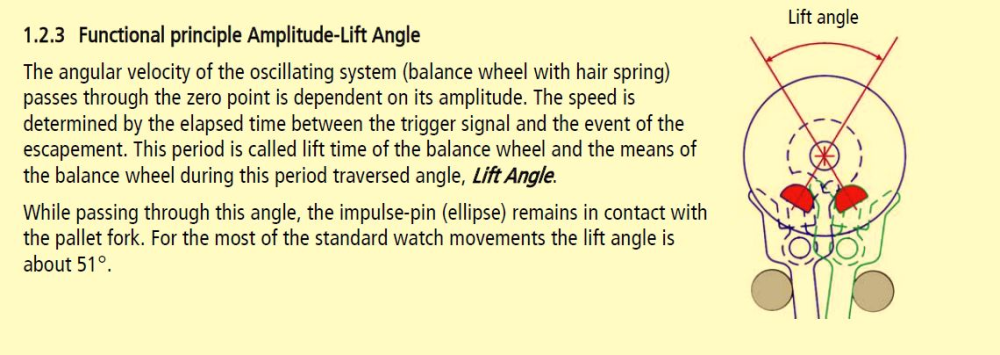

You’re making sense to me Rich, like you I am learning and this stuff is interesting. I am grateful for the information @JohnR725 gives us and his immense patience with us. Although his dictation software sometimes do make I laff . the Jendritski book I was reading John is “the watch repairers manual “ I think it is the same as you mentioned, just without the word “Swiss “. I have a theory as to why there is a progression from adjustable/adjusting banking pins to today’s that are milled into the mainplate. When most of the watchmaking material we have learned From manufacturing tolerances were no where as tight as can be achieved today. There is an old saying in engineering, “if you can’t make it perfectly, make it adjustable “. So now my theory is that as the tolerances of milling the mainplate have reduced they are now at the point they can be considered negligible compared to the end/side shake tolerances that are required for the pivots to function correctly. Previously part of adjustment of an escapement would be a larger part of the manufacturing process because of tolerances just to get the watch to work. If as Rich hypothesis the lift angle being used in timing machines is to be used to calculate the amplitude we have an inherent potential for error in that we look up the designed lift angle and use that whereas the real lift angle could be something quite different. This conversation is both interesting and thought provoking, always good in my book. I’m starting to get the idea, I think, of there is only one magic amplitude number when looking at a watches timekeeping not 270 degrees as a minimum but more like 220 degrees after 24 hours running would be closer to an ideal so that during the running time of the watch balance poise errors are minimised. as in all engineering there is a theoretical world and real world that a machine/system has to work in. Not having been immersed thoroughly in the theory and practice of horology it is sometimes too easy to latch onto something that has been read or heard that maybe tends more towards either theory or an old wives tale. Tom2 points

-

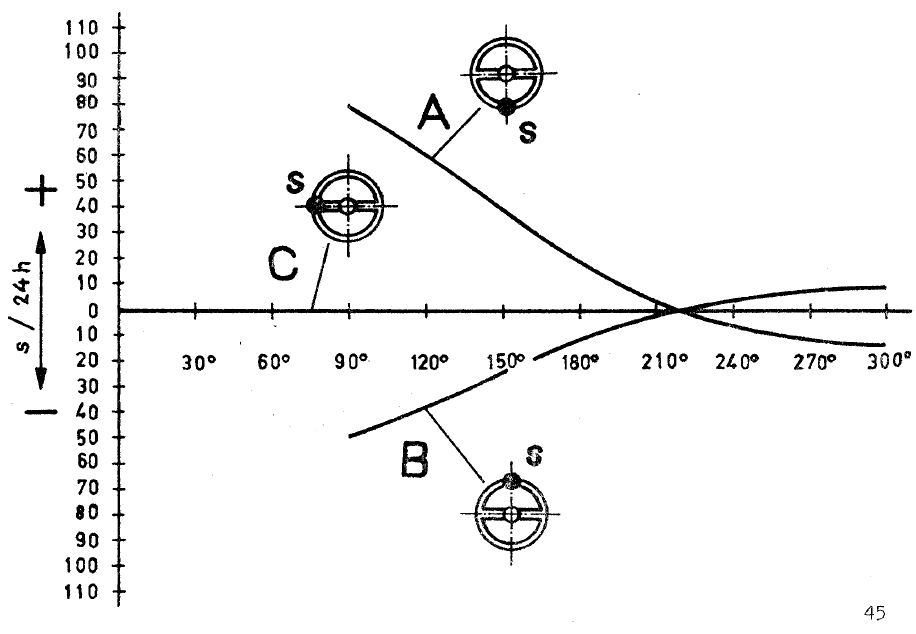

So I'll admit I'm still struggling to grasp something Tom that I bet is painfully obvious, I dont want to bother John anymore though. I'll try make it simple . I've mostly understood what lift angle is for a good while now. Just an angular measurement, the amount of arc that the balance travels through the escapement which is able to registered on a timegrapher because of the noises it hears from the impulse pin as it passes through. I know the timegrapher picks up other signals as well from different parts of the escapement, but to calculate the amplitude the timegrapher just needs to hear the first and last noise. It also needs the distance of arc it travels.....which it gets from us and it needs the time it takes to travel that distance...which it can time itself. The timegrapher now know the velocity of the balance, and from that it can calculate the complete arc of the balance during one whole oscillation...that we know is called amplitude. But what I'm not quite getting is that if we change the banking pins positions, yes the lift angle is now different and if we input into the timegrapher that new lift angle then the amplitude reading it will give us will have also changed from when before the pins were moved. So the amount of arc the balance is travelling is different because the pins have moved and that changes how the escapement performs has absolutely nothing to do with the change in lift angle ie. Lift angle in reality does not influence real amplitude only the reading that the timegrapher gives us. I think I've just super confused myself now and probably missed something really obvious. I think what I might be missing is the fact..that a movement with a low , small lift angle does not necessarily have a different amplitude or performance compared to a movement with hign or big lift angle.2 points

-

yes were missing information here is the problem okay why do we have banking pins well to annoy watchmakers but do they serve any other purpose? The best of my knowledge the purpose of baking pins are a safety feature specifically for porn clearance and it also gives the pallet fork some place to rest when it's blocked. So ideally the banking pins should purely be adjusted for porn clearance that's it that's although the used for except as we know they have secondary consequences of changing things but does that change the angle of the lift angle? We need somebody listen computer simulation simulate this forest we get interesting problems of from a timing machine point of view? one of things we can see is moving the banking pins changes the law if we increase the lock that means we take more time to unlock and the more time to unlock greatly reduces amplitude. It also changes when you get your impulse which would be much later which of course reduces amplitude. Then of course it changes the horn clearance with worst-case of the roller jewel rubbing on the horns or the guard pinned rubbing on the safety roller other things that shouldn't happen. If you have the right timing machine this will show up on a oscilloscope display. or worst-case if you play with the banking pins you get the watch where will not run at all. Sometimes on full plate watches were I can't see the banking pins or the fork I basically have to rotate for best performance which really is not the way you do these things but if you can't see what you're doing and ESC go too far in either direction the watch stops. now we get those interesting little problems. So obviously even though mentally I don't want to grasp this at all I think somebody said I'm supposed to be on vacation right now? If I'm on vacation what am I doing why am I here? Okay so moving the banking pins from where it's supposed to be as it's supposed to be adjusted for a safety feature not used for other purposes like it's being used for. Ours is not supposed to use to play with amplitude unless of course somebody played with it before you. Which unfortunately on pocket watches they do. so it looks like from the image if you move the banking pen it changes when the roller jewel hits the fork which is going to screw up things but how much angle of screw up to we get here anyway? Then on the other side of the timing machine is supposed to use locking with overlap crashing into the banking pins for the other part of the signal for amplitude which obviously change a little bit if the banking pins isn't where it's supposed to be. But how much angle change is there and even if there is you can dramatically increase the lock and that will dramatically decrease the amplitude.2 points

-

I can not judge about pivots condition from this photos. The hairspring is repaired, not perfectly, but more or less OK. Not well centered (internal end to the collet). The amplitude is normal (if timegrapher readings are correct), so friction in balance bearings is not increased. Clues like marks on the roller, stretched collet will say that the staff has been replaced. Probably staff from different factory is used and this is why the collet is stretched. So it is no wonder that there are big position errors. If the pivots are not bent and badly worn, it is worth to try poising - static and then dynamic. No poising scale? No problem at all, use tweezers. Dynamic poising - You have timegrapher, no other things needed.2 points

-

I once spent HOURS with this... But for me, it wasn't about the crown position (which I had pulled out as instructed), but that I used a pointy probe to depress the "button". That allowed me to push it down to far and dislodge the keyless works. If one uses a screwdriver that fits the entire width of the slot (I believe it was the 1.2mm one), you are safe. Lucky you!1 point

-

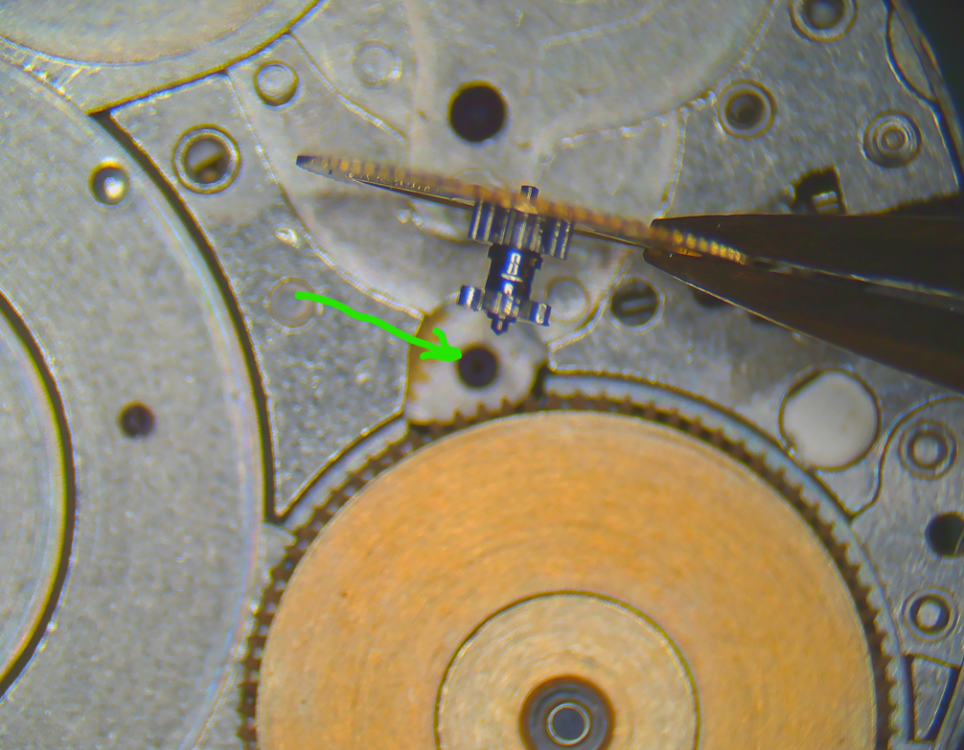

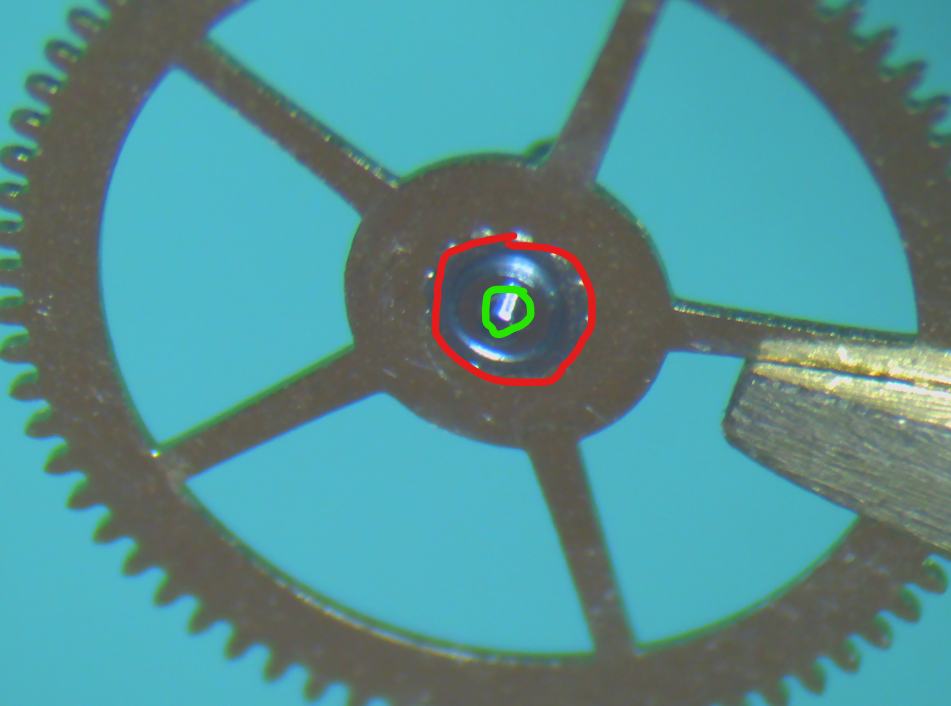

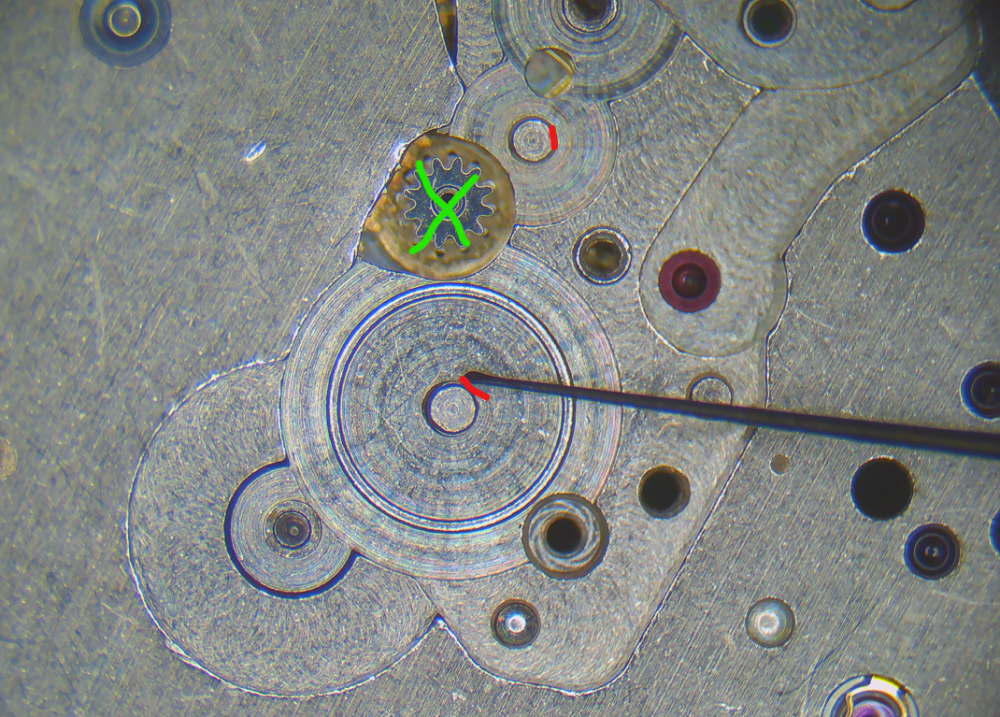

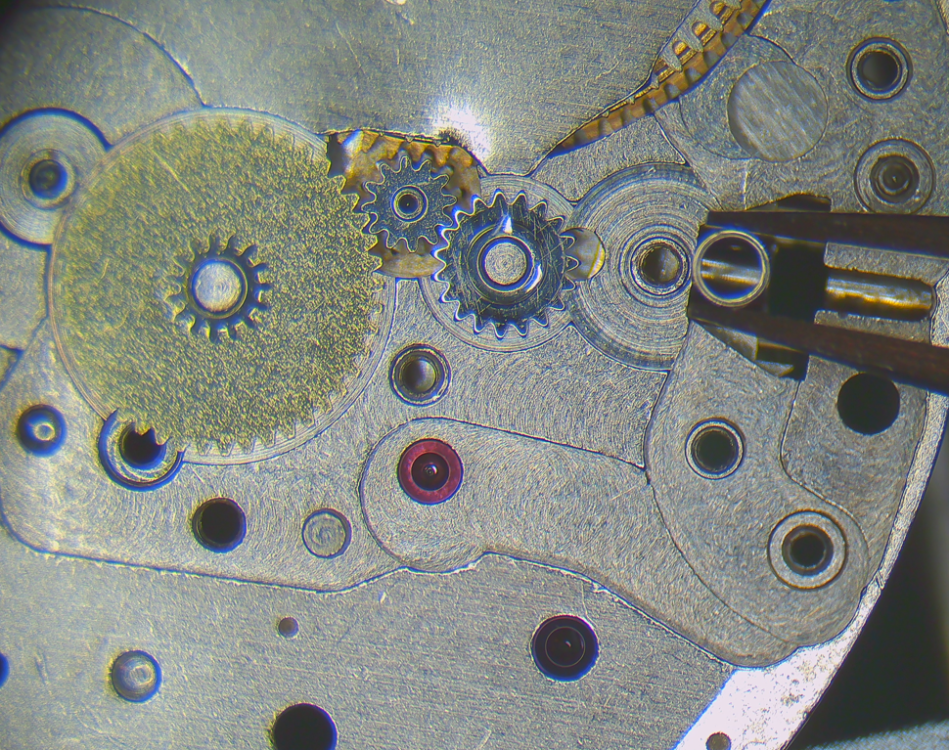

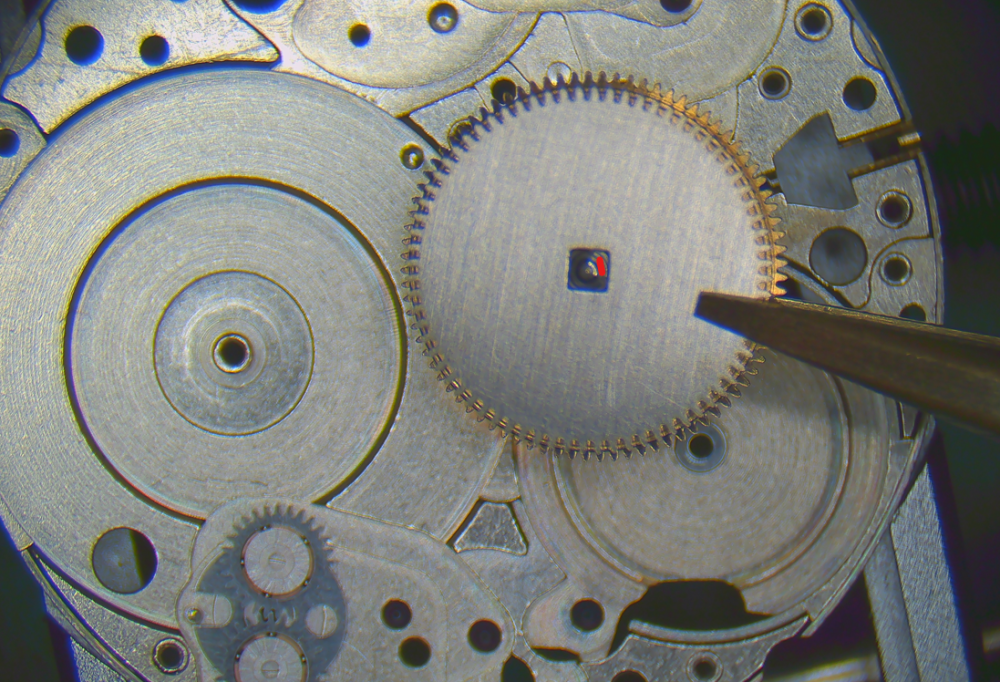

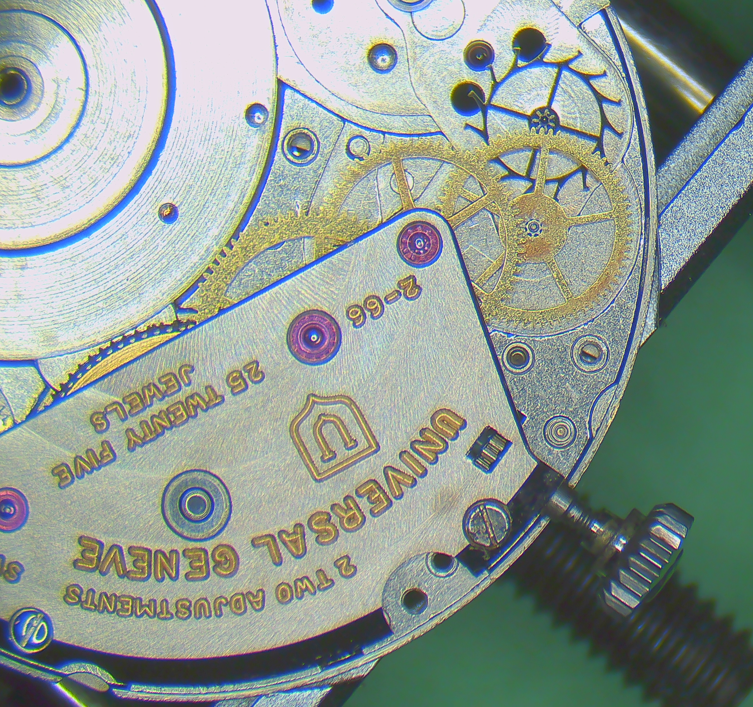

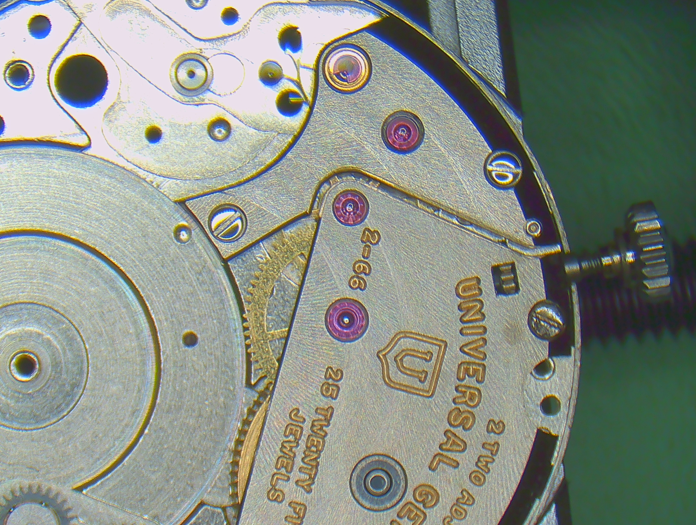

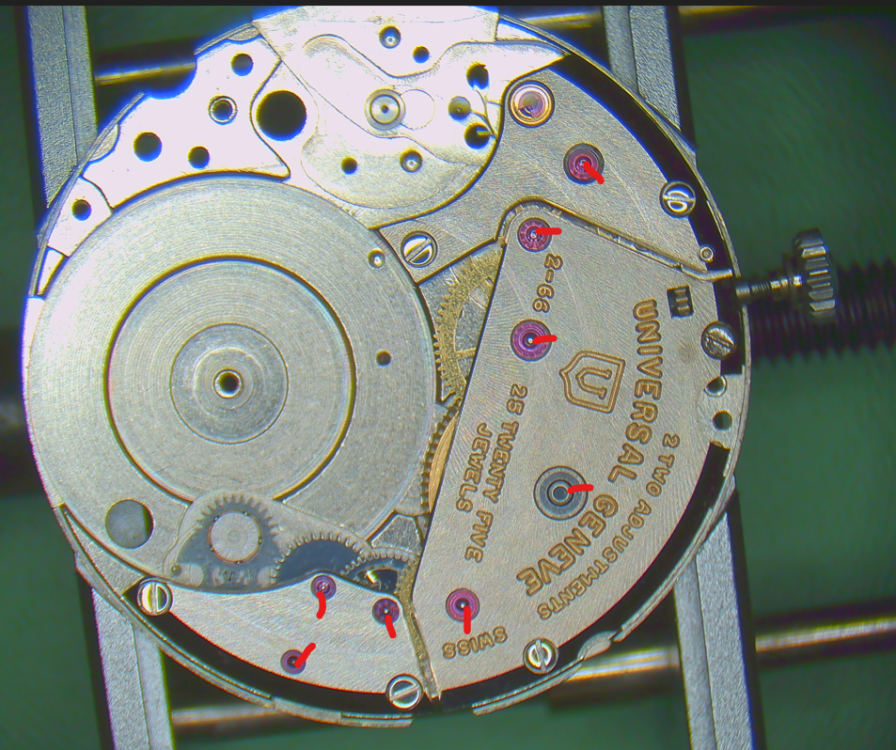

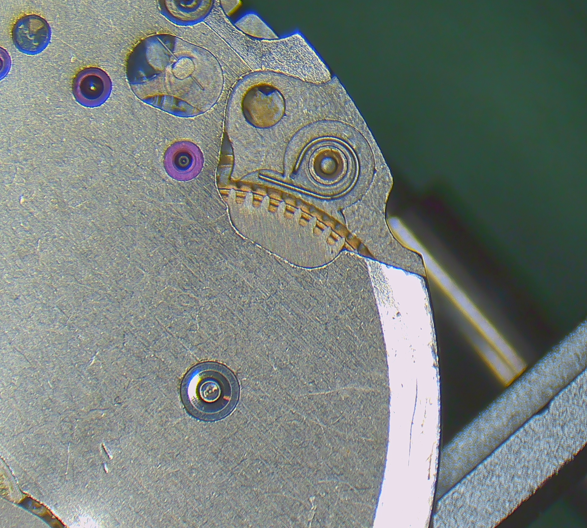

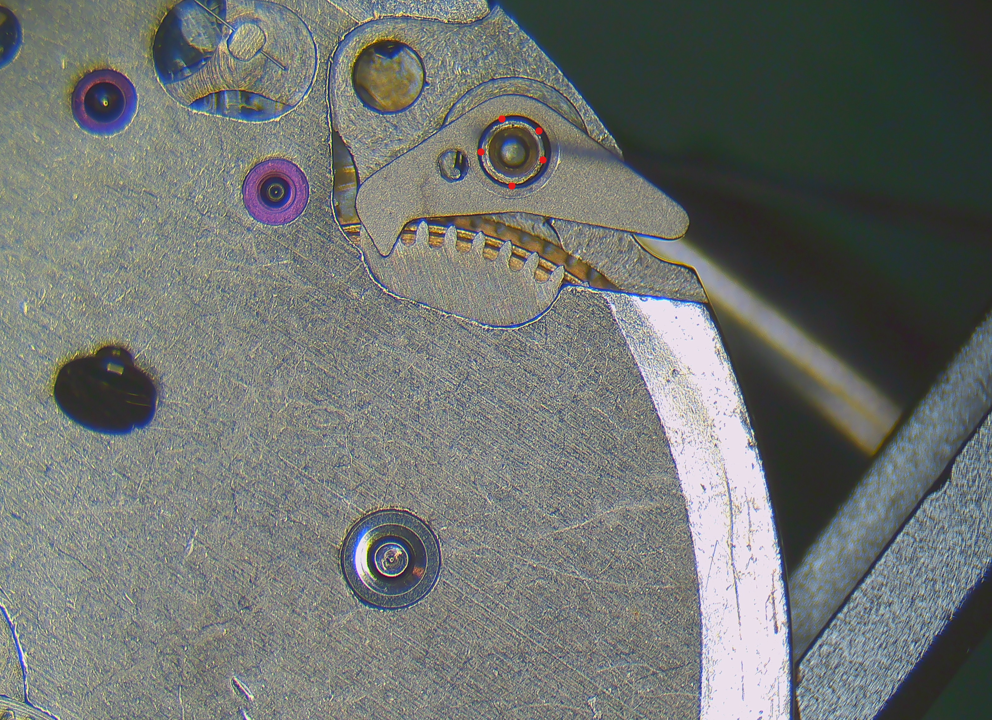

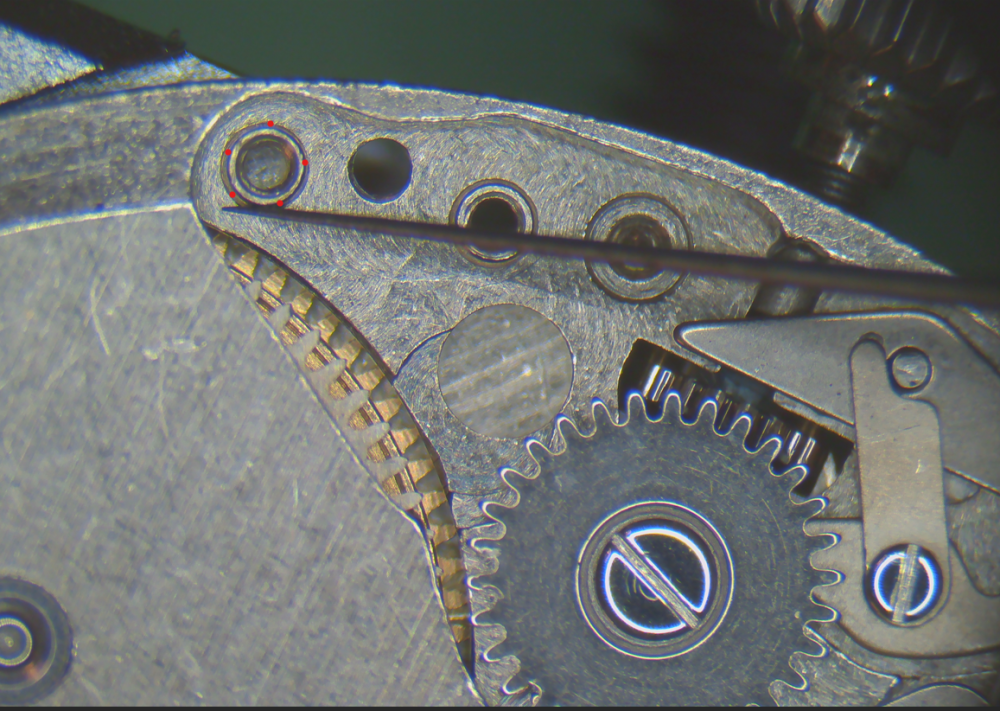

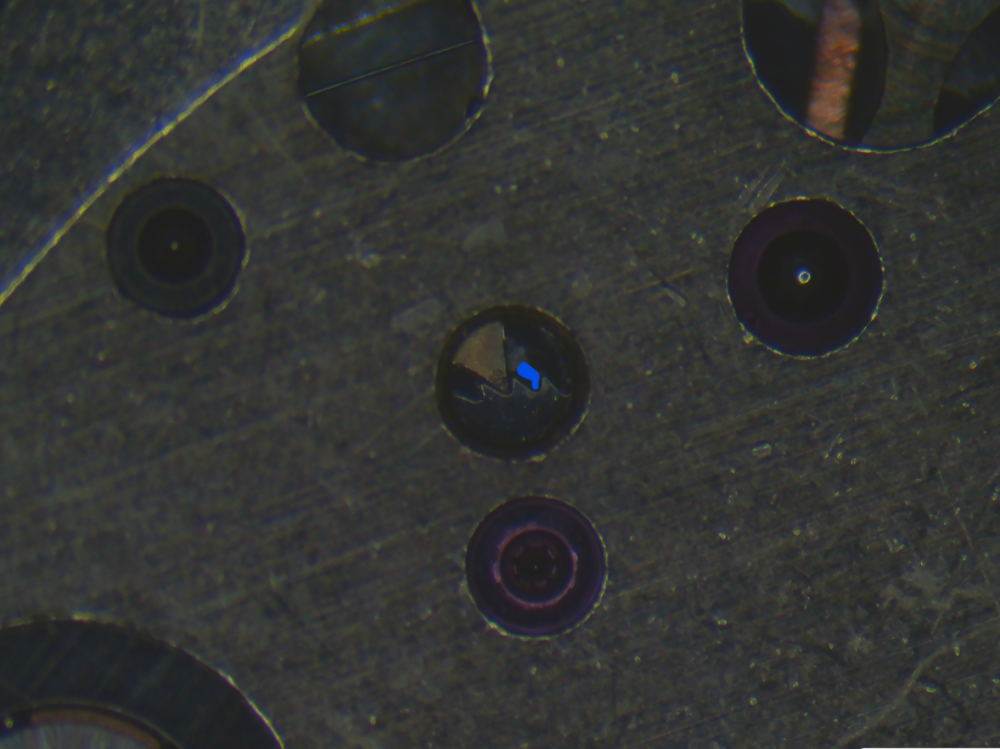

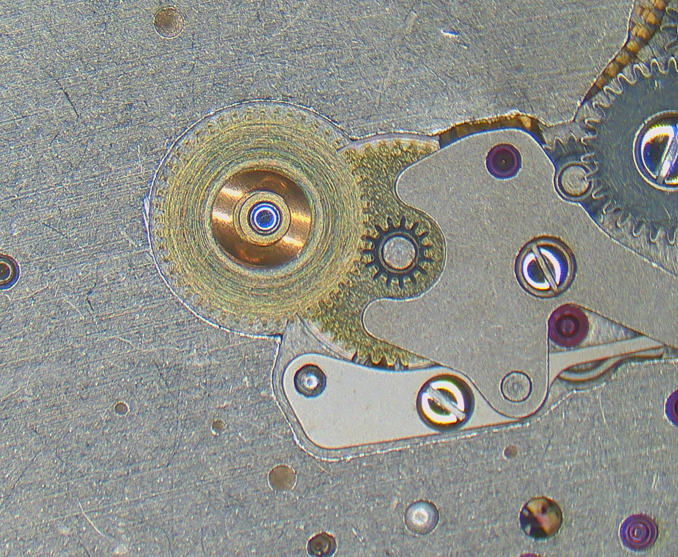

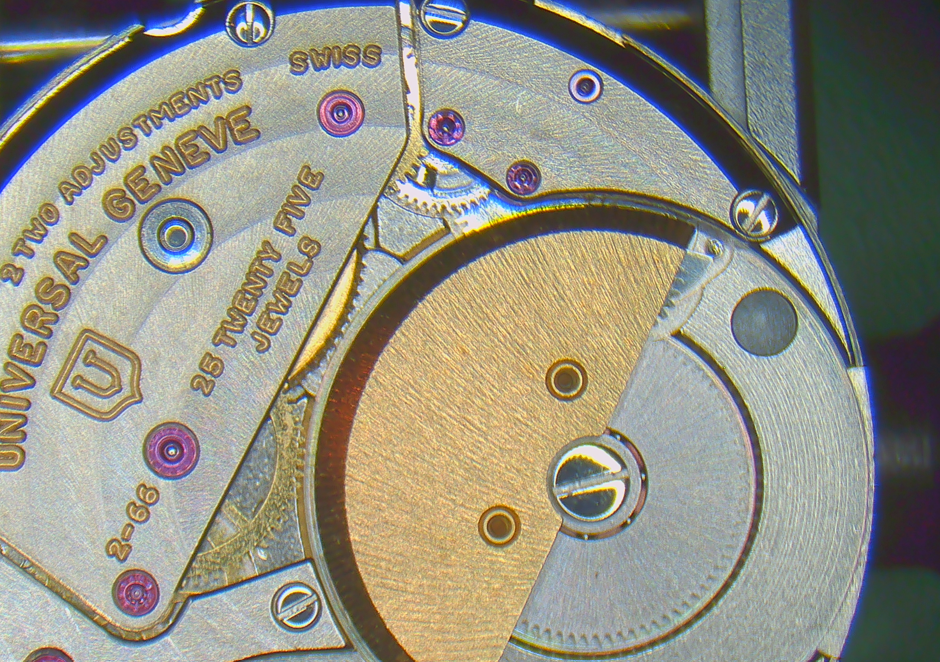

Ok, next one! First, the cannon pinion! Remember, this is the decentralized cannon pinion with integrated cannon pinion (and it goes where the green arrow indicates): First challenge: how to disassemble!? - do not use a Presto tool with its "feet" against the spokes/rim of the wheel! It'll bend the wheel. - using a scalpel or razor blade to slide between wheel and cannon pinion is also not working well --> I cut a triangular wedge into a spare barrel lid (of course, any other thin sheet of metal will do). Then I slide it between the two steel pinions, like so: Now I can use a presto tool to lift off the cannon pinion. Make sure the wedge is properly between the two steel pinions! No force should be on the brass wheel. Clean. In my case, the cannon pinion needed some tightening: Grease the staff of the (decentralized) centre wheel. I used 9504. To combined the two parts again, on the staking set, make sure the top punch fits over the whole staff of the centre wheel. It'll protrude from the cannon pinion and you don't want to punch on the staff.. Secondly, note that the wheel seems to "hover" over the staking block. You want to chose a hole on the staking block that just fits the green circle here, and NOT the red one (if you do the latter, you may punch out the staff from the wheel...) Push. Done. Now over to the barrel assembly. I distribute a thin layer of breaking grease around the barrel wall (I used 8217) New spring in (this is 0.70 x 0.1025 x 375, item number 266771 at CousinsUK) remember that the square part of the arbor points upwards close lid. then I oil with HP1300. Epilame treatment of pallet stones... ...and escape wheel (full submersion and then removing epilame again from the pivots) I take advantage of the balance still being installed on the movement (from cleaning) to oil the balance jewels on both sides of the movement. Just two pictures. It should be clear otherwise. 9010, of course. Now, disclaimer. Like in the assembly, I realized half-way through assembly, that another order would have been better. So I'll post the pictures in the order that I think is better. So please ignore the presence of some parts that were already installed in my less efficient, actual assembly process. I suggest starting with the keyless works before installing barrel bridge, train and automatic works. Why? The "decentralized" centre wheel and cannon pinion is held on the keyless side by a jewel in the cover plate for the keyless works. If you don't have that installed first, it's making the installation of the barrel bridge a bit tricky. So, first the pictures of the keyless works assembly. HP1300 on the posts (ignore presence of centre wheel here) add respective wheels and the seat for the other post place the pinions/wheels for the winding stem setting lever with some 9504 setting lever and stem replaced and adding some more 9504 (I spread this amount around by turning the stem while holding the oiler there) placing the yoke, adding some 9504 on the sliding points (excess will be removed later with rodico) and then the yoke spring unfortunately, I forgot to take pictures of the next steps, so I'm borrowing pics from disassembly. set lever jumper with 9504 as indicated and a bit of 9504 here combine the two parts of the crown wheel and the winding wheel and add HP1300 between them as indicated then add HP1300 on the seat and install them install the cover plate turn movement over add the tiniest amount of HP1300 to this rim (or don't, but don't let it flow over) combine ratchet wheel and barrel and replace them jointly (to get ratchet wheel into the right spot immediately and not smear the oil on the aforementioned rim). HP1300 on the arbor pivot as indicated. place wheels and then the bridge now the train wheels the 2-66 movement has this unusual fixed cap jewel for the escape wheel. I oil it from below and push the 9010 through with a sharpened oiler. Inspect size and position of oil circle from the top side. install train bridge I choose to proceed with the automatic works now first the secondary click (for auto winding intermediate driving wheel). the tiny spring needs to go through a small hole where indicated view from the other side of the movement place the intermediate winding wheel now there's this special wheel which which disengages the automatic works when the watch is wound automatically (same as JLC 889 that I serviced recently). The slipping "arms" need some grease (or oil). I used 9504 I then spread it around by gently moving the arms around (clockwise in below picture) place the wheel and install bridge I decided to use HP1300 on all these pivots (escape wheel pivot was oiled previously with 9010). I prefer the higher viscosity oils to avoid any creeping. Happy to drop a few degrees of amplitude for that. turn movement over and install primary click at the ratchet wheel very light use of HP1300 (sorry, screw not pictured) now back to the keyless works again small amount of HP1300 tiny bit of grease as indicated secure with screw and place spring (careful with this one.... it's a highly qualified candidate for the Swiss space programme) arm the spring and secure with screw dial side oiling with HP1300 (red) for everything except the escape wheel (9010, blue) I add a tiny bit of 9504 to the click/teeth here turn over again. pallet fork. as usual, I install the balance, let it run a few minutes. remove the balance. oil the exit pallet stone with 9415. one small drop every 4-5 teeth. then the rotor. NOTE: I didn't oil any of the four ball bearings! This is up to debate.... in some service manuals across different brands, ball bearings are oiled (with 9010 or Lubeta V106 or 9415), in other manuals they aren't. I chose to not oil because the watch case is barely dust-proof. And if any dust gets inside, it'll attract to oil. If it gets on the ball bearings, it'll quickly clog up. But happy to receive other opinions. and the complete train side then back to dial side again. Oiling the inside of the "false" cannon pinion with HP1300. then the outside with HP1300 and place hour wheel and dial washer a bit of regulating. Note from disassembly that the pallet stones lock was a bit excessive. The amplitude could probably be increased by moving them inwards a bit. But I'm happy with this result as it is and will let it be. Since I haven't done pallet stone manipulation yet, I don't want to practice on a movement where spare parts are extremely rare and expensive (the company has been out of business for about 50 years). dial (two screws) and hands on That's my new baby!1 point

-

The way of telling is the screws, and the counter sink of the oil wells and the type of pivot construction it all is modern.1 point

-

Seems to be behaving... passed the first test, I'll see where it is in the morning...1 point

-

It should rest on top. While the Omega one go underneath.1 point

-

Yeh it's confusing. All the pressure is on top of the pinion when fitting the seconds hand. I have a Longines 12.68ZS (pic) where the spring is a fork and goes under the pinion top. I have Omega's where the spring goes either over (Cal 565) or under (Cal 613) the top of the pinion. But it all these cases, there is a jewel, or solid surface just above the pinion, so it doesn't need the same support when fitting the hand. These are just the sorts of tips we need !1 point

-

Move the spring to one side a small stump to support the center seconds spindle in your staking tool then fit hand. That is the way I did them.1 point

-

Exactly how I do it without denting the brake spring, although half the time it has already been dented!1 point

-

Exactly as @Mercurial wrote. That must be it. If it's not the wheel, which it 99% is, also check that the bridge isn't bent (I had that once).1 point

-

No, I ended up going with a Proxxon FD 150/e for a few reasons. First, Proxxon has a U.S. branch. So if anything goes wrong, I just call them, and it's easy to work things out. I've emailed their support people before and called their hotline, and they're very responsive. If the Sincere failed, I'd have to communicate through eBay (or worse, AliExpress) and start worrying about sending a large, heavy item back to China... not fun. Second, while the Sincere is more watch-oriented, there's no guarantee that I'm going to be doing watch parts only, so I'd pigeon-hole myself into only being able to make small parts. The FD 150/e is a more general machine. It accepts ER11 collets, which are very accurate, inexpensive, and I only need a handful of them to accomplish the same range of diameters as an entire box set of WW collets. Next, afaik, the Sincere does not have zero-adjustable handwheels. The FD 150/e includes it in the base price. Speaking of price, I was able to purchase the lathe, and the accompanying MF70 mill for half of what it would have cost to buy the Sincere combo (not including the cost of the motor for the Sincere). The Proxxon does require a little bit of dialing in here and there to ensure everything is centered and square, but it's pretty fast to do, and you don't need to do it every time.1 point

-

Found the issue with the minute recording wheel. Actually it was the upper pivot bushing for the intermediate mimute recording wheel. It had fallen out (i did find it on the bench at the time and tucked it away thinking i would need it at some point). I found where I stashed it and now need to reinstall. It's not clear on the tech sheet that there is a bushing there, although it does have a note not to oil the axle. Will update as soon as I reinstall.1 point

-

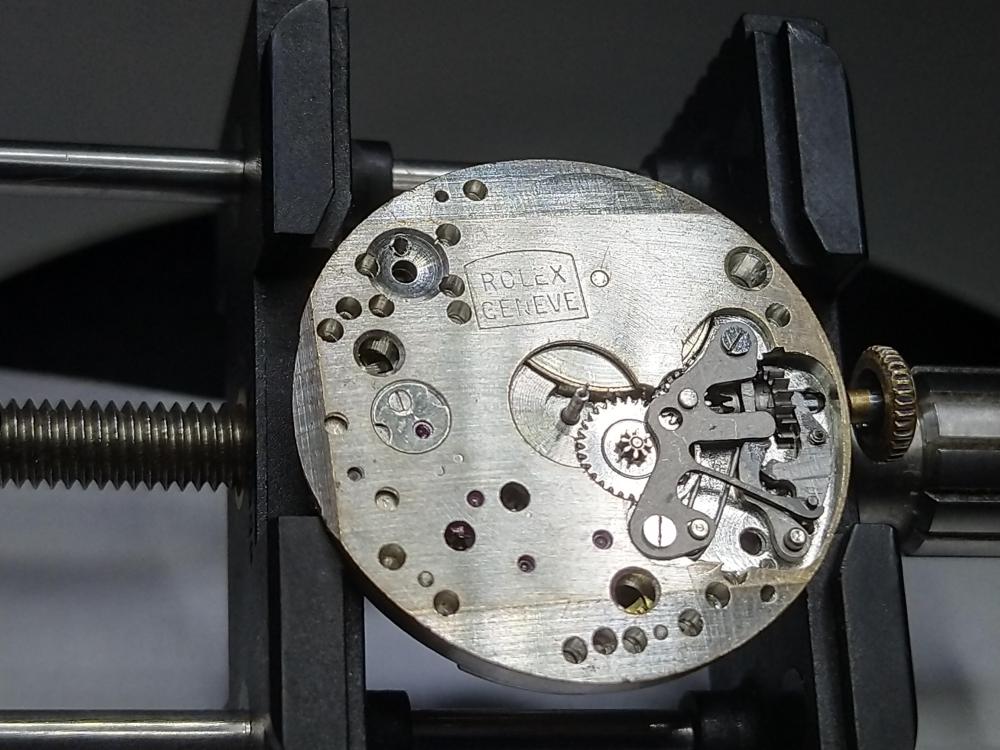

HWGIKE#34 Services Competitor, pin pallet. Full service. MS was broken, was very dirty and very oily, but all three together saved it in a good condition more or less. Started to polish the case back, it was a mistake as I slightly removed the plating on the edge. It didn't say stainless steel.. i still thought it would be anyway... it wasnt, as you would expect. I kept the old strap as I found it fitting, it belongs to my only one returning customer, Stephen. HWGIKE#35 Tudor, unknown caliber. Full service, this one also had a broken MS, boys size. The hole for the MS arbor was tightened. No mistakes were made this time, finished with the Services together last night.1 point

-

Tricky one. The earlier 10L has the cock inverted so the pinion would be supported by the jewel… If you could invert the pinion cock you’d be home free…but could you make a little ‘jig’ out of pithwood or something soft in the shape of the cock that would support the pinion, either curved like a C to avoid the 4th wheel, or a stick with a hole and countersink to let the pinion drop a bit and let you avoid putting pressure on the wheel? I have one of those Bergeon delrin tools with nice countersunk holes but I think it would be too wide to avoid the plate for the 4th wheel…1 point

-

Ha - I woke up to find I have an entire textbook to read on this thread. Right - The lift angle changed, and the timegrapher needs to be informed of the change. But the locking depth also changed (reduced in my case) which led to a more efficient impulse, which resulted in a real world amplitude gain of at least 25-35deg on the balance swing. Initially the timegrapher made it look more like a 40-50deg gain because it was not aware of the new lift angle. Two things happened, one of them matters to the performance of the watch and the other only matters to please the Weishi. This might have been in a PM with John rather than back in the thread but a few days ago he told me about: ...and I ran that test to find that the outer banking pin was noticeably farther off the balance jewel center than the inner one. The exit stone also had a deep lock. So this is why I moved the outer banking pin a little closer to the balance jewel hole. The two pins are now closer to the same spacing either side of it, probably correcting someone's change from 70 years ago.1 point

-

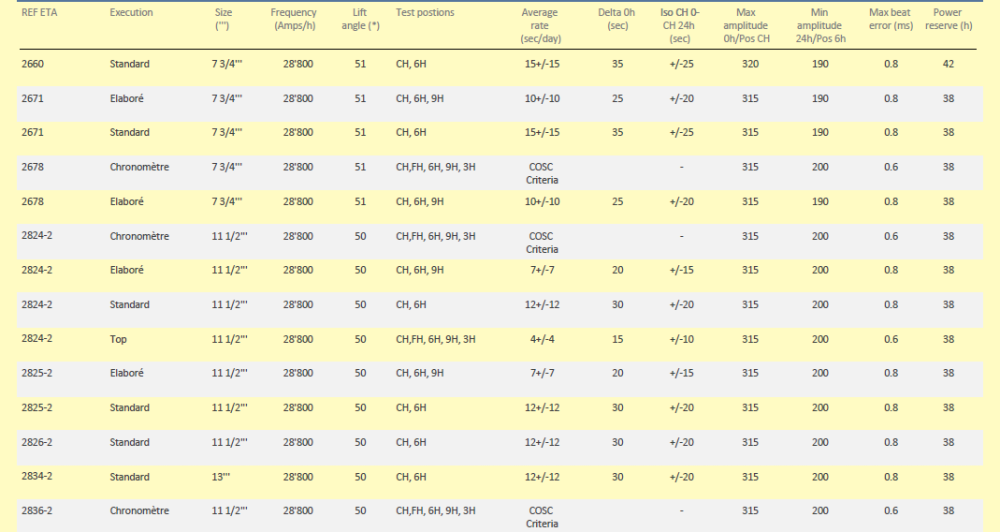

amusingly somebody in a private discussion suggested I should go to chat GPT and it would improve my? okay by theory artificial intelligence should be able to what exactly? I have a theory which goes like this garbage in garbage out. In other words if for variety reasons like probably a dyslexia thing which is why I'm using dictation software anyway Ike if I flip my words around because I'm slightly out of sync with my what my brain is thinking of what comes out is not exactly in sync. Or dictation doesn't hear whatever I say correctly puts the wrong word down. Or dictation just decides to do whatever it feels like because it can. Then something like chat GPT can't. I think at the time I was answering this for the person I was answering a question somewhere else and noticing stupid goofy knowing mistakes so I took my goofy paragraph pasted it into the chat and no it can't translated if maybe there is a command the say goofy dictation software not worded correctly please worded in intelligent fashion but it has to have something to work with and of course were discussing technical horology and that might be an issue. So basically everybody's frustrated. Although I would be happy if the dictation software would let me correct a paragraph at a time after I've done the paragraph versus what I'm supposed to stare at the screen and correct things as they occur which I do not. technically it's not the last noise. If you look at where the sounds come from there is actually five of them. Then the roller jewel is unique crashing into the fork. but typically if you look at the waveform when people are showing it they only show three sounds because the other two are actually two sounds each overlapping. So locking should occur before crashing into the banking pin but close enough they appear to be the same thing but if were going to be nitpicking its locking. thinking about that read the PDF I attached is a lot of things that affect the oscillation system namely the escapement the biggest offender. As we know moving the banking pins changes the depth to lock if it's too great the time to unlock increases so you're wasting energy unlocking and what happens if we change when the impulse occurs? Even look in the PDF and it explains that. Then the rest of the book on precision timing is really spent with other stuff I really wish there was a index in this book where I can look up and find out all the references to banking pins but it really doesn't look like they play a big part in the book. They probably assume there where there supposed to be obviously they never worked on American pocket watch yes the magical 220° would be really nice but not necessarily necessary. so for instance poise errors are not linear. In other words lower amplitudes have much greater effect than the high amplitudes. Then typically lower amplitude basically screws up everything across the board. Really what would be ideal it is consistent amplitude across the entire timing range which is why typically today we see watches with much longer running times as longer running times usually translate to more linear over the first 24 hours. then because I have way more Swatch group documents here's something for older watches. Notice we have a shorter running time as opposed to 48 hours or more. Or Illinois made a pocket watch with 60 hours in one of things that advertised and promoted was how nice linear the timekeeping was. Or Hamilton 992B is interesting because even though the parts list doesn't show it it also has a another spring that will power the watch for 60 hours and yes it does keep really nice linear time over the first 24 or actually all the weight practically to the end. Which brings up the effect of properly shaped mainspring which could be a problem for anything vintage as the modern springs tend to suck sometimes. I really don't know why there seems be an incredible inconsistency of the quality of aftermarket mainsprings so we get a variety of sizes from the sample I snipped out. Notice we get a quality difference and typically with quality will notice that the number of positions they look at the watch in increases with the higher quality watch. So while you're looking at the average rate and thinking they look similar not much difference as you get a higher quality watch more and more will of the positions have to deal of time within that range which is yes harder to do. Then notice minimum amplitude at 24 hours I think I've seen for Omega they'll take some watches down 260 but of course the watch has to keep time here some of these are down to 190. That's because the mainspring doesn't have as long of a power reserve. oh and if you want an amusement for amplitude because typically people in the group don't discuss amplitude at 24 hours or even if their watch keeps time. Which would be better if the watch stayed at 240° over 24 hours versus starting at 300 dropping to 200? Now according to the chart I have below that can amplitude fluctuation will be fine as long as the watch Time. The watches tend to keep better time if their linear and amplitude as unfortunately amplitude does affect timekeeping. another way to look at lift angle is the amount of time the escapement screws up the oscillation of the balance wheel. this is why ideally a smaller lift angle would be preferred that a bigger lift angle. But were not designing the escapement so were stuck more or less with what we have. Or we can go to a different kind of escapement like detent escapement for chronometer I believe it's lift angle is very very tiny. Although it's not a friendly escapement if something bad happens it can be very bad for Marine chronometer of something is not quite right or if you play with your balance wheel. we end up with all sorts of interesting problems and questions. So for instance I attached a PDF a light reading may didn't attach the entire book just couple of pages on the oscillations system-level watch. We end up with interesting issues like if the depth the lock increases because we move the banking pins what's the consequence? Well the roller jewel hits the fork and spends way too much time unlocking and receives its impulse late? You can see in the PDF the consequences of the act of the wasted a whole bunch a time unlocking when you shouldn't be unlocking that long and when you receive them Paul's has affect on thickness. But putting the banking pins where there supposed to be the watch definitely runs better and yes you can see an increase in amplitude. the oscillating system first three pages.pdf1 point

-

It's a five bar movement, made somewhere on the French/ Swiss border. Probably impossible to say who by.1 point

-

What happened to the canon pinion? Looks like it is still there!1 point

-

you're here because you are kind enough to answer Tom's and mine random obscure questions. When really you could have taken the opportunity to use the subtle excuse I supplied for you, to not be here1 point

-

I think it's a 1.0 or maybe even a 1.2 mm blade you need. It should match the diameter of the head without scratching the surrounding metal. Then you need to dress the taper to fit as deeply as possible into the slot without bottoming out. Once you've done that, use plenty of downward force on your screwdriver, and as much torque as you need to release the screw.1 point

-

Yes, the pin will be longer than the boot, shorten it to correct length so the boot can be closed. Frank1 point

-

Oh no, theory tsunami happening here... Here's what I know and have measured: The lift angle of 48° is not a Hamilton factory suggestion, but rather an anecdotal number from this thread - so 48 might have been the angle measured one time on one watch (whose banking pins may have been moved, remember these American watches mount banking pins on eccentric screws for too-easy adjustment) So I have been measuring at 48° all along, and previous checks of the balance at 180 were close enough that I didn't try to dial it in further. Until just now. I took all the wind out of it and brought it up until the 2 arm balance was landing in the same spot on both swings and adjusted lift angle until I had 180. That angle is 45°. I didn't do this precise a measurement before moving the banking pins, so either the LA went down 3° after moving them, or the original 48 number was a guideline that may not have been exactly right on this particular watch to begin with. With slow -motion video and laying a protractor over my phone to measure the angle beyond 180 per swing, I am seeing about 240° - so less than 255 as I suspected, and pretty consistent with the difference between measuring with LA at 48 vs lower at 45. And the tg calls this 235. If someone else wants to do the science and move their banking pins around to test amplitudes, you are welcome to. I am not messing with this one any further.1 point

-

The one or two watches I have been inside of with this caseback arrangement have been Russian, however I would expect like them that it would be one gasket and on the caseback. My reasoning is that the caseback makes the seal and the ring is to tighten and make that seal. Tom1 point

-

@mbwatch I don’t have a sincere lathe but I did look into them when I first got into this and was looking at doing the BHI DLC qualifications. The sincere has been sold, rebranded and boxed, as a vector for more money. All the sincere stuff I have seen is that they recommend their expensive version of an industrial sewing machine motor so does not need the extra torque that a counter shaft would give a domestic sewing machine motor. What you see that I think that you think is a counter shaft is for getting power to a milling attachment on the cross slide. Tom1 point

-

Yeah, I’m wondering if that’s plausible or totally outlandish. Anyway, outlandish suggestions tend to spark some interesting discussions in these threads, so I figured it wouldn’t hurt to ask.1 point

-

Maybe the balance staff was replaced at some point, and the repairer chose a staff whose roller table arbor and balance spring collet arbor were too large? This being a non-shock protected balance, I think re-staffing following a broken pivot is likely. That could explain both of the quoted problems. If that is the case, other dimensions might be off too... I'm working on a movement with similar symptoms: cracked roller table and hairspring collet. Old staff had a broken pivot so I replaced the staff, but I'm worried I based my replacement on measurements from the incorrect staff. Interested to heat what the expert detectives have to say.1 point

-

Hi. I believe that cousins at one time supplied pinsreads for insertion. Have a look through their catalogue. The distance is critical as in the fact that the spring beats between the boot and the pin so the larger the gap the longer the travel. This would have an effect on on the rate.1 point

-

Just my 2 cents: I must say my interactions with cousins have always been ok. They are real people ( not "bots") and basically run a family business, meaning that they tend to be friendly and respectful if you treat them that way as well.1 point

-

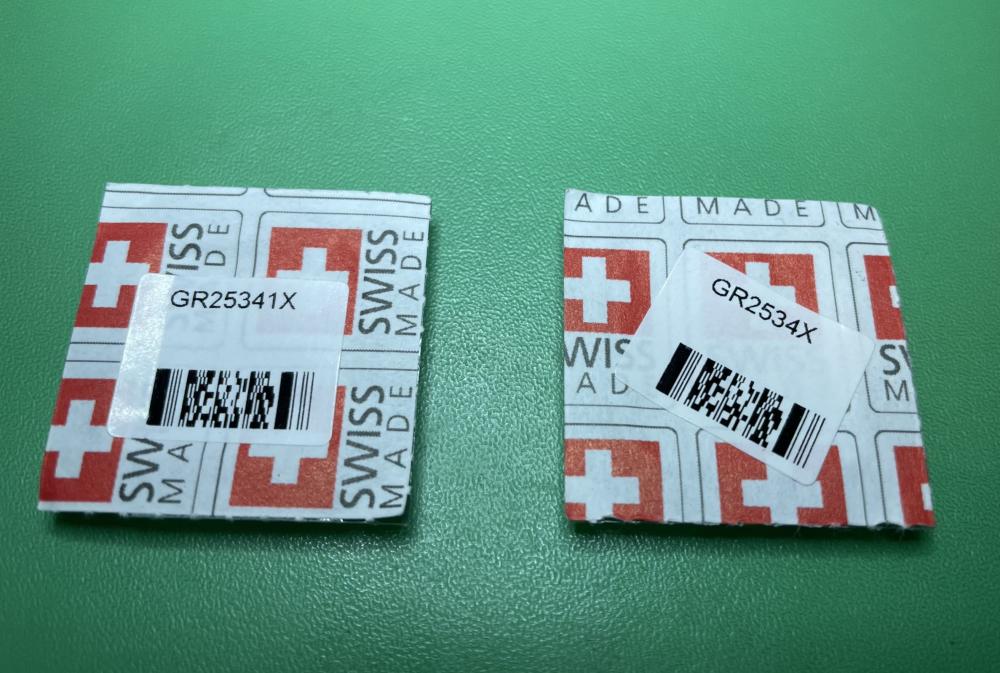

I know this thread is a bit dated, but I recently ran into some issues with 6138 and 6139 mainsprings from eBay being slightly undersized and underpowering the watch. I was finally able to find the exact correct replacement mainspring and thought I'd share it here for future reference. The correct dimensions for the spring are: 1.05 x 0.115 x 420 x 10.5 A search online references GR2534X, which can be found from Cousins. While the spring has the correct dimensions, the inner curve for the arbor is a bit wide and fits somewhat loose. This can be adjusted, but there is another (and cheaper) option. Cousins also has part # GR25341X, which has the exact same dimensions, but costs about 30% less. This part number is not referenced (anywhere that I could find) for the 6138, but the inner curve is smaller and fits the barrel arbor perfectly. If anyone is trying to source a mainspring for their Seiko 6138 chronograph, the GR25341X is what you'll want to get! I ordered a couple of them and just installed them in two of my watches. It brought the amplitude up from 190/200 (with the eBay spring) to 230/240. Here's a photo showing the difference in the inner curve between the two Cousins springs. The correct spring is on the left. FYI, the washers are the correct size and the spring drops right in. I hope this is helpful for someone in the future trying to find the correct aftermarket mainspring for their old Seiko.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)