Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/25 in Posts

-

Hi Mehmood, and welcome to the forum! There are some misunderstandings in what you’ve written, I hope that the information below is helpful. It is considered bad practice to let down the power in the mainspring by removing the balance and pallet fork. This releases the power in an uncontrolled manner, and it can cause damage to the watch. The train of wheels is not designed cope with a sudden release of power, and the rapid acceleration of the escape wheel as you remove the pallet fork can cause a destructive collision between the pallet jewels and the escape wheel teeth. Sometimes the pallet fork will move as you lift the pallet fork bridge, unlocking the escape wheel with the pallet fork still in close proximity, which can chip the pallet stones or damage the escape wheel. A watch with excessive amplitude can result in the roller jewel hitting the outside of the fork horns as you describe, which is known as rebanking or knocking. A shock to a watch that accelerates the balance wheel can also cause the roller jewel to knock, but this behaviour will stop once the shock stops, the amplitude will return to normal and the watch should run properly again unless the shock was strong enough to cause physical damage, such as a broken roller jewel. Overbanking, or the escapement going ‘out of action’ is a different condition, and occurs when the roller jewel ends up stuck on the wrong side of the pallet fork. A watch that is out of action will only start running again after the balance is removed and replaced in the watch with the roller jewel on the correct side of the pallet fork. A shock should not cause a watch to go out of action as the result of a shock unless the safety action of the escapement is set up incorrectly. Finally, you cannot overwind a watch, unless you wind it to the point that it is fully wound, the winding crown comes to a hard stop and you apply brute force to the crown in an attempt to wind the watch further. Overwinding in the sense that the word is usually used doesn’t exist. Best Regards, Mark5 points

-

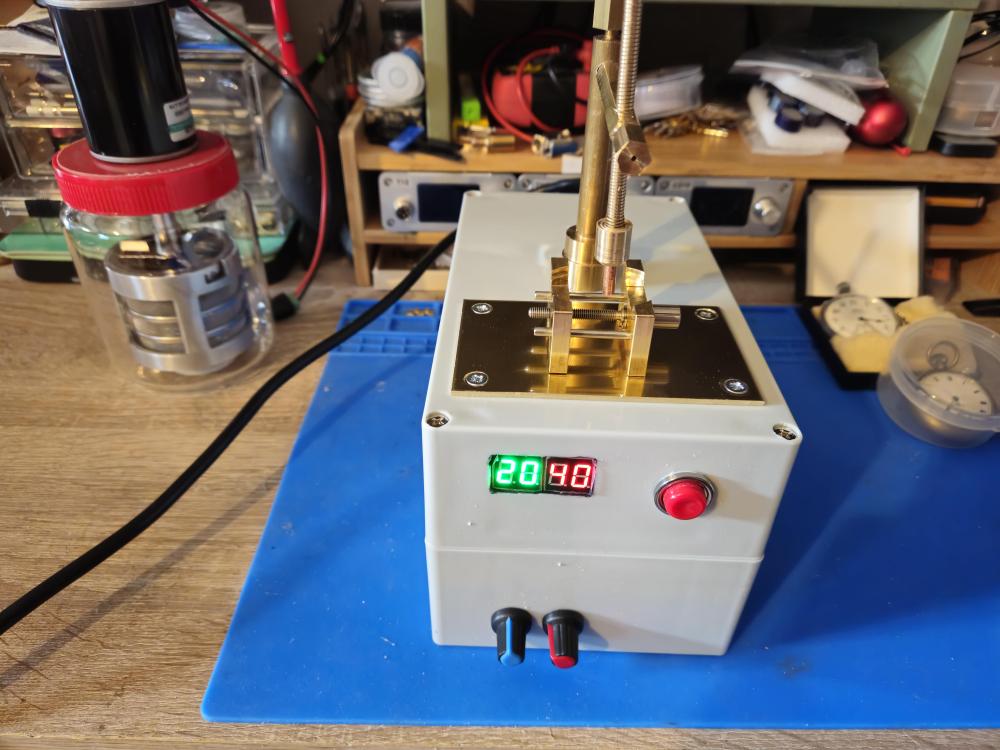

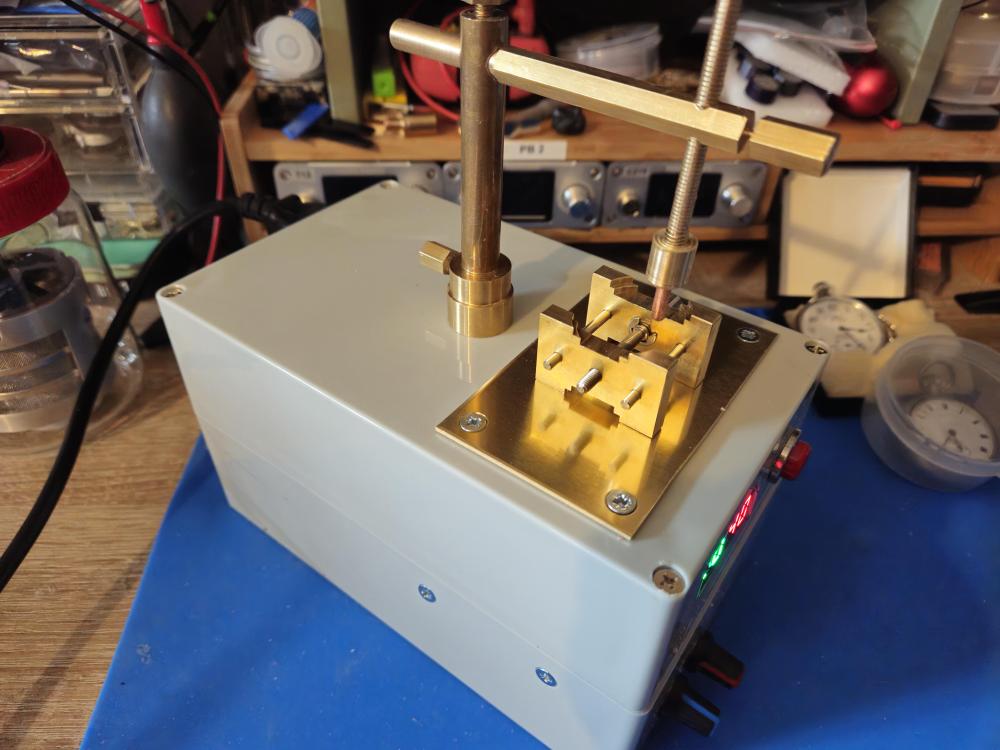

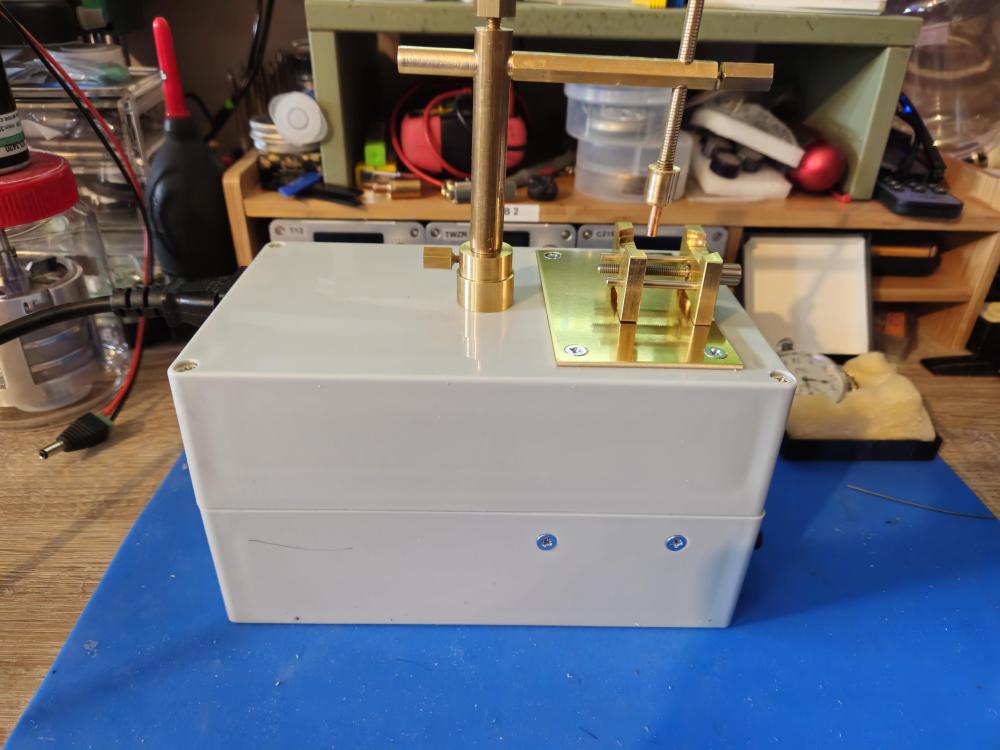

Hi all I alway fancied one of the Chinese Dial Feet welders like the one in the first photo below. The price of the Chinese one is around £200 with VAT plus £50 for shipping because its quite heavy. So as the Chinese are not against copying Swiss tools I tought it would be ok to copy the Chinse tool. So using a modified Microwave HV transformer, modified to output 12volts and one of the popular spot welding control boards from ebay I built my version. It worked in prototype so dont expect any issues now its built, just awaiting the arrival of some ready made dial feet to us it in anger. Total cost was around £30, the transformer was free Thanks Paul4 points

-

I just remembered I made a video showing how to perform the test I'm talking about. I hope it helps!4 points

-

I just re-serviced two of my anniversary clocks which I oiled with Windles clock oil. I think the last time I serviced them was 4 years ago. Is this an acceptable duration between service? This time I used all synthetic oils. HP1300 for the barrel arbor and 2nd wheel. Moebius 9020 for all the rest. I hope synthetic oils will give a longer service life. I also oiled the suspension fork, which I learnt from @oldhippy four years ago. I found the inside surface of the suspension fork a little rough and I burnished it with a suitable sized screwdriver blade. This resulted in an improvement in the amplitude.4 points

-

I get it in place, then rotate backwards while gently pressing down.3 points

-

Dan, sorry I didn't reply to your PM, I've been busy with so much lately that I forgot it. Unfortunately, you won't be able to find any spare parts for the Orient calibres unless they have changed their policy since I looked into it. This is regrettably the story for most brands today. Russian calibres and Sellita calibres don't have any restrictions. The way it should be, the right to repair! Anyway, your best option is likely to try to find a donor movement on eBay. Best of luck and welcome to WRT!3 points

-

It's not great, IF you did the test without the pallet installed. Assuming 18000 beats per day, 25 seconds is 125 beats or about 62 oscillations. You should get 100 or more. If the pallet was in place when you did the test it means nothing. Either way, this is not the principal issue. I was going to mention that I recently worked out that I get much better pics with a loupe held in front of the phone camera than trying to shoot down the microscope. I use a 20x loupe, but try with whatever you have. The roller jewel (or impulse jewel) could be an issue, particularly if it is loose, but this is also not the main issue. Get some clear pics so you can ask the experienced members here about it after you have addressed the main issue. Nothing in the escapement explains the rapid deterioration you're seeing 20 minutes after winding. That suggests an issue in the train rather than the escapement. The failure to self-start after it has been running a while confirms that power is not getting to the escapement. If it was me, and I was confident I had eliminated the barrel as the source of the problem, I'd be looking further down the train. I'd first make sure the canon pinion was out to eliminate the motion works as a source of the problem. Also make sure the centre seconds pivot is removed, if it has one, or the seconds hand if it has sub-seconds. If that didn't make a difference I'd then work my way through each wheel starting at the centre wheel. Is it sitting level? At the right height? Does it have just enough end shake? Does it have excessive side shake? What happens if you touch the upper pivot with a piece of pegwood with just a little bit of power in the mainspring? What about the lower pivot? Once I was certain there was no problem there I'd move on to the third wheel, and so on all the way down the train. Just because the train runs freely with the pallet out does not mean it has no problems as excessive side shake (for example) will only be an issue when the train is under tension. Finally, I advise you to stop re-cleaning until you have fixed it. I know the temptation, but it's just a distraction. You need to be systematic and methodical.2 points

-

This is great, thanks. Loads I can work on and improve here. I hadn't realise the barrel to arbor was such a big deal. Mine can definitely be improved.2 points

-

Here is a good video to cover the barrel, if it doesn’t spin on the arbor and rotate with a puff of air this is a great place to start. Tom You do need some side and endshake on all pivots and arbor or everything will just bind up with friction. Tom2 points

-

Yes, that's a furphy. If it runs for 12 hours, the centre wheel turns 12 full revolutions. The ratio between barrel and centre wheel is typically about 8:1 so the barrel must turn 1.5 full revolutions in that time. If you're only getting in one or two clicks on the wind the watch can't have been running for the 12 hours. (Unless you have elves who are pranking you by winding the watch just before you get to it.) It must have run for 15 or 20 minutes then stopped. Then perhaps it started up again when you touched it, and you assumed it had been running for the whole time. Dunno, but the centre wheel simply can't turn twelve full revolutions without the corresponding motion of the barrel unless the connection between them fails, and if the connection did fail the watch would lose its only source of power and stop anyway (and the mainspring would unwind all at once, possibly catastrophically). So, setting that aside, the barrel is the most likely problem, with wear where the arbor interfaces with the barrel and/or lid, or wear between arbor and bridge or mainplate. Very simple check: with the barrel installed and no wind in the mainspring try tilting the barrel with a pair of tweezers on each side. It should move an almost imperceptible amount due to arbor side shake. If it moves half a degree or more you have a problem. Have a look at this post for an example of excessive side-shake (and also excessive end-shake): If your barrel looks anything like mine in the video shown there, it needs work!2 points

-

That's a major red flag! It tells us the barrel isn't spinning as it should. Are you positively sure you don't have excessive arbor side shake? It takes very little for the barrel to start scraping against the barrel bridge or the main plate. It could be something else, but I'd say your problems begin at or in the barrel. That's where I'd look first. Is the barrel spinning freely around the arbor without the mainspring installed? That is, assemble the barrel (arbor and lid) without the mainspring and make sure the barrel spins freely around the arbor. More details are in the link below.2 points

-

VWatchie is still very active on the site. You may not know but all new members posts are individually moderated for a while so your post won’t appear immediately, we do try very hard to get to them as quickly as we can. Tom2 points

-

Hello, As I am in the learning process of servicing watches, I am struggling to find spare parts especially for this Orient Union cal. 46E40. I need a new mainspring and two DiaFix springs (which I managed to : loose one, break the other) - very nasty springs. I wonder if someone can give me a hand. I found this very nice thread , but I cannot reply there anymore and the owner @VWatchie is not active anymore ?! Any help will be highly appreciated. Cheers, Dan.1 point

-

I will check when I get to home base this weekend. Don't hesitate to bug me Oh wait! I am at the shop with the movement holder today! Yes, it will handle 18 size easy1 point

-

1 point

-

I polished the arbor and inside the barrel holes. It now spins freely even with a puff of air. I've put the new spring back in too. I'll lubricate it, close it up, and then strip and clean the rest of the watch again. I'll inspect it all super closely and take photos of anything I'm not sure is good. I suspected from the very first time I used the app that it was unreliable. I'll try some slow motion video when it's back together. The app seems to work enough to give a general idea. The first watch I serviced was a sekonda. Non running when I got it, runs like a champ now. I also did a josmar pin pallet. That runs decent too. The app though, I am not sure i trust the seconds per day. It's ok to get an idea, but then i go by what it's doing in real life. As far as the apps aplitiude goes, sometimes it won't read it at all. It does reasonably well when the watch is running strong though, and that's where I need to get them anyway. I will buy a proper timegrapher soon but I'm only into this journey 2 scrap movements and 2 working ones I don't care about. This 1917 watch is the first one I've done that I actually care about. Once I'm more confident I can actually do this hobby, I'll invest more. I'm very used to this kind of work, just not on anything anywhere near this scale!!1 point

-

I'm sorry to throw a wrench into your tests, but in my experience any amplitude readings out of that phone app are not reliable whatsoever. Maybe on a perfectly running modern movement they will get close to good results, but on any movement that has operational faults the amplitude numbers will be all over and usually don't make any sense. If you can visually confirm you are getting somewhere near 180° of balance swing (in each direction) by taking a slow motion video, that will be a better judge in absence of a hardware timegrapher.1 point

-

This will give us an idea of what it looks like when vibrating a hairspring with this doohickey. The balance I chose seems a little large for the saddle, even though it’s a men’s wristwatch balance. Could it be you can fuse the flat surface around the saddle? I don’t think so but am surprised the saddle isn’t a little bigger.1 point

-

1 point

-

The height of the stud in the stud holder should be adjusted to make the balance spring flat, so you've done the right thing. Congratulations!1 point

-

I remember watching this video a while ago. Really good! I really still don't understand how this can be possible. All wheels, including the barrel, should move advance (and unwind) the exact same, irrespective of high or low amplitude.1 point

-

Mike of my retro watches did a video about this very recently, concluded that a relume was the only option. Tom1 point

-

Not averse to some wabi-sabi but that lume has just about gone too far for me, it's close but will only get worse over time. Just my view though. I do love a 6105, and really need to add one to the collection at some point.1 point

-

1 point

-

That’s strange Dan, on the first page of a thread, right at the top there should be a reply button. In addition there should be a text box after the last post and you just enter your reply there. I’m not sure what’s going on there but if it happens again please post in the forum support section or contact any or all of the moderators. Tom1 point

-

Do you have the full details to confirm the mainspring is correct. Have you checked the barrel depth to suit the 1.75mm spring?1 point

-

It was some time ago when I read D.‘s pdf and don‘t remember the details. Just my impression, I remember many repetitions, a rather narrow focus and even few errors. Generally I welcome his attempt to spread knowledge about the topic. I suppose he also wanted to show the unknown efforts of a good watchmaker and do a little publicity for himself - but that is ok. He just is not practiced in good writing (as Jendritzki was). Frank1 point

-

1 point

-

Sounds like an interesting case. Can you post timegrapher pictures? This is very weird. I can't get my hand around it... if the watch runs during those 12h (does it?), it kinda has to unwind... Is the barrel closed properly? Does the arbor have a little bit of endshake inside the closed barrel?1 point

-

Hi Graeme and welcome! You will not find a more helpful or knowledgeable bunch anywhere. I'm originally from Chesterfield and still have family there.1 point

-

I'm somewhat curious as to why you thought that technique might work As with most arbors...reverse it in so it enters the wider spacing of the inner coil. A slight tilt will help it start. Brute force...lol...its not powerlifting...even that is mostly technique. If you made a shallow grunting noise....that was the moment to stop right there1 point

-

Have you tried inserting the arbor and then manipulate the spring through the gap so the collar will slide in.1 point

-

The hole for the hook does go all the way through Cees, so yes it is possible to push it further out as you suggest for the OP. I have a couple of sets of these, just a different brand. The hooks do stick out a bit further on mine, there is one that has broken off...needs pushing out and reshaping. Handy that they wind both ways. They are my goto set when nothing else fits, and if the arbor size works. They come in a set of 3 which gives a range from memory 7ish mm up to around 14mm, though there is a short gap in the range between the medium and large one around the 10-11 mm requirement. There is a bit of a technique involved when using them, the spring has a tendency when the bridle is fed in...to slip around to the next slot and poke back out. Let off on the winder before you feed it in so as to reduce the tension. But apart from those little idiosyncrasies, they're ok.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

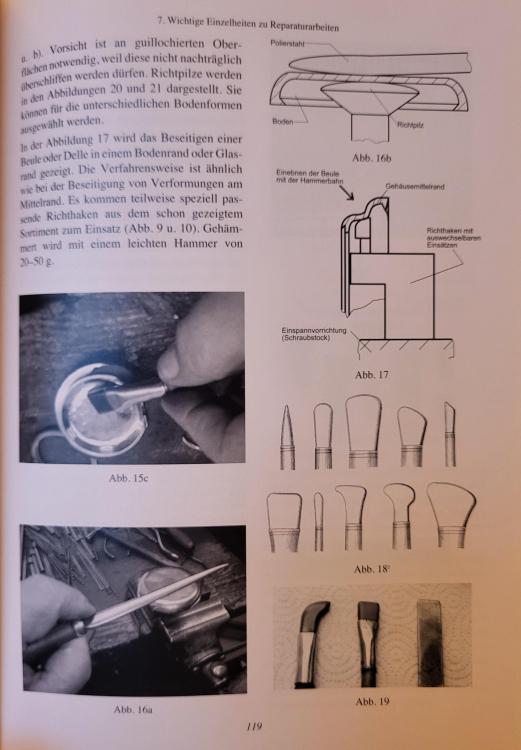

The first two tools seem like burnishers to me. For polishing pocket watch cases for example. They'd also be used for stone setting, but it's good to have different shapes for different jobs. https://www.cousinsuk.com/product/steel-burnishers I've added pics from Brittens Watch and clockmakers handbook and from Petzolds Das Handwerk des Uhrgehäusemachers. They depict the use for dent removal. Also good to tighten the snap of a case back or glass setting. The last tool looks like a knitting hook, good for the nerves when a watch job goes a bad way... Greetings Eero1 point

-

1 point

-

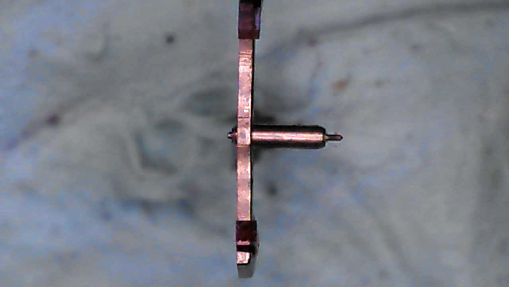

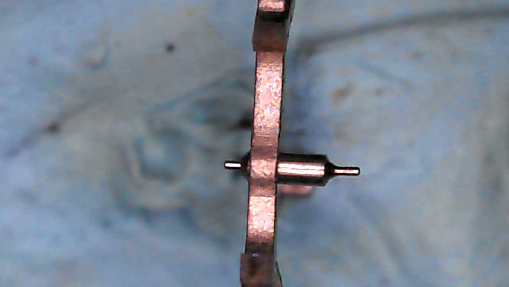

You haven't shown us a photo of the pallet pivots where one looks broken. Here's one of mine with a broken pivot (from a Seiko 7S26C movement). The pivot on the right is fine, the one on the left has been broken off. By way of contrast, here's one with both pivots intact (from an ETA 1080 movement): The photo you posted only showed one pivot, and it looked fine. It's possible the other has been broken, but in any case you should be getting the balance sorted before worrying too much about the pallet.1 point

-

Hello and welcome to the forum, plenty to enjoy. Two files added for your interest. TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

it depends on what I am doing sometimes I use diamond up especially when turning brass because it is best turned with negative rake and it’s easier to get negative with diamond up , I also use it for turning very small blue steel but then the graver is a lot smaller. Dell1 point

-

Yes, this is probably the hairspring rubbing, probably on the balance cock You can see it, just hold the movement dial up while watching.1 point

-

Dumont #7s are my go to tweezer for this. Ideally 2 pairs, but they are expensive. For me, my income depends on them so I shell out for the nice ones. I've tried cheap tweezers and they just don't hold up. Sure you can polish and shape them how you want, but the biggest issue I found was the closing force of cheaper tweezers. They are just too strong. Dumont's are just right. Gosh I must have $600 in tweezers alone! maybe I should cut back...1 point

-

This is what i used to do my watch oiler every other tooth of the escape wheel and on both faces of the pallets and to stop fluttering and to make it easy with the escape action using the same size oiler a wee drop each side of the pallet post that goes in between the pallet fork.1 point

-

Can you add a picture of handle Glen ? I think have the same ones but made by Star. Lol my mistake , I thought you started the thread Glen I'll start again.....Yokespring can you add a picture of the handle please1 point

-

1 point

-

Hm, the chipped entry stone might be a problem. See, evaluation of the escapement adjustment correctness by position of tooth edge against the edge of rest surface of pallet in banking position is not correct. This depends much on correct position of banking pins, and they are easy to bend. Wat You really need to check is if there is correct locking (the drop lock exists and is reliable) on every tooth of the wheel an on both pallet stones. When tooth moving on the chipped pallet impulse surface, it will leave it sooner as the surface is shorter. Thus the next tooth can drop not on the rest surface, but directly on impulse surface of exit pallet. Well, when this happens, the sound is different and I didn't hear such sound in the videos, but for sure even if the locking is still present, some amplitude is lost due to the chipped pallet. You have to better adjust the balance position by collet rotating, but deal with the hairspring position adjustment first. Every change of the hairspring position will change the 'beat error', so the beat error adjustment is the last adjustment to do on the hairspring1 point

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)