Leaderboard

Popular Content

Showing content with the highest reputation on 01/24/25 in all areas

-

Update: I think I have the balance oscillating freely at last. It's not always one thing. I adjusted the angle between spring and stud without unpinning the spring and did minor adjustments to the curve of the overcoil then put it back in the watch. It looked better, but didn't swing any better. I discovered the angled section of the spring where it transitions from overcoil to the flat coil was sitting too high and rubbing on the cock. After half an hour or so of patiently tweaking the spring and I was happy with how it was sitting. But it still failed the free oscillation test . I'm just about to leave it for a bit when I notice a tiny black fibre on the balance. I go to lift it out and find it is actually anchored at one end under the barrel bridge and I have to give it a decent tug with the tweezers to get it out. But such a tiny fibre, it's not even visible without the microscope. How much difference could it make? How about the difference between 40-ish oscillations and almost 140 oscillations from a 180º start! I need to make sure it's still good with the pallet bridge back in place, then I can get back to aligning the impulse jewel and hopefully getting it running with decent beat error and a modicum of regularity.5 points

-

Here is a small list of books I have to do with horology. Watch & Clockmakers of the world vol 1 & 2 The Horolovar 400 day clock guide mine is and old third edition. The French Marble Clock Carriage Clocks An old Fume watch catalogue White dial clocks Long case clocks Clock types.4 points

-

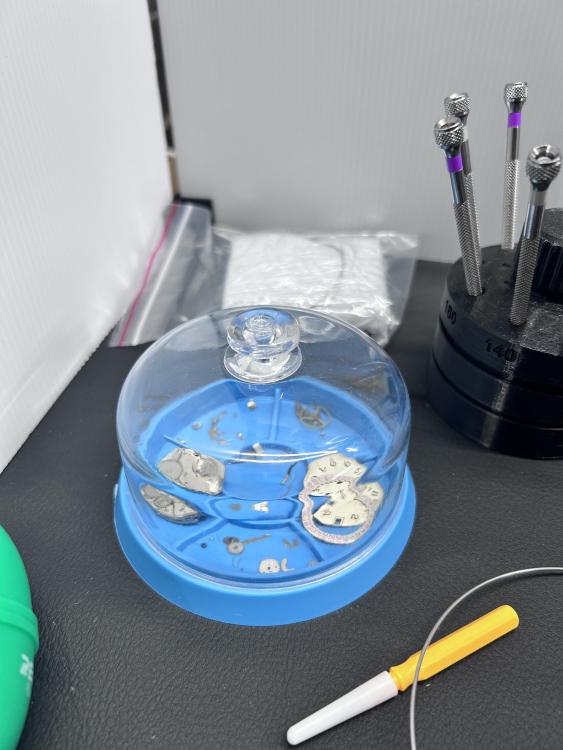

I haven't been able to work on any new watches for now because my tray is full with an existing movement. So I have designed this extension tray that goes on top of the existing tray and allows you to keep more than 1 movement organised at a time (or maybe organise a more complicated movement). https://www.thingiverse.com/thing:6924013 Designed for this cheap chinese trays. I have it printing now, so I will triple check it all works when I get it off the printer. Feel free to print as you need. I can modify it too should anyone need some tweaks.3 points

-

3 points

-

It’s the side projects that get you, the “oh, I’ll need to make that first so I can make this” every time. If you can keep them down to 3 or better for every real project you’ll be doing well. Tom2 points

-

2 points

-

Thank you for the warm welcome. Cleaning stakes is probably 80% of what I do daily . I had issues with severe flash rust with other things and I haven’t tried my ultrasonic cleaner with stakes yet. I probably will now just to see how it works out. I probably have 3-4 thousand stakes at the moment and was looking for a way to clean/polish large amounts at one time. I started out using Evap O Rust soaks, which worked but still required hand polishing and severe flash rust usually happened fast. I found a website that polishes jewelry in a vibratory type polisher so I picked up a large one to try out. (Eventually got a smaller one also). I started out with a ceramic type media, It did a great job, but I still had to hand polish each and every one and it left them like a muddy mess and clogged the ends easily. I then found out the big companies that specialize in polishing small pieces used a stainless steel media to clean and polish at the same time. Evidently using this method somehow burnished the stakes and prevented them from rusting easily. To get an even nicer finish they used a wet polish method and that has been the key to getting my best finish with large amounts of stakes. It just basically removes any rust and corrosion and leaves a very nice finish. I can’t measure any loss of material with a micrometer or a digital dial caliper. Some of these stakes are from the early 1900’s and are not as durable as the newer stakes, so it varies some. I have piles of damaged stakes that won’t make the cut but I’m saving in case I ever get a lathe . I did notice that sometimes the holes were clogged up and still needed to clean them manually. I wonder if the Ultrasonic process would fix that ? Before I ship a set I still manually go through each and every stake but sometimes I slip up and miss one or two. My processes are getting better and I’m getting more organized as I go. Thanks for sharing your process. I have some Boley stuff also that I am hoping to finish up one day. Thank you very much for the welcome and I hope to visit your country one day ! As a side note, we have 2 of your countrymen that have been living with us the last couple of years off an on while they study and play football at the local university , they are teammates of our sons “Soccer” team and we have really enjoyed hosting them and learning about . Every time they go home for a visit they bring us lots of sweets, chocolates and gifts from their parents when they return . They are exceptional young men and great ambassadors.2 points

-

In the process of laser engraving the plate, it is crucial to set the correct engraving depth. If the depth is too deep, it may result in a murky pad printing effect, while if it is too shallow, the lines may become disconnected, leading to broken lines. On flat dials without texture, using a harder silicone pad for pad printing will yield better results. The hardness of the silicone pad directly affects the thickness of the lines, and adjusting the hardness appropriately is key to achieving precise printing. Additionally, the ink ratio is another critical factor in successful pad printing. Adding too much thinner will cause the lines to become unclear, while too little thinner may cause the ink to cure too quickly, resulting in broken lines during printing. In summary, laser engraving, silicone pad hardness, and ink ratio are all interrelated, and each step can affect the final result. These steps require extensive practice and experimentation to find the most suitable formula. I hope these insights can provide some useful reference and help!2 points

-

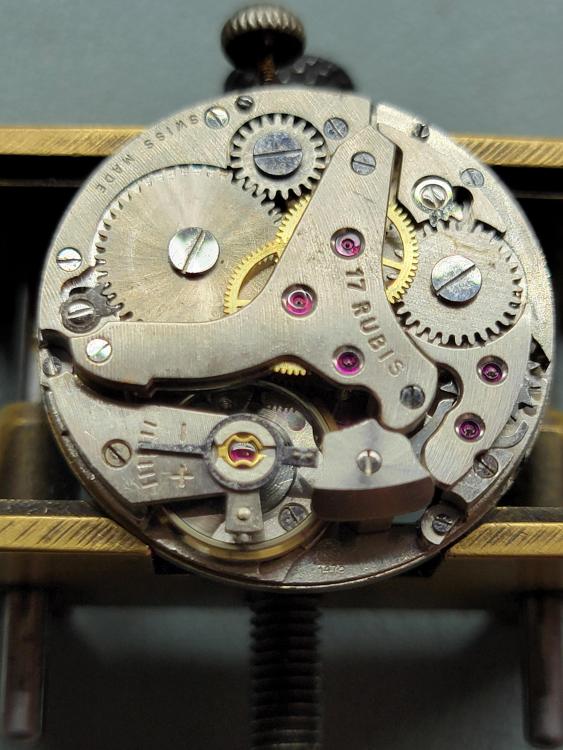

HWGIKE#36 Poljot 2614 2H Very nice condition inside and out. Very nice performance. This is the style I like probably the most, simple & clean. 17 jewels, Swiss lever. Hole for the barrel arbor tightened (staking set is used for this purpose the most), new glass, new strap. Barrel arbor plays hide and seek with me winning, but i had many other substitutes.2 points

-

2 points

-

Happy to report it’s been keeping excellent time on the wrist too. Calling this one closed. Feel a lot more comfortable to finally attempt the service on my Omega Cal.5652 points

-

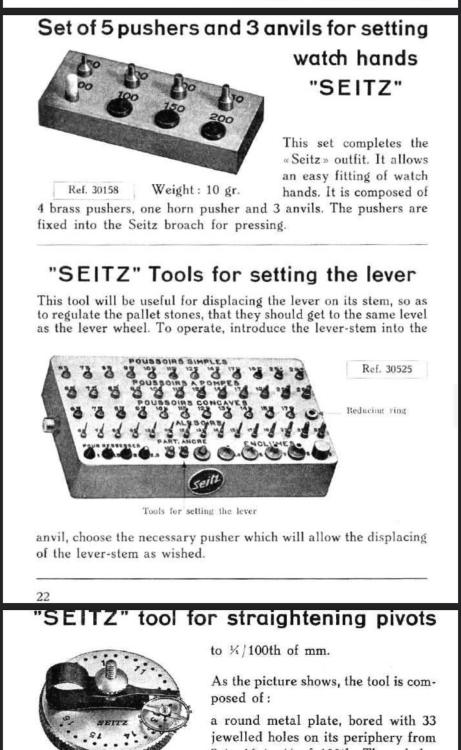

Seitz calls it a reducing ring in the catalogs I have available to me. In the sets I have I can put the ring in the 4mm base and use the 3mm parts from the older sets in it. Not sure if there’s other uses or not though I’m still slowly getting interested in restoring those and still learning as much as possible2 points

-

I get that, but you're making unnecessary work for yourself. Resign yourself to having to give the movement a final clean and lubrication once you've fixed the problem. You probably won't need to redo the balance or the barrel in any case. The oil captured between the hole and cap jewels will still be good even if you've had it in and out of the movement half a dozen times.2 points

-

I don't put dials under water. I put cling film on the desk, and work wearing latex gloves and a mask. I use cotton buds or cleaning swabs to wet each number in turn. Let them soak for a while, and the radium paint goes really soft. Then I gently push it off the dial with some sharpened pegwood - picking it up with a cotton bud, which goes in to a zip seal bag with all anything else contaminated for disposal.1 point

-

Well, I am having so much fun with the Sherline, I am not working on watches...need to fix that when the new wears off.1 point

-

The only usable video is the one under microscope. The amplitude there is about 175, so still far away from what is needed for this movement to perform well enough. For now leave the balance and hairspring alone. The free oscillations test is good. But is there difference in amplitudes DU/DD? At this point You don't have to worry about the rate, You only need more amplitude. You have to lubricate the pallets and see what the result is. Also, may be the total lock is bigger than needed. Can I have good picture of the escape wheel teeth? Is there significant free play between the guard pin and the guard roller when balance is turned left and right? Is the 'run to the banking' big or small? The autostart is expected to happen when winding the movement from fully unwound state.1 point

-

I picked up this alarm watch at a flea market several months ago and recently decided to investigate. I am not finished, but well on my way. As you can see, there was significant water damage. Running these parts through my L&R cleaner was not enough to clean them, so I did manual cleaning with one-dip and cotton swab (the dense pointed kind). The wig-wag was stubborn--the two gears would not release from the plate. I soaked it in Kroil overnight and that did the trick. There was some rust on the balance staff, but not actually on the pivots themselves. Nevertheless, I chucked it a step-chuck on my lathe and burnished the pivots. The watch is running and I have confirmed that the alarm drive train is functioning. Since I am missing a stem for the alarm, I have not done the final assemble of the alarm components. Surprisingly, there are lots of parts available for this movement on Cousins. I will probably get a couple of stems and maybe some other parts that I deem necessary. The watch is running at weak amplitude (about 190) and shows some poising issues. I will work on that. The last two pictures are after partial reassembly.1 point

-

1 point

-

1 point

-

Thank you. That's solved that issue. Centre wheel now runs. A bit more work needed to adjust the minute finger depthing now, and possibly a bit more lube. But nearly there.1 point

-

1 point

-

1 point

-

I had the exact same thing happen a few years ago, lost about a day trying to figure it out. Almost invisible little fiber sticking out from under the barrel bridge.1 point

-

I am working on an AS1475 myself. What did you have to do to get this to "set" properly in the watch case? I think mine is either missing something to hold it in place or something is not adjusted properly? Edit: I figured it out. Whoever took this watch apart prior to me had the caseback on incorrectly and I was just putting it back together as it lay. I tried different configurations until one of them worked perfectly.1 point

-

I never did find out the size of that piece. I am in the process of assembling a lathe and my first order of business is to make that part (or some approximation) when my 3 jaw chuck comes in. If that does not work out, then yes I may ping you! Welcome to the forum.1 point

-

I don't imagine the hands and dial are on the watch at the moment, but if they were I'd want the seconds hand removed while fault finding to eliminate the possibility that the problem was caused by the seconds hand rubbing on the dial. It's just about getting down the minimal working system: barrel/mainspring, train and escapement.1 point

-

1 point

-

This is good advice, a lot of beginners don't think to check function groups or train wheels in isolation. Seperate suspects, interrogate and investigate them under spot light to find your criminal. There may be half a dozen dodgy looking dudes in the line up, spotted at the scene of the crime. Seperate and interrogate.1 point

-

OP, several things to say here. You seem to have different behavior of the movement in different positions, more - You report it tends to stop with dial up. Nothing similar can be related with the barrel/spring problems. Playing with the barrel has nothing to do with searching for the problem. What You report about working well for 15 min. after full wind and then worsen may be because the spring is held tight by the click. Simply don't wind the movement to the end or release half revolution of the ratchet wheel back after full wind as to be sure You are in the normal area of the spring torque until diagnosing the movement is complete. I see You unpin the hairspring every time You remove the balance from the cock. Who told You to do that? This is stupid, You just have to remove the stud from the cock. The stud has a pin that tight fits in the hole of the cock. Just press the pin from above when the cock is supported on some edge near the stud No need to clean and lubricate everything every time. Make the movement run as it should, then if needed, re clean and re lubricate for last time if it makes You happy. Now, concentrate on balance. Try to make good pictures of the pivots. You have huge vertical positions differences, so we need to be sure no pivot is bent. Make some video of the free oscillations test. Make the free oscillations test in DU position too in order to compare with DD. The amplitude... You don't need software or timrfrapher for reading amplitude. This is one arm (2 spokes) balance, the amplitude is seen with naked eye. If it is hard for You to see it, put a dot with marker on the balance rim and observe it. Thus You will know the amplitude. We all can see the amplitude if we have slo mo video.1 point

-

That turned out fantastic ! That’s pretty much how I do my sets also. I have done a few with tung oil, but poly sure does provide more protection.1 point

-

hi @Mercurial thank you so much for your help! your explanation really clarified the concept for me, and i appreciate your patience in making sure i understood it correctly, from past years when the watches having the same issues were handed to me to fix the roots cause of the problem ,i did all this method and i'm grateful for your willingnesss of your knowledge and help me improve my understanding1 point

-

That, and your video, are not enough to be confident the balance is not rubbing on anything. You also seem to be testing without the pallet cock installed, so you won't detect any issue with the balance rubbing on the pallet cock. Replace the pallet cock and screw it down (without the pallet) then test the balance again. Give the balance a 180º turn (using an oiler or an artist's paintbrush) then when you release it count the full oscillations until it comes to a complete rest. You should get at least 100 full oscillations. For an 18000 bph balance that'll take at least 40s. Pay particular attention to how it comes to a complete stop: the movement should taper away to nothing; it should not come to a sudden stop. You really need to be systematic and methodical. IF the balance passes the free oscillation test then you can think about the pallet. Otherwise you'll just keep chasing your tail.1 point

-

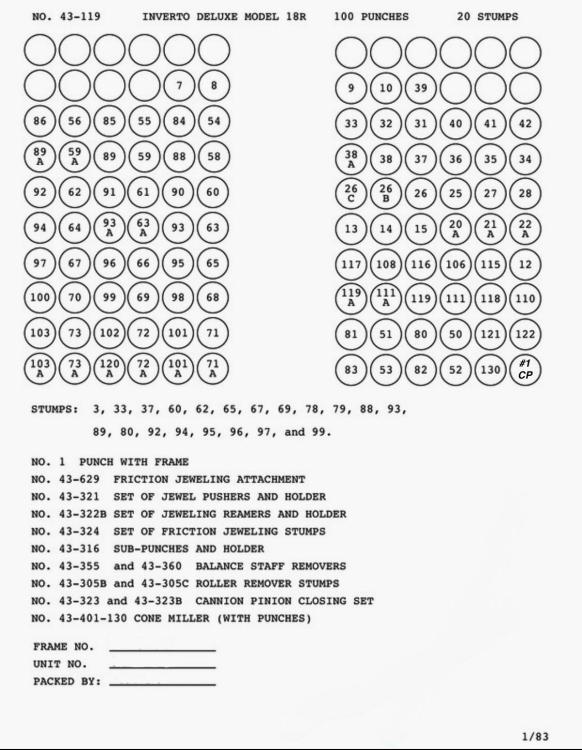

Claudio, Glad to find you on here and it’s great to see you learning and enjoying your new staking set ! If you have any issues please reach out and I’ll respond as soon as possible. Hopefully you’re still as excited as you were the day you got it. Did you make up your own stake mapping system ? That’s pretty cool ! Have you seen the actual factory build sheets/stake map for your set yet ? I’ve included it here just in case. There’s a rhyme and reason for the way they organize these stakes in these sets. Once you learn that system it becomes almost second nature and make sense. It’s not even close to being as easy as the C&E Marshall systems but it isn’t too bad. Take care brother and thanks again for trusting me with your staking set needs. Rick1 point

-

It's not great, IF you did the test without the pallet installed. Assuming 18000 beats per day, 25 seconds is 125 beats or about 62 oscillations. You should get 100 or more. If the pallet was in place when you did the test it means nothing. Either way, this is not the principal issue. I was going to mention that I recently worked out that I get much better pics with a loupe held in front of the phone camera than trying to shoot down the microscope. I use a 20x loupe, but try with whatever you have. The roller jewel (or impulse jewel) could be an issue, particularly if it is loose, but this is also not the main issue. Get some clear pics so you can ask the experienced members here about it after you have addressed the main issue. Nothing in the escapement explains the rapid deterioration you're seeing 20 minutes after winding. That suggests an issue in the train rather than the escapement. The failure to self-start after it has been running a while confirms that power is not getting to the escapement. If it was me, and I was confident I had eliminated the barrel as the source of the problem, I'd be looking further down the train. I'd first make sure the canon pinion was out to eliminate the motion works as a source of the problem. Also make sure the centre seconds pivot is removed, if it has one, or the seconds hand if it has sub-seconds. If that didn't make a difference I'd then work my way through each wheel starting at the centre wheel. Is it sitting level? At the right height? Does it have just enough end shake? Does it have excessive side shake? What happens if you touch the upper pivot with a piece of pegwood with just a little bit of power in the mainspring? What about the lower pivot? Once I was certain there was no problem there I'd move on to the third wheel, and so on all the way down the train. Just because the train runs freely with the pallet out does not mean it has no problems as excessive side shake (for example) will only be an issue when the train is under tension. Finally, I advise you to stop re-cleaning until you have fixed it. I know the temptation, but it's just a distraction. You need to be systematic and methodical.1 point

-

do I will have to track it down see if there's a way of doing a search to find it. I do know word is it just where exactly is it will be the problem is have to find it I did take a quick look at the PDF and yes is a lot of pages for just dynamic poising isn't there? oh and of course free PDF he does reference the Greiner timing machine manual which does have a nice section on dynamic poising. Which is relatively short and to the point without all the other bonus information that I have an objection to.1 point

-

It was some time ago when I read D.‘s pdf and don‘t remember the details. Just my impression, I remember many repetitions, a rather narrow focus and even few errors. Generally I welcome his attempt to spread knowledge about the topic. I suppose he also wanted to show the unknown efforts of a good watchmaker and do a little publicity for himself - but that is ok. He just is not practiced in good writing (as Jendritzki was). Frank1 point

-

Hi Mehmood, and welcome to the forum! There are some misunderstandings in what you’ve written, I hope that the information below is helpful. It is considered bad practice to let down the power in the mainspring by removing the balance and pallet fork. This releases the power in an uncontrolled manner, and it can cause damage to the watch. The train of wheels is not designed cope with a sudden release of power, and the rapid acceleration of the escape wheel as you remove the pallet fork can cause a destructive collision between the pallet jewels and the escape wheel teeth. Sometimes the pallet fork will move as you lift the pallet fork bridge, unlocking the escape wheel with the pallet fork still in close proximity, which can chip the pallet stones or damage the escape wheel. A watch with excessive amplitude can result in the roller jewel hitting the outside of the fork horns as you describe, which is known as rebanking or knocking. A shock to a watch that accelerates the balance wheel can also cause the roller jewel to knock, but this behaviour will stop once the shock stops, the amplitude will return to normal and the watch should run properly again unless the shock was strong enough to cause physical damage, such as a broken roller jewel. Overbanking, or the escapement going ‘out of action’ is a different condition, and occurs when the roller jewel ends up stuck on the wrong side of the pallet fork. A watch that is out of action will only start running again after the balance is removed and replaced in the watch with the roller jewel on the correct side of the pallet fork. A shock should not cause a watch to go out of action as the result of a shock unless the safety action of the escapement is set up incorrectly. Finally, you cannot overwind a watch, unless you wind it to the point that it is fully wound, the winding crown comes to a hard stop and you apply brute force to the crown in an attempt to wind the watch further. Overwinding in the sense that the word is usually used doesn’t exist. Best Regards, Mark1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Remove all hardware, sand everything down to bare wood, stain, and then apply a few coats of polyurethane. Let poly cure a few days before putting it back together.1 point

-

All the other watches I have so far are broken in one way or another- which is why I got them for free- so I haven't been able to get them working yet (need a staking set, etc). However, I did get a practice movement that I just took apart completely and reassembled. And if runs. I feel like it's a milestone.1 point

-

No reason at all not to. That's really the only way to fix them.1 point

-

That's the same set included in the 18R Deluxe Staking Set. Fortunately, you can use the reamer holder just as a normal stake.1 point

-

I've just finished refurbishing a Memostar Alarm with AS 1931 movement (same as 1945 but with date and running at 21600). I was also surprised how many parts are available at Cousins. Like you, I was missing the alarm stem (Cousins stock them) and I needed new crowns. It's a nice simple movement for an alarm, easier to service than a Seiko Bell-Matic. BTW I made a note in my Servicing spreadsheet: "Pull out winding stem before removal". It may have just been wear on my movement, but I found that the yoke could move out of the clutch if the stem was removed in the normal position (like some ETAs). You might find this interesting1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)