Leaderboard

Popular Content

Showing content with the highest reputation on 01/26/25 in all areas

-

A watch owners expectations are the polar opposite of a watchmakers expectations .4 points

-

Changing batteries of a dead quartz watch. You never know what you'll find inside. It could be a straightforward battery change, to a complete disassembly, clean and oil. Or even a total movement replacement. It becomes even harder when it's an expensive watch and the owner never expected anything other than a simple battery change.4 points

-

3 points

-

Fitting the hour and minute hands so that they line up perfectly when the watch is running.3 points

-

3 points

-

What's the watchmaking task you always think is going to be straightforward, but throws up some unexpected frustration or obstacle for you whenever you do it? I would especially be interested in hearing from the professionals! For me, a hobbyist with 3 years experience on maybe 50 watches, it is stem and crown fitting. Replace a broken stem, cut to length and file. Everything is feels right, put it into the case with the movement and find that something doesn't work once the caseback is screwed down. Maybe it's 0.1mm too short now, maybe the crown is binding on the case tube, maybe it turns out that the case tube is actually damaged out of round. Maybe the gasket is too elastic and pulling outward on the crown, fouling the keyless in some way. It should be easy. It never is. What's your frustrating task?2 points

-

Hi Rick, I am still ecstatic with my set. Still learning how to use it but have removed snd installed several jewels and reduced the size of a main plate hole!!2 points

-

Casing the movement. While the components of a watch movement almost always fit together perfectly, it is far from certain that one can expect the same precision between the movement and the case. Also, getting the movement out of the case can sometimes require a lot of research. You think it should be quick and easy, but no.2 points

-

thanks for the clarification but to be honest I was guessing that that's what was going on. You did the hard work of checking the serial number against everything I only checked it against Elgin and Waltham and could see it was definitely wrong. plus the watch that you did find that is look remarkably like the one that we have here you did the hard work. and yes that's definitely not a steel barrel. Even if it was plated which I've never seen they visually do not look the same there very different in the construction so it's very clearly not a Waltham watch. But that we do come back to the problem of what is it? The pocket watch database suffers from the problem of using parts books to identify watches which has lots of problems. the biggest problem of using parts books for identification is that the same parts can go in different watches it have different values. Then so many watch companies didn't exist long enough to even have a parts book. But we do have lots of books out there that identify all the American companies even ones that run business for limited quantity of time. So looking at the reference material I have at hand I can't find this company but this still a couple other places I was thinking of checking. Nine so no matter what we do have an interesting watch that no matter what currently only two of them appear to be in existence I wonder how many more these exist? I suppose I could done the math with the serial numbers we could probably guess usually by even numbers of when they started and when they ended. then there is the very very tiny possibility of a makers mark appearing somewhere else on the watch. I once saw a really nice small ladies cylinder watch that had no market anywhere that I remember except when it was disassembled it was marked on the main plate under one of the bridges. or last week a full plate American pocket watch that has the patent date in other words before patent numbers they put dates on things all nicely spelled out on the main plate where you can't see it as it's a full plate watch and it's hiding. Which I always find interesting things that are hidden? what's interesting with fake watches are there supposed to be cheap imitations of something. The only thing that this appears to be a fake version is a fake were version of a Waltham movement but not a Waltham watch as otherwise it would've said Waltham. I'm wondering if probably in Switzerland may be one of the counterfeiting companies may be branched out and made other watches maybe for other people that they could purchase an important put their name on. Then of course there is the likelihood of some very tiny American watch company perhaps. In any case here is talking about Swiss fake watches. https://mb.nawcc.org/wiki/Encyclopedia-Subjects/European-Pocket-Watches/Swiss-Fake2 points

-

The part is called the setting lever. In the standard Swiss numbering scheme it's part 443. IF you can identify the movement you might be able to source a replacement part. (There is a forum here called "Identify this movement or watch".)2 points

-

I don't think that's wear. Some watchmaker has filed it to adjust the clearance between the fork horn and the impulse jewel. Probably the same person who filed the banking pin. I couldn't comment on whether that was inspired or butchery but it was probably done by someone with a lot more experience than I have. Watches this old have probably been worked on by many different people at many different levels of expertise. Unless it's obvious that another hobbyist has had their grubby paws on it (like the ones that come drowning in oil), I'm beginning to assume that everyone who's touched a watch in the past probably knows what they're doing better than I do. So when I notice something like this, I think, "That's interesting. I wonder why they did that?" but I don't try to reverse it unless it's clearly causing problems.2 points

-

Do you know how to adjust the beat error on a watch like this? It doesn't involve touching the roller, only turning the hairspring collet. See this excellent video (but don't worry about the first bit where he gets the impulse jewel in roughly the right position as yours is already there; just do the adjustment he shows in the second part of the video after putting the spring back in place): BTW, you're not trying to do all this with the watch in its case, are you?2 points

-

I think this would be a good place to start, definitely an expert showing his skills I have sometimes wondered if there are any drawings around for the old standard sized pocket watch cases. Plenty of orphan movements out there that would be nice to resurrect into a useable timepiece, apparently pocket watches are coming back into vogue. Tom2 points

-

Working on a cheaper, heavy worn steel/titanium bracelet, when the splints are rusted, broken in many pieces, stuck in like hell. Customer thinks it's a 10min job and you need a bigger hammer, penetrating oil, hard metal drills, another pair of hands to help you...2 points

-

When I was first beginning to work on watches, EVERYTHING was difficult. The thing that most frustrated me was reinstalling case clamps. Should be easy, but I only had steel tweezers (that needed a heavy touch) and cheap steel "jeweller's" screwdrivers and no matter how much I tried they always had a bit of residual magnetism so the screw just refused to stay put. I had to hold it with the tweezers with my left hand while I got the screwdriver seated with my right, then turn the screw at least half a turn before I could safely remove the tweezers. Getting some decent non-magnetic tools was transformative.2 points

-

2 points

-

I'm a retired dentist and I used a pair of surgical loupes for over 20 years. Dental loupes are quite heavy and put additional strain on your neck and nose bridge. I changed my standard frames to a more ergonomic frame that has a strap that goes around the crown of the head and pulls the frames upwards to take pressure of the nose and prevent them from sliding down. Dental loupes must be adjusted correctly, centering each eyepiece with the optical axis of each eye. The inter-pupillary distance must be correct to get the maximum field of view and the declination angle must be adjusted correctly to reduce strain on the neck. Many dentist own loupes but do not use them, citing eyestrain and double imaging. It also took me a couple of years, with constant tweaking and modifications, before I could use my loupes for a full day's work. I seldom use my loupes for watch repair work, instead I prefer a stereo microscope. I think a microscope puts less strain on the neck.2 points

-

I'm not sure if I posted this one before but I recently serviced it and was able to get a crystal that fit. I had an issue finding one that was both the correct size and was an 'underlay' type but found one on Cousins. This one fits although the corners are more rounded than the original. The watch came as part of a watchmakers estate and was labelled as an AS970, which it is also marked on the dial side of the mainplate. These seem to be few and far between with the vast majority of AS970's having a sub-seconds hand.2 points

-

2 points

-

2 points

-

I'll probably get a tap and die set in 0.8, then if the screw doesn't fit nice, I can make one of those too. I'll see what steel I have lying about. I know I have a sheet of ground tool steel, but I think it's about 3mm thick. Could still use it, will just be more work. If not ill find something hardened and soften it up again.1 point

-

Personally, and I’m no expert bear in mind, would go for the ease of working tool steel. If I had the skills I would also look at making a new setting lever screw so I could get a suitable tap and die so they match perfectly. Once the setting lever is pinned and tapped I would consider hardening and tempering both followed by a right good polish to reduce future oxidation. hopefully a real expert will come along and say I have the right idea or shoot me down in flames so we can both learn something. Tom1 point

-

I believe it is K&D #150. Maybe you can find an instruction sheet. They do tend to be floating around for K&D tools.1 point

-

1 point

-

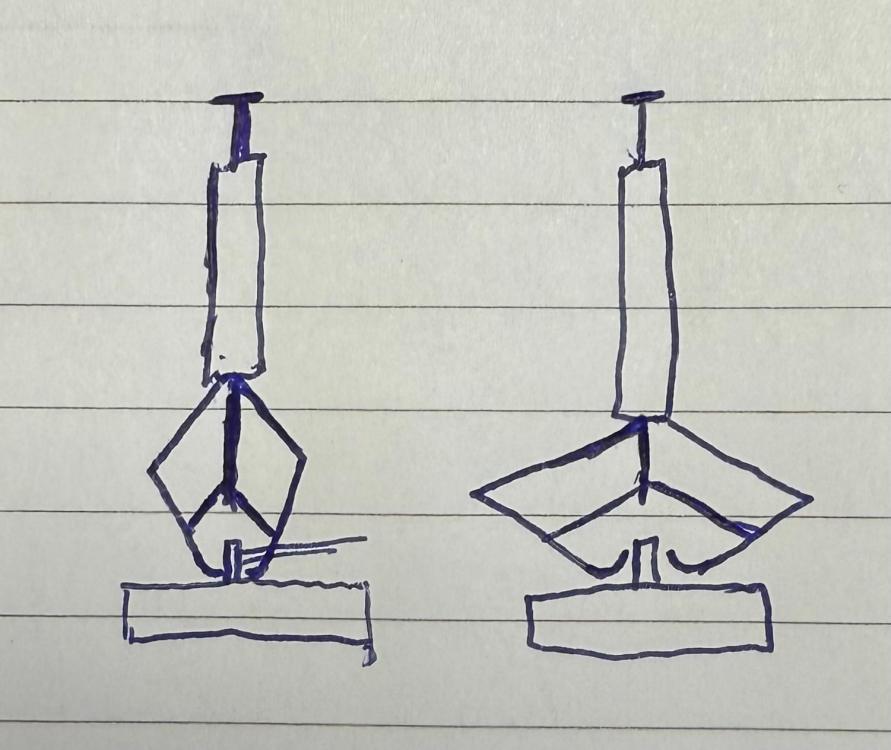

The one on the right is a roller remover, especially if it has some extra tips stashed in the handle to sit over different sized balance pivots.1 point

-

The one on the left is a hand remove although it appears to be slightly broken. The central plunger piece should be attached to the two things protruding just above each of the lever blades at the end of the arms. To use it you actuate the plunger until the ends of the blades are parallel with the dial and a slight gap between them. You then position the canon pinion in the gap so the blades are between the dial and hands and push down on the whole tool. This forces the arms to rotate and the blade ends to tilt upwards against the hands sliding them off the movement. They're ok to use but I almost always use standard levers over that type. Excuse the crude drawing but I'm not a great artist!1 point

-

Yep, and used a lot on 1930s omegas. They fail around the spring bar holes and then the lugs get cut shorter. A friend was telling me it's a 'thing' to be careful of in the vintage omega world. Took some photos. On no particular order they show where the fixed lugs were, the replacement plates, the pins holding them to the lugs, the mix of metals, the loss of plating, how rough the case is, the bezel fit, the yellowed crystal that I really like, and although it's super hard to photo, you can feel the crystal peaks in the middle like it's cone shaped. Unfortunately it's missing a seconds hand, the screw hole in the arbor is chewed out, screw is missing, click spring is missing and the movement in general is just really manky. But I really like this watch. Ill leave the dial as is, 're do the lume, sort the case (which I think the easiest way is to make one, unless an exact match donor comes up made in brass or stainless). It may end up needing a donor movement. I pretty much just bought a dial. Thought I'd check, would cost £70 in silver to make it, or about £10-£15 in brass depending on what shape I want to start with. £4916 to make it from 18ct gold. That's for a piece 4.5mm square and 200mm long. The first video he used 1/4", so about 6mm and 330mm long. That's £14320. And he treats it like it's a bit of brass1 point

-

So this is your movement which at least gives an approximate date and I've also seen another similar dated 1922. https://www.vintagewatchroom.com/product-page/1918-buren-sterling-silver-gents-trench-watch Edit Here's another dated 1916 but still no further on with a number. https://www.worthpoint.com/worthopedia/antique-wwi-1916-buren-solid-sterling-5321844541 point

-

1 point

-

1 point

-

1 point

-

That's good to know. Ill see whatbim feel is easier. Setting them in might be easier to get them in the right place and straight. I hate cad. I sort of just about got my bead around 2d cad, but 3d I haven't tried. To be honest, I could make it in the lathe in an afternoon so not worth messing. If I really wanted to, I could use a friend's mill to shape the outside of the case, but I already have the skills to turn one up and solder on the lugs so might as well stick with what I know. This may actually now come to the front of the queue as the bulb has just broken in my microscope so movement work will be on hold. Not sure If I already have any brass though. I deffinately don't already have enough silver. I might have some stainless though. Seems a shame to nickel plate stainless, but if I brazed the lugs, I'd have to. I'll have a dig in the workshop and see what I can find.1 point

-

If you want to shorten the working distance, wear a pair of reading glasses under the loupes.1 point

-

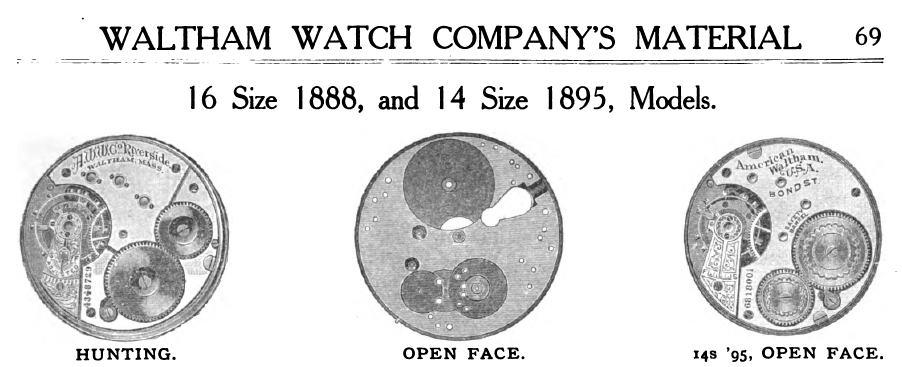

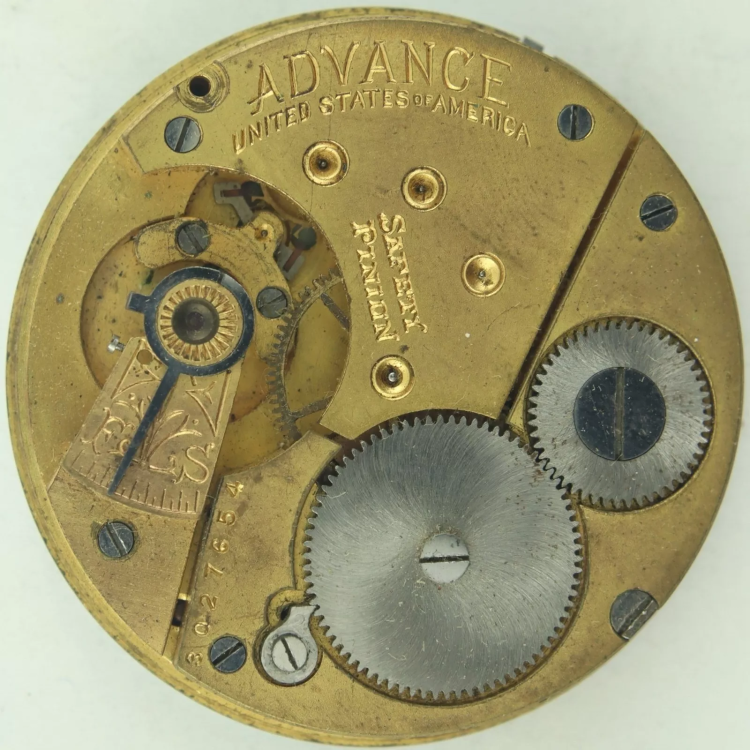

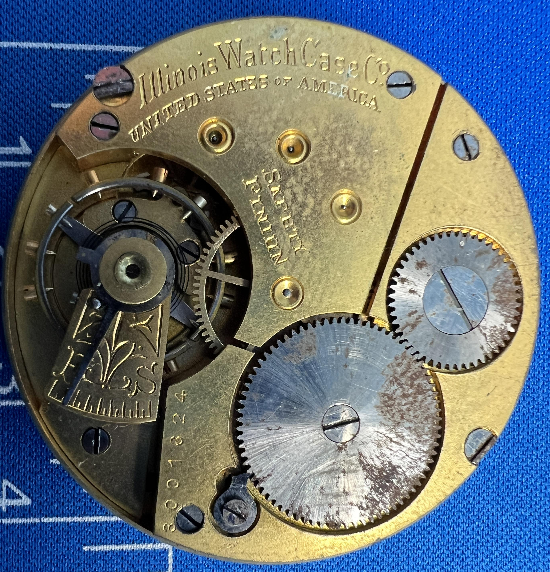

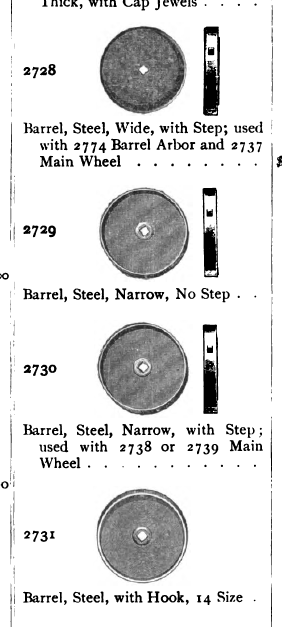

yes definitely that's a US terminology. Plus the letters F and S on the balance bridge versus the way the Swiss with market. Then the location United States of America would indicate definitely something? Oh did you read the description of the company on the pocket watch database at the link found above someplace? A really interesting company they like the name Illinois but they really liked another name much better which was this one Elgin Nation Watch Case Company. then it does appear a spelling mistake and I copied and pasted. Unfortunately for them the Elgin national watch company did see it as a innocent mistake and took legal action. At some point in time a judge said you can't do this but don't worry they really like Elgin and used in a whole bunch of their other products. this definitely brings up a problem? this also brings up a problem of serial numbers. The problem with this theory is Waltham has serial numbers and even a private label will have a serial number and this serial number isn't right for the watch. I'm having a confusion here the watch on eBay the serial number 3027654 is what I was reading and it comes back as a grade 15 which is an 18 size full plate pocket watch. But what I find interesting is the serial number in this discussion is 3001624 which comes back as a grade 25 also 18 size full plate. So whoever manufactured these at least the serial number is changing. The reason I point out serial number changing is I have seen some watches where Princeton somewhere I have a movement that I looked up the serial number just googling it and somebody else was auctioning my watch off with the exact same serial number. But here the serial number changes and even put it on the plate side. So it does appear to be a small production run. and have a can confusion with the quote above except I really like the link. In fact I like the link so much let's go to the wall from parts catalog four 1888 which is the model of this watch. I'm guessing that what we have is a clone of the 1888 and this is not Waltham yes the Swiss like to clone watches and annoy the Americans. So parts catalog image on top of the watch of this discussion and the watch off of eBay where they actually look quite similar at least of the things we can see. There does appear to be typical Waltham lots of variations lots of different balance bridges quantity of jewels the plating used typical Waltham lots of variations. then the mystery watch has some minor problems versus the original. Only one case screw. Waltham screwed up they don't mention safety pinion and I can't find a reference to that the parts listing. The crown wheel is interesting here there's one large screw and Waltham uses an insert with a smaller screw. But there is something else that would be a real giveaway as I doubt somebody would clone this aspect especially when it's not visible. so I need another photograph from @BirdNerd based on the images you already have it looks like you'll have to remove the two case screws and then remove the dust ring. I need a picture of side view showing the mainspring barrel. to understand what were looking at one unlikely to find a standard brass colored mainspring barrel versus the mainspring barrels that are supposed to be found in a watch of this grade which I pasted below. I find it extremely unlikely somebody cloning watches would clone the barrel itself. that has also trying to find a picture of the dial side of this watch like on eBay but conveniently everybody has their dials on.1 point

-

1 point

-

I'm looking at my scope and trying to imagine tilting the head backwards but I'm not seeing it. I'll do a search and see what I come up with. One thing that might be helpful for you or others is something I just found out a week or so ago after the pain started which is if you're on a windows computer you can press the windows key and the letter H and you can dictate by voice instead of typing. Most sitting and typing at this time is near impossible so this has been very helpful. And it's also very accurate.1 point

-

Hi hector, I appreciate your insights as someone who has used loops for many years. My big concern is that they won't have the working distance that I am looking for. I agree normally with my microscope I am very happy. Unfortunately it's not working so well with my old neck. thanks for taking the time .1 point

-

Another problem is the bearing on the rotor so this may have something to do with the lack of power.1 point

-

Yes but it is also exactly the kind of thing that would get stamped onto a Swiss Fake to mislead buyers. (I still don't think that's what this is)1 point

-

1 point

-

Is it a front loader? Do you need to remove the bezel, to drop it out of the front?1 point

-

In the process of laser engraving the plate, it is crucial to set the correct engraving depth. If the depth is too deep, it may result in a murky pad printing effect, while if it is too shallow, the lines may become disconnected, leading to broken lines. On flat dials without texture, using a harder silicone pad for pad printing will yield better results. The hardness of the silicone pad directly affects the thickness of the lines, and adjusting the hardness appropriately is key to achieving precise printing. Additionally, the ink ratio is another critical factor in successful pad printing. Adding too much thinner will cause the lines to become unclear, while too little thinner may cause the ink to cure too quickly, resulting in broken lines during printing. In summary, laser engraving, silicone pad hardness, and ink ratio are all interrelated, and each step can affect the final result. These steps require extensive practice and experimentation to find the most suitable formula. I hope these insights can provide some useful reference and help!1 point

-

I have the watch back together now and it is much better - looks like the ring the bezel clicked over was just worn ( the watch is maybe 70 years old!)1 point

-

The watch is a Roamer - says nothing more than Roamer 17 Jewels and Swiss on the dial. The movement is an MST 402 I think I have remedied the problem. I ran the back of my tweezers around the inside of the ring on the case the bezel clicks onto gently pushing outwards. It has made enough of a difference1 point

-

Yours is a nice set too! I actually bought two. I ordered one from the Czech Republic about a month ago, but I haven’t got it yet. It seems like there is a problem with the postage because I was supposed to get it January 14th. Then I saw this one that somebody else was selling on eBay and I went ahead and bought it because I needed it. Once I get the other one I will see if I will sell it since two are probably not necessary. I may have misspelled the name. I think is Steiner. I guess the other one I am waiting for is very similar to yours. here it’s a picture of it:1 point

-

Spent a nice Saturday morning on this nice Helbros that I picked up at the beginning of the month in a lot for $5US. Did not work, could barely get the minute hand to turn and was dingy. Stripped it down and had a bent 3rd wheel and it looked like someone tried to make an overcoil out of a flat hairspring. Has an AS 1660 with only 7 jewels so did not want to have to put any money into it. I did have a new acrylic and watch strap that fit beautifully and the dial cleaned up a bit with just IPA and water, carefully and gently of course.1 point

-

A design flaw Rolex refuse to let go of is the fixed axle, when others use bearings and because people listen to that chat about waiting for your watch to lose time, feeling stiff to wind, blah, blah... This is the obvious result of waiting for something to go wrong, which is a rotor turning without any lubrication which wears the axle to ridiculous proportions and takes the plating off the movement and rotor. If it is serviced often then this doesn't happen so often. The customer will give you a story with their watch, but the movement will always tell you the real story. I usually replace the axle, and definitely when it is like this Two things to watch out for, leave the calendar cam jumper spring in situ when cleaning and make sure you part the friction fitted cannon pinion that turns the date corrector. If it isn't taken apart, cleaned, lubricated, it will likely fail as a safety feature to stop damage if the quickset is engaged whilst close to midnight. Easily missed. Great movement to work on. Be careful not to mix screws up, as two are really similar and I've made that mistake. I think it was the crown wheel screw that is under the bridge, hence a normal right hand thread. All that wear created a great abrasive dust throughout the whole movement which settles in where there was something to stick to, such as lubricant. Now that has dissipated it has left that abrasive dust to do its work. Hopefully the damage isn't too bad, but I reckon you'll have some pivots to polish at least.1 point

-

Most welcome @VWatchie! I'm actually getting pretty excited when I'm able to provide ANSWERS instead of just asking questions all the time. Don't hesitate with any questions about this calibre. The rate and amplitude are just about acceptable, I guess. But if I bought it like this, let's imagine, I'd service it. When/if you service it, make sure you know how to deal with the reversing wheels (Epilame..). Also be careful not to break the balance stop/hack spring. The escape wheel jewel settings are easier to oil from below. In the date mechanism, be careful that the cam yoke, it's jewel and spring don't join the Rolex space programme.. Apart from these little details, it's an absolute joy to work on. PS: another detail: the casing screws release the movement in the opposite way, i.e. tighten the screw to release. Then turn the movement until the casing screw-rings line up with the two cut-out areas of the case (one is at the winding crown). The the movement can come out. PPS: to open the case, have you tried the rubber ball? Sometimes it works..1 point

-

1 point

-

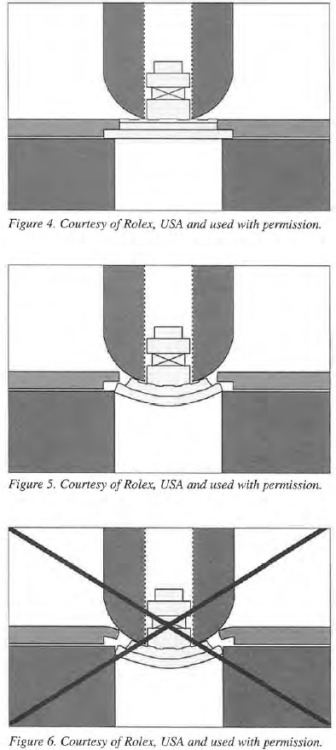

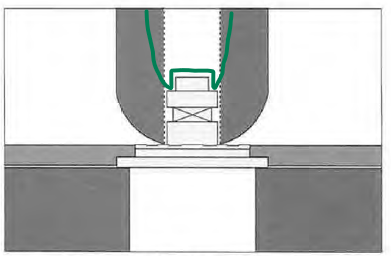

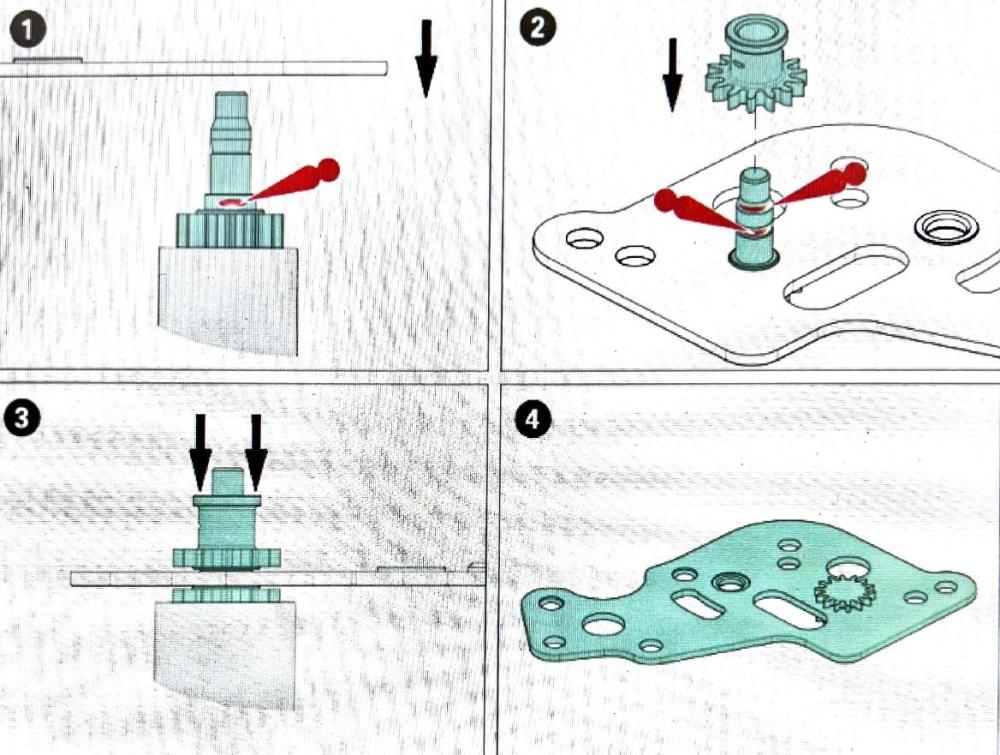

Yes, I have the set of punches and they are 4.6mm. And my staking tool (Boley) has the standard 4.7mm. It does, unfortunately, produce a little bit of play... in my attempt to use it, I wrapped a layer of aluminum foil around the stake to reduce the play. I think that worked ok (I failed for other reasons). A professional (Rolex trained) watchmaker told me that I don't need to worry about the play because it would somehow not matter when you actually hit the stake (with the axle and rotor flat on the anvil.... but I wasn't convinced. There are specific punches for each calibre. I doubt that they are interchangeable. This is indeed meant to be done that way. In my case, no damage was caused at that stage. I don't think you need plastic protection. The attached (as PDF file) article from the Horological Times is brilliant and goes into a lot of detail, see pages 10-14: 2009-03-web.pdf One screenshot from the article is below. NOTE: If you don't have a punch that fits as perfectly as shown in the picture above (and if you want to reduce the risk of hammering too hard and consequently hitting the rotor with the punch as the axle breaks away), you can use a punch that just fits over the top of the axle like drawn in green in the picture below.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)