Leaderboard

Popular Content

Showing content with the highest reputation on 01/28/25 in Posts

-

Explaining to a customer that what they have is utter crap. Trying hard to be tactful about it. This is something these days I couldn't do I'm not very tactful these days it's my age.5 points

-

OK, it is good to understand the maths, but this is of no big use when real poising needs to be done. The others in the thread give good advices, but I will try to summarize all shortly. You don't need to fill all this tables with the rate data in 8 positions. Finding the heavy spot is easy - by slowly rotating the movement together with the microphone, You find the exact position where the rate is fastest while amplitude is about 150. You don't care if it is crown up or half-norhteast or whatever. Then You stop the balance, bring it to neutral position and the heavy spot is down, under the balance staff. If You are afraid to forget where the heavy is, then put a dot with marker. Of course, You have already seen how big the rate differences are, so with the experience gained, You will be able to suggest how mush material You have to remove or add. In beginning You will make small changes and checks. Knowing the rate in horizontals, You decide to remove or add material. Now, If You deal with some Patek or Vasheron with golden screws, this is another business. Here You have simple and not expensive movement, so filing the screws is not a crime. But better choice is to drill holes in the heads with half smaller drill bit than the screw. No timing washers - use timing wire. Simply untighten the screw, make a wind of thin copper wire under it as the beginning and end are on the bottom side, then tighten the screw and cut the excess with office knife. Static poising helps to shorten the process when the differences are big. No poising scale - use tweezers. Of course, You can skip static poising. Have in mind that when differences are not big, the dynamic poising can be done by bending internal curve of the hairspring only, thus moving the center of mass of the spring relatively balance wheel .5 points

-

"I'm sorry sir, but a real Rolex ends with x and not with cks"4 points

-

There’s something to what you’re saying. When I’ve spoken to professional watchmakers over the phone (which I stopped doing a long time ago) to seek advice or inquire about spare parts, I’ve definitely gotten the feeling that they’re thinking, “Another idiot who thinks servicing watches is as easy as servicing cars.” Eventually, it becomes an “occupational hazard.” That, in turn, reminds me of a female student I had a few years ago who was above-average attractive. Every time I came near her to show or explain something, she reacted as if I were a drunk, obnoxious man trying to hit on her. And trust me, as a teacher, if you’re not professional and on top of your game in the private education sector I work in, you’re out of the game in no time. At a later point, I discussed this student with my boss and explained that her attitude could become a problem in a future workplace. I said she reacts as if she were working as a bartender in a nightclub, surrounded by a bunch of drunk, horny guys trying to get her into bed. My boss raised an eyebrow, looked down at her CV, and noted that she had primarily worked as a bartender! Speaking of occupational hazards!4 points

-

Shellacking impulse jewels is my hardest "easy" task. I always heat it up too fast and have to redo it. Hairspring straightening is another one. I think i'm close, and then my adjustments keep compounding into more and more adjustments.3 points

-

Oh but I have a plan m’lord, a very cunning plan, so cunning that you could put a tail on it and call it a fox! patent pending fractal movement holder coming sometime in the future if I can get another “round tuit” Tom3 points

-

3 points

-

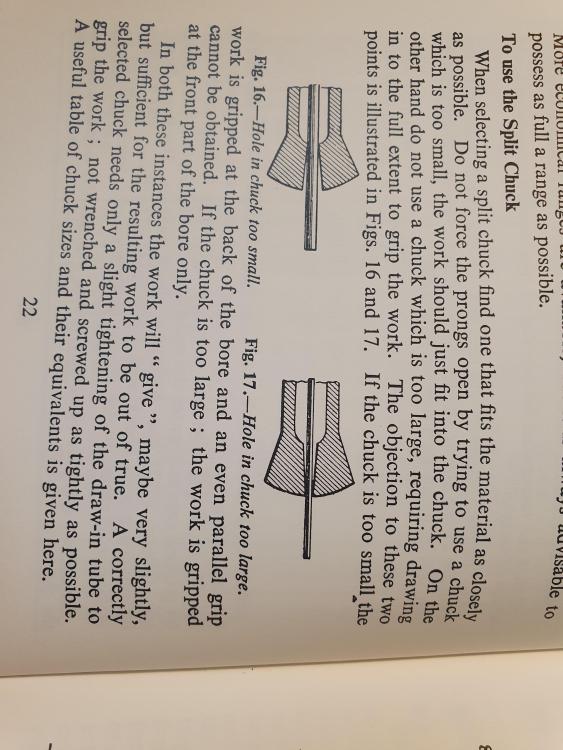

Basic rule for the type of collet used in watchmaker lathes, i.e. that close at the end (and not all over like ER), is you can go undersize a little with the stock, but not oversize. If you put a piece that measures 1.90mm in a 2.00 collet, it will hold OK. The collet will actually collaps a bit further down the bore, not complete contact, but decent. If you put oversize stock in, it's being held at the rear of the collet bore, and to get the front to close much at all isn't going to happen- so the stock is wiggling all over the place. One rare instance I might put oversize stock in a collet is holding a staff by the roller diameter. This is a taper, so I might put one that measures 0.45 in a 0.4 collet, as it kind of "matches up".3 points

-

Until you can find the correct collets ( not easy or cheap ) I would look at getting an 8mm to ER8 chuck, the good thing about ER is the grip range of each collet it will get you able to start getting used to using the lathe, they are available on eBay the picture is my 10mm ER 11 set although I don’t use it very often now . Dell3 points

-

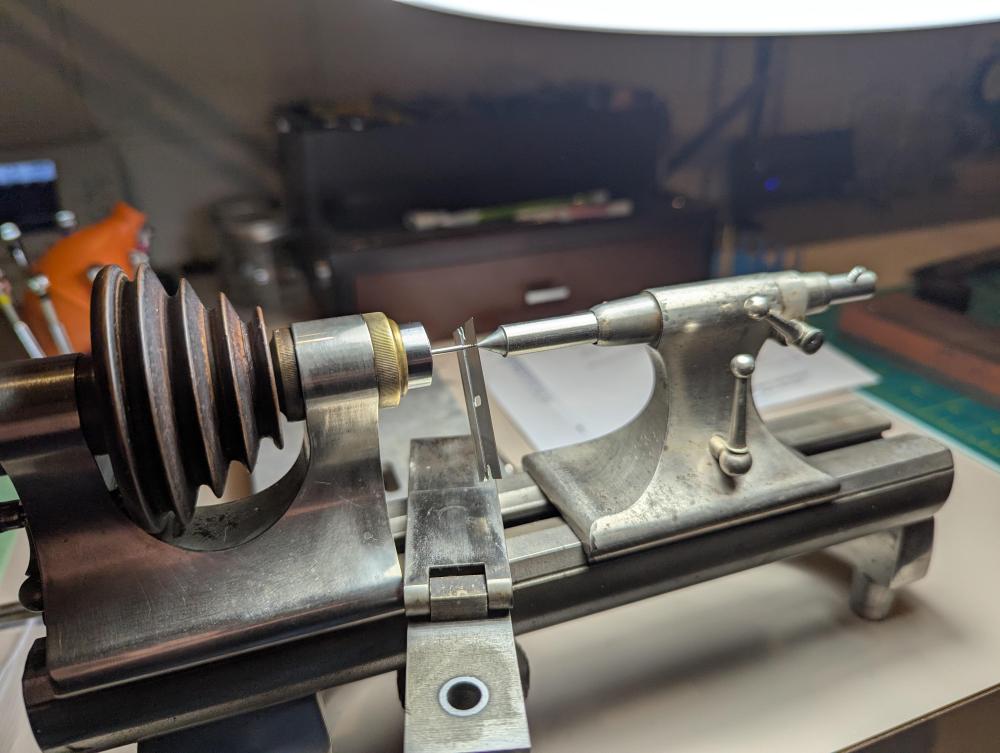

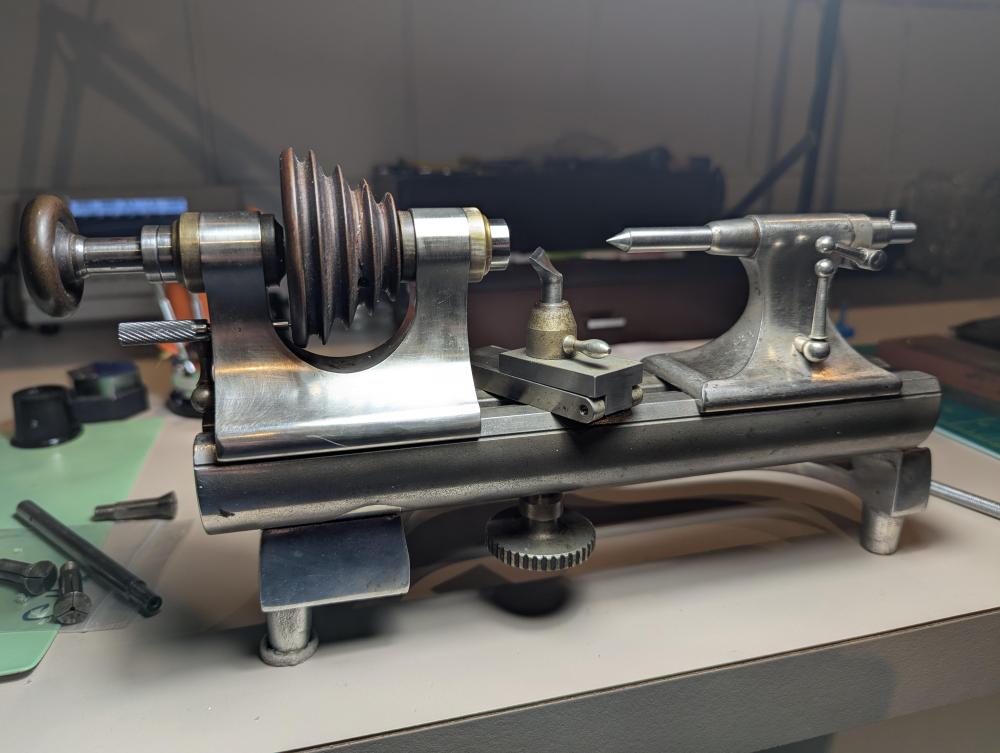

Looks cool on your bench Michael if nothing else. If its holding a razor straight up and down and if it spins as well then the headstocks alignment must be ok. That part is important for drilling operations but not essential as you will see when you watch Nev work his magic. If using a jacot accessory for polishing pivots or turning a staff between centers then its probably more crucial. But for face and short work when the tailstock isn't needed then obviously any misalignment doesn't come into it. Grinding wheels Cees3 points

-

I think the perfect ever movement holder would have to be something based on a fractal vise Tom3 points

-

There isn’t really a state as “overwound “ in a watch. Lighter fluid is a degreaser so will remove and oils in the watch and lubricate nothing whatsoever. there is a technique specifically for Timex vintage which does the dip in lighter fluid method but requires removing the hands and dial and it requires still to be lubricated with specific watch oils. Timex though simple and robust movements are not really suited to learning about watchmaking if that is your end goal. Tom3 points

-

Hahahah, yes, they are! But to keep costs down, I think Horia lets these vestal virgins work in a Chinese sweatshop. The unicorn horn is also from farmed unicorns that live under appalling conditions, according to animal rights activist. Yes indeed. These tips look like they love scratching highly polished hands. If you use metal tips, they need to be mirror polished (like the one on my vintage tool). Otherwise, delrin/nylon is safer.3 points

-

I don't think it's worth it. You can never hold you hand perfectly perpendicular (hence the need to check+adjust as @Neverenoughwatches explains). So there's no need to have a tool that is perfect. If you forget about the look under the loupe, do your hand-held tools work in practice (after checking, adjusting, checking, adjusting)? The check ones on Cousins have worked well enough for me. But I'm sure they won't look too perfect under the loupe/microscope, either.3 points

-

I used the simple, hand-held hand setting tools (that @AndyGSi showed) for the longest time. It worked just fine. Only recently, I managed to pick up a vintage, dedicated hands press for 50 bucks and I love using it. But it's definitely one of the last tools you really need.3 points

-

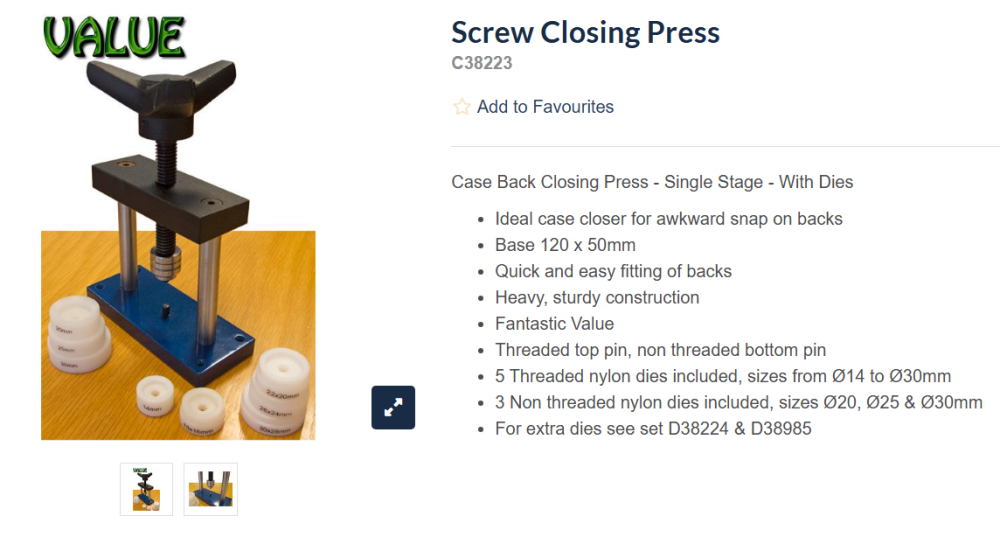

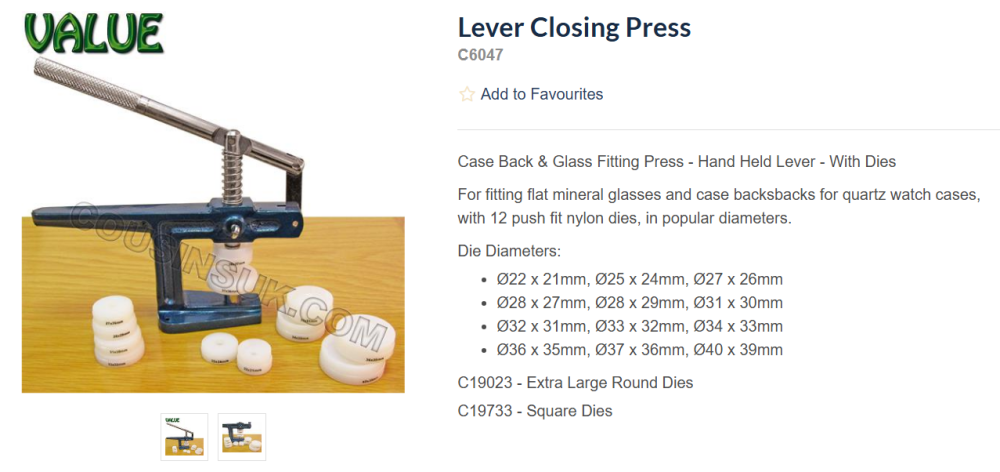

A press to double up duty as caseback and crystal press is the norm, there is an order of magnitude difference between these functions and hand setting however. A multiple use tool that can be used for hands, jewel setting and cannon pinion adjustment would be the clone of the Horia jewelling tool. using a crystal press to set hands is literally a sledgehammer to crack a nut Tom3 points

-

I think this is important to consider. Maybe he has something important/personal to deal with. He's still paying "our" bills for the forum. So let's just appreciate that for a moment and maybe just wait a bit.3 points

-

strange in that if you go to Facebook occasionally you're overwhelmed with lots of stuff. In the program that I used to get my emails does not allow me to click on the links to go to the Facebook when my friends post things. So I have to go to Firefox to look at Facebook which is why I typically don't look at Facebook because that's typically not the browser I use. So when I go there I am overwhelmed with all sorts of stuff and I've noticed that occasionally I can never find what my friends are posted and I give up. even sometimes the groups I joined I can't find by groups they should be in a category but they're not there and then I have to do a search and when I find my group and go there I find I'm subscribed but yet it's not in my group list? Then a course they make all these videos suggestions that I should watch him another nice videos I came to see what's going on with my friends or go look at a group discussion and I'm overwhelmed with all this other stuff plus of course there's always incredibly good deals on stuff to purchase really really good deal. Outstandingly good deals for somebody to make lots of money off the stupid people who attempt to purchase the deals that are really that good at all2 points

-

2 points

-

You could make a drawbar with a threaded section on the back as well, so you can adjust it's length. There is someone on ebay selling taps and dies for cutting internal and external threads for 6 and 8mm collets. I bought a tap for the 6mm collets and a die for 8mm, and I'm very happy with their quality.2 points

-

2 points

-

It would be the JLC or Patek of movement holders, and just as pricey to buy. If you go that far though it would also need anglage and perlage or Geneva stripes Tom2 points

-

The seller of the movement holder I messaged...replied with the suggestion of me looking up the caliber numbers as they didn't have access to the dimensions. I already did that 4 hours earlier. Anyways I took a chance and ordered it, I'm convinced I will need to make some more sleeves to fit into the holder to take up the 9-11 ligne slack. I have some light duty scaffold tubing that finishes at 32mm, might be too big...but tubing is just about everywhere you look. I will pop back when the holder arrives to review it and detail what size movements it can hold. This could be the one...the ultimate movement holder that I've been waiting for .....struggling to contain my excitement . Now I just need to sell the other 73 holders I've collected2 points

-

You want the collets to be as close to the diameter of the material as possible. Forcing them open will damage them. Screwing them tight as well. And they won't hold the piece properly if you do. Fortunately, 8mm collets are not rare and are often interchangeable between manufacturers. Worst case, you need to make an extra draw bar.2 points

-

yes, that is the movement holder. It is just a bit of bent wire that sits inside the case. Note that there is s "V" shape that should push the movement down. The rotors do get sloppy since they are just press fitted. You can try to pin down the area some but go lightly. Two scre3s hold it on the movement. take those off first before removing the movement holder \ clip.2 points

-

I think I have used this tip in the past but forgot all about it! I stripped the insulation off a stranded copper electronics wire and used the fine strands to wrap as "timing washers" when I didn't have the right size on hand. I have to do this again in the next week so I'm happy for the reminder before I went digging through my washers again.2 points

-

@Knebo I do know of the Horia ones lovingly crafted by vestal virgins and QA’d by angels from unicorn horns. That’s what made me think of making them from delrin or maybe nylon. I think Rich @Neverenoughwatches touched on something unintentionally, unless you are using a height adjustable desk or a proper watchmaker bench it is a struggle to see properly, hold the press, place the hands and operate the press all at once. The usual watchmaker conundrum of needing 3 hands for the job. Tom2 points

-

Its always best to go for good quality if you can afford it, which in this case probably won't be too much for bergeon or horotec. Honestly I dont even have that, might be nice to ...but mine is literally a pointy stick with different plastic tips...those i use for adjustment, to press hands on I use a taped up flat steel bar with a hole in it...that I use on its flat..this has really good control over applied pressure compared to an upright stick.2 points

-

These look like metal tips which is not what you want to be using.2 points

-

Sooo anyway after that short banter...personally I can't use any sort of hand press...i tried but visually it just doesn't work for. I would use it and want to pick it up and look at the movement from all angles to make sure I was happy. After a short while I excluded the press and just learnt to do it free hand. Once they are on and reasonably secure...pick up the movement..in its holder or case ...whatever the case may be , inspect and adjust at the same time with a pointy stick ( not a euphemism ) probe with a hole2 points

-

I must be destined for this then, soldier, IT now watch fiddling I have a cheap hand setting press, used it once and now it sits at the back of a shelf collecting dust. I exclusively use the hand tools though if I ever get around to chronographs I would be tempted to make some delrin/acetal pushers for my Horia clone. Tom2 points

-

Ok I'm back to normal..just...I dont know what happened there..some sort of shock to my system. placing hands...nothing too spectacular...for me just tweezers to position the hands and a modified pointy stick to push them on. Look at the alignments through 12 hours of adjustment, adjust it if needed, pick up the movement....check the clearances between them the dial, indices, lume dots, whatever might be in the way through a full 12 hours of hand adjustment. Check them for parallel for cystal clearance...check that they are not loose...tighten if necessary...I think thats about it.2 points

-

This looks a bit risky, by the way. The press pusher extends over the round base of the hand and presses on the actual hand (on the left). Like this, you are more likely to bend the hand. Marshall should better have chosen a slightly smaller pusher. as others have said, definitely can't use a case press for hands.2 points

-

Blimey, you had me worried for a second there! Glad you're back among the living—sounds like the missus and a strong cuppa have life-saving powers. Don't forget to thank her for her heroic brew! Thanks for stepping by.2 points

-

this is one of the things that I find interesting in a discussion group which is everybody's looking at something different. We all have different experiences were all looking at different things. I always find it interesting the things that I hadn't noticed. Like it was until I saw that the balance jewels and I went back and looked and realized oh these are definitely very strange but that just wasn't what I was looking at initially. So group discussions are nice because everybody sees something different and together we see the entire watch. that was something I was going to ask about because I was wondering where the case was? American pocket watch cases are quite interesting in that originally the pocket watch movement was separate a purchased a separate case for it. That often times over the years when the case wore out or for whatever reason the movement moved to different case. Then unfortunately anything resembling precious metals gets melted down and the movement is left without its case. as I wasn't paying attention to the one on eBay did it have a case? what's interesting is if you look at the reference material for American pocket watches they do a really good job of keeping track of all of the companies. Even little tiny companies I have a watch from a company that was in business I think two years. But as you move into the 1900s history of companies including even companies like Elgin a lot of stuff they did just slides in the radar because nobody was paying attention. basically sometimes it's easier to research a company from the 1800s because are so much material of verses later on where as I said people just weren't paying attention.2 points

-

2 points

-

Getting the crystal back in without mullering the thin white gasket.2 points

-

2 points

-

Oh, absolutely. I remember years ago visiting a watchmaker’s shop to get my watch serviced—what an experience! That dry, sarcastic sense of humor seems to be a hallmark of the trade. Honestly, watchmakers are a very special breed—kind of like the IT crowd but with fewer keyboards and more tiny screws.1 point

-

1 point

-

Absolutely Tom I just fainted. It's ok Im starting to come round and the missus has a strong cuppa on the way for me. It must have been bad because I'm missing words out, just give me a few minutes to compose myself.1 point

-

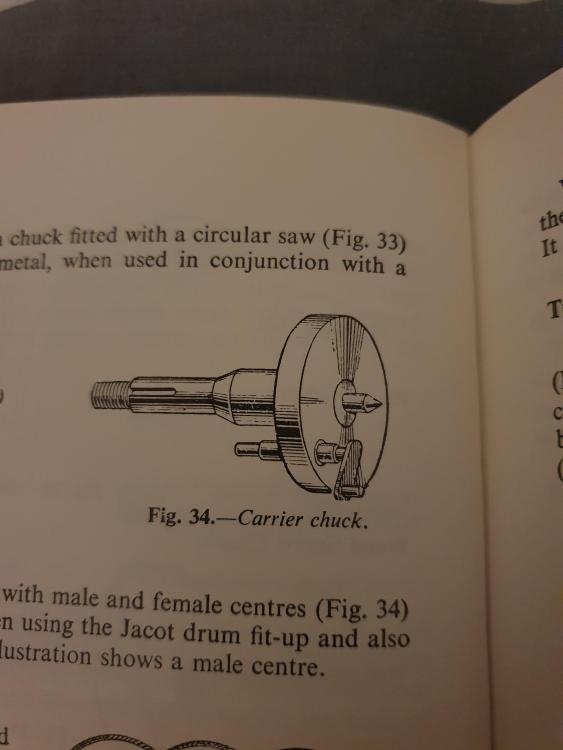

As tomh207 has said The arbor is for a slitting saw ( some call them slotting saws ) to check for true head to tail alignment put some mild steel in headstock turn to a point then use blade as you have done. I also recommend the book that caseback has posted about , as for turning between centres some carrier plates ( some call them catch plate ) have centre integral to the carrier but some have a larger threaded hole & use a collet to hold the centre so look for one caseback added a picture of, you will also need dogs. Dell1 point

-

I'd also be interested to hear about your experience. That being said, I'm happy with my 4040 and 4039 (metal) holders. What diameter is the base? Wondering if it fits the standard hand setting presses.1 point

-

I’m very sure the collet you’re unsure about is for holding slitting saws. Tom1 point

-

1 point

-

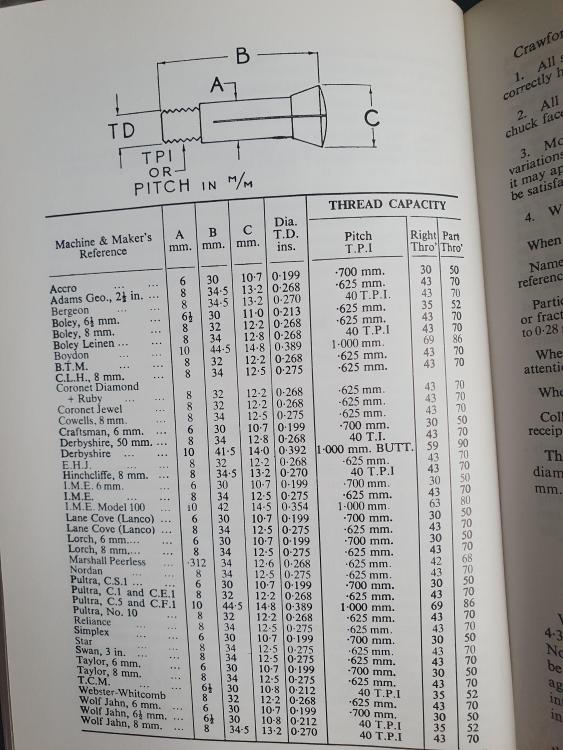

Just some points over breakfast (with disclaimer: I'm no lathe expert ), I'd say the bed is a bit short for this combination head/tailstock. There's very little room for the rest. But like you said it will get you started. If you ever find a longer one: as long as the headstock and tailstock are a decent match, mounting them together on another bed won't influence their alignment. I think the arbor you show is for holding cutters. I have 2 of them as well, but no cutters, so I'm not 100% certain. For turning between centres you can use a carrier chuck. I can recommend this book, tons of information! The base is small and flimsy. Getting a bigger one will improve stability. If you access to a bigger lathe or milling machine in your area, making one would be faster and cheaper then sourcing a "factory" base. I could help you with that, but I'm on the other side of the globe. A simple option for holding drills could be this. I got a ER8 (you could also use ER11 or bigger) collet holder. They sell these with different shaft diameters. In this video I used a 6mm version in a brass tube (7mm OD, 0.5mm wall thickness) but I have an 8mm version for my bigger WW-style lathe as well.1 point

-

Okay here it is! It needs cleaning of course. But more than grease and grime it's cat hair tucked in every crevice. I'm a dog person. I mounted a center in the tailstock but had none for the headstock, so I found the pointiest thing laying on my desk that would also fit in one of my collets - a springbar for the razor blade test. I cannot find a serial number on the tailstock so I don't know if they are matched but it does seem well centered. They are probably not matched, probably not even the same manufacturer because the locking levers have different profiles. I know you're all thinking what an idiot for buying a frankenlathe, but this was not a lot of money and I think is going to be just fine to get started. The bed is labeled "American Watch Tool Co" and the headstock "Webster Whitcomb." It came with 3 random collets - 5, 20, and something unmarked that looks to be around 40-45; I didn't measure it yet. And two tailstock spindles - the center, and another the seller says was made to hold 3mm drill bits with a grub screw but he hadn't used for the purpose and can't vouch for it being centered to the headstock - looks homemade. I'll cross that bridge when I come to it. I don't like the Borel base, as it does not appear to be a great match for the length of the lathe bed - the base could be an inch narrower for a better fit. As someone suggested up the thread, I will keep an eye out for a lone pedestal base and consider mounting it conventionally to a wood board. The back edge of the bed is a little rough, if the tailstock is all the way out at the end, but it's clean and smooth toward the tailstock where it will mostly matter. The collet lever on the tool rest might be stripped, or I might be using it incorrectly. The post can be inserted and has a strong friction grip, stable. But rotating the collar around it does not seem to have any tightening or loosening effect. Not sure what is happening there but I'll investigate further when I start cleaning. Lastly I have this arbor but I don't know what it's for. It has a large slotted screw and a brass ring about 1.5mm thick over the end of the arbor. I was thinking this might be for mounting a mop? Seems too small or not robust enough for a grinding wheel. Thoughts? So now I need a motor; I have seen plenty of information on what sorts of modern motors people like. And I live a short mile from a surplus store, the kind of place you'd go if you needed to build a robot from random parts for high school competition, which has bins and bins of motors of all types at like $10. And I'll need more collets and a lot of other stuff I'll start watching out for. I won a set of larger step collets at auction I hope will be the right size for pocket watch wheels when they come in. One thing I'm not clear on is what sort of arbor or faceplate is used when driving a lathe dog to turn between centers. I found a good source for new rather than vintage/old 8mm dead centers but I don't know what attachment is supposed to push the dog if a dead center is mounted in the headstock. So much to learn. And buy.1 point

-

Updating on the Standard 96-4 I have on the bench. I bought a rusty donor movement off the auction site and took the chaton off it. Night are getting the end stone off the cap but in the end some rodico whilst holding it did the trick. Super small getting some oil on the stone but I find my heavier steel tweezers are better at holding the small stones with less risk of them pinging. All back in and the movement kicked right in to gear, which is promising. Haven’t put it on the timegrapher yet but I’m hopeful for some good numbers. I also bought a replacement click spring, but also bought some spring steel in 0.2mm and today I had a go at making a spring. I was able to fashion a really good looking and functional spring. However there was a fatal flaw… 0.2mm is too think and it fouls the ratchet wheel. It’s unfortunate as I can’t easily source music wire in anything smaller than 0.2mm and my guess is I’d need 1.0 to 1.5mm. So that part is on hold now until the replacement part arrives. The NH35 continues to work great on the arm. I need to speed it up a bit after wearing it for a while as it’s losing about 50 seconds over a week but that’s an easy job with the timegrapher.1 point

-

I have wanted a Robur watch crystal press and dies for a long time, but when considering the cost of about £510 (CousinsUK, excluding shipping and VAT) I just couldn't defend it. However, as the Robur-like press, shown in my video, now and then shows up in various YouTube videos I got curious and ordered it from AliExpress. I don't think it's on par with the Robur press, but for the price, it seems like a decent option. In the video, I happened to mention that I was going to link to my WRT service walkthroughs, so below is the list in case anyone would be looking for it. Hope you'll find my video useful! My Service Walkthroughs: Citizen 8200A ETA 2892-A2 2804-2 2836-2 955.112 2772 2472 2824-2 Vostok 2431 2409 Enicar 161 Miyota 8205 9015 Tissot 781 Omega 268 Orient 46E40 Unitas 6380 63251 point

-

the manual is a guide so do not take everything it states as absolute. practice will be your best teacher.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)