Leaderboard

Popular Content

Showing content with the highest reputation on 01/29/25 in Posts

-

Hi - I missed this yesterday. The lighter fluid method does work, if you apply lubrication according to the service manual afterward. I do about 1/3 of my Timex watches this way without full disassembly and following the service guide. I don't do it if they are really dirty inside because I want an opportunity to clean the pivots thoroughly. https://heritage1854.com/m24 So it isn't a lighter fluid "trick" - it is actually the published cleaning method for these movements. They don't specify lighter fluid, but if that is what you have as a solvent it will work just fine. I follow that with a rinse in isopropyl alcohol. And as the manual says, keep it dial-side down so the mainspring drains properly.3 points

-

3 points

-

Many a newbie have tried this and have a black thumbnail to show for it. There is a proper tool for letting down the mainspring but you can easily make one yourself. Cut a 6" piece of 3/4" PVC pipe, cut a slot in one end to slip your winding key in it. You can also use a piece of broomstick too. I have a Smiths floating balance clock on my bench at the moment. Just spent the whole of last week cleaning and polishing all the pivots and steel arbors. Managed to get the going train running again and synchronized the wheels in the chime and strike trains last night. I guess I don't do chiming clocks regularly enough to be proficient at it. Getting the synchronization correct still takes me quite a bit of time. If this is your first clock, you might find it really challenging. Good luck.3 points

-

They would be movement-specific and $250 individually or sold in a $4000 set.3 points

-

@graemeW, mate, just a word of encouragement: The way you're handling this project is admirable. I hope you see how much you're learning. Probably more than most people learn in 10+ watch services. You are repeatedly handling very sensitive parts and seem to not to break them. That's all fantastic! Irrespective of what amplitude you'll eventually achieve, this experience was worth it and priceless. Kudos to you!2 points

-

See also this post, where a 3D printed crystal tool was used. You probably have a tension ring crystal here, which would be difficult to remove with a crystal lift and escape damage. Other non-Tissot sorts of tools like the 3D printed one in that post do appear around ebay. They grip more evenly than the brass claws of a crystal lift. I imagine any of them would work.2 points

-

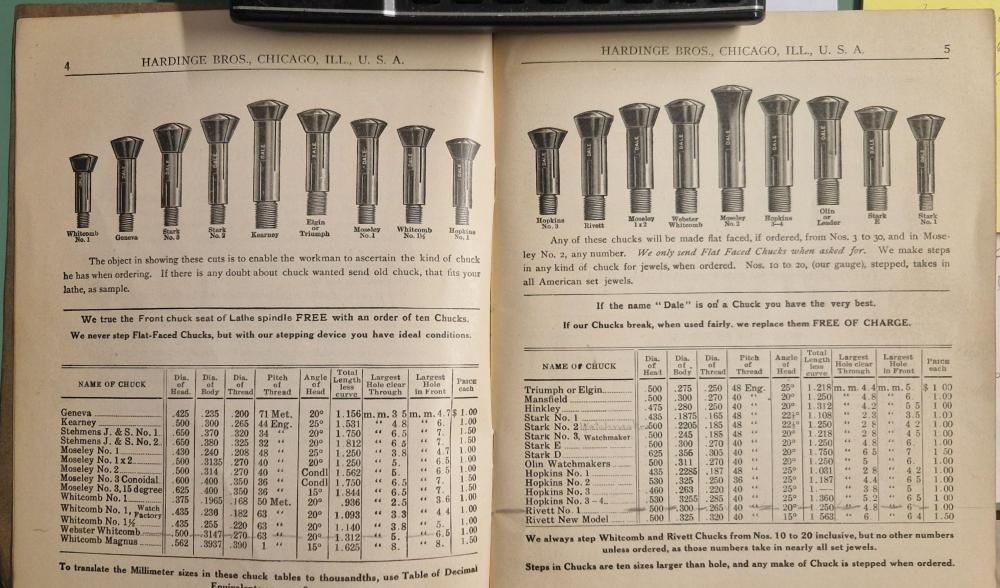

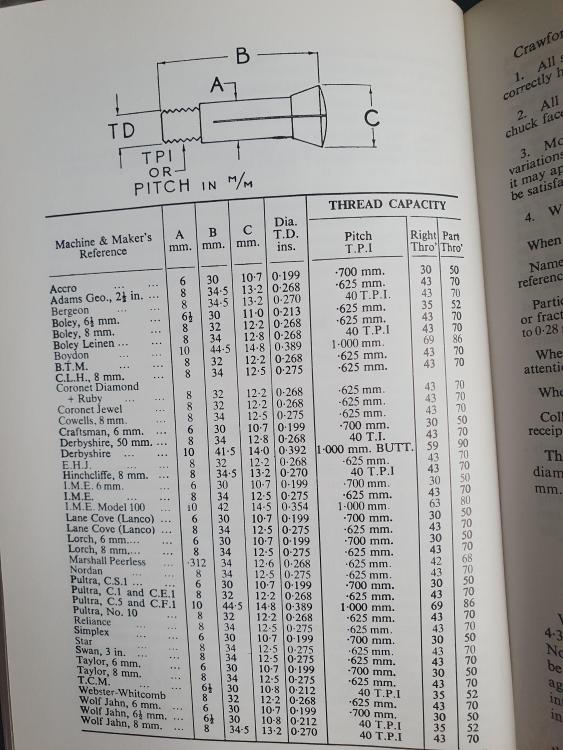

The American Watch Tool Co. made Webster Whitcomb lathes, which are really the origin of the "American style" 8mm lathe, with 50mm center height, and their corresponding collet is the prototype for most other 8mm collets. The WW collet has a body diameter of 0.3147", or just a hair over 7.99mm. This is to fit the bore of the headstock, which should be bang-on 8mm. The thread pitch as listed by Hardinge (another high class maker of lathes as well as collets) is 0.63mm. It is sometimes listed as above as 0.625mm, or sometimes 40tpi (threads per inch) which is 0.635mm. Schaublin, the current maker of the best 8mm collets, have a pitch of 0.625mm. I have used G.Boley, Boley-Leinen, Levin, Schaublin, and some others in my old American Watch Tool lathe with no issues (it was last century but I do remember!). And also do so in my Leinen "WW82" lathe- guess where the "WW" comes from? The AWT Co. morphed into Derbyshire early last century, who are apparently still in business. Your tip-over rest looks like a Derbyshire. Mosely came up with another collet style, with a curved head they called "conoidal". These were also longer in length than regular WW 8mm collets. Later they made similar length collets with a more standard straight taper. I would avoid them overall; high quality but they are too far from standard to be practical. In theory tailstocks for AWT Co. machines are interchangeable. As they are on (later model) Leinen machines. Levin, who made superb machines supposedly on the WW pattern, are a bit all over the map and don't really interchange in my experience. Your bed length looks fine. 12" was pretty standard, and looks like what you have. My Leinen is also 12", and it's never been a problem in decades of use. Here's an image from a 1913 Hardinge catalog showing the different collets they made then (it expanded later); you can see there are a number that are "around" 8mm, and many others larger and smaller. Best to get a seller to measure the body diameter as closely as possible when buying. And a pic of my Leinen for comparison.2 points

-

I bought that draw bar. Its ok, but its aluminum. Youll want to cut it to length as well, if too much material is out the back, itll vibrate like crazy. Not a super precise piece, but it works. I think it needs a small taper on the handle so that it centers itself on the spindle.2 points

-

The military used carrier pigeons during the war to deliver messages, kind of like spy pigeons. The bigger birds..they would strap clocks to those ones.... most often when the phone lines were down and folk couldn’t ring up for the speaking clock. The idea was to entice the bird down with a few seeds..get your time reading to set your watch and clock by...then send big bird on his way to help someone else.2 points

-

I expect a Yorkshire man to recognise this Richard, don’t you all have ferrets, whippets and pidgeons any more? Tom2 points

-

2 points

-

On this note- Just made a staff for a regular client. Eterna 852, 14"' movement, simple and gorgeous. Staff that was in was a cobble job, roller table glued on way off center, hs collet stretched out. New staff made and finished, didn't check on the poising tool. They just wanted the staff. Threw oil in all the needed places, on the timing machine. 17s delta in 6 positions on a dirty movement, 280-90 amplitude horizontal. I'm pretty sure any preemptive static poising would have made it worse. But- killer movement, escapement seemed ok, amplitude shows in spite of the mank it's ok. Still, I do use the static tool sometimes. But only after checking on the Witschi.2 points

-

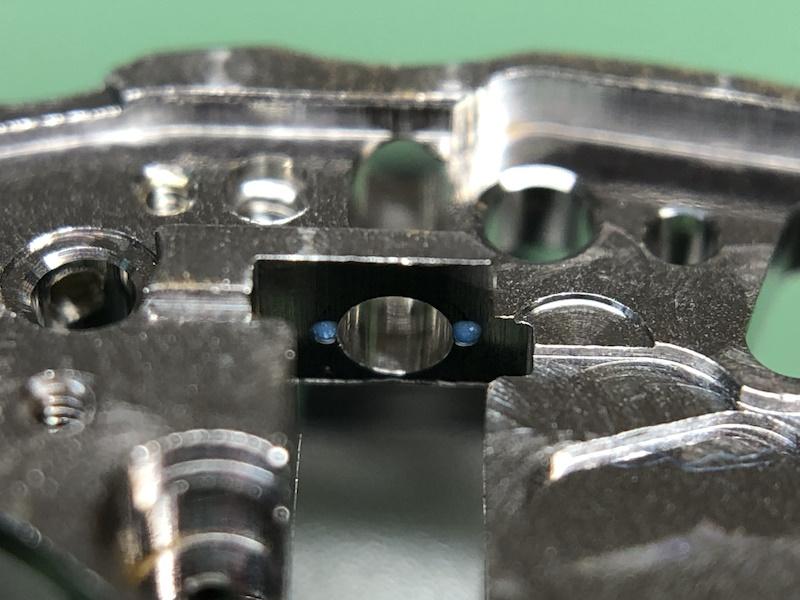

I've not had much spare time through November & December, as all the customers jobs that had been waiting for parts or other people through the year all came in a rush! I did do some browsing on ebay in the evenings though, looking at lathe parts when they were going at what seemed a decently low price..... I now have around 4 2/3 lathes! The G Boley 6.5mm one I posted early November, which I have since acquired some collets and a carrier chuck for - so just short a tool rest. An unbranded look-alike of the G Boley in 8mm. That has a bearing problem - but a good tailstock and specifically tool post, that fit the G Boley bed. A Boley Reform 8mm, complete except the tool rest insert for the tool post. [it looked like a WW style in the photos.] And, based on the comment I had about the problems with parts for non-8mm lathes, multiple WW style items, including two 8mm headstocks, a tailstock, a cross slide and some flat adapters to mount tool posts or the cross slide. (And a good selection of 8mm collets, fittings & ER11 chuck). And; three different "WW" beds: An 11" Boley, a 16" long double-foot Pultra and an unbranded ~ 9 1/2" one. Slight problem though - none of the parts fit to any of them! One of the headstocks is a genuine Webster-Whitcomb, so I'd think that would fit correctly on a standard WW bed. Neither that nor the tailstock will fit as the depth to the underside of the "T" slot is slightly too large, by a fraction of a millimetre. The fittings will also all wobble or rotate slightly when held down to the beds, which to me confirms the bed profiles are wrong, rather than the clamp stud lengths. The other headstock will fit them, though when clamped the clamp lever is dead in line with the index pin hole, so obviously also not the correct fitting. The beds all have the finished side tapers against the top edge, so they are intended for WW style attachments that use those for location. It appears they are ground too tall? If a fraction was ground or milled from the top surface, that would both allow the clamp stud head to fit, and the attachments seat slightly further down the taper sides, removing the side play. One of my engineering customers can skim one down, but I am very puzzled over the incompatibility, as I was under the impression that the WW bed style was standardised, so different manufacturers attachments could be used? The only mechanical fault that concerns me at the moment is with the WW tailstock in the photos below. I believe the 8mm inner sleeve should move freely, with the knurled centre wheel being a clamp for that. The wheel has just today freed up after many oilings and attempts to move things, but the inner sleeve is still absolutely solid. I just gave the end of the inner sleeve another tap with a tiny brass hammer - and the whole whole outer sleeve moved; that's now completely out, but the inner is still stuck solid. I've dumped it in a mix of used L&R rinse and 3 in 1 oil - which appears to be working its way well in to the thing through the clamping slots, as there are small mountains of crud appearing underneath those! (I will probably put some or all the non-WW lathes back on ebay eventually, but I'm going try and complete them first if I can - and keep them for now in case I need to make any small parts for the WW gear.)1 point

-

1 point

-

1 point

-

1 point

-

All right you fools pigeon clocks are used for racing pigeons. The only thing you have to worry about is cleaning out the pigeon shit. The same goes for Cuckoo clocks.1 point

-

It's an enamel dial. A brass / copper plate with an enamel coating. Looks like the enamel is chipped where the dial feet are. It's a cylinder escapement and I suspect that the balance staff is broken.1 point

-

one of the problems I have with the word vintage I think of actual vintage and you don't want to get vintage. But the good news is vintage definition of vintage is considerably newer. So basically on this group the last of whatever the vintage is this group would consider it basically a new watch. so basically you can look up when radium was discontinued but the reality is radium existed beyond that. It have to make sure the dial has typically the T for for the other thing or find a watch that doesn't have anything that forces at all but I don't know how, that is Rolex. as I was reading through this the reality is I would go with a different suggestion recommended by somebody else. okay without radium moves it somewhere into the 60s he can probably find discussion groups that will tell you when radium ceased on Rolex watches. Then Rolex has really beautiful service manual's probably the best service manual can find anywhere there in color they specify the screwdriver size everything almost sort of not really. All the watch companies have supplemental information which is not included in the service manual. the nonautomatic is interesting it have to do some research I don't know how many non-automatics they have. As Rolex is big for automatic watches. But everything falls apart with number five as Rolex parts are not necessarily readily available unless it's one of the more common automatic calibers probably like 3135. You could probably go back to the 3035 but go look on eBay go look up parts lookup a balance complete for Rolex. Go find yourself a really nice Omega watch they make really really nice watches. Where the parts are going to be more readily available unfortunately Swatch group doesn't want you to have parts so you're not to get him direct but Rolex doesn't like you either so they're the same that way but their way more Omega watches out there than Rolex watches. That if you want something different really unique go find it vintage grand Seiko. Because grand Seiko started with manual wind watches and they actually are really nice watches. Haven't you ever wondered why chronometer certification by the Swiss do not include other countries? This way then avoid the embarrassment of what grand Seiko deaths to their standards. To go find a nice manual wind grand Seiko other than vintage Seiko's it can be hard to find the parts. That might be best to go with Omega as it probably fits all of your criteria.1 point

-

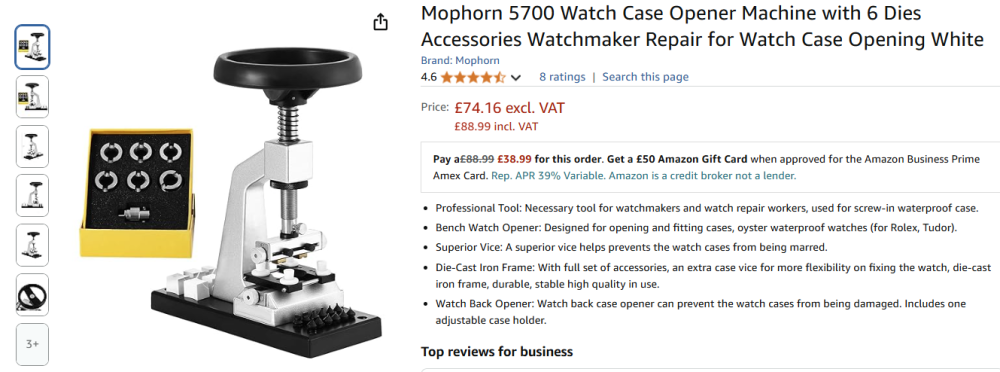

I've seen the Omega version of these. They still operate on the principle like the crystal lift of compressing around the edge. But instead of having a whole bunch of smaller jaws they have much bigger less of them nice and smooth. So in other words they put a lot of pressure and not damage the crystal. Plus like the Omega scepters a whole bunch of them there's about at least 10 of them succumb in a whole bunch of different sizes. Which means without that tool it's probably the crystal lift just be extremely careful and may be might want to get a replacement crystal. But he can't get a replacement crystal until you get the watch out of the case to get the case number.1 point

-

They're not beveled but kind of irregularly stepped so that they cannot sit level on a symmetrical holder like the Bergeon. You tighten the holder and the movement wants to pop up. Dial down they do sit level.1 point

-

It is a clock used to time pigeon races to determine the winner. I think the birds were ringed prior to the start of the race the ring being removed and inserted into the clock recording the time of arrival in its home doocote. Tom1 point

-

I just let the power down before doing anything then use the balance till it's @12 with the other hands.1 point

-

It looks like it is supposed to be a press fit - however the pin does not look to be aligned with the hole? The hole in the slide for the pin looks to be exactly half way between the edge of the circular counterbore and the outside of the slide - but the photo from above with the pointer in its slot has the pin somewhat too near the centre bore? Try using a straight edge across the slot and making a very light scratch across as an alignment guide (or use engineers blue to allow a visible line without scratching the metal), then try fitting the pointer again, with the pin centred on the line? If it's still too tight, I'd try clamping in a vice, with some kind of packing to avoid marking it with the vice jaws, plus a block over the pointer to avoid bending it. Use a bit of scrap brass with a hole in it for the top, it that protrudes.1 point

-

Yep! Just put a piece of cling film/saran wrap (the type you have in the kitchen) between the holder and the dial and don't tighten too hard. Yes, it's all too easy to drop, especially when doing the keyless before the barrel bridge. So if possible, I assemble the barrel bridge first. These days I don't lubricate the winding pinion but instead the contact point on the main plate.1 point

-

Fun thread, I'll go: Inserting the winding pinion without dropping it or getting grease all over my tweezers or the surrounding stem area. Keeping the mainspring free of dust while winding it with mainspring winders. Also: preventing the mainspring from rushing into the winder after nudging the bridle through the slit. Often the end of the spring will rush through the slit, rotate once, and I'll end up with the bridle coming out of the winder again and sometimes snapping.1 point

-

1 point

-

1 point

-

Floating balance clocks are normally very good time keepers. Unfortunately from that single photo I do not know what any of the train wheels are like I need to see inside the movement and the front plate. The oil sinks are hardly noticeable that is if you can call them oil sinks so be careful with oiling as the oil will run all over the place. A warning for you do not follow this person from that video he is a bloody menace to the clock repairing world, although this video is harmless enough you certainly will need a let down key.1 point

-

I'd forgotten about this, I could of been a multimillionaire by now. hehe.1 point

-

Yes. Plastic movement holder, and some care needed to avoid dislodging markers etc., but it was safe so far.1 point

-

Welcome, @Nerves69. There's a lot to be learned from Marshall on Wristwatch Revival and he makes entertaining videos but he repeatedly gives a disclaimer that he's an amateur doing this as a hobby. He should not be your only source of learning videos. Many members here use Mark Lovick's training course (that Marshall sometimes mentions as how he learned) -- follow the link at the top of this page to watchFIX.com. (Mark, or his business, is the host for this forum but that's not the only reason he gets first plug: his instructional videos are excellent.) There are also other YouTube channels that are run by professional watch makers/repairers including Mark's own Watch Repair Channel https://www.youtube.com/@WatchRepairChannel, Watch Repair Tutorials https://www.youtube.com/@watchrepairtutorials, Chronoglide Watchmakers https://www.youtube.com/@ChronoglideWatchmaking. There are probably others, but they're the ones I have found helpful. I feel I also need to mention My Retro Watches https://www.youtube.com/@MyRetroWatches -- this is another hobbyist channel, but if you enjoy Wristwatch Revival you'll probably enjoy these, too. This is a very friendly, helpful forum. Whatever problem you're encountering, you can post pics and ask questions here and someone will have something helpful to say, usually in less than 24 hours. I feel I learn so much just from reading other people's problems and the suggestions for addressing them, and I love it if I can make my own small contribution from time to time.1 point

-

The hairspring coils are still filled with fluid when the movement is lifted into the air, when submerged the dynamics are somehow different...surface tension maybe be a cause.1 point

-

I was asking the OP. Your response came in while I was typing . In my limited experience, cutting blued steel with carbide freehand down to 0.12mm is no problem. However, If you start out with a thin wire with too much stickout (and no slide or steady rest), I imagine that it could be difficult.1 point

-

Not sure who you're asking, but when I make anything it's standard full annealed steel. For a staff I turn everything with a slide rest and leave what will become the pivots a couple hundredths less than the next diameter up and then hand turn the pivots post heat-treat. The deviation in diameter is the length guide. Get them 0.01 oversize, cut the rivet, cut the roller table and hub tapers (also post heat-treat), stake to balance, Jacot, hit the pivot ends in the lathe and boom.1 point

-

It depends how far you intend going with watch repair but I'd recommend one like this if you're serious about it. https://www.cousinsuk.com/product/universal-case-back-tool-swiss-style I got mine from Amazon complete with the Rolex dies. If you're going for the tool suggested by @tomh207 you're best just holding it in your hand.1 point

-

Haha I totally forgot about this. I cant believe there isn't a Bergeon tool for this. They have their patented pivot Straightener(breaker) thats hundreds of dollars. Im going to do some thinking on this and see what I can come up with.1 point

-

Definitely this: After fitting the hands and before casing... removing the stem... With the left hand, gently holding the movement, balancing it on its side (on a gel casing cushion), avoiding to touch the hands and balance, and pulling the stem at the same time (as perpendicular as possible). With the right hand, trying to push the "button" with a probe to release the stem (sideways..). I hate it. Or is there a better way that I'm missing? Do you put it in a movement holder (clamping the dial???) ?1 point

-

"I'm sorry sir, but a real Rolex ends with x and not with cks"1 point

-

Explaining to a customer that what they have is utter crap. Trying hard to be tactful about it. This is something these days I couldn't do I'm not very tactful these days it's my age.1 point

-

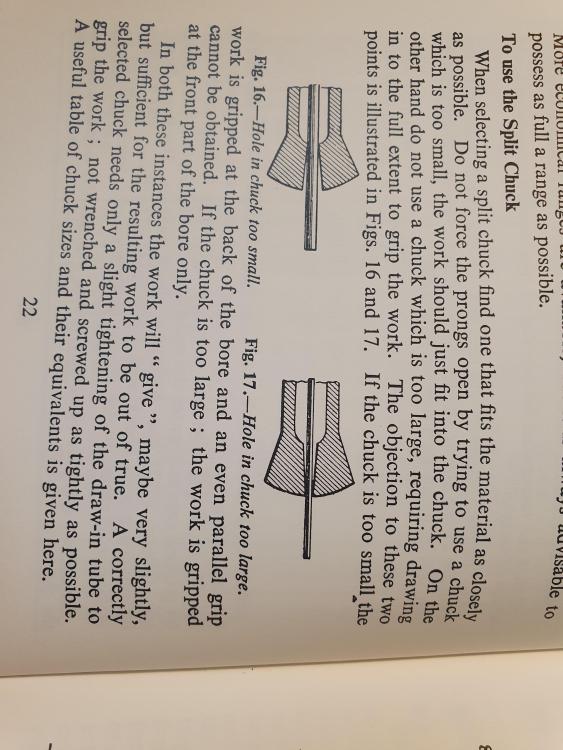

You want the collets to be as close to the diameter of the material as possible. Forcing them open will damage them. Screwing them tight as well. And they won't hold the piece properly if you do. Fortunately, 8mm collets are not rare and are often interchangeable between manufacturers. Worst case, you need to make an extra draw bar.1 point

-

Hi Mark, You can see my reaction too when I first met this PDF here Then You can see this to understand what I mean1 point

-

Indeed! I have serviced a few Timex watches in the traditional way I service Swiss watches. It is tedious, but in a strange way...almost fun. (I said ALMOST). I recently acquired boxes of timex movements as part of an auction at the local guild. Really did not want them, but was donating to a good cause.1 point

-

1 point

-

That’s a Hemel floating balance clock. Does it run when wound if not then it needs a service. You could try and lubricate the pinions and see if it runs BUT as I have found there really is not any shortcuts with clocks or watches.1 point

-

1 point

-

The pin might be hardened steel, drilling it out by hand... the hole could end up being quite a bit bigger and not uniform. Size isn't so much of an issue as the hook can be shaped to whatever you want on any size of a new pin.1 point

-

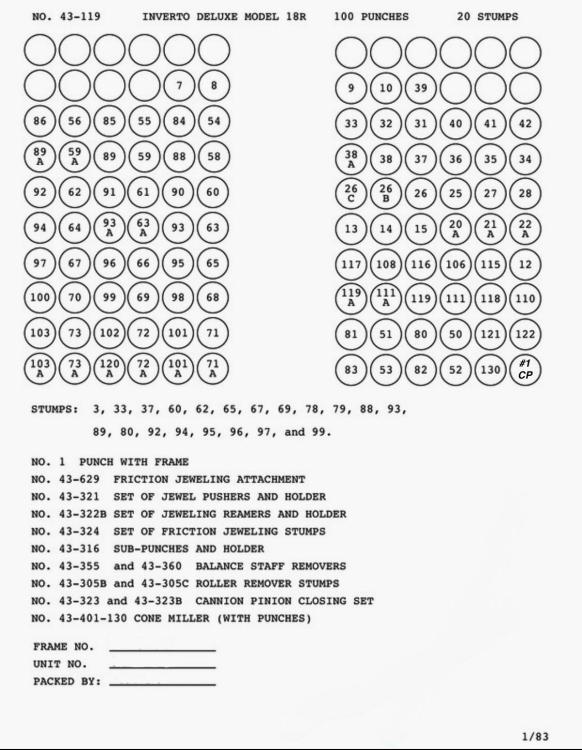

Claudio, Glad to find you on here and it’s great to see you learning and enjoying your new staking set ! If you have any issues please reach out and I’ll respond as soon as possible. Hopefully you’re still as excited as you were the day you got it. Did you make up your own stake mapping system ? That’s pretty cool ! Have you seen the actual factory build sheets/stake map for your set yet ? I’ve included it here just in case. There’s a rhyme and reason for the way they organize these stakes in these sets. Once you learn that system it becomes almost second nature and make sense. It’s not even close to being as easy as the C&E Marshall systems but it isn’t too bad. Take care brother and thanks again for trusting me with your staking set needs. Rick1 point

-

The WHAT? Well okay, today this place taught me one can drive seized automotive bearings out with a hammer and bread.1 point

-

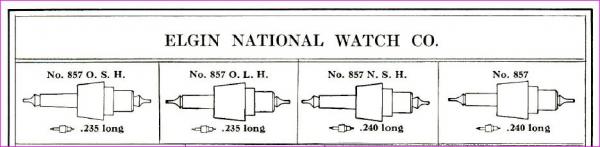

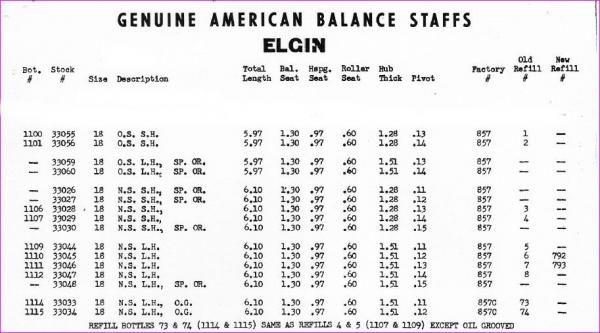

The most important thing when restaffing is to measure the old balance staff. This way you can verify the new staff matches the old staff. So the abbreviations are for new style and old style.. Then you have short or long hub. So if you measure your staff compared to the information I have you should be able to figure out what you need. Then the reason why all the different pivots sizes usually have to do with the number of jewels of the watch. In other words a seven jewel watch will usually have a large pivoted staff 21 jewel will usually be the finest. So ideally be nice to measure the pivots.1 point

.thumb.jpg.1d27a58691e1cdb3ca73af66fecafa0a.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)