Leaderboard

Popular Content

Showing content with the highest reputation on 01/30/25 in Posts

-

Hi @arron, The Air King and Oyster Precision models are usually 34mm in diameter. Some find it too small. Honestly speaking, I think you can see in the design that they are the cheapest Rolex. I don't think they're particularly appealing. If you can stretch the budget to the low-mid 3000s, you might be able to find a Datejust 36mm (even though both automatic and with date..). Maybe not on eBay, but local sellers, local classifieds. For most Datejust calibres, you can get generic parts, e.g. from Cousins. Have you considered vintage Omega? You could get a spectacular 1960s Omega Constellation for that price -- or even significantly below. In my opinion they are better value for money than the entry level Rolexes. One example here:5 points

-

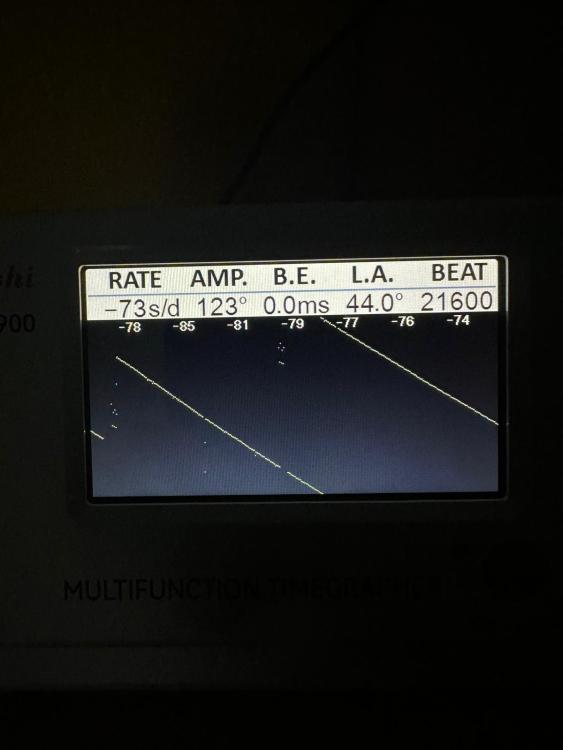

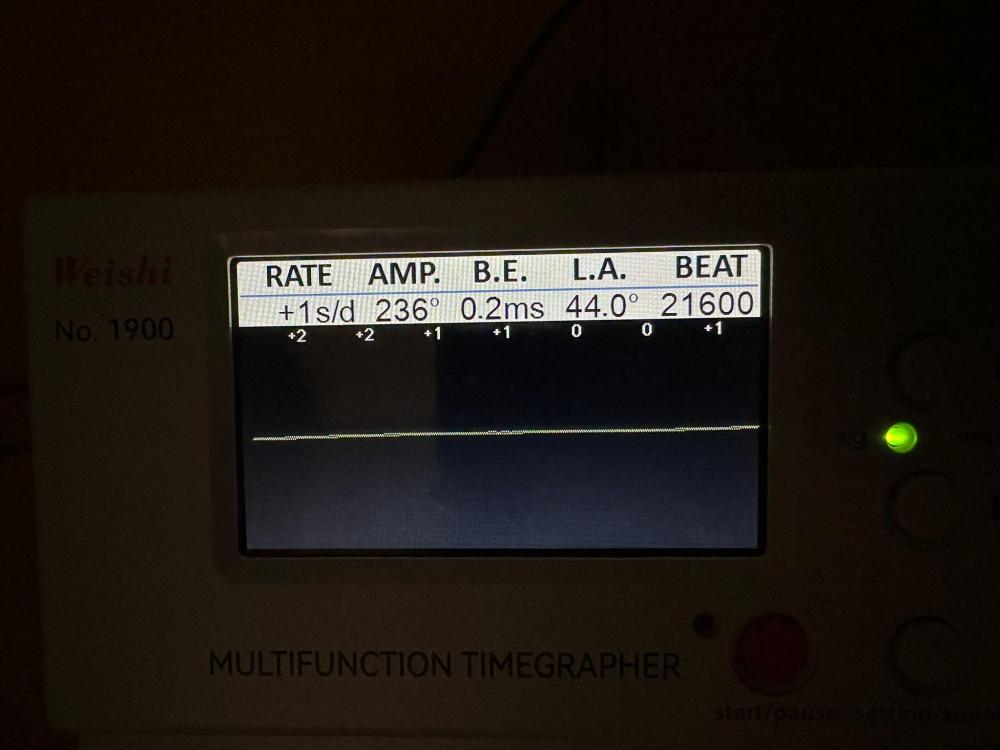

It's incredibly satisfying to see the positive results after servicing a movement, isn't it? For me, it was my first time doing it—after, of course, watching a few YouTube videos and learning the basics. I came across a used watch with an ST36 movement that still worked, but barely. The timegrapher showed poor performance, and the case back looked absolutely dreadful under a microscope probably due to intensive wear. Undeterred, I decided to dive in. I began by opening the case and carefully disassembling the movement, cleaning the parts and put everything back in place and of course lubricating. I know there are countless posts like this out there, so I won’t bore you with the usual flood of photos. Instead, I’ll just share a select few. I am looking forward to servicing and restoring older watches. I already have a few vintage watches waiting to be serviced Cheers from Germany, Dan Before : After:4 points

-

Nice watches, but yes there's a lot of hype. It's why they restrict production of certain models (like Ferrari) to keep demand and prices high. Which is why you have to beg/grovel to get certain new models. It's a name that everyone knows, and associates with quality. The modern ones are the most accurate mass produced mechanical watches you can buy. I recently read an article (wish I could find it) that said that at one time (50s, 60s?) Longines was considered the most desirable brand by the general pubic, above Rolex and Omega. But as it's a watch to hand down, to people who may not be as familiar with watch history, I'm sure they would prefer to see "Rolex" on the dial rather than Omega or Longines. Here's one I just bought for about 1/5 the price of an similar aged Rolex4 points

-

out of curiosity I not seeing what model brand number watch this came out of? The last time I saw something like this it was a Chinese watch which is why am asking. then because whatever is holding it in is no longer functional ideally it should be cleaned out and then some form of glue would probably be the best epoxy might be nice. Then here is a link are talking about pinning a hairspring which you can't do unfortunately because her snow hole in your stud. But they do show the stud holding table. In other words of the hairspring is removed and the balance wheel you can hold the stud in the holder which holds it nice and straight and then whatever you glue attach or whatever it will then be perfectly in alignment with the hairspring as opposed to trying to do it freehand. Unless you put the stud back in the watch and do it there but just have to be careful with what you're doing4 points

-

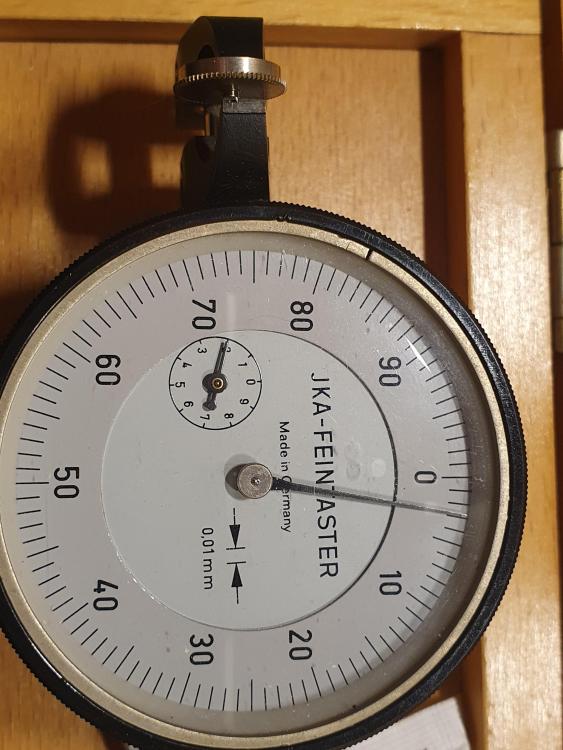

There were literally tons of these made, with spindles that took 3mm pushers as well as 4mm. Many were modified in factory settings for specific tasks. The difference between screw type and lever type is really a matter of preference. I have many examples of both, but for more than a couple of decades only use the lever type. Just today one of my workshop mate's employees asked me for a screw type and I gave it to him but realized it needed a good servicing as the oil in the threads had gummed up. As made, they both come with either 3 or 4mm spindles, 3mm being most common, with a 4mm hole in the base for stumps which matches most other makers as well as staking tools. Your image has extra holes that probably correspond to a purpose-made jig or holder. The central hole looks to have a stump, and is likely 4mm, but could be anything. A plus of the lever type is the spindle comes out and you can use standard (Seitz, Favorite, Chatons S.A.) holders for reamers and drills in it.3 points

-

if you mean the spelling, I just read that both pigeon and pidgeon are both correct. Who knew. Pigeon seems to be the commonly accepted norm these days, I stand corrected. I'm not a fancier so its not a word I often use I work with cryptography in cybersecurity as my main job. Pigeon/pidgeon racing, and the timing of it, is an interesting use case to solve. You need a shared accurate starting time, clocks to record the accurate finishing time, a method to identify the pigeon that's resistant to spoofing, and all in the hands of the participants who might have serious money in the game. I know these days it's gone more high-tech with NFC timing devices and internet connectivity, but it's pretty cool how this was all done with mechanical clocks back in the day.3 points

-

Unless it is broken, don't try to replace it. They are different enough in construction that any aftermarket spring will be hard to find and fit, and Timex old stock mainsprings are not very easy to find. In my experience, I have never needed to replace one. They are typically not "set" having lost the capacity to deliver good power and can be reused. With a Timex, unlike with a high quality jeweled movement, you are not trying to get maximum high balance amplitude in all positions. They were never made to achieve that and can't. The goal is to get them ticking and keeping time within about a minute a day, and you'll have done well. So replacing the mainspring is way overkill. But also, you cannot replace the mainspring unless you fully disassemble the movement, which takes you outside the lighter fluid cleaning strategy and into the much more involved and challenging one.3 points

-

That’s a classic case of being careful to buy complete watchmaker lathes Even though the WW bed is supposed to be the same with all manufacturers but even though they look identical they may not be that’s the reason I have a Pultra it was made in the uk and if I buy anything Pultra I know it will fit apart from anything for the 15/90 that is easy to see is a lot larger. If I was a watchmaker lathe manufacturer then I would make it very slightly different to others so people had to purchase my accessories, good business sense. Dell3 points

-

one of the problems I have with the word vintage I think of actual vintage and you don't want to get vintage. But the good news is vintage definition of vintage is considerably newer. So basically on this group the last of whatever the vintage is this group would consider it basically a new watch. so basically you can look up when radium was discontinued but the reality is radium existed beyond that. It have to make sure the dial has typically the T for for the other thing or find a watch that doesn't have anything that forces at all but I don't know how, that is Rolex. as I was reading through this the reality is I would go with a different suggestion recommended by somebody else. okay without radium moves it somewhere into the 60s he can probably find discussion groups that will tell you when radium ceased on Rolex watches. Then Rolex has really beautiful service manual's probably the best service manual can find anywhere there in color they specify the screwdriver size everything almost sort of not really. All the watch companies have supplemental information which is not included in the service manual. the nonautomatic is interesting it have to do some research I don't know how many non-automatics they have. As Rolex is big for automatic watches. But everything falls apart with number five as Rolex parts are not necessarily readily available unless it's one of the more common automatic calibers probably like 3135. You could probably go back to the 3035 but go look on eBay go look up parts lookup a balance complete for Rolex. Go find yourself a really nice Omega watch they make really really nice watches. Where the parts are going to be more readily available unfortunately Swatch group doesn't want you to have parts so you're not to get him direct but Rolex doesn't like you either so they're the same that way but their way more Omega watches out there than Rolex watches. That if you want something different really unique go find it vintage grand Seiko. Because grand Seiko started with manual wind watches and they actually are really nice watches. Haven't you ever wondered why chronometer certification by the Swiss do not include other countries? This way then avoid the embarrassment of what grand Seiko deaths to their standards. To go find a nice manual wind grand Seiko other than vintage Seiko's it can be hard to find the parts. That might be best to go with Omega as it probably fits all of your criteria.3 points

-

The military used carrier pigeons during the war to deliver messages, kind of like spy pigeons. The bigger birds..they would strap clocks to those ones.... most often when the phone lines were down and folk couldn’t ring up for the speaking clock. The idea was to entice the bird down with a few seeds..get your time reading to set your watch and clock by...then send big bird on his way to help someone else.3 points

-

2 points

-

My inclination would be towards longines, such a storied history compared to the others in this list. Tom2 points

-

Just be careful some of those really cheap crystal lifts are rubbish. When it comes to tools buy the best you can afford, cheap tools will not last while the best will last you a lifetime. When you pick a tool there is no harm in asking us.2 points

-

Just as I've found Complete working lathes in good clean condition generally sell for rather more than I've paid for all the bits I've accumulated separately, though, so I'm not bothered about a bit of extra work to get them up to working condition. Luckily most of my customers are engineering companies & I can get a bed "adjusted" to suit the fittings. I can probably get it skimmed next week, then hand grind or linish it if the initial finish is not smooth enough. I think that should give a similar finish to grinding then curling, with the traces of milling marks acting as oil pockets. I'll use the longest WW one with the double feet. I've managed to get the tailstock runner apart after an overnight soak in the solvent and oil, then heating it to a bit over 100'C. There was quite a bit of rust in the back half of it, so it's now in the EDTA rust remover solution to try and clean it up. The brass hammer head is wrecked, but for a good cause. Also, when cleaning up the bearing in what I though was the unbranded V bed one, I found that is is actually another G Boley, so quite happy with that!2 points

-

At that price range, with manual wind an option, I'd go IWC, Longines, Omega over Rolex, in that order (though the first two are tied), whatever you see that tickles your fancy. Vintage rolex is an issue for parts, and, it's Rolex.2 points

-

BEFORE Polishing: AFTER Polishing: After almost a year and a half, I have finally reached the finish line with my project—to acquire an Audemars Piguet Royal Oak in stainless steel with a blue dial. Well, not quite, but I think I get a bit of that feeling now that I'm wearing my serviced and polished Maurice Lacroix Aikon. I must say that the case is very well-crafted and feels solid, heavy, and luxurious. In fact, I would be surprised if I experienced any significant difference between the original and this homage. When it comes to the inside—that is, the movement (calibre ML115 based on the Sellita SW 200-1)—we obviously can't compare it to an AP, but then again, the price difference is around £40,000. That being said, I must say that I'm impressed by how beautifully decorated the movement is and how well it keeps time. In the long run, I plan to write a small review of the movement and compare it with ETA's calibre 2824-2. I'm far from a professional when it comes to polishing, but I've made some progress, and I'm happy about that. My goal wasn’t to achieve perfection but rather to get rid of dull, scratched, and worn surfaces, which I think is important for this type of dress watch. If it had been a field watch, I wouldn’t have cared. In that case, the only thing that matters is that it’s properly clean, and I actually think a few scratches and dents just add to the watch’s character. It’s a bit like comparing a limousine to an off-road vehicle or jeans and a T-shirt to a suit. A dirty and worn-out limousine or suit doesn’t exactly feel fresh. The reason this project took so long is that several other interesting projects came up in between. However, I’m still very happy with my Proxxon 230/E Micromot rotary tool, and I use it for all sorts of purposes. The vice in the picture allows me to either secure the rotary tool itself or the watch case, depending on what feels most convenient. On top of that, the fact that the tool is quiet and vibration-free makes it an absolute joy to work with. When it comes to the bracelet, however, I used a proper but simple polishing machine since the surfaces are far too large for it to be practical to polish with a rotary tool. Unfortunately, I do not have the equipment or the expertise to restore the original finish, which was probably done with very fine sandpaper. Instead, I polished the bracelet to a high shine and then brushed it. At least it resembles the original well enough not to draw any negative attention. Unfortunately, I accidentally rounded off a few sharp edges. I knew the risk was there, but I lost focus for a moment. I take it as a lesson learned.2 points

-

2 points

-

Some years back I vibrated a hairspring for an old cylinder watch. It was for another watchmaker, and they didn't want anything else, just the hairspring. I did it for 18.000bph, and of course, the watch was a slower beat. Should have counted the gear train!2 points

-

Nearly every village had someone with racing pigeons, we have one here in St Combs. Top class birds were used for breeding and were well sought after or sold for big money. They have their own newspaper/ periodical They have international races from Europe and the owners don’t all wear flat caps and have whippets. Some of the bird lofts are cleaner than most houses and the birds pampered. Special food stuffs to build up stamina A popular hobby at home and abroad.. Never raced any but have nursed exhausted stragglers back to health for return to their owners.2 points

-

2 points

-

My father left me two of those. They come in nice wooden boxes and have a seal applied before a race. No pigeons on the dial. Do cuckoo's have rings (please don't go that way.. no really..). "Fun" fact: you had to persuade the pigeons to come to you to get the ring. In some of these competitions, there was a lot of money involved. So much in fact, that owners have been known to shoot pigeons down in order to get the ring faster...2 points

-

All right you fools pigeon clocks are used for racing pigeons. The only thing you have to worry about is cleaning out the pigeon shit. The same goes for Cuckoo clocks.2 points

-

It is a clock used to time pigeon races to determine the winner. I think the birds were ringed prior to the start of the race the ring being removed and inserted into the clock recording the time of arrival in its home doocote. Tom2 points

-

I had an Elgin 18s transitional watch on the bench. Simple COA. When I put it on the timegrapher, the machine couldn’t get a read on timing. Kept trying but would put two quick traces up and then start over. It took me a bit but when thinking through it, I realized this watch is from 1871 and remembered not all watches were 18,000 bph. Researched and found this watch was “course train” at 16,200 bph. Had to manually set the timegrapher and the watch is running great. It is interesting that my timegrapher couldn’t tell it was 16,200 bph even though the watch is running with nice straight lines and beat error at 0.5.1 point

-

The 371180 is just the barrel without the arbor and a classis case with Cousins if it were the right part then you'd go for that even if you didn't need the arbor.1 point

-

This is a discussion that could go on forever Rolex is king when it comes to public brand recognition. But second would likely be Omega (James Bond Seamaster and moon landing Speedmaster). Longines, unfortunately, has really gone down the pecking order to "entry level luxury" in today's perception. IWC is more niche, less recognisable in the wider public. Between Rolex and Omega, it's funny. Give me 5k, and I'd go for Rolex. But at 2.5k, Omega all the way. Car analogy (sorry, Euro-centric)... Rolex = Mercedes Omega = Audi But the Rolex Air King or Oyster Precision are a bit like the first gen A class. But you could get an Audi A3 (Omega) in great condition instead1 point

-

I just watched this video, may answer all your questions1 point

-

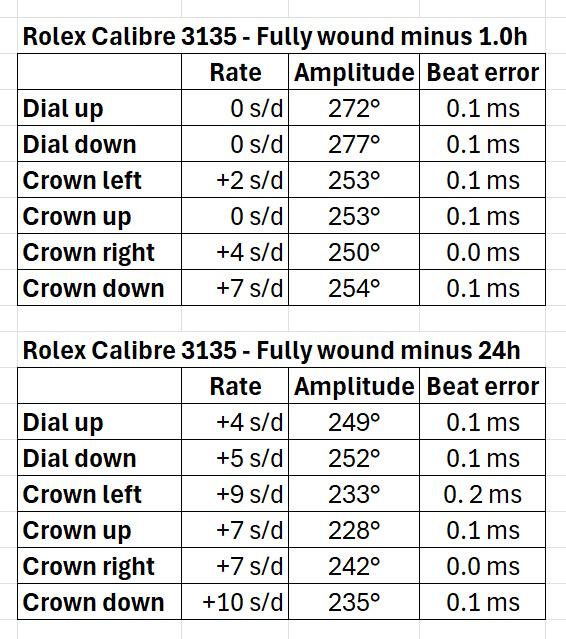

Not everyone at once!!! No worries. It's settled. At full wind, it was starting to run in the high 260s / low 270s (horizontal). After 24h, the lowest is 210 (vertical). Positional variation is very low (delta of 8 between all positions at full wind and after 24h). The lock on the pallets is on the heavy side (but not excessive). That may explain it. I'm calling it good.1 point

-

1 point

-

1 point

-

Lid & Barrel are the same complete on the 352 & 357. Where are you getting the 400 arbor from?1 point

-

I would advice no to turn insert for the pivot hole from blue steel rod but use thin guitar or violin string. This will be 0.2mm. I will show how to thin it slightly tapered to fit the hole. I do it using diamond disk or plate, pin wise and wooden plank. The string piece in pin wise protruding 1cm, supported in a notch on the plank, one hand with the plate grinds it while the other hand rotates the pin wise. This method will not guarantee the insert to become fully round in cross section. That's why I drill bigger hole and insert thicker pivot wire, then turn it to size in the lathe1 point

-

It's one piece. But sure you could drill it and press in a new arbor, very low risk as there's basically no force on these.1 point

-

I am happy now that there are no issues with the movement. The escapement is all fine too. The hair spring is flat, level, and not touching anything. My assumption at the moment is, like yours, I've introduces some contaminant or removed too much oil. I have had the balance out a few times, and cleaned the pivots to check them, each time oil will be lost. I also haven't been using cots or paying any co moderation to contaminating it as I knew it would all need a final clean/service. Maybe I'll clean and lubricate the balance to make sure I can get the free oscillation back before I commit to a final clean.1 point

-

I've only ever used a crystal lift to remove and insert tension ring lenses on Seikos.1 point

-

Yes it's 19mm but didn't get time last night to pull the strap so will have another look tonight.1 point

-

1 point

-

You can remove the old crystal with a crystal lift and that will quite possibly break it or at least deform the tension ring. You can insert a tension ring crystal with a crystal press.1 point

-

if is a monoblock case (no removable caseback) then the stem most likely split stem. If you pull out the crown and the half stem,then you can use compressed air through the tubeto pop out the crystal.1 point

-

It doesn't say _not_ to use lighter fluid, but just says to use a cleaning fluid and ideally that would be in a parts cleaning machine. You can use whatever is available as long as it is something like naphtha. Ronsonol or VM&P Naphtha from a hardware store works just fine. I do recommend rinsing it in high concentration isopropyl alcohol after. 91% at least, and you can dry it with a hair dryer. I clean mine in a small jewelry ultrasonic cleaner, naphtha in a little jar with the movement face down on a movement holder. I don't put the movement directly down on its face because that will bend the seconds hand. But you can do this without an ultrasonic. But you shouldn't dunk the whole movement without disassembling the outermost parts (as directed in the manual) because that would likely leave a lot of grease under all the winding and setting parts. Dealing with the weird domed copper washer that holds the ratchet wheel down takes some practice. You have to press down on it while rotating and it can fly off. Same motion to put it back on, but a little more difficult. Also, the manual instructs how to remove the balance for cleaning. I would say for your first one, don't remove it. It's very difficult to reinstall and easy to mangle the hairspring, and easy to lose its pin. Lastly, if you _like_ that Timex I would recommend buying another one for as cheap as you can find and practicing on it first. It's usually easy to find one ending at auction without bids and grab it for a few dollars. Aim for one without a calendar, and also aim for one that looks about the same age as yours. There are 3 screws that hold the 2 plates together. Only remove the one as instructed for the winding and setting bar. If you remove the other two, you will be stuck putting the whole thing back together and that is quite challenging & frustrating until you've done it about 20 times.1 point

-

1 point

-

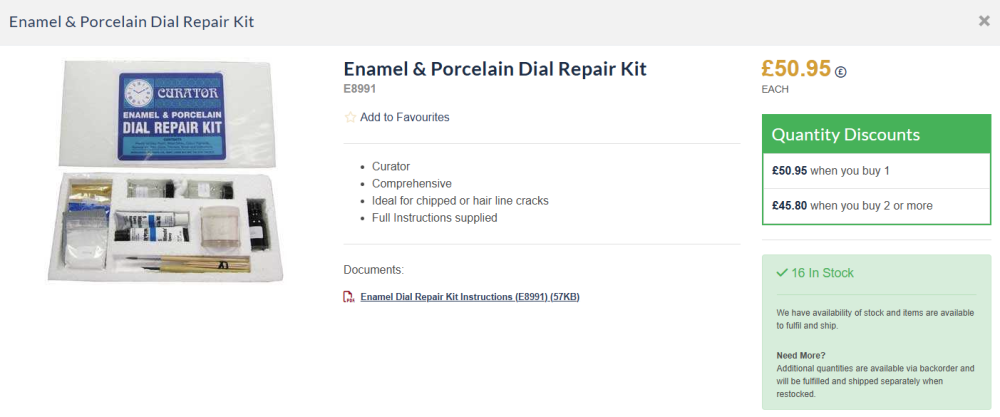

I have read that you can use nail polish, with something to colour it. Getting a good match will be difficult.1 point

-

1 point

-

1 point

-

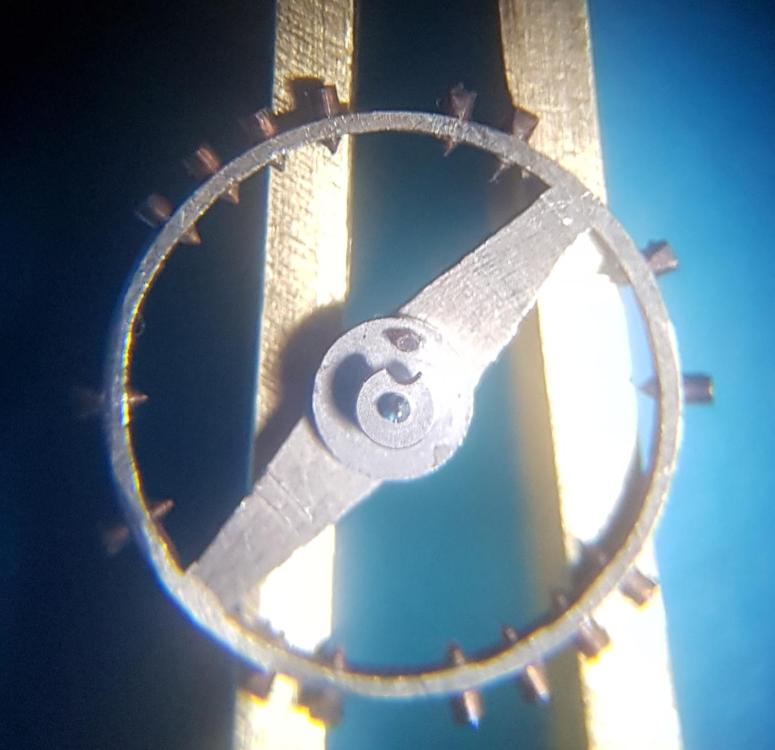

I might get some terms wrong, but had chance to look at this more today. Checked the lock on the pallet jewels. Couldn't quite get my head around the 2° of lock thing, but the pallets seem to lock and release at the right times. The run to the banking is there, but small, I believe that's good. The shake between the guide pin to roller and pallet fork to banking pins is good too. Only thing I found wrong was the guide pin was a little bent. I discovered that when checking where it points in each direction in relation to the level hole when the pallet jewels release. Straightened that before checking the shake between the guile pin/roller and fork/banking. The shake is the same on both sides. Probably wouldn't have been before so straighter the pin. I also tweeted the hair spring some more to get it more convincingly between the regulator pins while the collar is central. I think it's pretty good. Collar doesn't move at all when sweeping the regulation range. The bottom of the balance wheel has seen some serious action! The screw at 3 ocklock is the heavy point according to the tweezers poise set up. The pins, and indeed the wheel itself, have had loads taken off from 12.30 to 2. Also at 9 and 7. At least that means when I poise it I don't have to worry about how I do it. It's had loads taken off though. Maybe I'll end up adding weight to poise it, I don't know. But I'll try and do it dynamically once it's back together. At least I'm happy now I've checked the escapement that there are no issues, at least none big enough to show up to a novice. Edit, I can't poise it yet. Need to set beat error, see how it runs to make sure it's all ok, and then service it again really. Edit Beat error is a 2, I'll adjust that. It's about 200sd slow, but that's not an issue right now. Amplitude is back down to 200 though. It has just gone back together though. It's been apart maybe 10 times since it was cleaned and lubricated. Maybe all the oil just isn't where it should be. I'll leave it for a bit. Watching the hair spring though, it's moving back and forth with each rotation, hitting the banking pin and the boot (is that what's it's called?) In a rather satisfying manor. This pleases me. I believe that's how it should be. Edit again, beat error is a pain to set! I think the hairspring collar is too loose. I can gently hold the balance wheel and poke the collar with an oiled and get it to move. Checked free oscilations and it's back down to 25 seconds. I think strip, clean, lubricate, go through all the checks as it goes together hopefully for the last time. Then try and poise it.1 point

-

The hairspring coils are still filled with fluid when the movement is lifted into the air, when submerged the dynamics are somehow different...surface tension maybe be a cause.1 point

-

1 point

-

Yes, that's a furphy. If it runs for 12 hours, the centre wheel turns 12 full revolutions. The ratio between barrel and centre wheel is typically about 8:1 so the barrel must turn 1.5 full revolutions in that time. If you're only getting in one or two clicks on the wind the watch can't have been running for the 12 hours. (Unless you have elves who are pranking you by winding the watch just before you get to it.) It must have run for 15 or 20 minutes then stopped. Then perhaps it started up again when you touched it, and you assumed it had been running for the whole time. Dunno, but the centre wheel simply can't turn twelve full revolutions without the corresponding motion of the barrel unless the connection between them fails, and if the connection did fail the watch would lose its only source of power and stop anyway (and the mainspring would unwind all at once, possibly catastrophically). So, setting that aside, the barrel is the most likely problem, with wear where the arbor interfaces with the barrel and/or lid, or wear between arbor and bridge or mainplate. Very simple check: with the barrel installed and no wind in the mainspring try tilting the barrel with a pair of tweezers on each side. It should move an almost imperceptible amount due to arbor side shake. If it moves half a degree or more you have a problem. Have a look at this post for an example of excessive side-shake (and also excessive end-shake): If your barrel looks anything like mine in the video shown there, it needs work!1 point

-

Unfortunately this device is not electrically safe and could not be sold in Europe (certainly Australia, too) legally. However no one cares. It has no protecting earth connection while at the same time has a touchable metal part - that you will touch 100% each time, the metal pusher! Frank1 point

-

Tomorrow it is finally time to hand over the watch to the owner so this may be my last post in the thread. It feels a bit solemn. It has been an educational and fun time to have had the privilege of servicing and repairing this beautiful Rolex Oyster Perpetual Date with its fantastic movement calibre 3135. All the help and information you have so generously shared has been crucial, so again a big, big thank you. Special thanks to @Jon for sharing his professional and in-depth experience and to @Knebo for the encouragement (and facts) between us enthusiasts. I am sure many others will appreciate and benefit from this thread in the future. The final challenge was to regulate the rate with the Microstella tool as described in my previous post, which I did in two rounds, most recently yesterday. Here are the final results measured with PCTM. Each measurement is averaged over three minutes. It is very satisfying to see that all values and performance tests, including the rate, are now well within Rolex's specified limits.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)