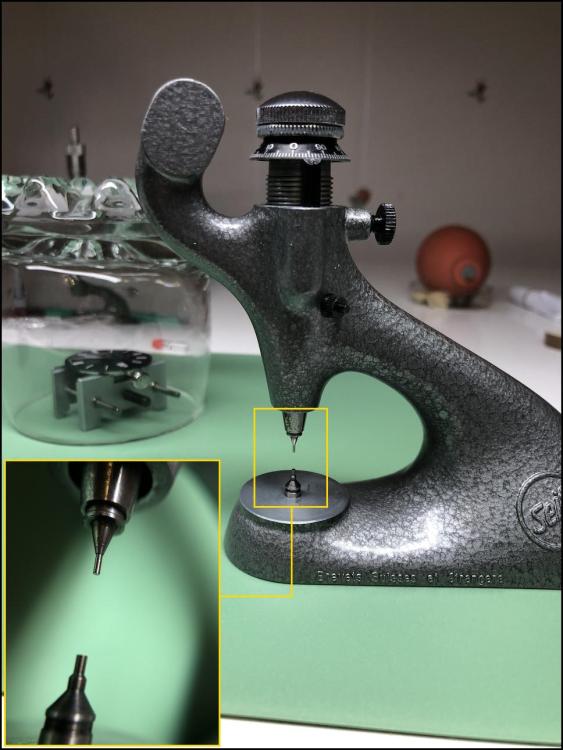

Leaderboard

Popular Content

Showing content with the highest reputation on 01/31/25 in all areas

-

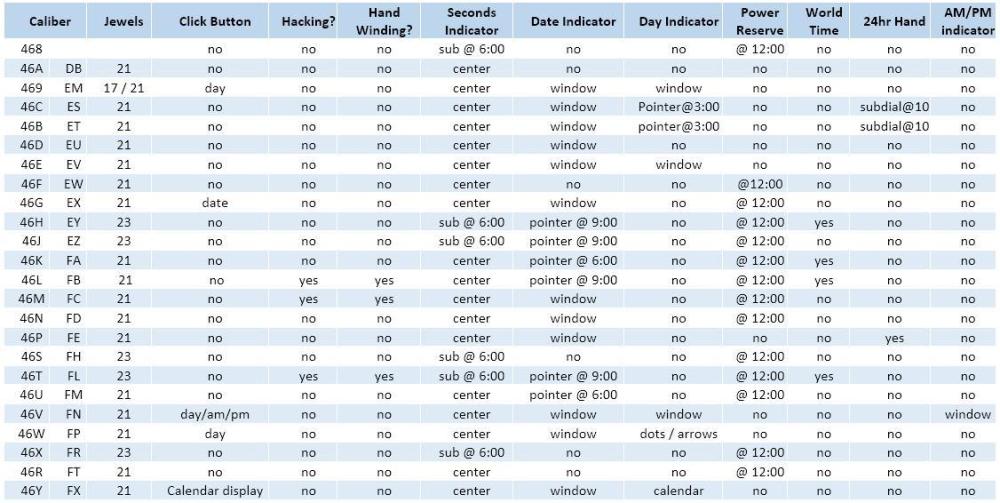

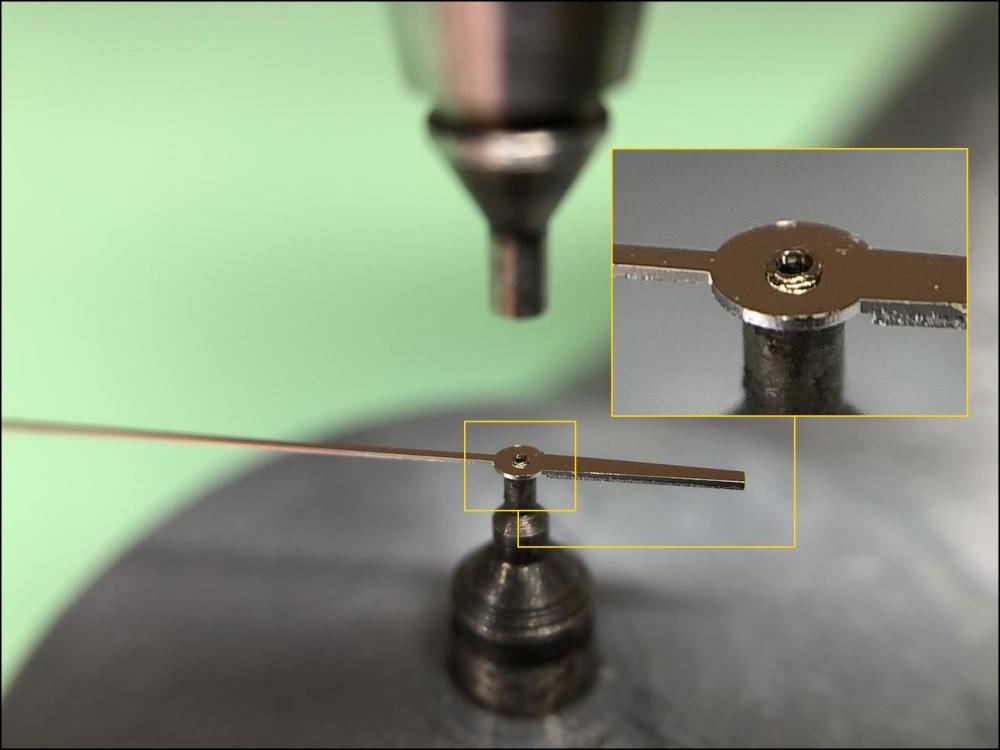

So, this project is finally complete, and to wrap up this thread, here’s a brief description of how I reattached the second hand to the fourth wheel pivot. Normally, I just press the second hand on, but this time, I thought it would require quite a bit of force since it was firmly in place when I removed it. I figured that if I didn’t manage to push the hand down far enough, it would end up touching the underside of the crystal. Keeping this in mind, I realized there was a significant risk of disturbing the jewel on the barrel bridge—or, in the worst case, even pushing it out. My first thought was to order a movement holder with hand-setting support, but impatience and budget constraints put an end to that idea. Instead, I used my Seitz jewelling tool in screw press mode to support the jewel properly. Initially, I was a bit worried that I wouldn’t be able to keep the movement level enough, but fortunately, that concern turned out to be unfounded. When the pressure becomes high enough, the movement naturally settles into a flat position—just like when adjusting end-shake on a jewel. Isn’t it amazing how versatile a jewelling tool can be!? Looking back, I think I could have just pressed the second hand back on without supporting the jewel, but at least I’ve gained some experience from it. Here’s a picture of my freshly serviced "Royal Oak." More pictures are available here if anyone is interested.5 points

-

For let's say 1950s, absolutely Longines or IWC. Omega was also doing amazing stuff, but not the same level. Definitely there technically, but not on the finishing. IWC was often called "the poor man's Patek". I hold that mid 20th century and some decades before, Longines was at least Patek level and more likely over. So Rolex, it was good, but not even close to IWC, Longines and Omega. I've worked on enough of all the above brands to say before Rolex came out with its famous purple inversers for their automatics (60s? a bit later?) they didn't hold a candle to those others.5 points

-

After waiting around for a few months I got lucky and found a face plate for the jeweling tool on eBay. Paid far too much, but I couldn't resist restoring the set to completion (good as anyway, I'm one hand tube adjustment pusher and one reamer I think) Spent some time restoring the faceplate. Lost some rhodium, but it all looks lovely. Very satisfying! (Last photo is just before the strip and clean)4 points

-

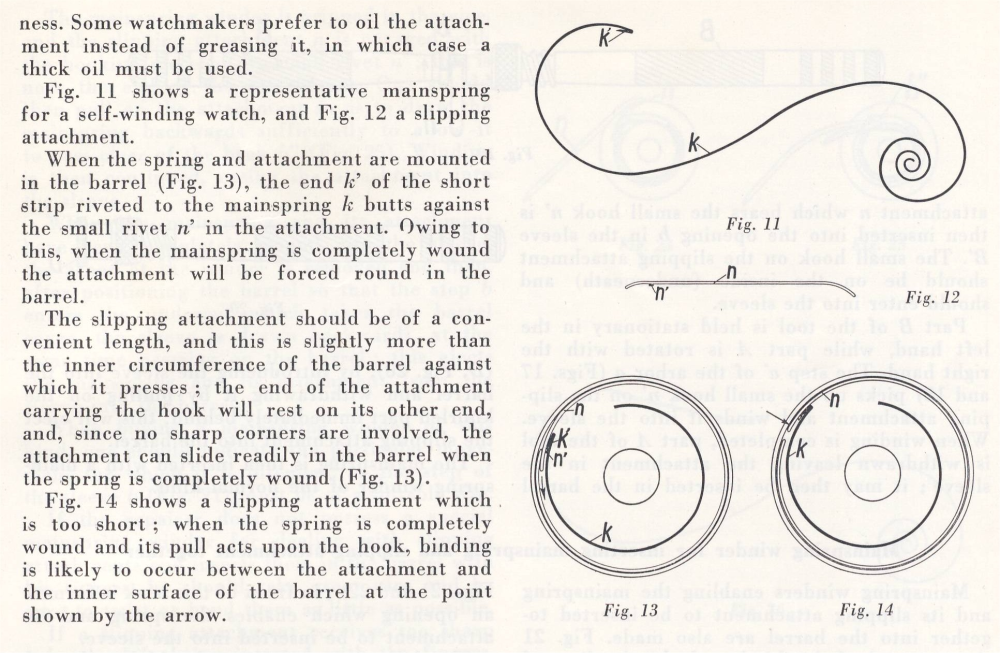

Thanks to everyone who took the time to respond. We really do have a great community of helpful people on this forum. This did turn out to be a 2-part mainspring as described in JohnR725's post. The "slipping attachment" had become nearly welded in place by dried up grease and corrosion, which is why I thought it was part of the barrel. Once I felt emboldened by the info you all provided to be a bit more persuasive I was able to remove it. I will now order the appropriate modern style automatic mainspring and be able to proceed with reassembly. Many thanks!4 points

-

I went through a similar exercise with each of my children. When they were born, I found a watch that I would wear during their childhood, build memories and association, and hand down to them. Had to be of good quality (speaks for itself), something someone would want to wear whenever (not a fashion exercise), and have something for them to play with (extra crowns, pushers, etc.). My daughter is now 5, and she has a (doesn't matter what brand because brands don't matter) with dual rotating inner bezels. She has spent many hours in my lap turning those crowns and playing with the bezels. It's 2824-2 powered, and when it was due a service, I upgraded to a top grade Sellita movement (notably, not ETA). My son is only 6 months old, and he got a parts chronograph (doesn't even have a brand) with a top grade 7750 (yes, ETA, but I got it for a good price, and can swap in a Sellita down the road when I eventually find a vendor selling them in top grade). He grabs at it during diaper changes, and the shininess seems to do a good enough job at keeping him from alligator rolling off the changing table. He's just getting started with his watch. I've explained the deal to my daughter, and she's very excited about it. She has a butterfly Timex child's watch that she wears for "practice". I'll probably give it to her when she goes off to college or something. The thing about branding in this exercise is that it SO doesn't matter. DADDY is the brand. Memories and association are the brand. If I do my job(s) right, monetary value is 0% consideration. Both of these intentionally have the most broadly available workhorse movements where, even with Swatch's cartel-like practices, parts will ALWAYS be available forever and ever by way of donor movements if nothing else. The price of a Rolex is about 10% watch, 90% marketing. If you took the name off the dial, and just assumed it wasn't a fly-by-night outfit that stood behind the product like most manufacturers do, a $50,000 Rolex stainless dive watch would probably go for about $5K. They're good, don't get me wrong, just not 10X better than reality. Ads in magazines and manufactured scarcity don't actually mean anything. If you're into watchmaking, you can look at watches with a less marketer influenced eye, and see what watches are really worth the time and money. Rolex never makes the cut for me, because branding carries $0 value in my world, and the street price makes them far too expensive for what they are. Add in the fact that Rolex won't sell parts to repairers, and you get a pretty steep reduction in value. Given a brand new Rolex, I would immediately turn around and sell it while it's "worth" maximum dollars, because to me the watch has a negative valuation, and every day I wear it is a day's worth of wear that I can't repair. There are a lot of extremely excellent watches to be had for your purpose in your price range. If I sound anti-Rolex, know that I'm not. I'm equally anti-(anything Swatch) right now, and that's most of what's been suggested. What I am is very pro-craftsmanship and engineering. Good engineering extends beyond blueprints though, and into things like maintainability, which the owner of a design can ruin by refusing to allow the end user to keep them going. Which is a bummer, because I REALLY like Omega's Co-Axial escapement. Right now, I'm pro-anything that I can "keep on the road". For $2500 if you're looking for new (which you aren't currently, but should the tides change), look for something with a Sellita movement. If you're looking for something used, keep an open mind, and do your homework on a per opportunity basis.4 points

-

¡Bienvenido y gracias por tu publicación! Sin embargo, ten en cuenta que este es un sitio en inglés. Por favor, publica futuros mensajes en inglés. Si prefieres escribir en español, utiliza, por ejemplo, Google Translate, Deepl.com o ChatGPT antes de publicar. "Welcome and thank you for your post. However, please note that this is an English site. Kindly post future messages in English. If you prefer to write in Spanish, please use tools like Google Translate, Deepl.com, or ChatGPT before posting."4 points

-

Femtoseconds..... Wow! What is a femtosecond scientist doing in the realm of...er... "macroseconds"? Do you laugh at what we consider accuracy? Sorry. Welcome to WRT. Where vintage time prevails.4 points

-

I believe John is right; it may look like part of the barrel, but if you lift it you will find that it comes out. A new automatic spring with integrated bridle will work fine in its place.3 points

-

As the resident "Timex Guy"...wait as the resident "Vintage Timex Guy" The new stuff is imported crap... I can state confidently that the soaking in lighter fluid is not recommended. I use a 3 stage soak and rinse followed by lubrication and grease. This process was pioneered by the members of the now offline "Vintage Timex Watch Forum" on Network54. Of which I was a very vocal member and our mantra was "Keep them ticking". Beware it is not as simple as it sounds and the professionals will be quick to have a chuckle and inform you that Timex watches were not built to be serviced. And you know they are 100% correct. They absolutely were not meant to be serviced in the traditional strip down method. But they can be made to run again. and that bugs the crap out of them...... YEP! this is spot on....3 points

-

Local auction had a box of random watchmakers tat. Nothing amazing, but I spotted a few bits in the box, so I bought it. Just had a dig through to assess what's there. First off, some watches. I ignored these. Some limit, a sekonda quartz, and a rotary quartz. I may or may not see if these work. I know nothing about them but I know if they weren't tat, they wouldn't be in the box. Next layer of items were some empty tins, a glass globe (this might actually be handy!) And a tray of glass watch crystals. It's slim chance I'll have the right size if I need them, but I play with early 20th century watches, so glass is nice rather than plastic. Next grouping is all the little boxes. The watch pins will be handy, as will the dial washers and the screws. An entire tub of setting lever screws there. There is some other bits and bobs too. Don't know how the enamel is ment to be used. No idea what clock bouchons are, or what the cylinder pivots are. Bottom of the box has this assortment of hands. I need some sub seconds hands. I bought a new selection, but I think there might be something better in here. That brings us to the small selection of tools. A broken something, adjustable winder maybe? Not sure if both bits belong together, but it's broken, and not all there whatever it is. A glass pippette maybe? An old oil pot, ill mix lume in this rather than using a teaspoon. There is a packet with a load of broaches though. I figured these would be handy. Not sure if cutting, smoothing or both. Might be handy for the seconds hands! There are also some small drill bits, and a nice surprise, a tin of taps! I need a 0.8, hopefully there will be one in there. Then some pocket watch and clock bits. The dials are nice. One is a chronograph, the other says chronometer. The movements are incomplete, but I think that's the one for the chronograph. Looks way more complicated than what im used to, even with a load of bits missing. Has depose stamped on it. And lastly, the other thing that made me tempted to buy the box. A zenith trench watch movement. I think the black dial might go with this. Not sure about the case parts though. Few bits missing on the movement but some of them might be in here somewhere. I love black dial trench watches so as soon as I saw this, along with the broaches and hands, I figured I'd buy the lot. all in all, worth the £26 I think. I expected more radium, but luckily only 1 hand and the dial.2 points

-

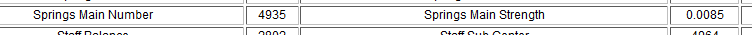

As @JohnR725 has explained and from my original post of possible sources it's the Elgin 4935 you need. https://www.ebay.co.uk/itm/2332789243442 points

-

2 points

-

Even though it is feasible and sometimes even necessary, the best option is of course to use a mainspring winder. For example, it is more practical to wind in mainsprings with T-shaped bridles by hand, as it can otherwise be difficult to get the bridle to fit into the hole in the mainspring barrel. Regardless, as I previously mentioned, GR mainsprings do not work particularly well in Japan-made automatic movements, as the bridle on Japanese mainsprings is much thicker and there are no notches on the inside of the mainspring barrel. This is why I strongly recommend using the original mainspring. It's sad to hear, but it's just as I suspected. Taking chances in this industry rarely works out. It was so long ago that, unfortunately, I don’t remember any details. Unfortunately, I believe it is the only possible option.2 points

-

on the older automatic watches the mainspring was to parts and it probably is the outer part. So basically in the early days it's a smooth barrel with a short piece of mainspring with the hook like a manual wind watch with a manual watch mainspring attached. So all you have to do is pull out the inner peace and replace with a modern mainspring where they come together. I'm attaching an image for it explains.2 points

-

2 points

-

Welcome to the forum. Don't know where in the world you are but these are probably worth messaging for more details. https://www.ebay.co.uk/itm/233278924344 https://www.jewelerssupplies.com/elgin-22s-alloy-mainspring-959.001.0135.html https://www.ofrei.com/shop-bin/sc/productsearch.cgi2 points

-

Well done and thanks for sharing! I'm always happy when I see the Seitz in micrometer-screw-mode. I feel that many people don't know about it.1 point

-

I had exactly the same issue when I tried removing the hands from a TAG I was servicing as a favour, didn't have VWatchie's luck or was is skill in getting it back together, ended up costing me £120 for a new set of hands. So much for doing someone a favour. Shan't be doing that again.1 point

-

Not normal, the mechanism should stay comfident in setting position. Pressing the stem part which is in the movement in must bring the mechanism in winding mode. I have video to show this somewhere...1 point

-

actually you do not know the movement number that's part of the problem you know the serial number. armed with the serial number you can go to a pocket watch database at the link here https://pocketwatchdatabase.com/search/result/elgin/38416337 then we get the grade number of 508. Sometimes on the pocket watch database on the left-hand side they will list the parts not always so if they don't list it I go to the source http://www.elginwatchparts.com/ which then gives us this then armed with this the easiest way would be just to go to your favorite search engine and say Elgin 22 size mainspring and see what comes up on the list like this or just go to eBay directly because that's the most likely source easiest source to find a mainspring. Then to get a link like this one this just happened to be the first one I'm sure there are others. https://www.ebay.com/itm/1664317786831 point

-

Hello there, thanks for letting me join the watch repair talk forum. I'm an engineer/scientist with expertise in femtosecond accurate timing (PhD in femtosecond laser time systems). I recently discovered mechanical watches and I started restoring old pieces as a hobby. I've come here to exchange information and get assistance to questions.1 point

-

disturbing and that it's not listed as there is a lot of springs to look at their? currently I'm looking at a different source which is best fit online. Does not list the Hamilton number at all I was hoping for a confirmation of yes they really are exactly the same. Then the editor part number comes up very clearly as a 170.03. Which your spring in your picture very definitely is not that spring. this brings up the problem of assuming that a watch has only been rebranded when typically they are not 100%. So basically the base caliber is ETA but Hamilton has modified it. Which is why the balance jewels are not right because they're not ETA balance jewel assembly or the spring for that matter1 point

-

1 point

-

Once the hand is fitted back on the pipe it helps to rivet it to make sure it doesn't detach or move1 point

-

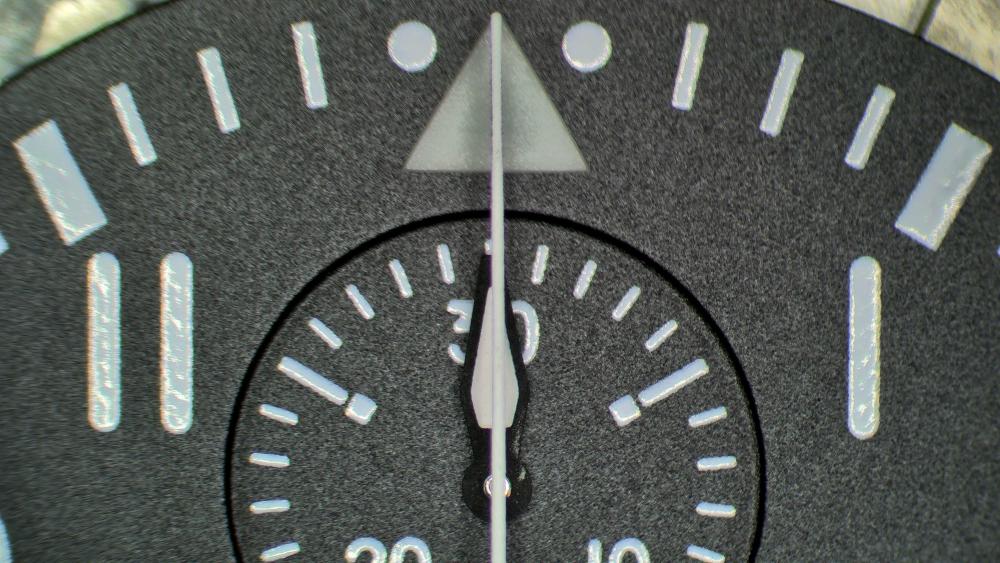

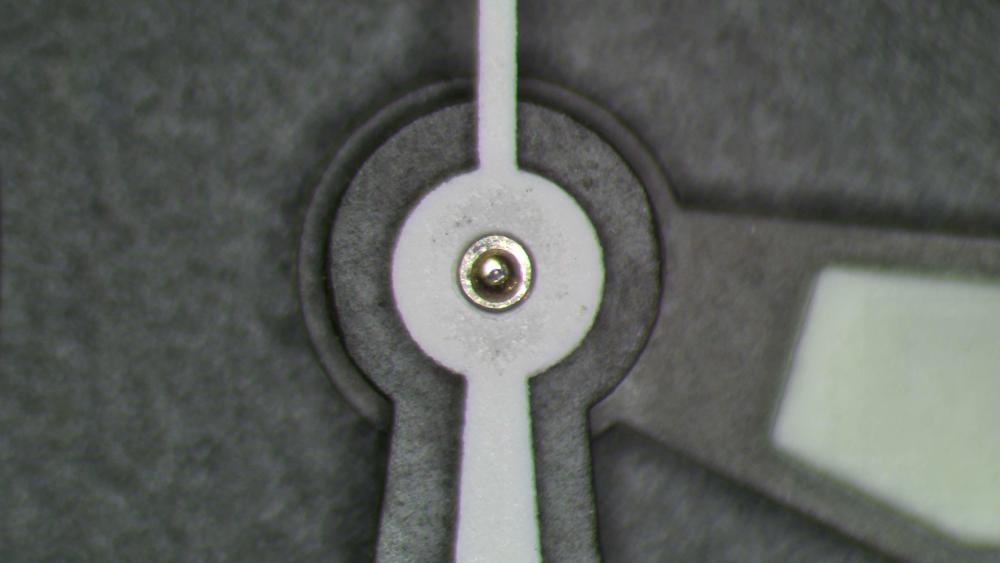

Hi Guys, I was just setting the chronograph hand on this IWC 7750 and noticed how far out the minute counter sub-dial is from centre. The chronograph hand is set pretty much exactly at 12 O'clock, but if you look at the track of the sub dial it is off to the left. Clearly the chronograph sweep second hand is central as it is also central to the rivet of the sub-dial hand. Incidentally, I had to close up the pipe of the sweep second hand by 0.01 mm to have a tighter fit on the arbor and re-rivet the rivet on the top of the hand, so the hand wouldn't slip whilst returning to zero. I find a lot of these sweep second hands need work to get them to fit really tight and not drift, as this one was. The last pic shows the rivet that I re-rivetted. You can see how it is slightly flattened on the top to create a tight fit between the rivet and pipe, so the hand doesn't flap about on the pipe when returning to zero.1 point

-

There is no such idea. This is just hand method that can not guarantee the pin will be uniform.1 point

-

It doesn't look like anyone addressed this directly. Damage like this to enamel dials is common, almost ubiquitous in watches that have taken a hard drop. The dial attaches to the movement with usually copper wire "feet" - the tips of which are visible in the missing enamel holes. When the watch is dropped then the dial feet will either flex horizontally or be pushed up or vertically and dump some of that energy right into the enamel, which shatters where it contacts the dial feet. They may bend a little dimple into the brass dial too. And Richard suggested checking the balance staff because a drop strong enough to have done this to the enamel almost certainly will break the staff too. Or at least bend the pivots.1 point

-

From the photo (It's hard to see clearly) it looks like a slipping bridle, which turns in an anti-clockwise direction. The same direction as the spring and when the spring comes to full wind that bridle will pull in on itself with less friction holding it in place and then turns and slips. I bet the mainspring that came out looked like a manual spring with a hook on the end?1 point

-

Hey @VWatchiethank you for the reply. I am looking for an used movement but again, 46E40 cannot be found anywhere ...however I found a list with similar calibers from the 46 family...so I will probably give it a shot, what else can I do ?! I am very stubborn because I want to get this watch fixed ! If that takes time, no problem...in parallel I am practicing on cheap vintage watches.1 point

-

Ok, upon closer inspection, I realized that it is a 1.8mm diameter, one sided spring bar of length 17.5mm. There is no notch for pulling back the internal plunger, you just stick a spring bar tool between the plunger and the case on the smaller diameter side and push in. By the way, do not bend back the shroud. It's not meant to be bent back, but rather to fill in the case.1 point

-

Hola aficionados como yo por los relojes. Soy nuevo en esto y los desarmo por sumo gusto. Cuando no entiendo algo, pongo todo en una bolsa y al amigo relojero a que me ayude. Creo que no tiene nada que ver ese barrilete (barril) cómo le decimos acá en Argentina con un mov automático. Tengo un ETA 2452 al que le hice el service hace poco y no recuerdo que tenga ese formato. Creo que es de un mov de cuerda manual. Saludos y espero que haya servido de algo!1 point

-

Are you sure it's a 2452 and are you sure it's not part of the old spring left in the barrel?1 point

-

It looks Horia! If it's been modified beyond those holes is to be seen. My gut says it's A-ok.1 point

-

I’ve recently refurbished a spare bergeon vigor 4266 crystal lift. Buy cheap, most are expensive on eBay. For a non refurbished but complete I would definitely be looking at paying no more than £30.1 point

-

Just be careful some of those really cheap crystal lifts are rubbish. When it comes to tools buy the best you can afford, cheap tools will not last while the best will last you a lifetime. When you pick a tool there is no harm in asking us.1 point

-

Unless it is broken, don't try to replace it. They are different enough in construction that any aftermarket spring will be hard to find and fit, and Timex old stock mainsprings are not very easy to find. In my experience, I have never needed to replace one. They are typically not "set" having lost the capacity to deliver good power and can be reused. With a Timex, unlike with a high quality jeweled movement, you are not trying to get maximum high balance amplitude in all positions. They were never made to achieve that and can't. The goal is to get them ticking and keeping time within about a minute a day, and you'll have done well. So replacing the mainspring is way overkill. But also, you cannot replace the mainspring unless you fully disassemble the movement, which takes you outside the lighter fluid cleaning strategy and into the much more involved and challenging one.1 point

-

It's an enamel dial. A brass / copper plate with an enamel coating. Looks like the enamel is chipped where the dial feet are. It's a cylinder escapement and I suspect that the balance staff is broken.1 point

-

I was asking the OP. Your response came in while I was typing . In my limited experience, cutting blued steel with carbide freehand down to 0.12mm is no problem. However, If you start out with a thin wire with too much stickout (and no slide or steady rest), I imagine that it could be difficult.1 point

-

Well, I am waiting on Jersey Mo to chime in here. He is the consummate Timex guru and has forgotten more than any of us will ever know about Timex watches.1 point

-

The 2312 under the balance is a red herring. https://www.emmywatch.com/db/movement/caravelle--rk/1 point

-

That's what I believe but on this scale not even my stereo scope is magnification enough to reveal all the details. Anyway, it's a solid fit so I'm more than happy. The ones I published before are as close as I can get so I'm afraid not. I believe that tube is some of the tiniest pieces I've ever handled, except perhaps for the dreaded Seiko Diafix springs for the escape wheel.1 point

-

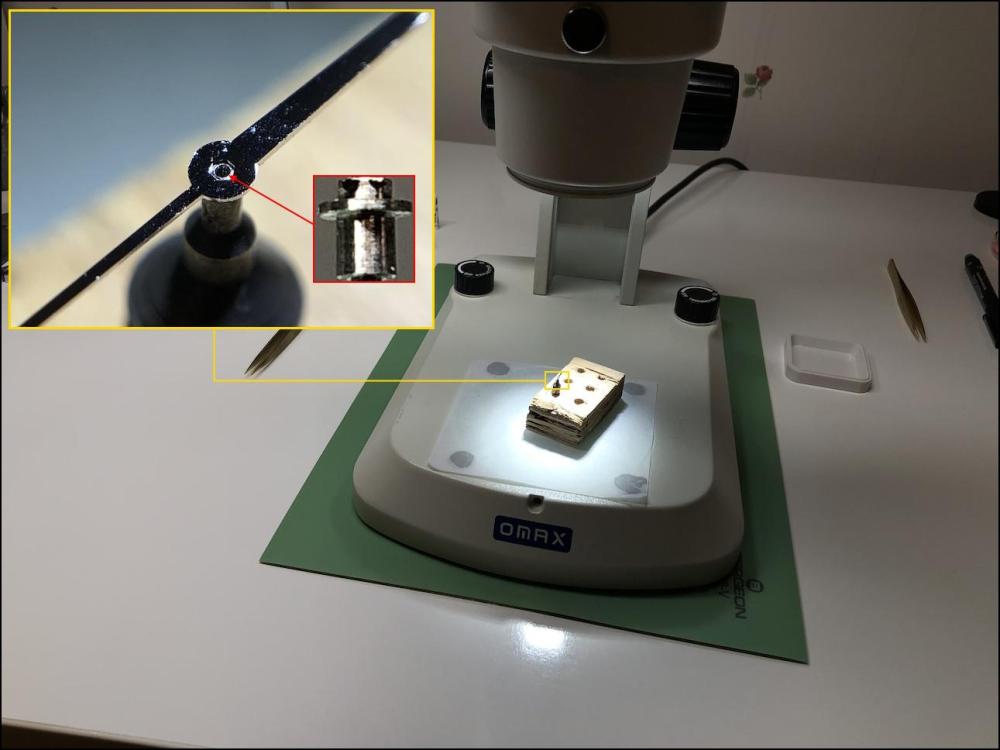

As the proverbs say, "necessity is the mother of invention" and "where there is a will, there is a way." After much thought and several failed strategies and attempts, I finally managed to figure out and carry out the mounting or riveting of the second hand. As I mentioned earlier, I don't consider myself particularly skilled when thinking outside the box (and thus probably one of Bergeon's best amateur customers), but practice makes perfect, so I can't help but feel a little proud today OK, it's not rocket science, but still. I placed the second-hand tube into the hole of a suitable pusher from my jewelling tool. To work under my stereo microscope, I placed the pusher in a hole in a wooden block. Without the stereo microscope, the operation would have been impossible, at least for me. Then, I manipulated the second hand with two brass tweezers until the hexagonal hole in the hand aligned with the hexagonal top of the tube and gently pressed the hand, hoping it would attach well enough not to fall off. Fortunately, I got the hand to attach, albeit slightly crooked and very loosely. After this, I very carefully transferred the pusher to the jewelling tool so the hand wouldn’t fall off in the process. I had pre-set the micrometre to minimize the risk of crushing or damaging the hand if it became necessary to apply relatively high force on the jewelling tool lever. Finally, I carefully lowered the lever, and almost immediately, without applying much force at all, the second hand clicked into place. It was a distinct click—the kind that gives you a satisfying feeling in your body. My only concern was that the tube or hand might have been damaged when I removed them, causing the hand to spin freely on the tube. Luckily, my concern proved unfounded, and the hand fit perfectly onto the tube. Now, all that remains is to press the tube onto the fourth wheel’s pivot when the time comes.1 point

-

There are alot of movements where the stud is tight fit in the hole of the cock. The stud has tapered pin that gets in the hole. This way of stud fixing dates from french verge watches, and is used in huge variety of cylindre and lever movements in pocket and wrist watches. This way of fixing is for convenience, it is meant to ease the assembling and disassembling. But not staking set is needed, and I actually wonder how exactly to use staking set safely here.1 point

-

Nevereboughwatches. Envy you. However, like Tom, I also looked at this course. Discounted it quickly for three reasons. Cost, age and space. Cost. My bride would strangle me. Age. 75. But I am capable of learning visually. The written word would defeat me. Space. I live in a parkhome. One bedroom and a 6' x 9' study which has 2 tables. One for my bride's craft work, the other for my computer and watchmaking. I have no room for the required lathe, but I have purchase a 3" bench vice. Judging by your and other's posts. I think our hobby standard is far better than many of the professionals. The amount of watches I have received that are scrape marked, parts missing or even put back in the wrong place is many fold. I have gained a good appreciation of the application of care to a watch and the movements. Mark, and Alex's courses cover most bases. YouTube videos offer a plethora of information and structural advice. These make it my distance learning course. The only thing I don't have is a tutor. I do feel that I overcome this by having the members of the forum guide me. I'm still learning. But going professional? I think that the B H I is the way for recognition. As I said. I envy you1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)