Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/25 in Posts

-

As I lost trust to this new balance, decided to take a different route. Removed roller jewel from new roller, made liquid shellac, installed new jewel into old roller with liquid shellac, heated by touching soldering iron to other side of roller. Works just fine, no rate or regulation problems.5 points

-

Thanks everyone. Progress update. I've repinned the hairspring to the stud (lost the brass pin - no idea how or where it went - but had some replacements) and rotated the collet by the same amount. It now can run fast or slow depending on the position of the regulator, and in the middle it's keeping good time. Beat error is 4ms so I'll need to adjust the collet a bit more, but apart from that I think it's solved.5 points

-

I also live near the see and it is humid here. I have dehumidifier in every room and they work non-stop all seasons but summer. I drain in the sink 3-5 liters of water from every dehumidifier every day3 points

-

@tomh207 @nevenbekriev - thanks very much. I managed to get the bezel off and the movement out. It turned out to be a pop-off type and I was able to do it using firm upwards pressure with a screwdriver and working my way around the bezel.2 points

-

Well, I used a conical punch on the dial side and a flat stump on the train side and gently pressed it in. The watch is running with good amplitude! I used a Seitz jeweling tool that was also part of this purchase. It was dirty but 99% complete. I had to clean it up before I could use it. Worked great.2 points

-

2 points

-

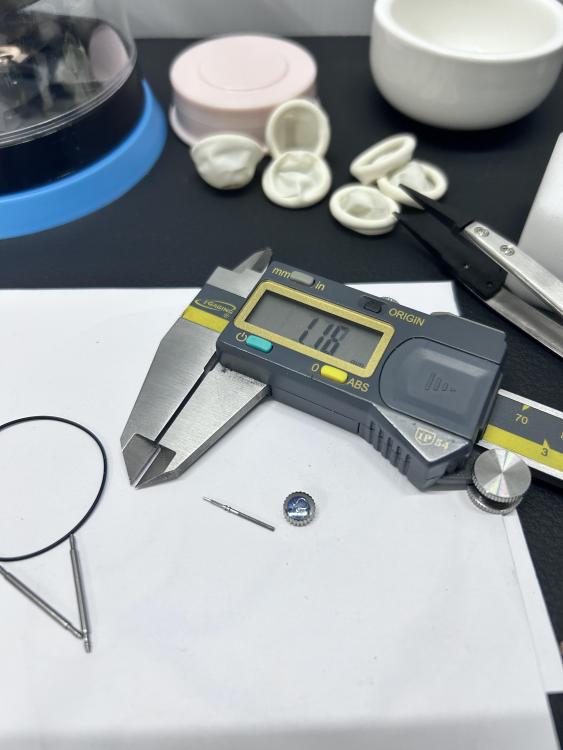

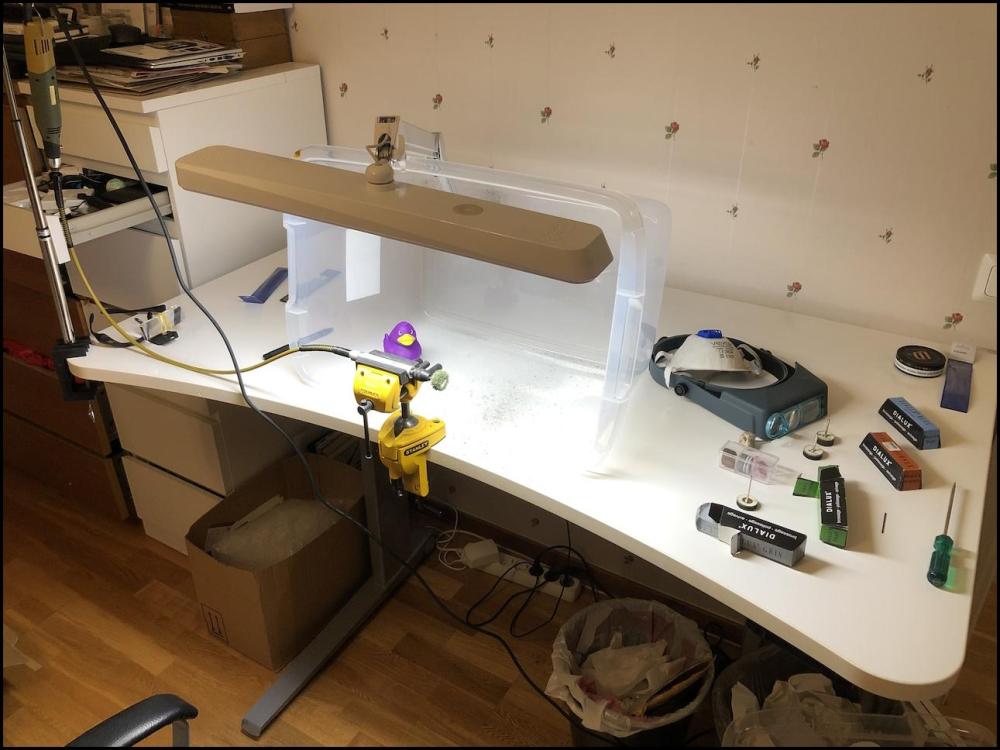

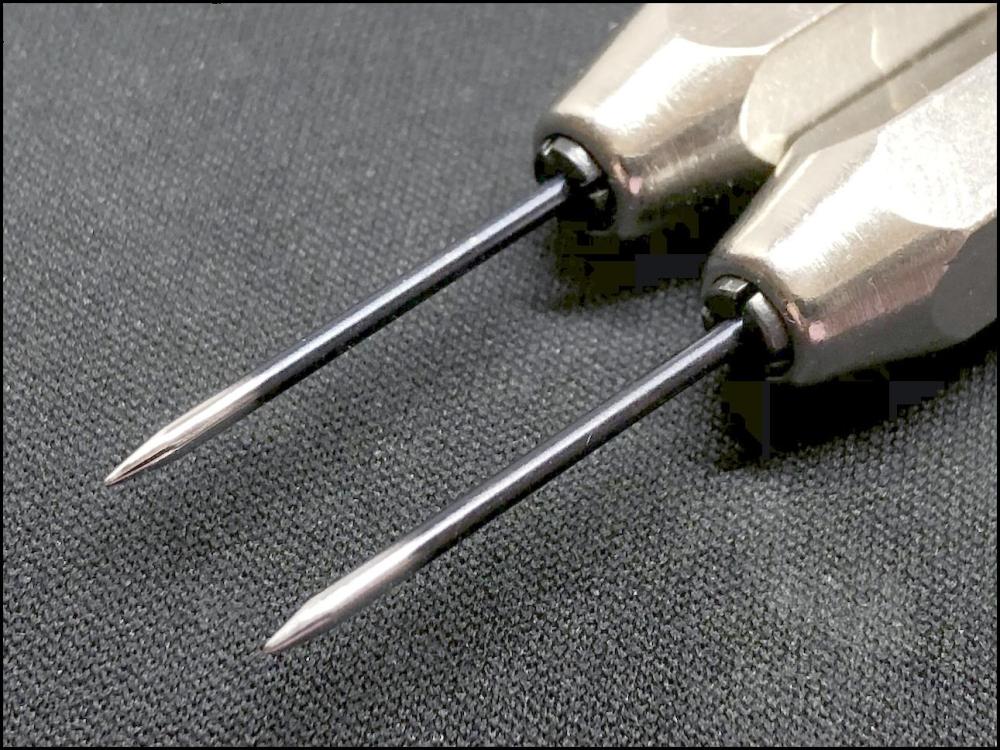

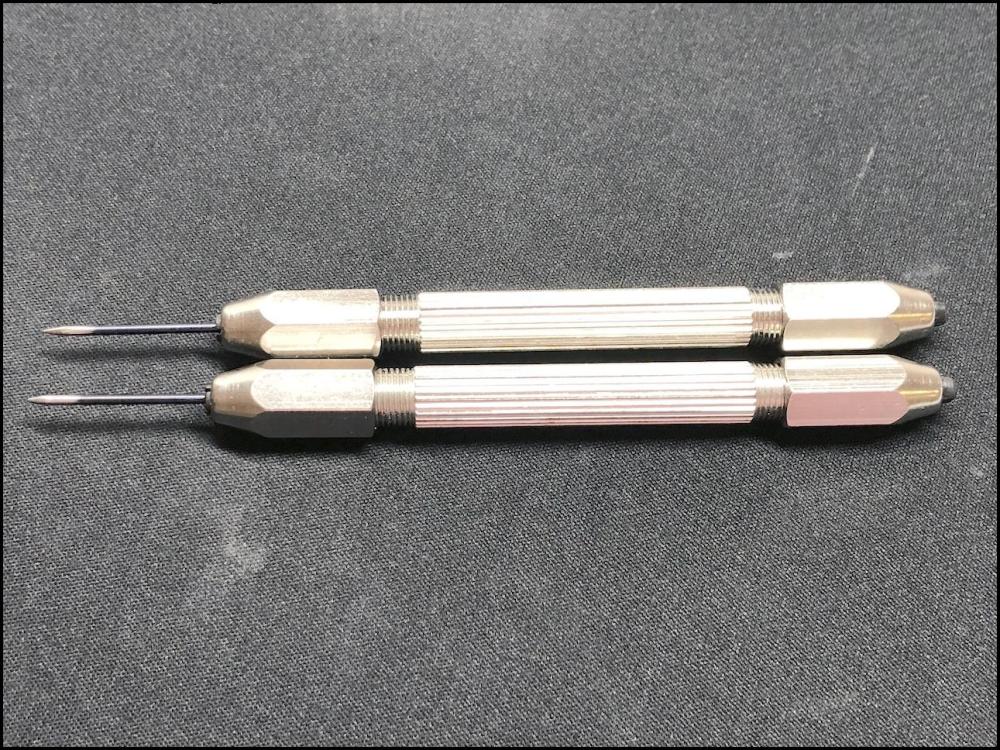

Inspired by the section (18:53) in the video, I’ve just made myself a pair of custom rods for manipulating anti-shock springs, etc., but in steel instead of brass. BTW, I do recommend the videos on the Macro Time Youtube channel. Excellent and entertaining! To minimize the risk of scratching anything, I’ve rounded off and polished the tips. I’ve avoided Seiko and Orient watch movements for several years now due to the difficulty of handling the nearly microscopic Diashock and Diafix springs for the escape wheel and third wheel. With these rods, I’m hoping it will become a bit easier. I’m really pleased with my work, even though I haven’t had a chance to test the rods yet. My only regret is that I ordered steel pin vices, instead of brass, as they feel unnecessarily heavy. On the other hand, they might be more stable in handling that way. We’ll see. To make the rods, I used the tools and accessories you can see in the pictures. The grinding wheels for cutting and rough polishing the steel were included with the multitool kit. Sweet! One thing I figured out this time was that I could use the sides of the felt mopping wheels. Very practical and probably obvious to most people, but I always feel so happy and almost surprised when I manage to come up with something on my own! Anyway, I hope you will find this post inspirational and useful!1 point

-

1 point

-

1 point

-

1 point

-

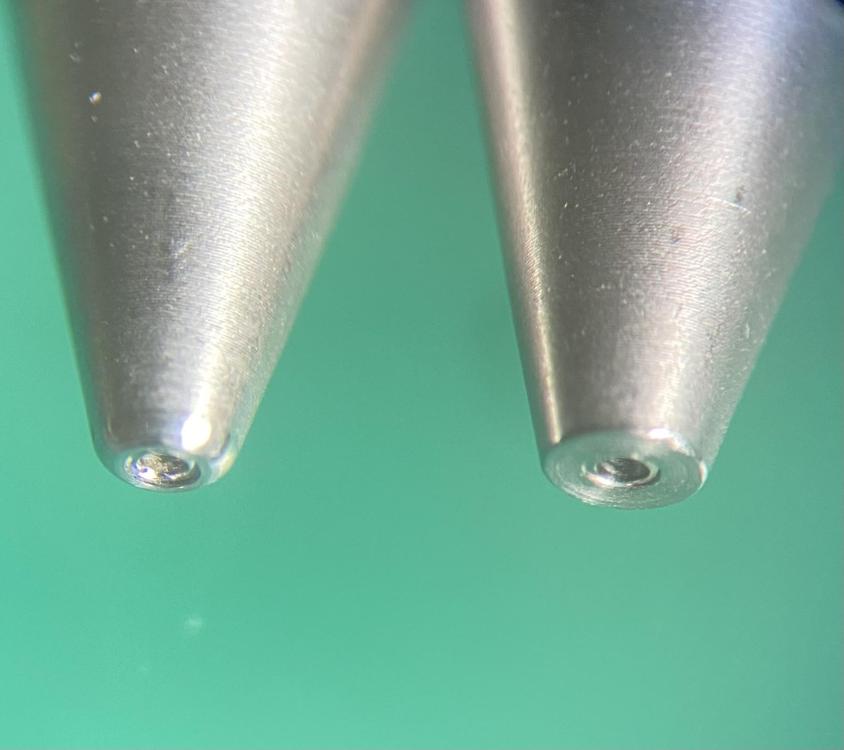

I just bought this Chinese Bergeon clone for €107,- and was curious to see if it would actually be usable. Unfortunately, I got very disappointed. The punches are apparently not hardened and are therefore unusable for tasks such as riveting a balance staff. Here an image of the tips after the riveting process. The staff was harder than the punches.1 point

-

I hate this watch. Cleaned it all, built the train. Runs super free. A puff of air spins the whole train including the barrel. Put the balance in without the fork, 58 seconds of free oscillation from 180 degree release. Fantastic. Pallet fork back in and it's snapping lovely. Balance back in, left it running for a few hours, 230°. Beat error is 0.3, speed can be set to zero with the regulator. Push the barrel edge a bit and it goes up to over 300°. I'm sure it's a spring/barrel/arbor issue. But, every time I even slightly adjust a screw of move a cock by the tiniest fraction, everything changes. I am beginning to think I need to forget this watch until I have more experience. It has a problem that I'm just not knowledgeable enough to spot. I'll do a few others and come back to this.1 point

-

On a watch like that I'd use IPA and stand them in a piece of foam to dry but most of the time I just replace them.1 point

-

1 point

-

It's probably in that part of the twilightzone where your socks disappear to..1 point

-

1 point

-

HWGIKE#39 Slava 2414 Russian bi-turbo movement. Full service very nice performance. Managed to cut the hairspring at the stud by accident, luckily it was long enough, nice straight line around zero beat error, amplitude around 320. Also lost one of the MS arbor, but found it after a bit of carpet surfing aaand I put the MSs back into the barrels the wrong way.... Kept the strap, its fitting.1 point

-

I have mantle clocks, anniversary clocks, carraige clocks, table alarm clocks, cuckoo clocks, grandmother clocks, marine clocks and an Atmos clock. I just wonder why clocks are not made with stainless steel.1 point

-

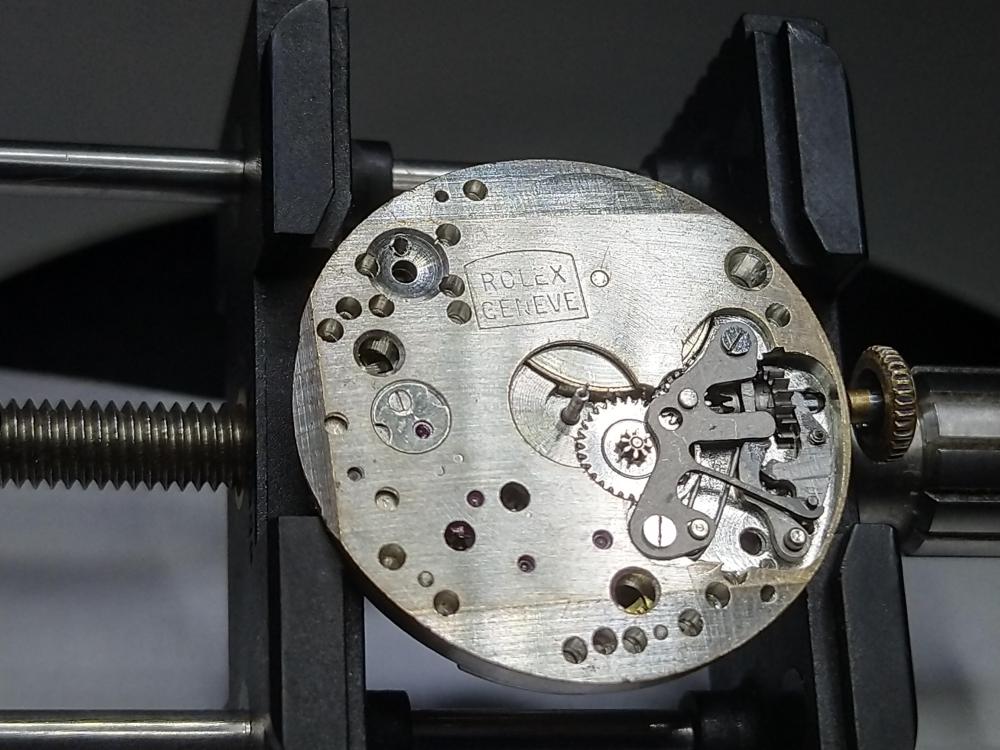

@Knebo This exercise has been done and includes: Seiko 4r35 | ETA 2824 | Rolex Cal 300 (3035) | Rolex cal 1560 (1570) and some others. Since I am getting 48-49 hours power reserve on manual wind and wearing, I bundled it with others not realizing its supposed to be 50 technically. Sometimes I don't think things through before posting on the internet.1 point

-

This is negative set system, so the stem is part of the case. Pull the crown out in setting position, then press down side (6o'clock) of the movement to get out first.1 point

-

Pocket watches generally are front loaders, many of them the stem is captive in the crown tube. You will need to remove the bezel, some are screw on some click on. There are two case screws there at 7:30 and 2:00 on the photo of the movement, once the bezel is off remove these and carefully drop it out the front. Tom1 point

-

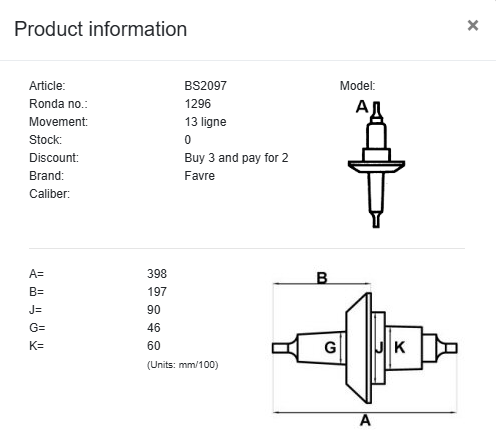

Hi @Bill241, Yes...SPECIFICALLY for these Omega calibres (55x, 56x), there are several GR springs that are supposed to fit (I think Cousins sells 3 different ones that all are supposed to fit). However, some of them are literally 0.1mm too large (in their retention ring) for the actual diameter of the barrel. So yes, they won't fit straight from the ring. This is very annoying. I can tell you from my own frustrations - as someone who's also without a mainspring winder. Unfortunately, for that reason, I doubt that your plunger trick will work. But I'll keep my fingers crossed for you. In addition, some of these GR springs also have inner coils that are too large for the Omega barrel arbor. These are the springs I tried: G62040: 1.01 x 0.11 x 380 x 10.20 GR2535X: 1.05 x .12 x 340 x 10 M64791: 1.05 x .12 x 400 GR2533X: 1.05 x .11 x 360 x 10 IF (and I really hope so), I remember correctly, at least the GR2533X worked right away (barrel diameter and inner coil. Hope this helps.1 point

-

I've got that same set on the way. I also ordered a set of hollow ground blades for them to try out.1 point

-

I'm not sure why it didn't work. I too use brass tweezers. First I use the flat handle end to push the spring down flush with the ring, then use the tips to start pushing the outer coil in to the barrel, starting at the bridle. I've never had a problem doing it this way. Why not re-use the springs? Have a look here :1 point

-

I'm interested how this pans out. I like that you're making a tool to suit this situation rather than buying a set of winders!1 point

-

I have most of the watch built up and for now and I am just waiting on my Incabloc spring to turn up before I can properly button up the movement. Ive put the dial on so I can have a dry run test fit of all the parts. First job was the shorten the stem. Completely overkill but I used my Deckel S0 which makes short work of the stem and I can put a neat chamfer on the end afterwards using the diamond stone edge: Its a shame all of this is going to be hidden: Whilst the movement is in there the original case clamps I got with the movement are not correct. So I need to swap them out for ones I already have on the way. Currently the movement has a tiny bit of wiggle and it’s because the case clamps cannot be orientated to pull the movement tight against the case. The new ones will fix that. A test fit with my olive Nato strap. I have a few more options on the way so I can decide which one I want to use at the end. Hands are obviously not on yet as I’m waiting to finish up the movement. I also had an issue with the quick set date which was not fully rotating the date wheel. It was working fine then it wasn’t and now it’s working fine again. Something for me to triple check before I put it away in the case. Update: Found the problem with the date quick adjust. The user! Turns out the hands were near the midnight part and therefore part of the date mechanism was engaged. Luckily no damage.1 point

-

Thanks to everyone who took the time to respond. We really do have a great community of helpful people on this forum. This did turn out to be a 2-part mainspring as described in JohnR725's post. The "slipping attachment" had become nearly welded in place by dried up grease and corrosion, which is why I thought it was part of the barrel. Once I felt emboldened by the info you all provided to be a bit more persuasive I was able to remove it. I will now order the appropriate modern style automatic mainspring and be able to proceed with reassembly. Many thanks!1 point

-

HWGIKE#34 Services Competitor, pin pallet. Full service. MS was broken, was very dirty and very oily, but all three together saved it in a good condition more or less. Started to polish the case back, it was a mistake as I slightly removed the plating on the edge. It didn't say stainless steel.. i still thought it would be anyway... it wasnt, as you would expect. I kept the old strap as I found it fitting, it belongs to my only one returning customer, Stephen. HWGIKE#35 Tudor, unknown caliber. Full service, this one also had a broken MS, boys size. The hole for the MS arbor was tightened. No mistakes were made this time, finished with the Services together last night.1 point

-

Here is how I installed one of mine. I actually found that I needed to have the jewel in the chaton or else the spring wouldn't stay level and I couldn't get it in. I use the plastic to position it and then an oiler with the force applied the long axis to snap it into place. You can see that when I first tried to apply force with the oiler perpendicular to the direction the spring needed to move, the oiler would flex. Once I came at the spring along the direction of force it snapped right in.1 point

-

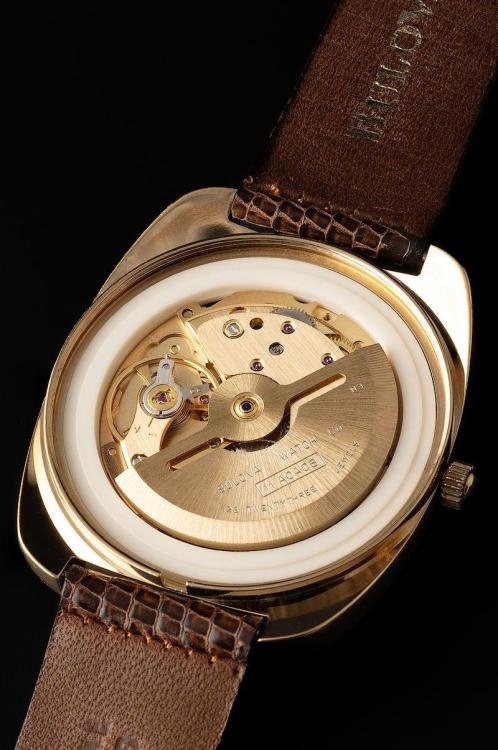

Here's another link with some practical info. https://mybulova.com/sites/default/files/file/Joseph Bulova School of Watch Making - Unit 10a.pdf1 point

-

pallet folk jewl setting.pdf Not easy job see PDF. Also see this from a previous post which includes a pic of the tool I use.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)