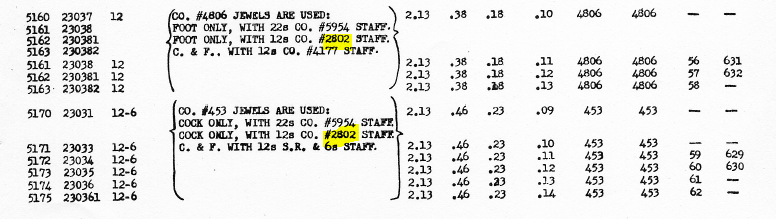

Leaderboard

Popular Content

Showing content with the highest reputation on 02/05/25 in all areas

-

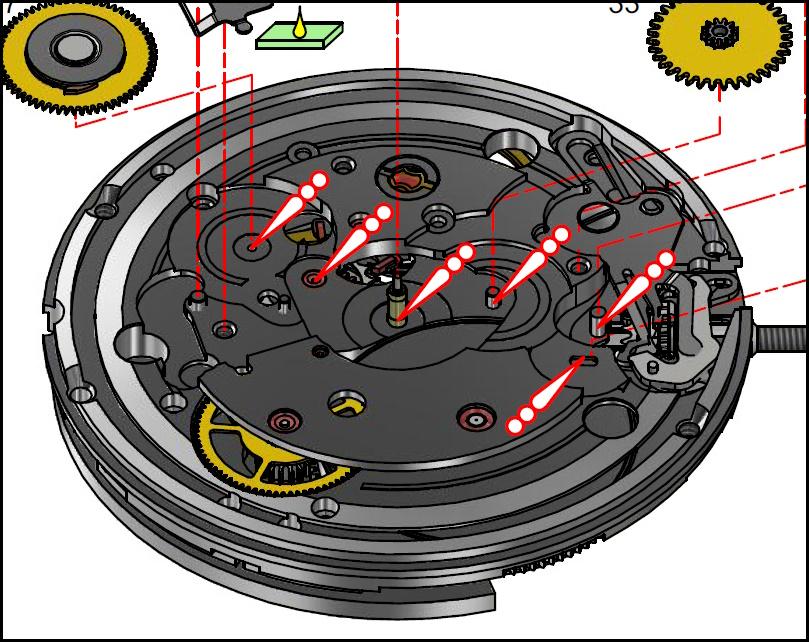

I recently serviced my first Sellita movement, the SW 200-1 calibre. It was my very first Sellita movement, so it was a bit more exciting, especially since I could compare it with my experience of servicing and repairing several ETA movements, including the famous 2824-2. The first time I heard about this movement, it was described—and still is—as an ETA clone. The impression I got back then was that the SW 200-1 was a fairly decent and relatively inexpensive copy, though it didn’t quite reach the same level of quality as the original. After servicing it, however, I’m pleased to say that my overall impression is that Sellita's movement is at least as good and, in some aspects, even better than ETA’s. When I disassembled the movement, the only unexpected thing was that the cap jewels and pallet stones were somewhat overoiled. Whether Sellita or someone else was responsible for this, I don’t know. Regardless, the movement performed well, but after seven years of 24/7 use by the previous owner, it was time for a service. One thing I really appreciate about the Sellita SW 200-1 is how easy it is to pull the crown to its second position to set the date. There’s absolutely no risk of accidentally pulling the crown too far out. This, I believe, is an improvement introduced by Sellita. My memory of the corresponding function in ETA's movements is that it’s far too easy to overshoot, inadvertently stopping the watch when you only intend to set the date. In fact, it works about as well as on the Rolex calibre 3135, which is perfect in this regard. ETA’s 2824-2 has 25 jewels, while Sellita’s SW 200-1 has 26 jewels. I’ve long been curious whether this difference was simply a way for Sellita to outdo ETA in the jewel-counting competition. To my delight, this turned out not to be the case. The extra jewel is placed exactly where, in my opinion, it does the best: as a bearing for the barrel arbor on the barrel bridge. Very nice! It’s also my impression that the click spring is stronger in Sellita’s movements, to the point where it became a bit fiddly to fit the click itself. I think there’s a good reason for this. When the cogs of the winding pinion and sliding pinion begin to wear (which only happens when you manually wind the watch), the pressure from the click on the crown wheel (which can move sideways away from the ratchet wheel) needs to be high enough to prevent the teeth of the crown wheel from slipping over those of the ratchet wheel. This could result in the ratchet wheel losing grip on the mainspring (not good!). This issue only manifests when you wind the watch manually. I’ve written about this issue in this thread/post. In short, I believe Sellita has solved this problem by making the click spring stiffer. Another sign of good manufacturing precision is the wonderful feeling when setting the time. The play you almost always feel in the crown of ETA movements is almost completely eliminated. It’s not at all stiff, just very precise. What unfortunately doesn’t impress me is Sellita’s assembly instructions. However, the documentation, unlike ETA’s, includes several exploded diagrams with part measurements. Personally, I don’t find this particularly useful, although it’s a nice touch. As for the assembly instructions themselves, there’s certainly room for improvement. The documentation is not particularly easy to understand and contain a few outright mistakes, such as showing that the escape wheel bearing on the main plate should first be oiled with 9010 and then with HP-1300. ETA isn’t entirely free from this issue, but their documentation is significantly more useful. And, of course, there’s nothing stopping you from using ETA’s documentation, as both movements are built in exactly the same way. This is something I actually recommend if you’re not experienced enough to not need the documentation. All in all, I would recommend the Sellita SW 200-1 over the ETA 2824-2. Not least because spare parts are readily available for independent watchmakers, meaning owners of watches with Sellita movements can generally expect faster and cheaper service and repairs. This also means they’re not dependent on the Swatch Group, which owns ETA, as well as brands like Hamilton, Tissot, Omega, Longines, Rado, Certina, Mido, and others, and doesn’t sell parts to independent watchmakers. In this respect, it’s better to choose a watch that houses a Sellita movement from brands like Oris, Baume & Mercier, Maurice Lacroix, Christopher Ward, or Stowa, to name a few. Additionally, ETA has started using plastic in some of its movements, which, for me at least, is a red flag and something I struggle to associate with high-quality Swiss movements. Thankfully, as far as I know, Sellita's movements are entirely free of plastic. Thanks for reading!4 points

-

The bearings on these are a double angle, with both angles contacting at the same time. If things get worn, for example the short steep taper (which takes the axial loads, and will wear faster over time), the long taper will make too much contact and lock up. Regrinding something like this is basically impossible without very special machinery and skills. But- they can be lapped to darn close to like-new condition. I remember one of my teachers in school was an ex-toolmaker, and he had me lapping some of the beat up school lathes using silicone carbide lapping compound. This works on spindles like this where everything is nice hard steel, but it's still a pain cleaning out all the lapping compound with a lingering fear that there will be a lingering lapping effect over time. Years later I found out about Timesaver lapping compound, which if you read up on it appears to possess some truly magical qualities, but the really magic thing about it is it breaks down into a non-abrasive product and doesn't imbed. You can use it on steel as well as softer alloys safely. There are two types, green and yellow cans, the green being for steel-on-steel. If you get it all together and find that it binds a bit, I think it would be totally safe to use some of that product to "bed in" the bearings.4 points

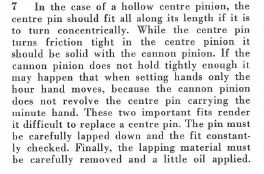

-

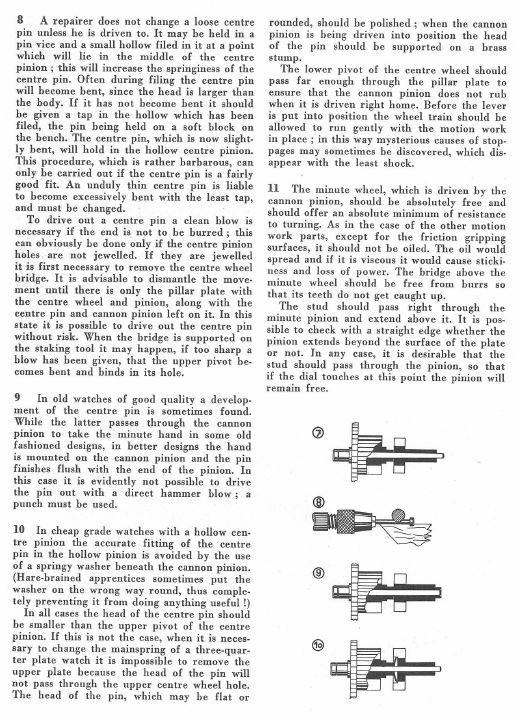

A lot of reading here this morning. Yes, the rubbed jewels rarely come out by pushing them. They will break rather than get out intact. One way to get jewel out is to use cutter or graver to cut the rubbed fold above the jewel. This of course can be done on the lathe while the part with the jewel is in face plate, but it is much more simpler to do it by hand while scrubbing the fold with cutting edge of the cutter. Well, another obvious destructive way is to etch the part. FeCl3 will do it easy. The jewel will start wobble in the 'nest' first so one will have to check when the etching is enough for the jewel to come out wit slight pushing. Searching for the jewel on the bottom of the vessel will be possible but the solution is not transparent. Reaming the hole to use press fit jewel is another good solution, but it is easier applicable for the balance cock than for the plate. This is because the direction of preparing the nest for the stone - on the plate it is done from outside and the hole that will be needed to cut the entire nest is huge, so huge stone will be needed. That's why bushing is used in this case. Even for the cock often there is not enough 'meat' so again bushing is needed. About lapping stones with diamond plate - the easiest way is to glue the jewel on the face of a rod in the spindle of the lathe. Of course, small motor like from some toy or tape recorder or VHS player.... can be used and the tip of the shaft can be turned by rotating the motor. A screw fixed in the threaded hole for motor fixing and You have rest for the cutter, supply the motor and You have lathe. You can turn a balance staff right from the motor shaft... When the jewel is glued on the face, rotate the motor and use the diamond plate as a file (move it forward/reverse) to grind the jewel. Holding the plate still will do the job much harder. You don't need polished surface here, so grit 1000 is OK. I don't know how big a lathe should be as to be too big for watchmaking. I for sure use what they call 'mini lathe', which for sure is not watchmakers lathe and is 70-80 cm long. People often don't believe, but I can turn balance staff on it for the smallest lady's callbres and I am pretty sure that if I try, will do it on every big industrial lathe. If You put something like T-rest before the rotating piece, You can do all needed.4 points

-

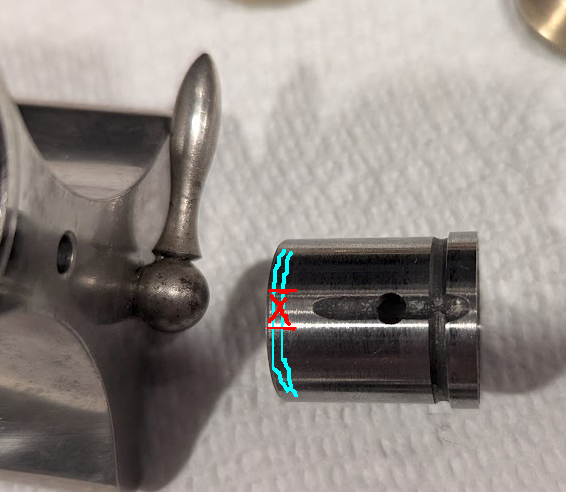

Really quite interesting I was looking for something I saw last night when I didn't have time to respond. You'll notice the other discussion which I have now found is basically very similar to yours. But not exactly the same It's supposed to be tight on the pin otherwise the whole thing is not going to work right. You really want to have both plate screwed together. This will keep the center wheel from moving around and possibly breaking a center wheel jewel if it has one. So holding the movement in one hand I take a small hammer and just tap the pin that's sticking up typically. Otherwise it would have to go into a staking set to something pointy if the pin is not sticking up. Also you could use a staking set the first place. But in the staking set your be very careful how your supporting it on the other side that you don't break things. Then of course you can use the staking set of a reassembly as you do want the cannon pinion tight on the pin. Seeing as how this question comes up so much I asked him a folder of pictures with text3 points

-

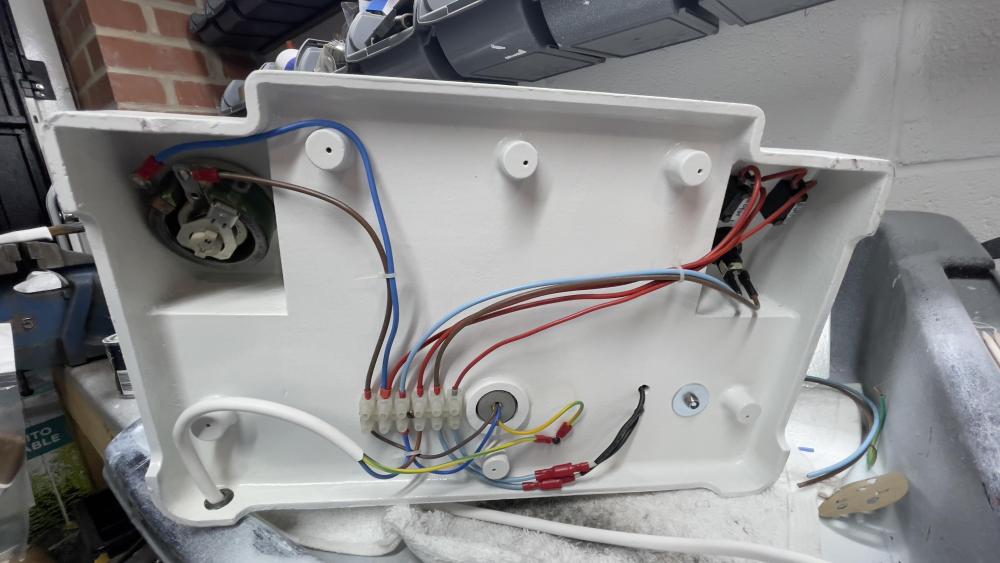

After a few weeks of frustrations, mistakes and blowing my house RCD due to a dodgy vintage bulb holder, I reassembled all the parts and have successfully restored my first watch cleaning machine!! It has been a real journey of discovery. I’ve learned so much along the way having to teach myself new skills and understand the workings of vintage motors, electrical wiring circuits and how to strip old powder coat and repaint (as best as I could) from scratch. I am immensely proud of what I’ve achieved and now have a fully functioning watch cleaning machine! I was not confident that I could take on this project but with help and guidance from some great fellow enthusiasts, I did it!! Now onto those pesky Elma Super Elites I have waiting for some love and attention!!3 points

-

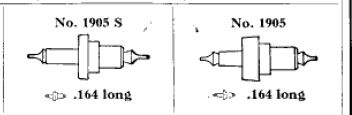

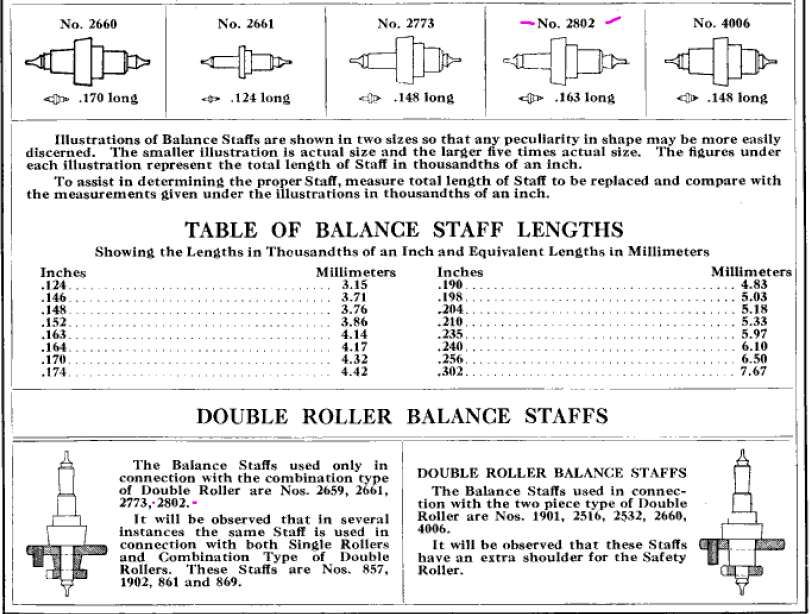

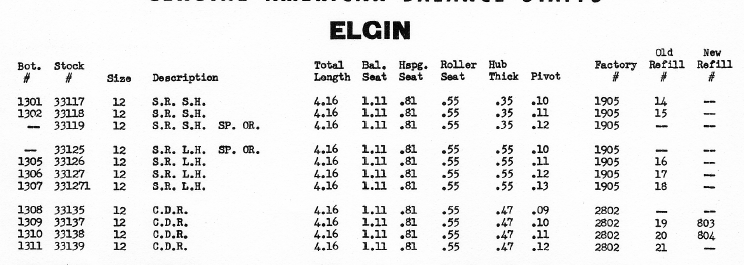

Yes the pivots look a little bit worn. This is where it's really nice to have a timing machine because they work really good at showing Pivot problems. Then yes it's very common to have to refinish the pivots on anything vintage as they will wear with time. Then there's the other peculiar thing? Notice in your image that I snipped out below the color of the jewels is definitely a concern. The upper jewel is a replacement. That is because it's a modern red color the lower jewel is an original jewel or at least an original color. So if someone has replaced the jewel did they replace with the right diameter? Plus as they replace the jewel was it cracked or broken and that would be bad for the balance staff because crack jewels are not good for pivots as they tend to disintegrate. Oh and when you're looking at jewels like this it's also good to remove the end stone and check because often times there could be a crack chip flaw or something that you can't see from the side. In addition to having lighting on the other side helps to see cracks as opposed to just looking at the jewel you really need to look through the jewel. Just a couple thoughts on replacing the balance staff. Yes you have the grade number of 315 but there is some minor problems typical of American pocket watches. Like which balance staff would you like to use? My favorite place to look up Elgin part numbers is at the link below. Then some of the problems would affect the replacement balance jewel for those people who did not pay attention. So you'll notice that there are two separate balance staffs and a reference to you have to look at something and a serial number. In other words you need the parts book to look at the section on balance staffs. Which typically is still missing a piece of information. Okay so one balance staff is 1905 but it appears to come in two variations Then the other staff would be to 2802 and in the fine print is a reference to double roller which is what you have. Then looking at another reference we can see that the 2802 is for the double roller and the other one is for the single roller that you don't have. So we've narrowed it down except there is the problem that would affect the balance jewel which is one part number and how many different pivots sizes? This is another interesting problem with American pocket watches typically for balance staffs they will come in different pivots sizes not always listed and of course you have to have the right jewel that correspond to the diameter of the pivot. http://www.elginwatchparts.com/3 points

-

If you want a little light entertainment, try asking the various AI bots the following question. "What date was Donald J Trump the current incumbent in the United states White House born on, and how old is he today? This is basic mathematics. Surely you can manage to answer a simple question like this." Aside from the slight trolling nature of the question, it is in fact remarkably simple to answer. However try the question on Gemini, and you will get a very evasive answer. Try it on ChatGPT and you will (at the time of posting this) get a straight and factual answer. However perhaps the most interesting answer comes from the new Chinese offering "deepSeek" So, it seems that the AI doesn't understand the concept of real time. Not a problem. Nothing to see here, its just the date it completed its large language model training, right? Or... perhaps it is a very subtle piece of Trolling by the Chinese... https://en.wikipedia.org/wiki/Executive_Order_14110 I'll let you decide. It Was a Bright Cold Monday, October 30, 2023 and the clocks were striking thirteen...3 points

-

Mark posted this video - which might explain what your are seeing in an extreme case3 points

-

I will advise NOT to dress smart...wearing a tie Cees I stopped wearing those some 30 years ago. My work brings me to a lot of machineshops. Stepping inside those wearing a tie immediately gets you put in the "total waste of space" category by the shop owners (and rightly so..).3 points

-

I'm sure you can, but getting in up close with a loupe and my hands (especially if you don't have a collet chuck) would get some part of my anatomy puckered up...3 points

-

@nickelsilver: Thank you for the tip. I have another lathe with some lightly scored bearing surfaces that I'm going to try this out on. Fortunately I found a supplier for this in the Netherlands, saving me about $110 in shipping and tax..2 points

-

Absolutely. I fully agree that it doesn't "understand" anything, perhaps I should have put "understand" in quotes, but it is designed to give the illusion of understanding, which is why it is quite jarring when it entirely fails to be able to do perform what is in fact a remarkably simple task that I could probably figure out on the back of the proverbial fag packet. Having said that, I wonder how many of the current generation could actually manage that calculation... Actually now that I think about it, in light of all I have discovered over the last few years about the depressingly low average intelligence of the human race, I wonder how many of any generation could actually make a stab at solving this problem. When people are fretting over the "power" of AI, and what it can do, I must admit I am far more concerned about the things we will assume it can do that it will spectacularly fail to manage, and the resulting chaos that will ensue.2 points

-

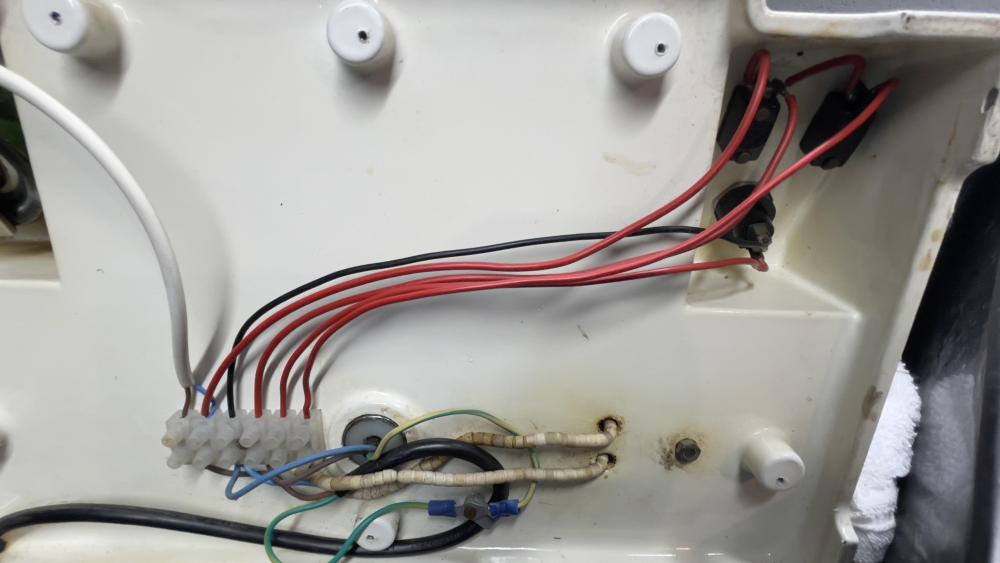

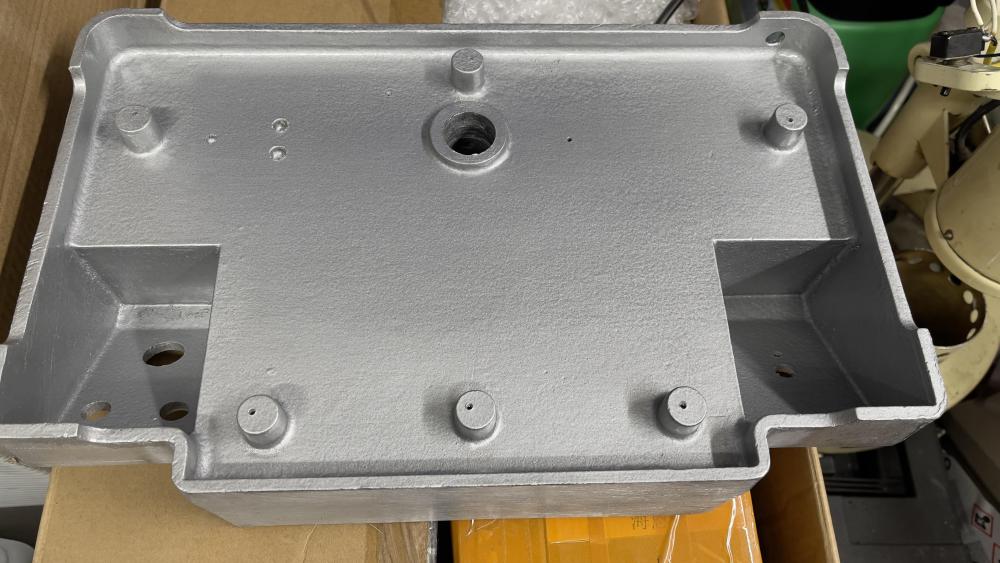

Hi, I thought i’d share a bit of a journey I’ve been on in restoring my Brenray Watch Cleaning Machine. I have been inspired and helped along the way by some kind forum members. So I bought the machine on the Bay of E and whilst it was working, I wasn’t totally happy with the condition and worried about the wiring. I sought advice and decided to pluck up the courage to take on the project….. Here is my progress so far…. I have completely disassembled the machine, removed and rewired the loom assembly, cleaned the switches, lamp, chromeware, rheostat, replaced the heater, disassembled and rewired the motor, and stripped the powder coated paint (what a drama that was!). Then it was ready for new paint…… decisions, decisions?? I toyed with many options Cream? Silver? Or Elma Blue? I really liked the hammered silver option but in the end when with original white in hammered finish as this colour came in brush on and spray options. Repainting ended up being a real pain, the coats took ages to cure and did not take well to the new bare metal (despite being a direct to metal paint!) so it was back in the acetone bath to be stripped, primed this time and fresh coats of paint!2 points

-

The bit about the Sellita movement being as good or in some parts improved is less of a surprise when you find out that they were for many years the primary manufacturer of ETA movements. Not clones but actual ETA movements. When ETA stopped the partnership the movements we consider work horse ETA movements had gone out of patent. So if your company is wholly setup to make a range of movements that are no longer IP restricted? well it does rather make sense to make some improvements your engineering team have identified and carry on manufacturing in your own name. Sellita also do design and manufacture of movements for other Swiss brands not ETA “clones” but I have not found any connections to others. More secretive than Swiss banks. Tom2 points

-

For sure! The essence of what a Rolex is all about! Yes, she has been wearing it 24/7 probably because I told her it would stop running if she didn't wear it, or maybe she's just so fond of it (I would be). Maybe I should let her know that she can safely take it off for at least 24 hours before wearing it again without any problems. I'm not sure she knows that2 points

-

One way to locate high/contact points is to clean both surfaces and treat one with a dye. In machining, a blueing compund is used, but here a white board or permanent marker will do fine. So colour one part and fit them together and twist slightly (no full rotations). Then take apart and study the transfer pattern and rubbed away dye.2 points

-

I do agree! Breguet, free-sprung, and the microstella screws on the inside of the balance rim seem to be the trick! I'd love to have a Rolex someday, perhaps an Explorer, but the prices are still crazy, at least for me. Regarding regulation, I contacted the owner of the Rolex this thread originally discussed. I set the owner's watch to the second on November 10th last year, and when I asked how it was running, she said she hadn’t felt the need to adjust the time yet. When I asked how much it was gaining or losing, she told me it was less than four minutes fast. That's about 2.7 seconds plus on average per day. Pretty sweet!2 points

-

You're half way there. AI doesn't "understand" anything at all, ever. Understanding is not a feature of its design. It is a sophisticated pattern matching algorithm, that strives to match phrases from a question with whatever it has managed to dredge up from the festering cesspit that is most of the Internet. Since there are some sites, like this one, on the internet, that have genuine information, AI will sometimes fluke onto a sensible answer, but don't bet your house on it. Really, referring to it as "intelligence" should simply be regarded as false advertising.2 points

-

I finally also had the chance/need to regulate a Rolex balance (cal 3035). I also arranged the ergonomic setup like you, @VWatchie. That really helps. Thanks also to @Jon for your guidance. As you said, in the end, it wasn't as scary as expected. Quite fiddly to get it onto the star-screw, but turning precisely was easy - the screw had just the right resistance. And well, one has to give it to Rolex... the precision is just incredible with these free-sprung balances. I'll have to wear it a few days to see real-life precision, but I think it's going to be 0 to +1. At almost full wind, across all positions, the delta is only 3 (-1 to +2).2 points

-

2 points

-

2 points

-

Looks to be M104. The difference from M24 is the click spring. On the older 24, it would be a little folded triangular steel thing but on these is a very thin strip of copper wedged into a rectangular hole on the plate. There are hardly any other differences. https://heritage1854.com/m1042 points

-

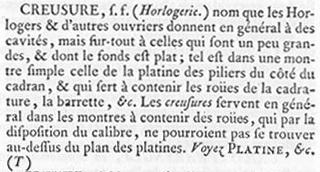

This has been bugging me for a while now, so I went down a bit of a rabbit hole trying to figure out the meaning of "Creusure plat." and "Creusure cad.". TL;DR creusure plat. is the cutout in the roller, creusure cad. is the cutout in the dial (depth, in 1/100 mm) Firstly, "creusure" literally means a cavity, hollow, depression, excavation, etc. In horology it refers to a flat-bottomed hole in a plate that is usually wider than it is deep. A creusure could be used to accommodate the barrel, the minute wheel, a dial foot, a locating post, etc. See Jean-Baptiste Le Roy's entry in the 1751 Encyclopedia, or Reasoned Dictionary of Sciences, Arts and Trades (Encyclopédie, ou, Dictionnaire raisonné des sciences, des arts et des métiers): CREUSURE, s. f. (Horlogerie.) nom que les Horlogers & d'autres ouvriers donnent en général à des cavités, mais sur-tout à celles qui sont un peu grandes, & dont le fonds est plat ; tel est dans une montre simple celle de la platine des piliers du côté du cadran, & qui sert à contenir les roües de la cadrature, la barrette, &c. Les creusures servent en général dans les montres à contenir des roües, qui par la disposition du calibre, ne pourraient pas se trouver au-dessus du plan des platines. Voyez PLATINE, &c. In the context of Incabloc, "plat." is short for "plateau" (roller), and "cad." is short for "cadran" (dial). So creusure plateau is the depth of the recess (in hundredths of a millimetre) that must be cut into the bottom of the roller to accommodate the lower shock block where it protrudes through the main plate. Similarly, creusure cadran is the depth of the recess that must be milled into the underside of the dial itself to accommodate the lower shock block when it sits proud of the dial side of the main plate. Here are a couple photos of an Omega 661 that I'm working on which has both cutouts.2 points

-

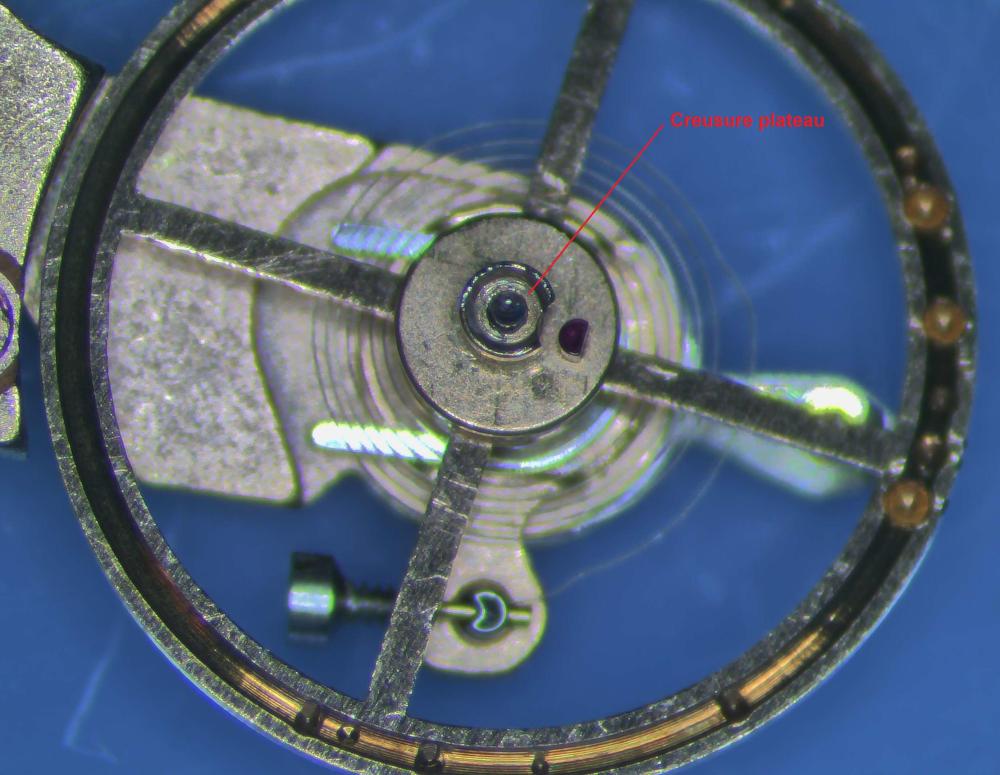

When you're looking for pivot issues the most common place where they show up would be dial-up and dial down amplitude differences. If the watch hasn't been cleaned often times it could be just bad lubrication. Otherwise when your watches clean and properly lubricated bad pivots will show up as amplitude differences. I think where having a terminology confusion here? There are actually two separate jewels on each side. There is the hole jewel and the separate cap jewel. Let's look at the parts list which gets even more confusing as usual. Notice there is a X in front of some of the parts which I believe usually indicates conceivably a variation of that part. So we see that part 453 is the upper hole jewel and it's also the lower jewel except. Then we see 4806 is the lower jewel with a reference to note 323. This is where we would need to know the serial number because they change the jewels based on a serial number. But I may go find a reference and see what the difference is. You also notice that the upper and lower cap jewels are different typically in the one on the main plate is thinner because it doesn't have all the regulator stuff. Then a lot of times on the balance bridge it might even be a separate color like gold is used because it looks Tyson pretty usually found on higher grade watches. So as we can see below different hole jewels. Toll diameter is the same which is very common. Next number is the total thickness and the third number is the shoulder thickness. Then of course you'll notice the different diameters for the pivots. Which does not show up as part of the part number or even referenced in the part number. I have seen somewhere in the Elgin catalog which said if you ordered a dozen balance staffs and you did not specify a pivots size they will actually send you an assortment of different pivots sizes. Several problems with this approach of determining whether the watches ever been serviced. First many times American pocket watches get re-cased and the new case would not have any prior markings. Then some shops don't mark the case at all. So you have no idea if anyone had serviced if they didn't mark. With American pocket watches it makes it easy to keep track of because the movements of serial numbers. You really do not want to discover you have a problem at this point in time. In other words if your pivot is physically too big for the jewel the best time to deal with that is before it's in the balance wheel. Replacing a balance staff is a very procedural operation. So for instance if you are replacing a balance staff you would measure the old staff just to make sure the new staff you order is the right staff and you also measure the new staff when it comes to make sure it actually corresponds to the dimensions you think it is supposed to be as unfortunately often times there can be variations. It is best to find out if your staff is not sized right before you start attaching things and bad things will happen conceivably like if it's slightly too big lots of things can get damaged or broken trying to force things on the staff is not quite right1 point

-

That is an interesting comparison. Congratulations!1 point

-

Maybe sometimes it's better not to watch the videos as this really isn't that difficult operation at all. So before the video with both plates together and the screws in place. In other words you do not want the center wheel flopping around as if it's jeweled you could crack the jewel that it's in. So holding the watch in one hand and a small hammer In your other hand just The center pin gently. You really don't need a lot. Then the problems would be some of these watches do not have a pin sticking out and then you really should have a staking set. Which is also very useful for putting this back together again. But you do have to be careful staking set of how you support the backside not to break anything. Often times their stuff sticking out on the back side like if it is a key setting that would be sticking out on the backside that has to clear the staking set. This is an example of key setting on the backside. Where fear using a staking set versus holding it you have to be careful that the stuff here is over a hole as all of it will come out with the pin. Here's what the parts look like out of the watch at least for one like this Then some additional information just in case you need it1 point

-

They're a different stems so that's probably why you had the problem, YM57 (351584) and 7T27 (351580).1 point

-

1 point

-

1 point

-

I need to read several or as many documents as possible to form an opinion, well aware of bias, both in myself and others. My conclusion, without working on a Stellita movement is they are just as good, as ETA, if not better (subjective). At least parts are freely available1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

It's an understatement to say that it's an understatement to say that the universe is huge, and that too is an understatement, and so on Wanting to go to the nearest exoplanet I made this little calculation a few years ago: Nearest Exoplanet (Proxima Centauri b -39 grader celsius) Distance from Earth: 4.22 ly = 39,896,955,919,553 km. Time from earth VASIMR* speed: 25 302 years. Time from Earth passenger jet speed: 5 358 173 years. *Variable Specific Impulse Magnetoplasma Rocket1 point

-

After cleaning up, I find that the headstock bearing is a very close, smooth fit with no holding friction at all. It could be that it was run this way with the cone seized inside. It is a perfect fit, no play at all, but no friction so I have some Loctite sleeve retainer on the way to affix it. I just have to be cautious about not getting any into the oil reservoir so I will probably try to apply it only toward the inner 1/4 of the bearing length, and skip the area in front of the reservoir to minimize how much adhesive spreads near there The bearing and the spindle cone fit well and rotate, but do want to bind up slightly in one spot. I do not think either is out of round, but there's a high spot possibly at or near the oil groove. I don't have the equipment to measure it accurately but if I can pinpoint it and try to reduce it by a couple microns with fine grits I think it will stop binding. I just don't want to put it back together and then find it seizes up in the bearing again so i'll try to attack this before I affix the bearing with loctite.1 point

-

Finally, I had time to do the research I wanted to do before ordering my ultrasonic cleaner, and now it's done. I went for a small device (0.7 litres) that should work with the cleaning basket from my Elma watch cleaning machine. I would have preferred to get Elma's ultrasonic cleaner, but the price, £423 including tax and shipping, feels unjustifiable for me as an enthusiast. The machine I ordered cost me £64 including tax, shipping, and a 3-year extended warranty, which I paid an extra £6.4 for. I chose this particular ultrasonic cleaner because of the serious and detailed presentation on the website and the site's German (which often indicates quality). After completing the purchase, the feeling was confirmed in the email they sent, which not only congratulated me on my purchase but also included detailed purchase information on delivery time, warranty, and right of withdrawal, as well as the manual for the ultrasonic cleaner in several languages, including English. I love the German precision! Now, it remains to be seen if the machine meets my expectations, but I’ll get back to that. Here is the link to the page for anyone interested: https://www.expondo.de/ulsonix-ultraschallreiniger-0-7-liter-basic-100500331 point

-

I would add that depending on how tall the seconds hand pinion is, this could also be 105 or 106 to accommodate the extra height of a calendar complication. But I don't know how those were packaged, especially since this does not include the dial rest plate. Those would have different dial plates and you don't seem to have any at all.1 point

-

Hi. Run a little wd40 under the screw around the flange and leave it for a while then re try. If it’s just turning on a bad thread put a screwdriver under the flange and apply a little pressure upwards and unscrew whilst under pressure1 point

-

Welcome to the forum. If you can get it out a bit you'll need to apply some upward pressure as you unscrew it. The problem then could be if the hole is stripped how it will go back.1 point

-

This is it. I think the broken one came put easily purely because it was broken, allowing it to fold and come out in bits. If it came out in one piece, it would have spread the rubbed area over almost enough to get the new one it, and that doesn't happen. I think it would take alot more force to get a jewel out in one piece.1 point

-

1 point

-

Yep, I'm making that and a tilting table. I'm on my 3rd prototype of the holder. The first one I made the center hole throughout the body too small, and I'm too lazy to machine the entire shaft to diameter. Then I had issues on another aspect, but the current one should work out well. I have the bearings pressed in, just need to finish the other end of the shaft.1 point

-

1 point

-

Interesting link published in the Daily Telegraph. Well worth a read IMO http://digitaleditions.telegraph.co.uk/data/1964/reader/reader.html?social#!preferred/0/package/1964/pub/1964/page/54/article/NaN1 point

-

Not beeing deterred by the fact that you're specifically asking "experts" (which I'm definately not!), I would say it would depend on whether or not originality is an issue and what the impact on the value is..1 point

-

Thanks tlB, That’s great info and I’ll get one ordered. im worried its a lot of hassle and it may go wrong. I will have to try and ask someone to fit the movement once I get it. Would any jeweller or watch repair center do it do you think? Or would it be best to try and find someone on the forum to fit it for me?1 point

-

It's an enamel dial. A brass / copper plate with an enamel coating. Looks like the enamel is chipped where the dial feet are. It's a cylinder escapement and I suspect that the balance staff is broken.1 point

-

1 point

-

I'm a software engineer as well, although, for the past 8 years, I've been making a living teaching it (.NET) to others. When it comes to programming, ChatGPT impresses the h-ll out of me and I'm sure it's already being used all the time. If you can formulate the task well enough, the AI solves it without problems and not infrequently in a very elegant way. Of course, you have to be able to program to formulate the assignment, but you don't have to be a genius, which has become a problem in connection with examinations. When it comes to watch repairs and understanding horology, the answers I've gotten have mostly been completely unreasonable as shown in the post by @Kalanag1 point

-

Supposedly ChatGPT & Co are coming for the jobs of all the software engineers like... robots came for the auto industry, or self-driving trucks are coming for the teamsters. If you distilled my job down, I'm essentially a glorified software engineer, but I can tell you for certain I'm not concerned in the least.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)