Leaderboard

Popular Content

Showing content with the highest reputation on 02/06/25 in all areas

-

3 points

-

You could do that. Most would use a slide rest for this work; quite often it would be used to put a step on a setting, modify the diameter/s seat height etc. Also useful when making new settings. All depends of course on how true it runs (the ones I've encountered haven't been great).3 points

-

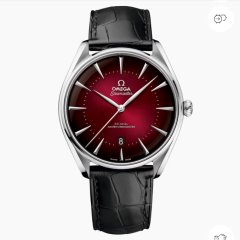

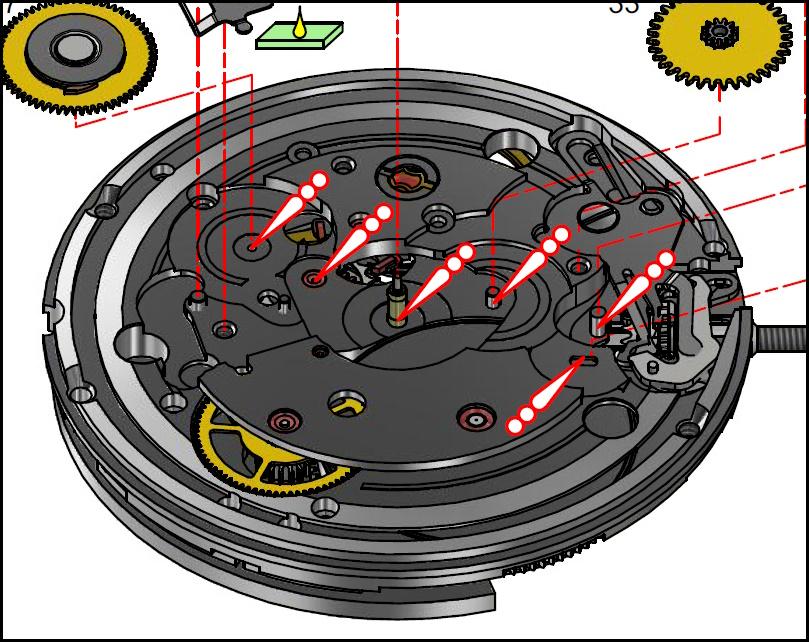

I recently serviced my first Sellita movement, the SW 200-1 calibre. It was my very first Sellita movement, so it was a bit more exciting, especially since I could compare it with my experience of servicing and repairing several ETA movements, including the famous 2824-2. The first time I heard about this movement, it was described—and still is—as an ETA clone. The impression I got back then was that the SW 200-1 was a fairly decent and relatively inexpensive copy, though it didn’t quite reach the same level of quality as the original. After servicing it, however, I’m pleased to say that my overall impression is that Sellita's movement is at least as good and, in some aspects, even better than ETA’s. When I disassembled the movement, the only unexpected thing was that the cap jewels and pallet stones were somewhat overoiled. Whether Sellita or someone else was responsible for this, I don’t know. Regardless, the movement performed well, but after seven years of 24/7 use by the previous owner, it was time for a service. One thing I really appreciate about the Sellita SW 200-1 is how easy it is to pull the crown to its second position to set the date. There’s absolutely no risk of accidentally pulling the crown too far out. This, I believe, is an improvement introduced by Sellita. My memory of the corresponding function in ETA's movements is that it’s far too easy to overshoot, inadvertently stopping the watch when you only intend to set the date. In fact, it works about as well as on the Rolex calibre 3135, which is perfect in this regard. ETA’s 2824-2 has 25 jewels, while Sellita’s SW 200-1 has 26 jewels. I’ve long been curious whether this difference was simply a way for Sellita to outdo ETA in the jewel-counting competition. To my delight, this turned out not to be the case. The extra jewel is placed exactly where, in my opinion, it does the best: as a bearing for the barrel arbor on the barrel bridge. Very nice! It’s also my impression that the click spring is stronger in Sellita’s movements, to the point where it became a bit fiddly to fit the click itself. I think there’s a good reason for this. When the cogs of the winding pinion and sliding pinion begin to wear (which only happens when you manually wind the watch), the pressure from the click on the crown wheel (which can move sideways away from the ratchet wheel) needs to be high enough to prevent the teeth of the crown wheel from slipping over those of the ratchet wheel. This could result in the ratchet wheel losing grip on the mainspring (not good!). This issue only manifests when you wind the watch manually. I’ve written about this issue in this thread/post. In short, I believe Sellita has solved this problem by making the click spring stiffer. Another sign of good manufacturing precision is the wonderful feeling when setting the time. The play you almost always feel in the crown of ETA movements is almost completely eliminated. It’s not at all stiff, just very precise. What unfortunately doesn’t impress me is Sellita’s assembly instructions. However, the documentation, unlike ETA’s, includes several exploded diagrams with part measurements. Personally, I don’t find this particularly useful, although it’s a nice touch. As for the assembly instructions themselves, there’s certainly room for improvement. The documentation is not particularly easy to understand and contain a few outright mistakes, such as showing that the escape wheel bearing on the main plate should first be oiled with 9010 and then with HP-1300. ETA isn’t entirely free from this issue, but their documentation is significantly more useful. And, of course, there’s nothing stopping you from using ETA’s documentation, as both movements are built in exactly the same way. This is something I actually recommend if you’re not experienced enough to not need the documentation. All in all, I would recommend the Sellita SW 200-1 over the ETA 2824-2. Not least because spare parts are readily available for independent watchmakers, meaning owners of watches with Sellita movements can generally expect faster and cheaper service and repairs. This also means they’re not dependent on the Swatch Group, which owns ETA, as well as brands like Hamilton, Tissot, Omega, Longines, Rado, Certina, Mido, and others, and doesn’t sell parts to independent watchmakers. In this respect, it’s better to choose a watch that houses a Sellita movement from brands like Oris, Baume & Mercier, Maurice Lacroix, Christopher Ward, or Stowa, to name a few. Additionally, ETA has started using plastic in some of its movements, which, for me at least, is a red flag and something I struggle to associate with high-quality Swiss movements. Thankfully, as far as I know, Sellita's movements are entirely free of plastic. Thanks for reading!2 points

-

As currently implemented, possibly never. The problem is that we don't actually fully understand how organic life forms "understand", so it is difficult to define understanding in the context of anything else, including AI, however current AI does not work the way most people think it does, and certainly does not work the same way the human brain for example works. By that definition, it will never understand. That is not to say that we will never be able to make a system that is truly self aware, and genuinely understands its own existence. AI is however, not that system.2 points

-

Nice to see the extra jewel on the barrel bridge. As a lot of the watches I service need some "hammertime" on the barrel bridge, it's surprising that it's not more common to have a jewel there. I guess that a large jewel with a big hole is quite expensive to make and prone to cracking ?2 points

-

2 points

-

The users in question have been investigated and removed from the forums. If anyone has anything to report like this please use the report function or message the moderators. Thanks Tom2 points

-

@ChrisInOz indeed, the invention of what would become the most prevalent database in the world, excel. Tom2 points

-

Yes, that is a very realistic concern. 30 years ago I watched a similar thing happen when spreadsheets first hit the market, and cheap desktop computers put them into the hands of millions of untrained people. Business decisions began getting made based on spreadsheets that were riddled with logic errors, double counting, and who knows what else. I feel sure that some businesses would have gone under as a result. Before I retired, I had a forty year career in software development. I'm pretty sure that in every one of those years, someone confidently told me that I was about to be redundant, because a new whizzer of a product could do everything that I could. In fact, my analysis and development skills were still very much in demand on the day that I retired in 2019. Most amusing of all was the day I discovered that I had been "redundant" before I was born. A technical article from 1958 breathlessly announced that all computer programmers were now obsolete, since an amazing new product would allow the end user to simply tell a computer what they wanted, and it would all be done for them at once. The name of this miraculous product? FORTRAN.2 points

-

The grub screw is usually dog point & the lubrication is the total loss system designed to flush through, use high speed spindle oil.2 points

-

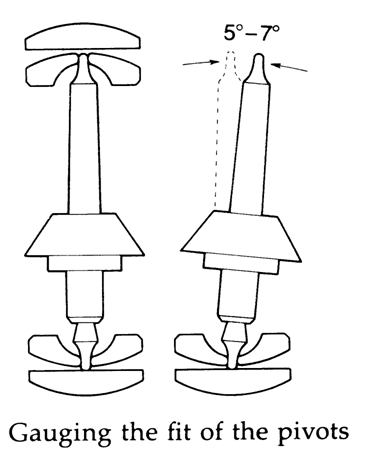

Pretty good and helpful conversation till here. Just few things to say OP, before You decide to replace the staff, please show good pivots side pictures. Replacing the staff - are You ready for this? In order to take pivots side pictures, You will need to disable 'autofocus' (to lock the focus). In most phone cameras, touching area of the screen with finger activates focusing on this area, and holding the finger for several seconds locks the focus (symbol with locked keypad appears). Once the focus is locked, move the camera to/from the pivot until the image of it is on focus. As John said, the upper side pivot has to be checked how free it gets in the hole stone. But not only - the other thing is the pivot tip must be able to pop a certain amount above the upper surface of the setting. Thus it will be sure that the tip rests on the cap stone and in the same time there is healthy free play of it's cylindrical part in hole stone.2 points

-

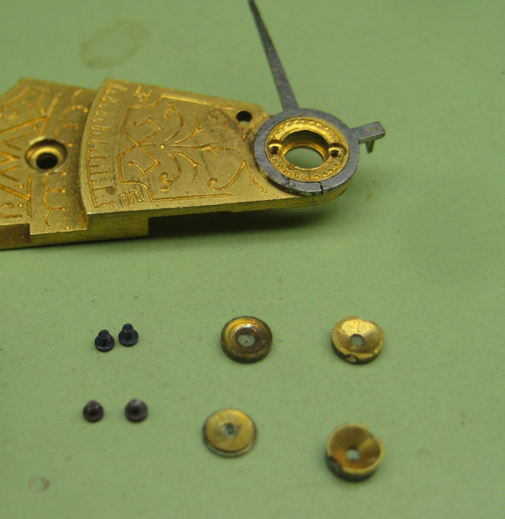

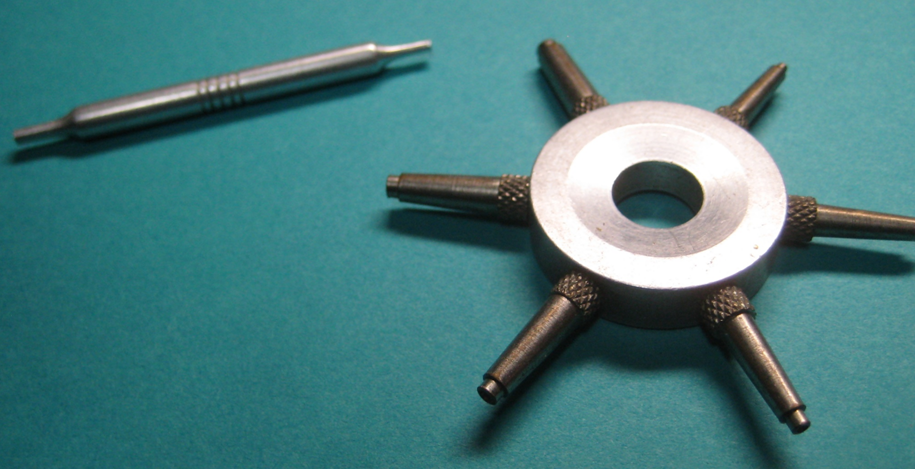

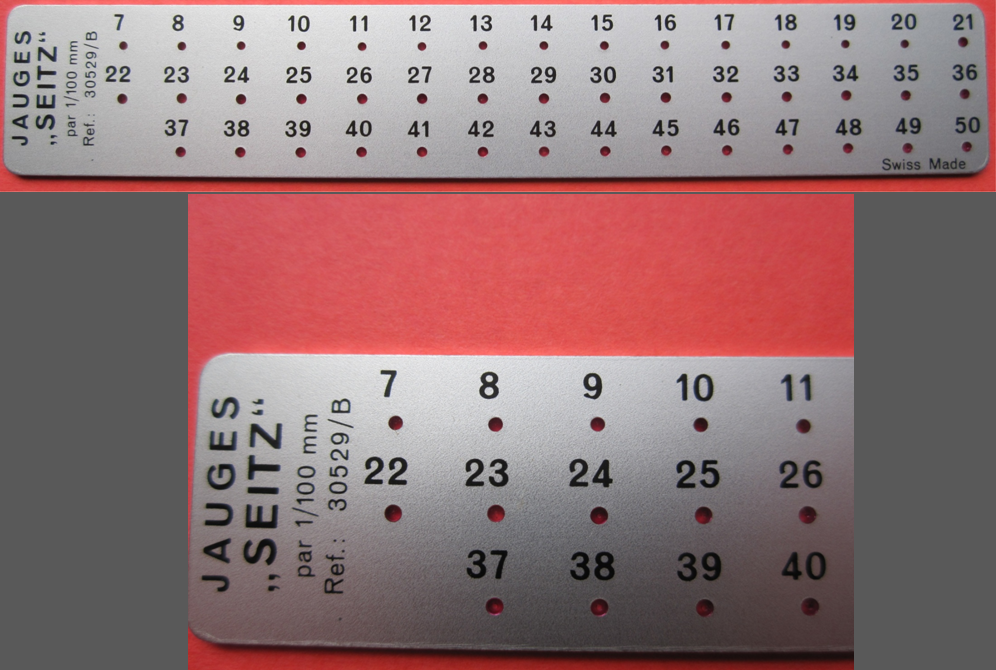

We have unknown variables. For instance I did a project for somebody who used a vast quantity of 12 size Illinois watches. The particular watch was picked because the parts catalog indicated no variations and this watch was made over 30 years roughly. The problem is over 30 years a manufacturing there were variations lots of them. But the parts catalog as far as I remember makes no reference at all to the variations. Typically the older pocket watches will have more variations as they improved and then of course changed things even modern watches will have parts changes but typically the changes are not in the parts lists. Oftentimes the watch companies will have supplemental information that the watchmakers typically never see which has the updated parts. One of the things I always like to ask is what is the history of the watch so in other words did the problem occur before you repaired the watch or after? If it's before conceivably somebody was having an issue and just gave up on the watch. Watch repair is filled with lots and lots and lots of variations. For instance American balance wheel jewels typically held in with two screws. Very tiny screws that oftentimes get stripped. So to disassemble you just have to remove the two screws and push the jewels out. You don't actually need a special jeweling tool although it's nice to have the tool for pushing but you could use peg wood. For instance here's a picture of the jewels from an 18 size pocket watch we can see the screws that hold them in and the jewels themselves in their brass settings. Then this is what the tools for pushing the jewels look like. But you could use anything that's round just a push on the edge of the settings preferably not your tweezers as you leave marks on the brass depending upon how hard you have to push. In other words the friction then there supposed to push out by hand you don't need any tools other than something to push on them That would be a pretty poor micrometer wouldn't it that can only measure to 1/10 of a millimeter. Micrometers are better than veneer calipers then they do make special watchmakers bench micrometers which would be the best but they're expensive. You do have to be careful in measuring pivots though that you don't squeeze too much and crush the pivots or break it off of your not careful. For instance here's a picture of a micrometer. Notice it breaks the millimeter up into basically one hundredths. With those big numbers being a 10th of a millimeter. Then if you like buying tools you can buy something like this a plate with lots of jewels and all you do is stick your balance vivid in the find out what size it is Then you could always buy something like this if you can find one. Jules on the top to see the diameter of your pivots and the lower part our pivots to try In the jewel although they have a habit to getting broken off Or there is the other way you don't need any fancy tools you just need the watch and the staff. In other words you see if the staff fits in the jewels. You can also when you have your jewel out see if the staff pivot will fit in the whole of the jewel.2 points

-

1 point

-

1 point

-

Great! I like to have a working plan that I can execute with the tools at my disposal (though I really do love cool tools, and may acquire more in the future). Regarding the 0.15mm, I'm certain I'll be able to judge the difference between 0 and something (i.e., if the pivot at least sticks out of the hole jewel). Beyond that, no guarantees. The great thing is, I have one donor movement with a pivot that's heavily worn if not just sheared off on the top end, so I'll be able to try things out with that. I might even be able to cannibalize the hole jewel if it's original. Sincerely praying that I don't have to buy more Moebius lubricants.1 point

-

COBOL as well, know a couple of folks who work 4-6 months of the year and earn 6 figures working with it. Tom1 point

-

That's an interesting question and one I haven't thought much about. Googling "Maurice Lacroix ML115" I get this page: https://calibercorner.com/maurice-lacroix-caliber-ml115/ This page says: "Grade: Special (Elaborated)" Unfortunately, I don't know the grade of the ETA 2824-2 movements I've serviced. As far as I can remember, they were all from rather inexpensive watches. Not "top of the line". I guess the memories of other ETA calibres I've worked on (1080, 2472, 2763, 2772, 2804-2, 2836-2, and 2892) lurk in the back of my mind when comparing, so it may not be completely fair. Nevertheless, overall, the Sellita left me with an excellent impression, but I don't know if Maurice Lacroix has made any other changes to it than decorating the rotor. Finding detailed information isn't easy. As @tomh207 said: "More secretive than Swiss banks". I couldn't agree more. In my opinion, it should rather be the rule than the exception. As you point out, there are probably some disadvantages, but in my view, there are definitely more advantages than disadvantages.1 point

-

1 point

-

I would side with the shim idea as it does not deface the watch in any way. If at all later date you decide to change the staff/balance all is origional1 point

-

Which grades of both movements were you comparing?1 point

-

Saw that 3 in fact in 3 hours. Tom , just have a look at the profiles, one has way too much information on.1 point

-

Thanks for alerting us. We have had the usual cycle of bots this week. All new members are moderated for a period and we keep an eye on them and deal with them appropriately if required. Tom1 point

-

Hi all, This is a bit delicate and I don't want to be offensive to any new members... but I've noticed a couple of new members joining over the last few hours, that may well be AI creations or phishing attempts. All young ladies... Just be careful if you receive personal messages asking you for your credit card details Cheers1 point

-

1 point

-

OK, so once the jewel setting is installed in the chuck (plus #50 collet), then what? Do you use a graver to cut out the jewel?1 point

-

These typically fit in a 5mm collet, and have adjustable depth stops. They are used to hold the setting that takes the jewel for doing lathe work; these jewels-in-settings are most often seen in American made pieces.1 point

-

Sorted this, thanks for the above info. I rolled the original shaft between 2 bits of hardened steel to reduce the bend and burnish down some high spots and it fits lovely. Hopefully just the right amount of friction.1 point

-

I'd suggest your first try a shim. Just to be 100% that the issue is solved by the height of the balance cock. You can use kitchen aluminium foil (single layer or folded one for a double layer). If then everything is fine, you can try the semi-permanent solution by making a notch with a screwdriver or a smoothing/cutting broach (with pointy tip). It doesn't need much at all. When you poke a hole, it naturally shifts to metal to create a bump. Take any spare movement plate/bridge to practice. Also see the video about from Mark, it takes him 2sec to poke the bridge with his screwdriver.1 point

-

Reading through this post I would say at some time in its life it has had its balance staff changed and it is a tad to long. As quick fix if the new staff is to long what is added is a thin shim under the balance cock or some create a notch in the plate., Both of these methods work but are a bodge. The correct method is to hone it down to make the balance shorter using a lathe or Jacob tool.1 point

-

I guess you meant endshake. Posting past you bedtime? This "very little" maye just be the shock settings doing their job. Have you checked this? I'm quite sure that's your issue.1 point

-

With the balance cock screwed down does the balance have any up and down -side shake- movement ?1 point

-

I’m currently servicing my own cal 48, and it has the same problem on the mainplate. I decided to use the most gentle cleaning solution (not the Elma 1:9 ammoniated fluid I normally use). I guess it is either poor quality control (in an otherwise very good movement), or the movement has been cleaned too harshly in the past.1 point

-

Absolutely. I fully agree that it doesn't "understand" anything, perhaps I should have put "understand" in quotes, but it is designed to give the illusion of understanding, which is why it is quite jarring when it entirely fails to be able to do perform what is in fact a remarkably simple task that I could probably figure out on the back of the proverbial fag packet. Having said that, I wonder how many of the current generation could actually manage that calculation... Actually now that I think about it, in light of all I have discovered over the last few years about the depressingly low average intelligence of the human race, I wonder how many of any generation could actually make a stab at solving this problem. When people are fretting over the "power" of AI, and what it can do, I must admit I am far more concerned about the things we will assume it can do that it will spectacularly fail to manage, and the resulting chaos that will ensue.1 point

-

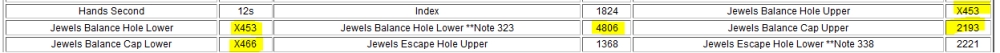

When you're looking for pivot issues the most common place where they show up would be dial-up and dial down amplitude differences. If the watch hasn't been cleaned often times it could be just bad lubrication. Otherwise when your watches clean and properly lubricated bad pivots will show up as amplitude differences. I think where having a terminology confusion here? There are actually two separate jewels on each side. There is the hole jewel and the separate cap jewel. Let's look at the parts list which gets even more confusing as usual. Notice there is a X in front of some of the parts which I believe usually indicates conceivably a variation of that part. So we see that part 453 is the upper hole jewel and it's also the lower jewel except. Then we see 4806 is the lower jewel with a reference to note 323. This is where we would need to know the serial number because they change the jewels based on a serial number. But I may go find a reference and see what the difference is. You also notice that the upper and lower cap jewels are different typically in the one on the main plate is thinner because it doesn't have all the regulator stuff. Then a lot of times on the balance bridge it might even be a separate color like gold is used because it looks Tyson pretty usually found on higher grade watches. So as we can see below different hole jewels. Toll diameter is the same which is very common. Next number is the total thickness and the third number is the shoulder thickness. Then of course you'll notice the different diameters for the pivots. Which does not show up as part of the part number or even referenced in the part number. I have seen somewhere in the Elgin catalog which said if you ordered a dozen balance staffs and you did not specify a pivots size they will actually send you an assortment of different pivots sizes. Several problems with this approach of determining whether the watches ever been serviced. First many times American pocket watches get re-cased and the new case would not have any prior markings. Then some shops don't mark the case at all. So you have no idea if anyone had serviced if they didn't mark. With American pocket watches it makes it easy to keep track of because the movements of serial numbers. You really do not want to discover you have a problem at this point in time. In other words if your pivot is physically too big for the jewel the best time to deal with that is before it's in the balance wheel. Replacing a balance staff is a very procedural operation. So for instance if you are replacing a balance staff you would measure the old staff just to make sure the new staff you order is the right staff and you also measure the new staff when it comes to make sure it actually corresponds to the dimensions you think it is supposed to be as unfortunately often times there can be variations. It is best to find out if your staff is not sized right before you start attaching things and bad things will happen conceivably like if it's slightly too big lots of things can get damaged or broken trying to force things on the staff is not quite right1 point

-

Looks to me like it's a crystal press. Edit Just done a quick search and it does look like a jewel press. Are you sure the stump is fixed? Can you post a closeup photo.1 point

-

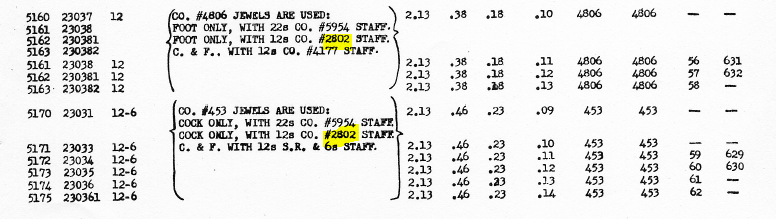

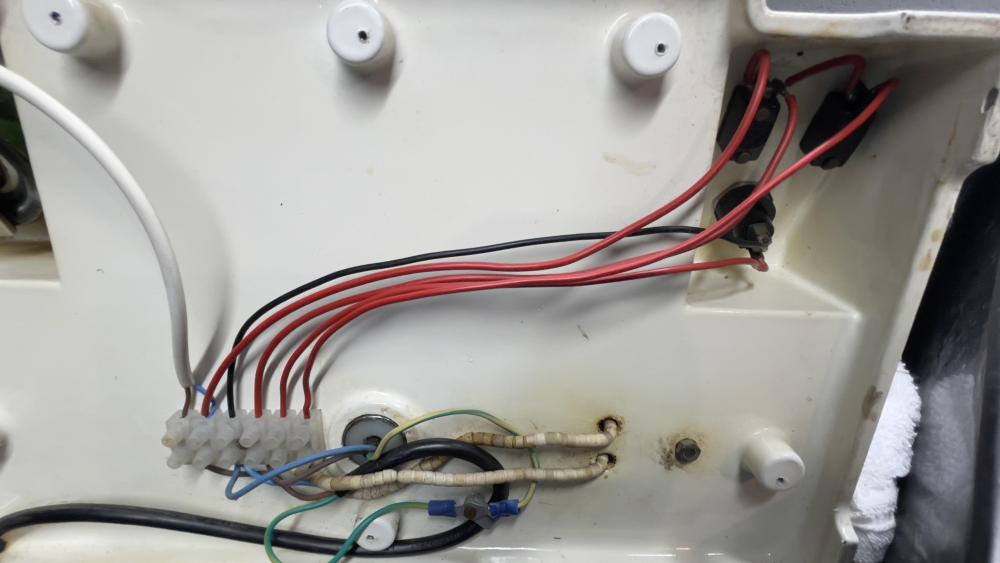

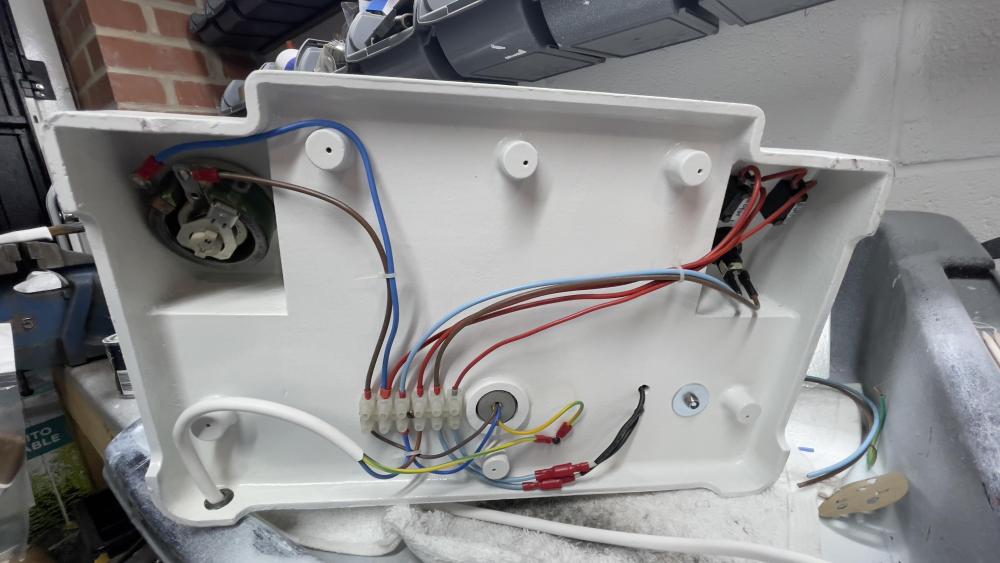

Hi, I thought i’d share a bit of a journey I’ve been on in restoring my Brenray Watch Cleaning Machine. I have been inspired and helped along the way by some kind forum members. So I bought the machine on the Bay of E and whilst it was working, I wasn’t totally happy with the condition and worried about the wiring. I sought advice and decided to pluck up the courage to take on the project….. Here is my progress so far…. I have completely disassembled the machine, removed and rewired the loom assembly, cleaned the switches, lamp, chromeware, rheostat, replaced the heater, disassembled and rewired the motor, and stripped the powder coated paint (what a drama that was!). Then it was ready for new paint…… decisions, decisions?? I toyed with many options Cream? Silver? Or Elma Blue? I really liked the hammered silver option but in the end when with original white in hammered finish as this colour came in brush on and spray options. Repainting ended up being a real pain, the coats took ages to cure and did not take well to the new bare metal (despite being a direct to metal paint!) so it was back in the acetone bath to be stripped, primed this time and fresh coats of paint!1 point

-

After a few weeks of frustrations, mistakes and blowing my house RCD due to a dodgy vintage bulb holder, I reassembled all the parts and have successfully restored my first watch cleaning machine!! It has been a real journey of discovery. I’ve learned so much along the way having to teach myself new skills and understand the workings of vintage motors, electrical wiring circuits and how to strip old powder coat and repaint (as best as I could) from scratch. I am immensely proud of what I’ve achieved and now have a fully functioning watch cleaning machine! I was not confident that I could take on this project but with help and guidance from some great fellow enthusiasts, I did it!! Now onto those pesky Elma Super Elites I have waiting for some love and attention!!1 point

-

If it's a gold case I'd strip it down and put in my heated US. If you've not got a Heated US then just try hot water to start with. Edit Failing the above you're onto things like IPA or Acetone to try and soften it.1 point

-

What do you (or indeed anybody else here) think of the idea of some kind of unofficial Timex museum?1 point

-

Where did you find a replacement crystal? I’m also learning on a pocket ben style 5. I’m for sure going to play with more pocket watches before even thinking about a wrist watch1 point

-

I did realize later it only has two leads, top and bottom.1 point

-

1 point

-

All I know is I never wanted to get into watchmaking at all, but there was simply too much beat error in the world. It was, like, everywhere I looked. I didn't qualify for military service, so I felt it my duty to do my small part to minimize whatever beat error I could.1 point

-

This is the intro, the book is 135 pages long and my scanner's very slow so it's going to take a bit longer than I thought... a Sunday job. KIF Spare Material Catalogue P1-17.pdf1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)