Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/25 in Posts

-

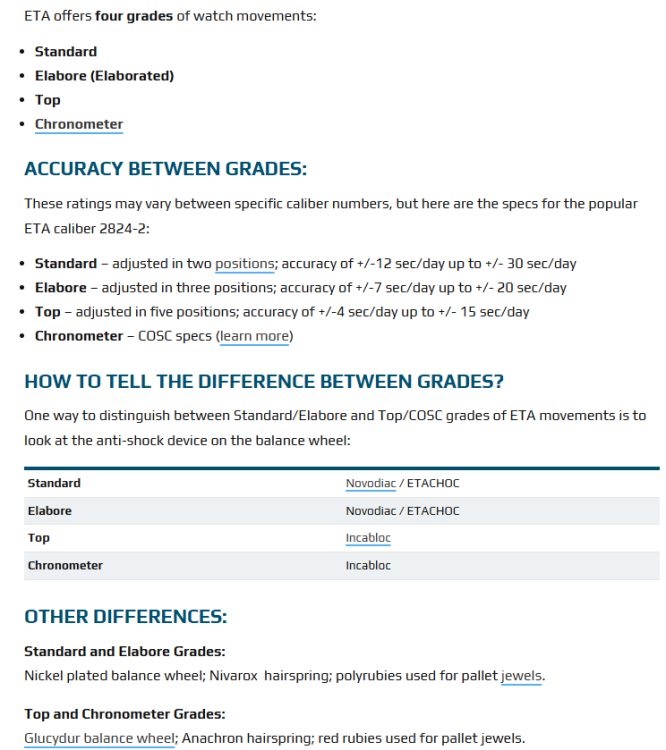

I recently replaced the elabore grade 2824-2 in one of my dailies with a top grade SW200-2. The 2824 turned out to be modified in an unknown/unpublished way (extra long hand shafts) that required moving some parts around between movements. Zero (non-self-imposed) issues. The only difference between grades, as I recall, is in the escapement. Balance wheel and balance jewels. There's a middle grade, which I think has 100% to do with finishing, but I'm not certain about that off the top of my head. I knew that Sellita made ETA's movements for a long time, and wasn't at all concerned with there being any degradation in quality. The extra jewel was expected and appreciated. There's a difference in one of the plates, as I recall (a locating pin in lieu of a screw hole or something like that) as well. Mostly, I didn't want to throw any more money at ETA. Sellita will sell me parts, so I'll buy their movements (even if their parts will work on the ETA just fine). I'm all about right to repair, and Swatch is firmly affiliated with the dark side on that.4 points

-

I was looking up these numbers just the other day, as I've just finished working on an ETA movement and wanted to see the spec for accuracy. The easy way to spot Top/Chrono grades is that the Glucydur balance has curved arms, as opposed to straight on the standard balance. I read that the Chrono movements are stamped with a number. I've never come across one. From https://calibercorner.com/eta-grades/3 points

-

Can you tell us exactly what a kg Heuer is please? Heuer were high end until they got involved with TAG but even TAG movements don’t look like what you are showing us. Tom2 points

-

Crown probably is original is just worn down. The 3 key dimensions are Diameter, Depth & Pendent Tube size. Here's the general area to be looking on Cousins. https://www.cousinsuk.com/product/ss-non-swiss-big-0s2 points

-

Ruling out the timegrapher: Put a minute hand on it and let it run for several hours to find out if it is running on time vs >+999s/d I did two Raketas recently that my Weishi would not lock onto unless the movement was directly against the metal clamp on the microphone. The movements clamped in the holder, clamped in the microphone would not hold steady readings. I think mine showed correct rates but very wrong beat error (9ms instead of 1ms)2 points

-

Locks look great, if anything a little light for such a watch. Rotate the balance by hand and check drop lock on every tooth, on both stones. After drop lock rotate the balance a few degrees more and push the fork so the horn contacts the roller jewel, the escape tooth should remain locked and not go on the impulse face. Could you get a good image of the roller table and its interaction with the fork from the side (balance stationary)?2 points

-

1 point

-

I've got the same lume-rot problem in my Suwa 6309-7049L. I had some slight moisture intrusion as well, which turned the hands black in a heartbeat. I replaced the hands and crown gasket, but have just had to embrace the "patina" on the hour markers. I don't have either the tools or the materials to attempt a re=lume.1 point

-

@spectre6000 yes, iirc the primary differences from standard/elabore and top is the glycedur balance wheel, maybe a different spring. They are adjusted to different levels though, standard 2 positions, elabore 3 positions, top and chronometer 5 positions with the chronometer obviously having cosc testing and certification. I think chronometer is restricted and very expensive, I haven’t seen any for general sale. Tom1 point

-

1 point

-

I really did not understand the guy's thinking, a lot of newbies would actually be looking for this " special 315T key "1 point

-

1 point

-

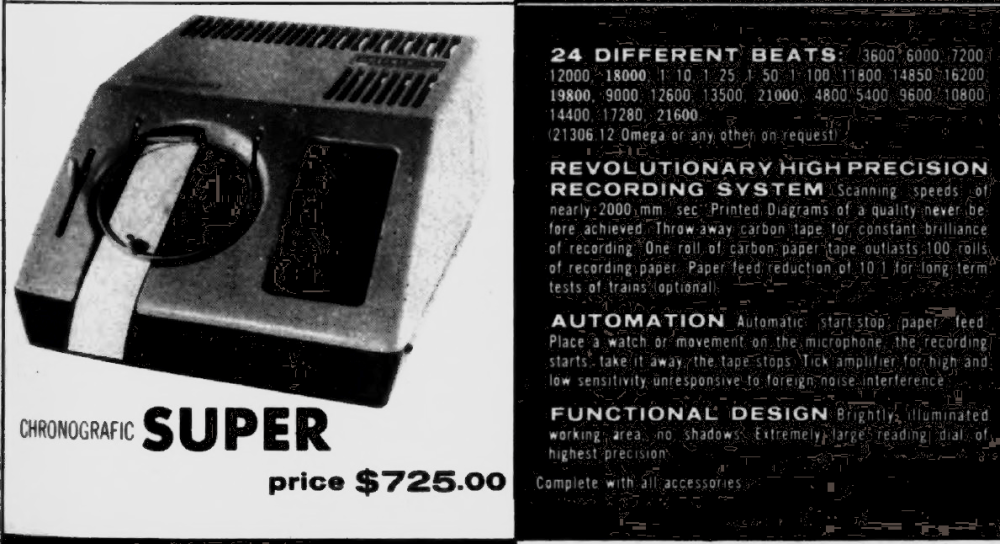

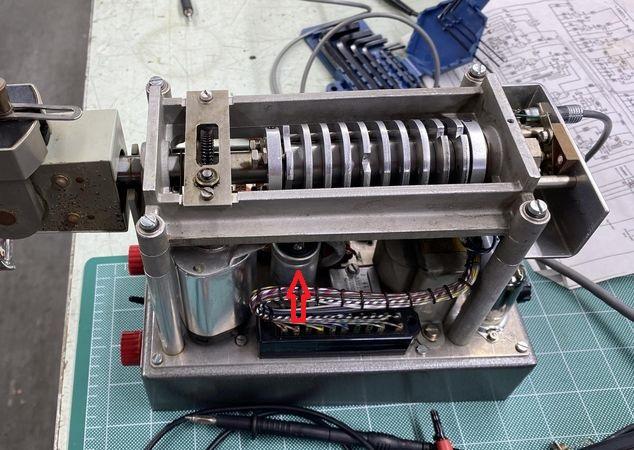

don't have anything on the microphone. I don't think I have the manual for the super but I seem to be missing one of my Greiner manuals. I do have a manual for something that looks similar to the cheaper one in the advertisement I found below. One of the problems is Greiner have lots of variations of timing machines. that I thought I could see if I can enhance the readability of the description which does answer a question of unlike the cheaper machine that you have to spin the knob on the right-hand side the start the motor it looks like this one starts and stops if a watches on the microphone. this is a rather handy feature for paper tape machines because occasionally walk away and without it the paper will just keep on feeding until you notice that a lot of paper has now come out in your machine.1 point

-

I wouldn’t worry too much about it as it’s not under any stress all it does is lock the pulley to the spindle, on my Pultra they are just alloy steel.1 point

-

Probably just stuck with old, dried up lubricant. They'll probably come apart after a few seconds (or minutes) in solvent. If that IS the case, it's likely a major contributor to your balance not moving freely.1 point

-

1 point

-

It's was all just a bit tongue in cheek Obviously he was just using a standard crystal lift to perform the same function as the special tool. Clearly showing the "Special" is not realy needed. Things sometimes just fly over some people's heads don't they1 point

-

That's an interesting question and one I haven't thought much about. Googling "Maurice Lacroix ML115" I get this page: https://calibercorner.com/maurice-lacroix-caliber-ml115/ This page says: "Grade: Special (Elaborated)" Unfortunately, I don't know the grade of the ETA 2824-2 movements I've serviced. As far as I can remember, they were all from rather inexpensive watches. Not "top of the line". I guess the memories of other ETA calibres I've worked on (1080, 2472, 2763, 2772, 2804-2, 2836-2, and 2892) lurk in the back of my mind when comparing, so it may not be completely fair. Nevertheless, overall, the Sellita left me with an excellent impression, but I don't know if Maurice Lacroix has made any other changes to it than decorating the rotor. Finding detailed information isn't easy. As @tomh207 said: "More secretive than Swiss banks". I couldn't agree more. In my opinion, it should rather be the rule than the exception. As you point out, there are probably some disadvantages, but in my view, there are definitely more advantages than disadvantages.1 point

-

1 point

-

1 point

-

ML61: check the 4uF cap. Voltage on its terminals shall reach 120V, the threshold of the thyratron valve. This will start the motor. With too high internal loss of the cap, this cannot happen. The unit will sequence through the selected positions by itself, no external control needed. Start by pulling down the mic! Frank1 point

-

You could do that. Most would use a slide rest for this work; quite often it would be used to put a step on a setting, modify the diameter/s seat height etc. Also useful when making new settings. All depends of course on how true it runs (the ones I've encountered haven't been great).1 point

-

These typically fit in a 5mm collet, and have adjustable depth stops. They are used to hold the setting that takes the jewel for doing lathe work; these jewels-in-settings are most often seen in American made pieces.1 point

-

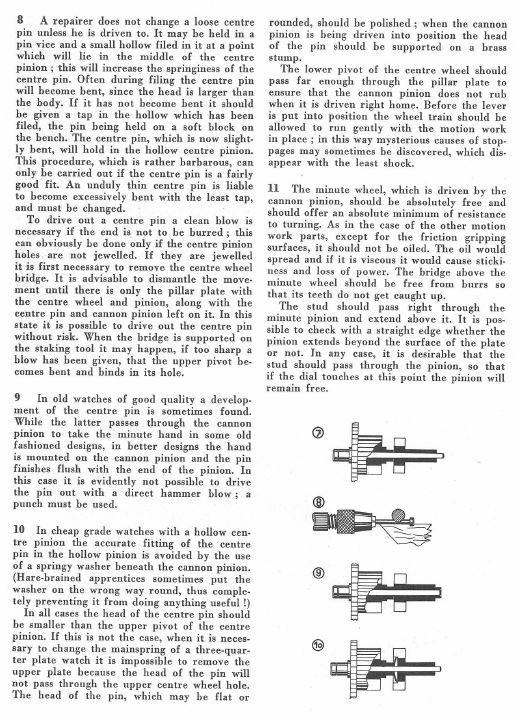

Maybe sometimes it's better not to watch the videos as this really isn't that difficult operation at all. So before the video with both plates together and the screws in place. In other words you do not want the center wheel flopping around as if it's jeweled you could crack the jewel that it's in. So holding the watch in one hand and a small hammer In your other hand just The center pin gently. You really don't need a lot. Then the problems would be some of these watches do not have a pin sticking out and then you really should have a staking set. Which is also very useful for putting this back together again. But you do have to be careful staking set of how you support the backside not to break anything. Often times their stuff sticking out on the back side like if it is a key setting that would be sticking out on the backside that has to clear the staking set. This is an example of key setting on the backside. Where fear using a staking set versus holding it you have to be careful that the stuff here is over a hole as all of it will come out with the pin. Here's what the parts look like out of the watch at least for one like this Then some additional information just in case you need it1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)