Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/25 in all areas

-

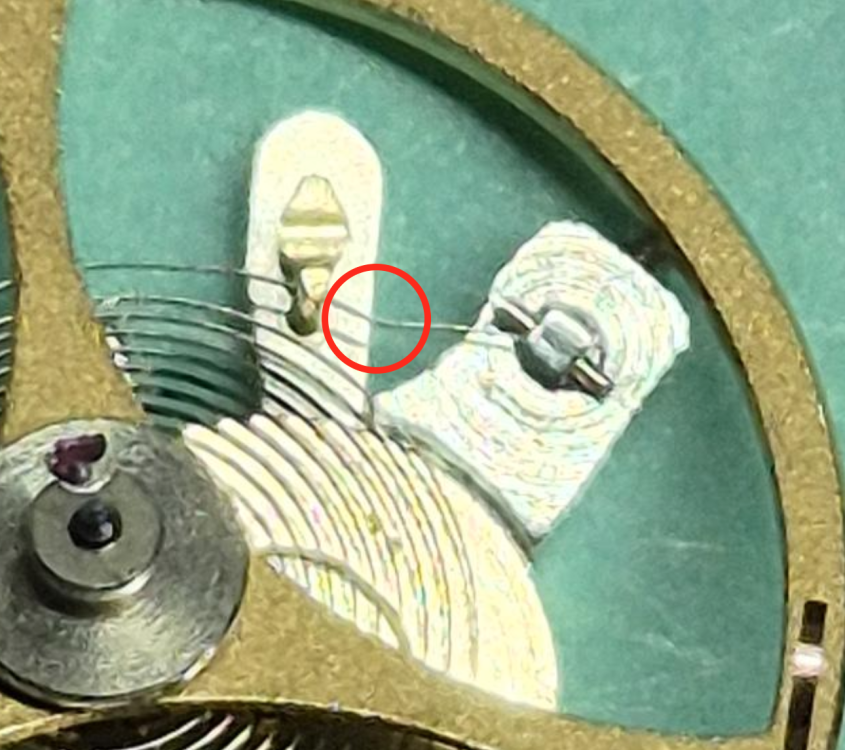

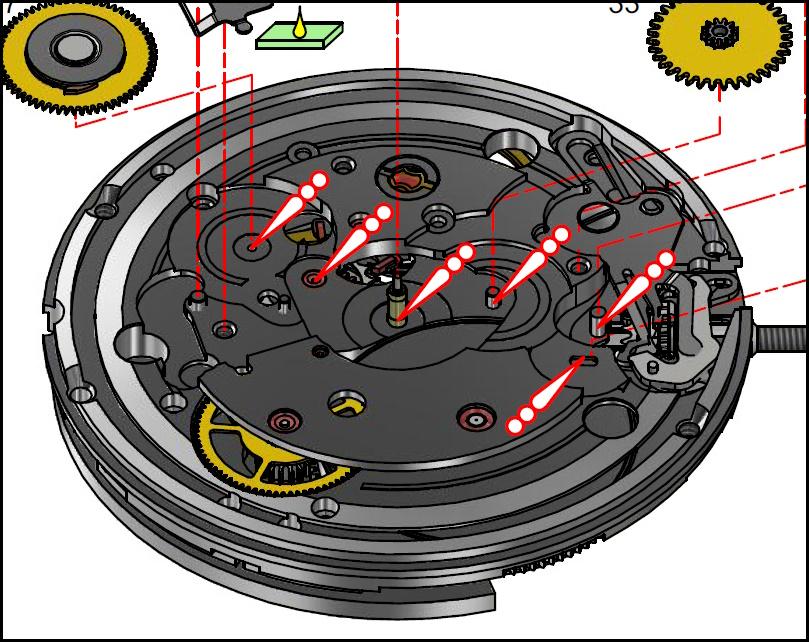

Let me guess: it's running very fast? I am no expert at adjusting hairsprings, but I have a little experience. I think the issue is a combination of the incorrect position of the stud carrier (it should be about 45 degrees further anticlockwise, looking at it with the balance installed) and too much bend in the hairspring just after it emerges from the cock. I would move the stud holder like this: Then, depending on how the spring looks after making that change, I would adjust this bend: See how the spring goes through the regulator pins at an angle? That should be straight across, and fixing that will move the whole spring towards the centre. One wonders why the stud holder was so far around. If that was done to adjust beat error it may be necessary to adjust the hairspring collet so the impulse jewel sits in the right place with the stud holder where it should be. But you'll need to get the spring properly centred first. I recommend moving the stud holder around, then posting some more pics from below showing how the spring sits then, and hopefully one of the more experienced members will direct you from there.4 points

-

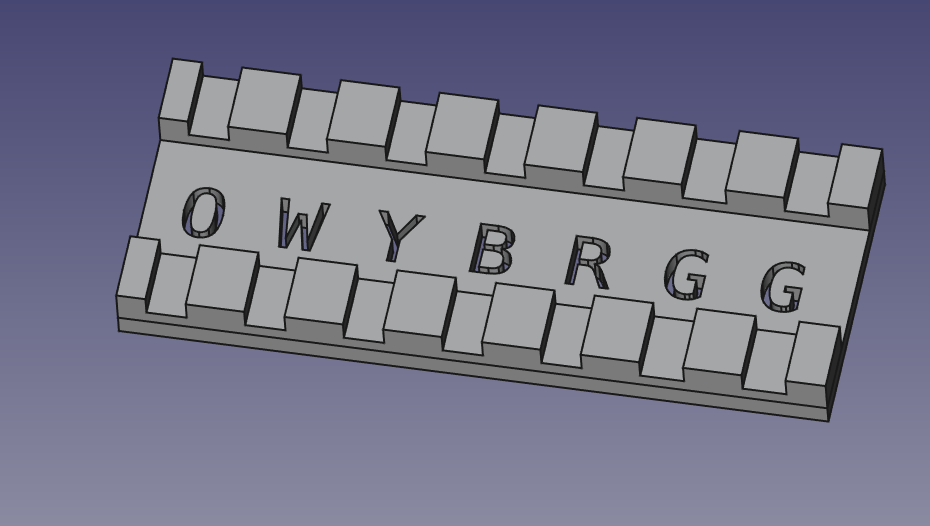

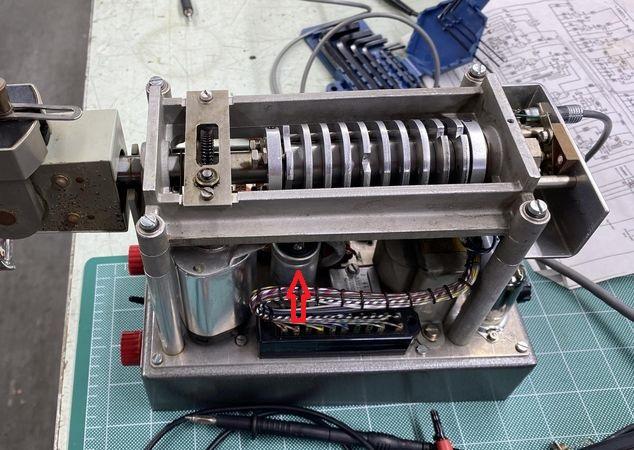

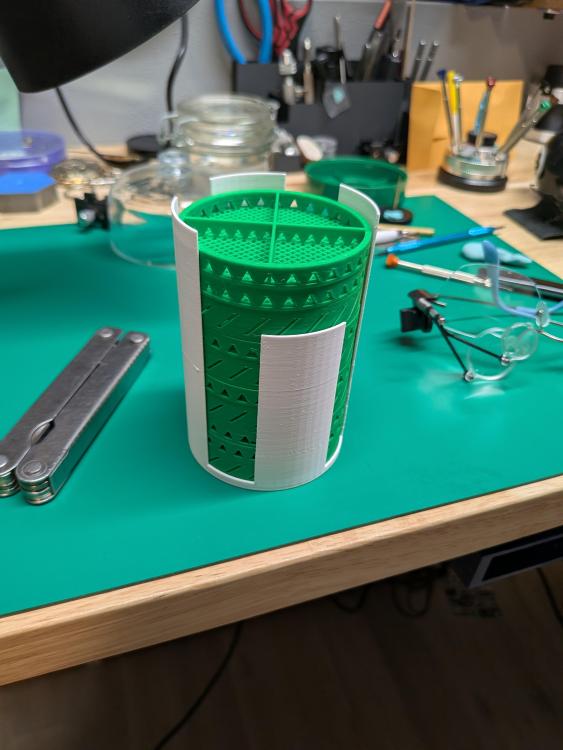

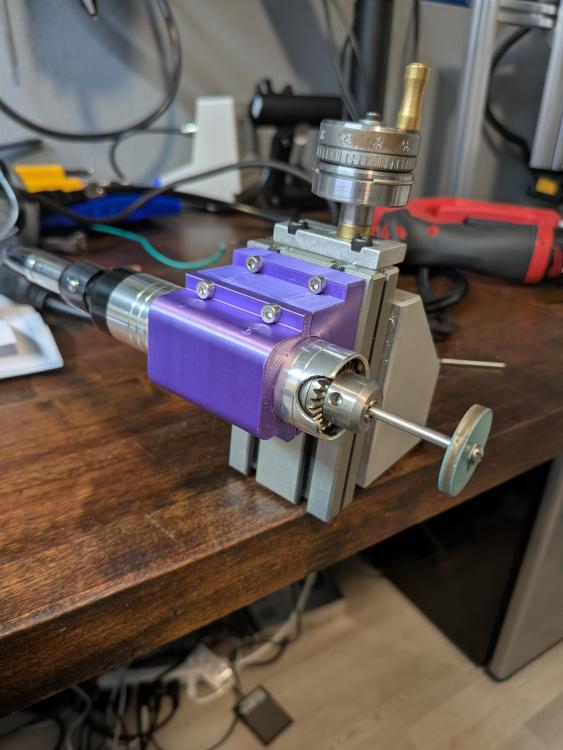

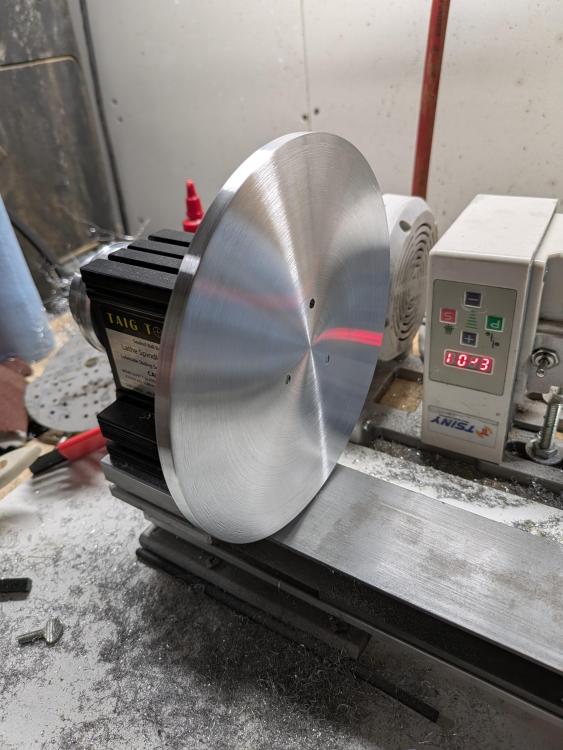

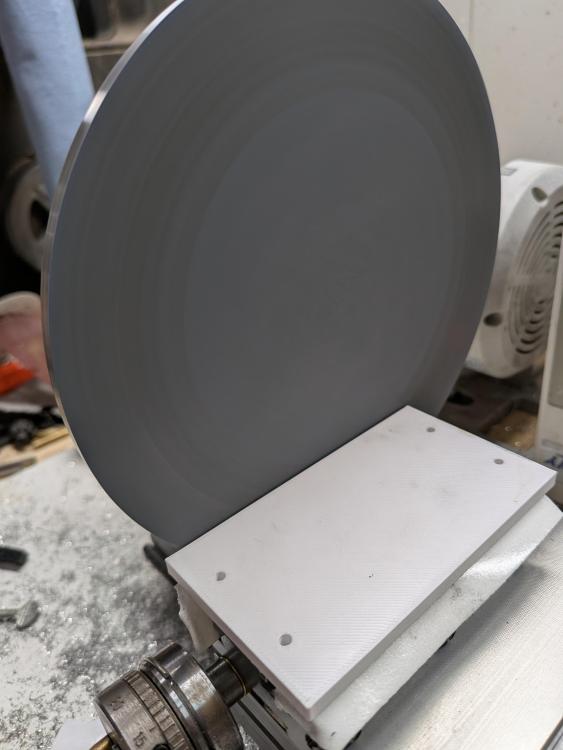

I figured I should actually post my tool builds here. I like making tools almost as much as I like watchmaking. I'll post new tools I make below and label them. First up, my cleaning machine. You can see my other post on it. Next up. Some parts I make for the cleaning machine. Baskets and such. Then I made a toolpost grinder setup for my flex tool. This will be used for precision grinding, and also for wheel and pinion cutting. Then we have the lapping table for the lathe. The is a simple build. Next is a 2 axis polishing vise. I'll add more later on3 points

-

3 points

-

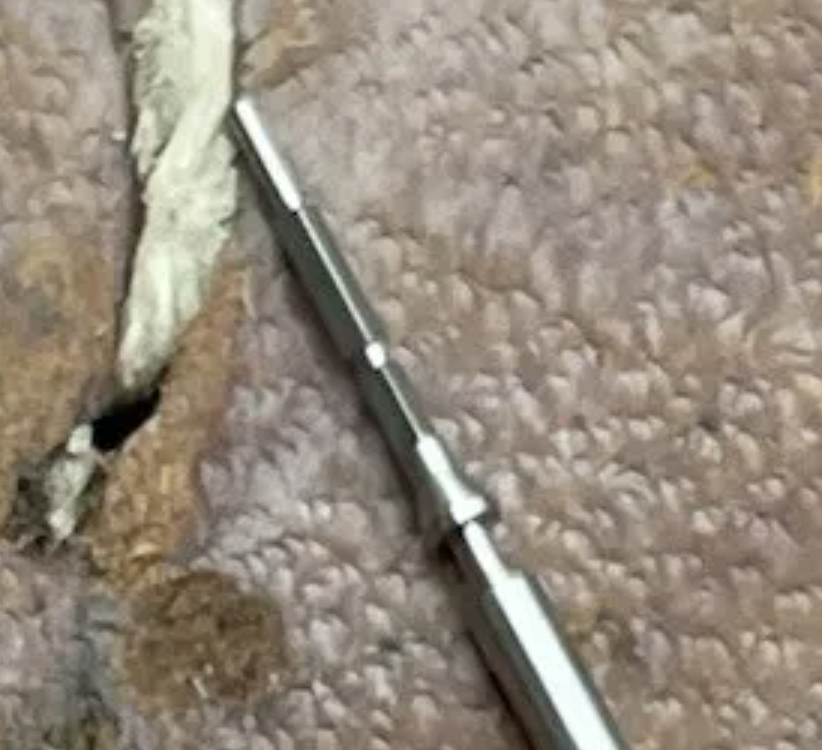

I wouldn't bother with the spirit level. Assuming you can get the screw perfectly vertically mounted in the tool, I doubt the level would be accurate enough. With my homemade tool, I find hard to get small screws mounted perfectly vertical, so I adjust the feet by eye, then I run it lightly over the lapping film and look where the screw head is marked. Then I just tweak the screws to level it up and repeat. Once you've done it a couple of times, it's quick and easy. I reckon I can polish a screw head in 2-3mins.3 points

-

Balance wheels and hairsprings cannot be manufactured to <0.07% tolerance (=1min/day)! So the factory will measure hairspring (elastic moment) and balance wheels (moment of inertia) separate, sort them into classes and combine matching ones. @Knebo mixed parts from different classes and logically got a huge error. Frank3 points

-

Organize? What's that? My bench is "organized" by chronological stratas. If I can remember roughly when I last used a particular tool, I dig down to where the stuff in that layer corresponds to that timeline. I hate it when someone cleans up my stuff. Then I can't find my stuff anymore.3 points

-

2 points

-

Timex did not maintain crystal size information. So you will have to measure it.2 points

-

Welcome Rachel, Old Hippy is the resident clock expert here. I'm sure he will answer you shortly2 points

-

Partly as an experiment to find out whether we can still get these deliveries in the USA, I ordered a screw polishing frog. I'd been meaning to try to build one myself but am missing half the tools I'd need so I'll give this a gamble at a little over $100. Look for a review if they succeed in sending it to me.2 points

-

I recently serviced my first Sellita movement, the SW 200-1 calibre. It was my very first Sellita movement, so it was a bit more exciting, especially since I could compare it with my experience of servicing and repairing several ETA movements, including the famous 2824-2. The first time I heard about this movement, it was described—and still is—as an ETA clone. The impression I got back then was that the SW 200-1 was a fairly decent and relatively inexpensive copy, though it didn’t quite reach the same level of quality as the original. After servicing it, however, I’m pleased to say that my overall impression is that Sellita's movement is at least as good and, in some aspects, even better than ETA’s. When I disassembled the movement, the only unexpected thing was that the cap jewels and pallet stones were somewhat overoiled. Whether Sellita or someone else was responsible for this, I don’t know. Regardless, the movement performed well, but after seven years of 24/7 use by the previous owner, it was time for a service. One thing I really appreciate about the Sellita SW 200-1 is how easy it is to pull the crown to its second position to set the date. There’s absolutely no risk of accidentally pulling the crown too far out. This, I believe, is an improvement introduced by Sellita. My memory of the corresponding function in ETA's movements is that it’s far too easy to overshoot, inadvertently stopping the watch when you only intend to set the date. In fact, it works about as well as on the Rolex calibre 3135, which is perfect in this regard. ETA’s 2824-2 has 25 jewels, while Sellita’s SW 200-1 has 26 jewels. I’ve long been curious whether this difference was simply a way for Sellita to outdo ETA in the jewel-counting competition. To my delight, this turned out not to be the case. The extra jewel is placed exactly where, in my opinion, it does the best: as a bearing for the barrel arbor on the barrel bridge. Very nice! It’s also my impression that the click spring is stronger in Sellita’s movements, to the point where it became a bit fiddly to fit the click itself. I think there’s a good reason for this. When the cogs of the winding pinion and sliding pinion begin to wear (which only happens when you manually wind the watch), the pressure from the click on the crown wheel (which can move sideways away from the ratchet wheel) needs to be high enough to prevent the teeth of the crown wheel from slipping over those of the ratchet wheel. This could result in the ratchet wheel losing grip on the mainspring (not good!). This issue only manifests when you wind the watch manually. I’ve written about this issue in this thread/post. In short, I believe Sellita has solved this problem by making the click spring stiffer. Another sign of good manufacturing precision is the wonderful feeling when setting the time. The play you almost always feel in the crown of ETA movements is almost completely eliminated. It’s not at all stiff, just very precise. What unfortunately doesn’t impress me is Sellita’s assembly instructions. However, the documentation, unlike ETA’s, includes several exploded diagrams with part measurements. Personally, I don’t find this particularly useful, although it’s a nice touch. As for the assembly instructions themselves, there’s certainly room for improvement. The documentation is not particularly easy to understand and contain a few outright mistakes, such as showing that the escape wheel bearing on the main plate should first be oiled with 9010 and then with HP-1300. ETA isn’t entirely free from this issue, but their documentation is significantly more useful. And, of course, there’s nothing stopping you from using ETA’s documentation, as both movements are built in exactly the same way. This is something I actually recommend if you’re not experienced enough to not need the documentation. All in all, I would recommend the Sellita SW 200-1 over the ETA 2824-2. Not least because spare parts are readily available for independent watchmakers, meaning owners of watches with Sellita movements can generally expect faster and cheaper service and repairs. This also means they’re not dependent on the Swatch Group, which owns ETA, as well as brands like Hamilton, Tissot, Omega, Longines, Rado, Certina, Mido, and others, and doesn’t sell parts to independent watchmakers. In this respect, it’s better to choose a watch that houses a Sellita movement from brands like Oris, Baume & Mercier, Maurice Lacroix, Christopher Ward, or Stowa, to name a few. Additionally, ETA has started using plastic in some of its movements, which, for me at least, is a red flag and something I struggle to associate with high-quality Swiss movements. Thankfully, as far as I know, Sellita's movements are entirely free of plastic. Thanks for reading!1 point

-

From the information I've got you need a Timex #37 lens. Edit There are also a number of lenses in the GS Catalogue for Timex. GS Crystal Catalog.pdf1 point

-

Hi I believe it’s a 108 movement made in 1979. Manual atteched 108.pdf1 point

-

Yes this is correct. You don't have to care if the pivot is 0.11 or 0.13 or whatever particular size if it fits the pivot hole well. You have enough pictures shown here of how the pivot size is related to pivot hole size. You can check how the downside pivot fits it's hole stone as to have some reference, as there all seems to be OK. I still don't see picture of the upper (hairspring) side pivot. I see good picture of it on another balance with broken downside pivot, which I think is of a donor movement balance? This donor movement, does it have good cock jewel settings? The setting that Yow have is home made by someone, it is not made in the regular way with two parts, it is made with one part with reamed hole and both jewels are pressed in the hole. This is possible to work, but is not good as cleaning is practically impossible. And, it is not done good as it doesn't work for some reason. So may be the hole stone is with smaller hole or the pivot is short. I really need to see the pivot as to be able to advice if it is needed to replace the staff.1 point

-

I know little about Timex other than what I've read on here. You need to remove the bracelet for cleaning, remove the back and the movement, we can advise m , how to do so, once the back is removed. The crystal needs removing and measuring, however, I believe that Timex had cas numbers that would tell you the crystal size. @JerseyMo, can you help?1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

I thought the same, 2000s/d out of time seems a lot for a mis-matched hairspring and wheel for a relatively modern mass produced watch. Though I figure the Soviet manufacture ethos was to churn them out thick and fast then re- adjust the ones that were under par. As seen with the brass balance cock shims. My initial thoughts were an incorrect movement frequency, the smallest increment is half a beat or quarter oscillation which calculates to 66 minutes of hands movement in one hour.1 point

-

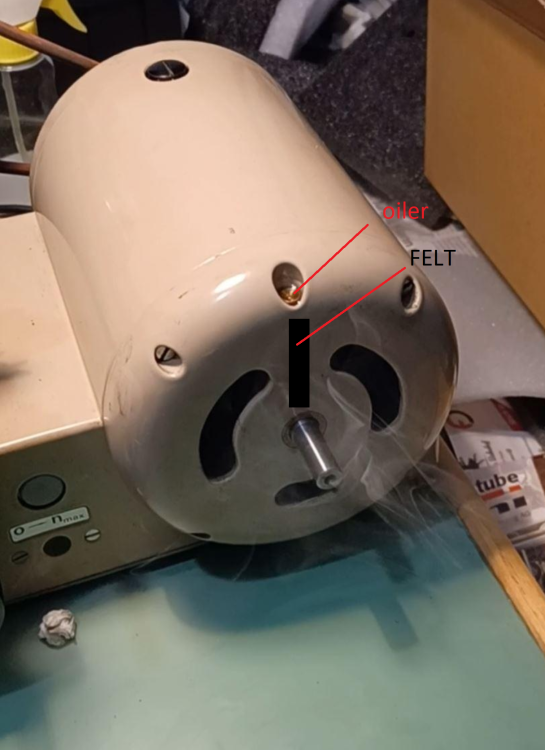

Hi, I don't know. You're right about the felt, there is one, on each side, between the oiler and the bushing. I already tried to push some oil through the oiler but I'm not sure if the felt is getting "loaded" lubricating the bushing. At the moment I bought one of those 150W sewing machines motors as a temporary replacement, it seems to be working fine and is even quieter than the original. I will disassemble the original motor and regulator and try to fix it later on, my neighbour has been complaining about the smoke..... Dario.1 point

-

1 point

-

If the drawers are to stay ,then think about layering them up. Battern up the sides of them inside, and lay sheets of stiff cardboard or plywood/mdf depending on their size, across the batterns. Making trays that you can lift out - finger holes in the sides of the trays- will make them easy to remove. Layer your tools in the drawers according to usage, most used in the top trays. Second hand office equipment ...steel pullout drawers make for. great storage . I like to keep stuff on my bench down to a minimum, just the tools required to do the work plus a little extra of what I think I might need. Finding lost parts is much easier when there is no clutter, that's less important now, but it became a habit from when I started. A clear bench is also easier and quicker to wipe down, dust can be a real problem in some environments. If you are new to the hobby, then every new tool that you buy, you'll want to proudly display on your bench. That will soon change when it becomes overloaded . Your working style will evolve over time. So basically when you first start...everything will be out on your bench, and when you've learnt that isn't good...you'll put it all away in drawers .1 point

-

FYI a load of NOS YM57 have gone up on eBay this week - no idea on seller/quality or anything and they aren't cheap.1 point

-

1 point

-

Some further information on ETA grades: https://omegaforums.net/threads/horology-101-eta-grades.77882/1 point

-

The spirit level is actually not essential. It doesn't help in squaring up the end of the screw. Unless your grinding surface has been levelled with a spirit level first.1 point

-

I use an ancient and slow Lulzbot Mini with an upgraded extruder. I print horological related stuff all the time. Printing something now! I am not particularly fond of that style of screwdriver holder. I like mine lying flat. But, nevertheless, yours looks quite fine! ...and am well north of retirement age...btw1 point

-

I'd say they both appeal to a specific type of person, and if it wasn't for the generational gap between your average watchmaker and 3D printing enthusiasts I would expect many more to have them.1 point

-

1 point

-

Balance wheel, yes. Not sure about hair spring. The shock settings are different as well. Memories are being poked at here a bit, and there might be some different jewels as well; not sure if that's in specific locations or throughout. I take the adjustment bit to be a matter of being able to get really consistent adjustments with the glucydur balance vs the lower grade nivachron, but could just be man hours. The top vs. chronometer difference is probably a matter of pulling off the movements that can be regulated out better and getting paper for them. May not even be a cull metric, but it wouldn't surprise me. I was surprised to be able to find top grades from both ETA and Sellita from a seller on eBay, and availed myself of them. A 7750 and a SW200-2. This is the quick and dirty way to tell them apart. I didn't know about the number, but that would make sense. Also never seen one in person. Can confirm Sellita follows ETA with the balance spec on that. I recall (and stated above up there) that the jewels might be different between the lower and higher grades. I didn't pay too much attention to the color of them while I had them in my hands though. The ETA (elabore grade) would for sure not have been specd with any special jewels. They didn't even spec it without the unused date function... though they did spec it with extra long hand shafts... Still, I doubt they'd make a change like that on that particular watch.1 point

-

I recently replaced the elabore grade 2824-2 in one of my dailies with a top grade SW200-2. The 2824 turned out to be modified in an unknown/unpublished way (extra long hand shafts) that required moving some parts around between movements. Zero (non-self-imposed) issues. The only difference between grades, as I recall, is in the escapement. Balance wheel and balance jewels. There's a middle grade, which I think has 100% to do with finishing, but I'm not certain about that off the top of my head. I knew that Sellita made ETA's movements for a long time, and wasn't at all concerned with there being any degradation in quality. The extra jewel was expected and appreciated. There's a difference in one of the plates, as I recall (a locating pin in lieu of a screw hole or something like that) as well. Mostly, I didn't want to throw any more money at ETA. Sellita will sell me parts, so I'll buy their movements (even if their parts will work on the ETA just fine). I'm all about right to repair, and Swatch is firmly affiliated with the dark side on that.1 point

-

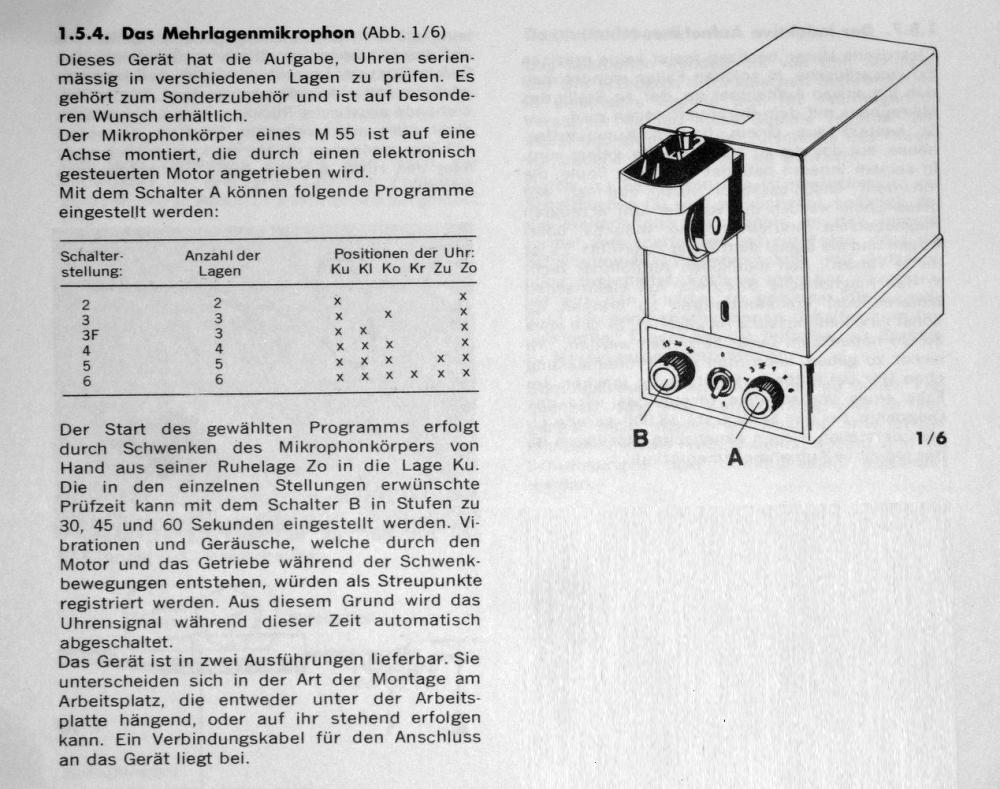

ML61: check the 4uF cap. Voltage on its terminals shall reach 120V, the threshold of the thyratron valve. This will start the motor. With too high internal loss of the cap, this cannot happen. The unit will sequence through the selected positions by itself, no external control needed. Start by pulling down the mic! Frank1 point

-

The bit about the Sellita movement being as good or in some parts improved is less of a surprise when you find out that they were for many years the primary manufacturer of ETA movements. Not clones but actual ETA movements. When ETA stopped the partnership the movements we consider work horse ETA movements had gone out of patent. So if your company is wholly setup to make a range of movements that are no longer IP restricted? well it does rather make sense to make some improvements your engineering team have identified and carry on manufacturing in your own name. Sellita also do design and manufacture of movements for other Swiss brands not ETA “clones” but I have not found any connections to others. More secretive than Swiss banks. Tom1 point

-

I went through a similar exercise with each of my children. When they were born, I found a watch that I would wear during their childhood, build memories and association, and hand down to them. Had to be of good quality (speaks for itself), something someone would want to wear whenever (not a fashion exercise), and have something for them to play with (extra crowns, pushers, etc.). My daughter is now 5, and she has a (doesn't matter what brand because brands don't matter) with dual rotating inner bezels. She has spent many hours in my lap turning those crowns and playing with the bezels. It's 2824-2 powered, and when it was due a service, I upgraded to a top grade Sellita movement (notably, not ETA). My son is only 6 months old, and he got a parts chronograph (doesn't even have a brand) with a top grade 7750 (yes, ETA, but I got it for a good price, and can swap in a Sellita down the road when I eventually find a vendor selling them in top grade). He grabs at it during diaper changes, and the shininess seems to do a good enough job at keeping him from alligator rolling off the changing table. He's just getting started with his watch. I've explained the deal to my daughter, and she's very excited about it. She has a butterfly Timex child's watch that she wears for "practice". I'll probably give it to her when she goes off to college or something. The thing about branding in this exercise is that it SO doesn't matter. DADDY is the brand. Memories and association are the brand. If I do my job(s) right, monetary value is 0% consideration. Both of these intentionally have the most broadly available workhorse movements where, even with Swatch's cartel-like practices, parts will ALWAYS be available forever and ever by way of donor movements if nothing else. The price of a Rolex is about 10% watch, 90% marketing. If you took the name off the dial, and just assumed it wasn't a fly-by-night outfit that stood behind the product like most manufacturers do, a $50,000 Rolex stainless dive watch would probably go for about $5K. They're good, don't get me wrong, just not 10X better than reality. Ads in magazines and manufactured scarcity don't actually mean anything. If you're into watchmaking, you can look at watches with a less marketer influenced eye, and see what watches are really worth the time and money. Rolex never makes the cut for me, because branding carries $0 value in my world, and the street price makes them far too expensive for what they are. Add in the fact that Rolex won't sell parts to repairers, and you get a pretty steep reduction in value. Given a brand new Rolex, I would immediately turn around and sell it while it's "worth" maximum dollars, because to me the watch has a negative valuation, and every day I wear it is a day's worth of wear that I can't repair. There are a lot of extremely excellent watches to be had for your purpose in your price range. If I sound anti-Rolex, know that I'm not. I'm equally anti-(anything Swatch) right now, and that's most of what's been suggested. What I am is very pro-craftsmanship and engineering. Good engineering extends beyond blueprints though, and into things like maintainability, which the owner of a design can ruin by refusing to allow the end user to keep them going. Which is a bummer, because I REALLY like Omega's Co-Axial escapement. Right now, I'm pro-anything that I can "keep on the road". For $2500 if you're looking for new (which you aren't currently, but should the tides change), look for something with a Sellita movement. If you're looking for something used, keep an open mind, and do your homework on a per opportunity basis.1 point

-

Hi everyone, been a while since I posted, but just moved house and then getting ready to move back to the UK to start a whole new career, so my watch shenanigans have had to take a back seat. Anyhow, I recently managed to sneak in a Seiko 7005, I think it was made in April 1969. Here are the before and after shots. Here is the front, I had to replace the cracked crystal, but it was hiding a nice dial, not 100% convinced it's original, but suits the watch: Here is the back of the watch, with a generous helping of arm cheese: And here is the finished watch, I managed to save the bracelet and everything else is original, apart from the crystal and mainspring , and bearing on the rotor.1 point

-

now that it's out for future reference can you give us a picture of the case without the movement so everybody can see the locking ring. then a picture of the back side of the movement so people can see the locking tabs on the movement themselves. probably warped because somebody was trying to pry their movement out not recognizing that its locked in place with the ring.1 point

-

I turned the locking ring to line up the tabs and with some very carefully prying it popped out. Thanks everyone.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)